3 minute read

Level of assumptionsis very lessas compared to othertypes ofmeshing

DESIGN, ANALYSIS AND MANUFACTURING OF SAE INDIA BAJA ATV ROLLCAGE

Abhishek Pandey1, Ayush Nigam2, Saumya Singh Tiwari3

Advertisement

1-3B. tech in Mechanical Engineering Rewa Engineering College Rewa (M.P.)

Under the guidance of – Mr. Sonu Navgotri4

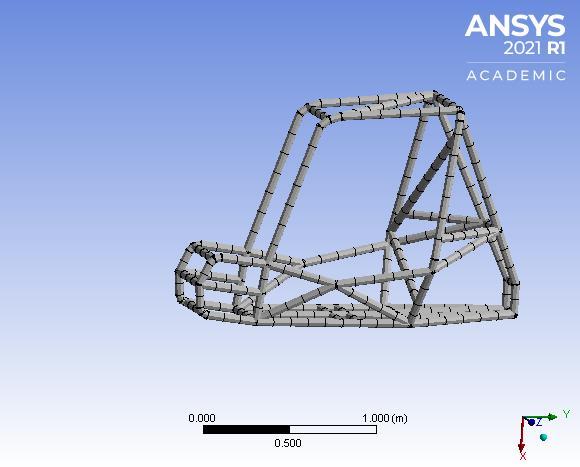

4Assistant Professor Department of Mechanical Engineering Rewa Engineering College Rewa(m.p.) --------------------------------------------------------------------*** --------------------------------------------------------------------Abstract – This research paper is about Design and analysis of Roll Cage of an ATV (acronym for ALL TERRAIN VEHICLE). It is one of the main systems of the ATV on which the other subsystems like Engine, Steering, and Transmission systems, seat, suspension systems etc are mounted. Itcomes under the spring mass system of the vehicle. The forces acting on the vehicle from different directions are accountable for the breakdown and deformation in the vehicle. Therefore, the stresses are generated viz maximum combined stresses, minimum combined stresses, direct stressesetc in this paper we have made an attempt to figure out these areas by doingcrash tests of the roll cage designed on CATIA V5. We have carried out crash analysis (front, rear, side impact, rollover, Bump) and torsional analysis. All these analyses have been carried out in ANSYS R21.0 academic version. The design procedure follows all the rules laid down by SAE rule book for Baja ATV2021.

Key Words: Roll cage, Finite Element Analysis, Strength, Factor of safety.

INTRODUCTION:

For a finer performance of an ATV, it is very crucial to make sure that all elements work as per the planned design calculations. Being an important system roll cage absorbs all the static and dynamic loads, the structure should be such that it can withstand the stresses generated without getting damaged. different forces from different directions act on the vehicle when it is in static or in dynamic situation. These forces cause deformation which results in stress generation at different pointsof the roll cage. The stiffness factor of the roll cage should be able to resist these forces. The primary function of roll cage is to absorb all the loads from the suspension with minimum deformation and secondaryis that it should act as a mounting member for all the other components on the vehicle. The final and most vital function of it is that it must have more continuous members to distribute the stresses and high torsional stiffness to resist the forces during the competition. The roll cage is made by joining seamless tubes welded together. First a proper design of the roll cageis to be made by taking desired dimensions from as mentioned in the rulebook of SAE India Baja 2021. The pipes are then formed into desired dimensions by cutting and bending. thereafternotching is done onthese pipes. Finally, the pipes are welded together to form a roll cage. MATERIALS AND METHODS: Material of sufficiently higher yield strength should be selected to maintain the optimum level of stresses in the roll cage. Herethe strength of the material especially the ultimate yield strength plays a crucial role. The factors affecting the selection of the material are as follows: 1. The stresses generated and the factor of safety of the roll cage. 2. The allotments given to other elements (or components)to be mounted on the roll cage. The factor of safety (FOS) plays a significant role, it is defined as the ratio of the ultimate yield strength to that of the stresses generated in the roll cage. This value of factor of safety for the roll cage must not be greater than 3 and less than 1. If the value is less than 1, it will lead to a significant deformation before reaching the maximum stress value. If the value is greater than 3, then the weight of roll cage will cross the optimum level up to which it should have to be. The vehicle is supposed to perform in various situations such as muddy and offroadterrain conditions. The elementsofroll cageneed to be either welded or nut bolted. Thus, the material selected must be weldable. Thus, we need a material which has high strength, stiffness and is weldable. considering these requirements, the material selected is AISI 4130Alloy steel.