COOL POWDER * Compared to the standard 170/180°C. The estimation considers a reduction in energy costs up to 5-10% for each 10°C lowering of the curing temperature, a value influenced by different factors, for example the type of oven that is used. LOW CURING TEMPERATURE POWDER COATINGS STARTING FROM 140°C ENERGY COSTS REDUCED UP TO 20-30%* www.stpowdercoatings.com ISSN 2280-6083 The smart journal for surface treatments ® INTERNATIONAL PAINT&COATING MAGAZINE ipcm digital on www.myipcm.com 13th Year - Bimonthly N° 78 - NOVEMBER/DECEMBER 2022 In this issue: SPECIAL ON ACE & OFF ROAD VEHICLES & INDUSTRIAL CLEANING TECHNOLOGIES

WATERBORNESYMPOSIUM.COM FEBRUARY 12 - 17, 2023 ASTOR CROWNE PLAZA | 739 CANAL STREET | NEW ORLEANS, LA. Topics covered include Waterborne, Polymerization, High-Throughput, Nano, UV, Additives, Corrosion, Bio-based, Formulation, Automotive and more. Intensive training offered through our two- and three-day short course options. Proceeds

Symposium are used to endow scholarships for students

the Polymer Science and Engineering program at Southern Miss. EOE/F/M/VETS/DISABILITY UC84851 Celebrating 50 Years of Coatings Research! THE INTERNATIONAL WATERBORNE HIGH-SOLIDS AND POWDER COATINGS SYMPOSIUM

from the Waterborne

in

KleerAid ® EZ Treat 2.0 is designed to provide the most efficient, powerful, and consistent paint detackification in the market today. The high-performing and cost-effective process is environmentally sound and efficiently treats waterborne, solvent-borne and mixed paint systems. The process improves paint sludge quality by eliminating stickiness and increasing flotation rate, even with high solid paint.

KleerAid ® EZ Treat 2.0 provides consistent water parameters (pH, TSS, COD) while reducing maintenance and equipment cleaning requirements. It also addresses typical odor issues without using biocides, toxic or hazardous products.

info @ atotech.com www.atotech.com

Atotech Group

�Improves sludge quality, resulting

reduced sludge

associated disposal costs �Eliminates associated unpleasant odors �Eliminates

�Reduces chemistry consumption by up to 60% �Cost-effective, efficient and consistent performance with low service requirements

Powerful. Consistent.

A drive towards high performance

in

quantity and

the need for biocides

Efficient.

CONTENTS NOVEMBER/DECEMBER 2022 05 EDITOR’S LETTER 12 BRAND NEW 16 MARKET CLOSE UP The Powder Coatings Market in North America is Expected to Cross USD 3.4 Billion By 2027 20 BRAND NEW 24 ASK JOE POWDER The "Ask an Expert" Column 28 HIGHLIGHT OF THE MONTH A Return to its Roots Turned Towards the Future: SAMES KREMLIN Becomes Sames 32 HIGHLIGHT OF THE MONTH Merck Effect Day 2022: Back to the future 36 SUCCESS STORIES Chery Automobile Relies on 146 State-of-the-art Robots and Intelligent Software from Dürr 38 FOCUS ON TECHNOLOGIES C.P.C. Group’s Painting Division Relies on Nine Articulated Robots to Coat Carbon Fibre Car Parts 45 BUSINESS CARDS 47 SPECIAL ISSUE - ACE & OFF ROAD VEHICLES 54 FOCUS ON TECHNOLOGY User-Friendly, Self-Learning Robot Programming Simplifies Production Management for Real-Time Delivery of Automotive Spare Parts 60 INNOVATION: PRESENT&FUTURE VIANT – A New and Innovative Technology for Corrosion Protection 64 SUCCESS STORIES More Efficient Liquid Coating of Hydraulic Cylinders Thanks to Electrostatics 68 FOCUS ON TECHNOLOGY The Potential of Nanotechnology Passivation in RIMA’s Pre-Treatment Cycle 82 FOCUS ON TECHNOLOGY Balfor Revolutionised Its Entire Production Flow with a New Cartesian Powder Coating System 90 FOCUS ON TECHNOLOGY Zero-Liquid Discharge Cataphoresis: The Goal of IVECO’s Megafactory in Suzzara 06 ANALYSIS Are You Ready for the Green Effect? Filling the Line and Reducing Energy Consumption FOCUS ON TECHNOLOGY The New Powder Coating Line with a Glass Booth Installed by Zoccarato Industrial Coatings for Finishing Its Construction Machinery Parts 74 FOCUS ON TECHNOLOGY Frandent Limits Production Costs and Increases the Sustainability of its Agricultural Machinery Coating Process with Water-Soluble Paint and a Biomass Power Plant 48 30 HOW IT'S COATED Paint it Black: Behind the James Webb Space Telescope’s Signature Colour SPECIAL ISSUE ON ACE & OFF ROAD VEHICLES SPECIAL ISSUE ON ACE & OFF ROAD VEHICLES © Adobe Stock © Frandent © Riccardo Sottoriva © HangOn

