SUCCESS STORIES

The Application of Hydrophobic Epoxy Coatings to Pumping Systems Allows to Save in Energy Consumption Belzona developed a hydrophobic epoxy coatings solution for pumping systems that allows to save up to 20% on energy costs.

M

anufacturing operations are faced with many challenges in today’s

Fluid handling equipment can suffer from several physical and

marketplace. With global energy prices soaring, many industries

mechanical problems, including general and/or localised corrosion,

are being impacted in the form of rising production costs, supply chain

cavitation or reliability linked with poor efficiency or performance. All

issues and lower output. With this in mind, now is the time to think

these parameters may affect the power consumption of the equipment,

about reducing your business’ energy costs.

increasing considerably its lifetime running cost.

The British Pump Manufacturers Association (BPMA) estimate that

One effective way to reduce the loss of equipment performance is to

pumping systems account for almost 20% of the world’s electrical

protect pumping systems using erosion/corrosion resistant coatings.

demand and the cost of energy represents 95% of the cost to run

In this area, Belzona Polymerics Ltd has provided coating technology

pumping equipment. It is clear that solutions developed to increase

solutions for over 70 years within all industry sectors.

pump performance would be of great benefit to industry.

Belzona 1341 offers a unique hydrophobic surface coupled with high

© Belzona

© Belzona

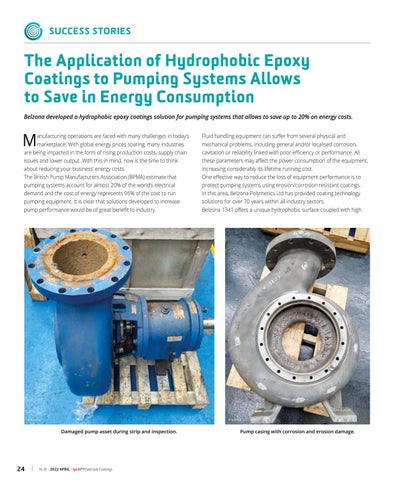

Damaged pump asset during strip and inspection.

24

N. 41 - 2022 APRIL - ipcm® Protective Coatings

Pump casing with corrosion and erosion damage.