CONTENTS NOVEMBER/DECEMBER 2022 106 INNOVATION: PRESENT&FUTURE Hydrogen-Powered Catalytic IR Panels: A Technology with a Zero Carbon Footprint 110 INNOVATION: PRESENT&FUTURE Breaking the Ice 112 FOCUS ON TECHNOLOGY Aluminium Tubes for High-voltage Equipment with High-quality Coating 122 INNOVATION: PRESENT&FUTURE Saving Energy by Recovering the Oxygen Released During Paint Application with On-Site Nitrogen Generators: The Latest Evolution of the Polifluid and Nitrotherm Spray Machines 124 BRAND NEW 128 SUSTAINABILITY Industrial Testing Platform for Clean Water 136 BRAND NEW 138 SUCCESS STORIES Large Castings Reliably Desanded Using Blasting Technology 142 STANDARD & LEGISLATION The Past, Present, and Future of Surface Treatments 144 THE MARKETING CORNER 10 Things Not to Do on Social Media 148 ZOOM ON EVENTS 159 ICT - INDUSTRIAL CLEANING TECHNOLOGIES 160 INDUSTRY NEWS 164 CASE STUDY Volumetric flow control reduces energy consumption in pre-treatment for painting 168 TECHNOLOGY OVERVIEW Reliable and sustainable process for cleaning high-tech components in cleanrooms 176 TECHNOLOGY OVERVIEW A patented vacuum cleaning system using low-boiling point solvents in a hermetically sealed vacuum monochamber performing thermocompression distillation 178 INDUSTRY NEWS 180 HIGHLIGHT OF THE MONTH FiT Cleaning Association: A compass for the industrial cleaning world 184 ZOOM ON EVENTS 98 FOCUS ON TECHNOLOGY A New Dispenser for Multi-Component Paint Mixing Reduces Waste and Confirms Komatsu Italia Manufacturing’s Efforts Towards Climate Neutrality ICT - HIGHLIGHT OF THE MONTH STS Presents Aquasealer®: Innovative and Energy-Saving Impregnation Technologies 172 ART WITHIN SURFACES Lucrezia Roda Explores the Changing Forms of Glass with the Exhibition “GLASS POWER. The Power of Fragility” 132 116 HIGHLIGHT OF THE MONTH Kolzer Celebrates 70 Years in Business with a New PVD Technology and an Innovative R&D Hub SPECIAL ISSUE ON ACE & OFF ROAD VEHICLES © ipcm © Kolzer © Lucrezia Roda & Cortesi Gallery © ipcm

The only European producer of customized electrodialysis cataphoresis / anaphoresis cells with tubular extruded membranes . info@avin.it www.avinsrl.com professionality know-how punctuality ENERGY SAVING | QUALITY PROCESS | IMPROVED LIFETIME | REDUCED MAINTENANCE models available: AUF65 DIALYSIS CELL d. 65 mm - AUFL80 DIALYSIS CELL d. 80 mm

WE ARE COLOURS ENGINEERS

Richiedi la versione in italiano a info@ipcm.it

Over the past year, numerous ipcm® advertisers have asked our editorial office for the names of potential candidates for their sales and, more specifically, technical sales job openings. I deduce that our customers are probably convinced that the editorial office of an international magazine is informed about a lot of job offers and applications. Actually, this is not the case. Of course, it happens, but only sporadically, all the more so when it comes to sales professionals.

Together with our own difficulty in finding salespeople with an “editor’s soul” to employ in ipcm®, this has certainly been highlighting the critical nature of the search for sales personnel, which is a crucial part of a company’s staff as it is directly linked to the development of business volumes. In turn, this prompted me to reflect: how much has the role of salespeople changed in the last twenty years?

The profile of a salesperson is extremely articulated and constantly evolving, mainly because it is very difficult to draw a precise list of proficiencies that, regardless of the industrial sector, certainly include a combination of soft and hard skills.

I still believe that the main one of them is a natural aptitude for selling, a sort of innate talent for public relations and for negotiation, an inclination to connect with people. However, specific technical skills are also indispensable, especially in the light of the digitalisation process that is spreading across all sectors and, as far as the industry is concerned, of the advent of i4.0-oriented productivity.

Back in 2016, Forrester Research1 stated that 1 million traditional “salespeople” in the US would lose their jobs by 20202. This is happening because salespeople can no longer just be the ones who know the products, the company, and the customers: they must acts as consultants, focus on technical sales, and use social networks as sales channels – especially because, thanks to digitalisation, cognitive computing, machine learning, and predictive maintenance, they are no longer required to collect orders, which can be recorded automatically. Their role is therefore to support customers in making choices, solve their problems, and provide information and insights to guide them in carrying out their work.

For the salesperson role to evolve in this way, candidates must therefore be specifically trained (university masters courses on sales techniques have multiplied in recent years), know at least two languages (in non-English speaking countries, English should be considered a commodity and no longer a plus), and have a deeper knowledge of the product (or service) they are selling than their own customers.

The latter point is the most complex, because only a thorough apprenticeship at a firm can enable a resource to become a salesperson 4.0. This means that a salesperson should actually be trained over time within a company, rather than being sought after externally. This is the only way to create, over the years, a breeding ground of young people who will grow from technicians into salespeople, becoming a strategic resource for their company.

You may wonder why I chose to reflect on this in the editorial of the last issue of 2022, a year that has seen our industry keep on growing strongly and portfolio forecasts remain positive despite, once again, the rising energy costs and the difficulties in sourcing certain raw materials and components? Because the numerous reports and articles that you will find in this issue, traditionally dedicated to surface treatments for the ACE and commercial vehicles sector, deal with technical and innovation projects that have involved many young people who have understood that “selling” is synonymous with “growing”.

Happy reading and best wishes for the holidays!

Alessia Venturi Editor-in-chief Direttore Responsabile

1 https://www.forrester.com/bold

2 Source: https://www.adamiassociati.com/ricerca-personale-commerciale/ (in Italian)

05 international PAINT&COATING magazine - NOVEMBER/DECEMBER 2022 - N. 78

LETTER

EDITOR’S

Are You Ready for the Green Effect? Filling the Line and Reducing Energy Consumption

Gabriella Mellergårdh, Freelance Journalist for HangOn Hillerstorp, Sweden

Gabriella Mellergårdh, Freelance Journalist for HangOn Hillerstorp, Sweden

With energy prices skyrocketing all over Europe the question of lowering your energy consumption has never been more urgent. But there might be an easy solution with an enormous hidden potential – cutting costs and increasing profit while at the same time making the coating industry greener.

The coating industry is very energy demanding. This is a fact that has been known to us for long, but we never knew exactly how much energy escapes during the process. HangOn AB is a Swedish developer and manufacturer of solutions for hanging, masking, and handling that today are distributed to more than 40 countries around the world.

At the very beginning, HangOn business idea was mostly about helping

customers to increase efficiency and profitability in their coating process. But the question that has been eating away during the last couple of years, while visiting customers and exploring their needs for further development, is the question of sustainability. And it is obvious that finding the right solutions for sustainability in the coating industry by increasing hanging density is the most important thing HangOn can do for its customers.

06 N. 78 - NOVEMBER/DECEMBER 2022 - international PAINT&COATING magazine

ANALYSIS

© HangOn

Sustainability – a top priority

For the last decades, sustainability in the coating industry has been a top priority when it comes to limit emissions, preventing air and water pollution and putting effort to reformulate and produce environmentally-friendly coatings. Furthermore, the coating industry has gone long ways to explore the development of bio-renewable technologies to reduce the carbon footprint. An array of certified environmentally-friendly paints and coatings are available, which all together have much lower levels of toxicity, while also having recyclable content. Some of these paints are not only environmentally friendly, but also more cost-effective than conventional paints.

Energy consumption in the coating line

Nonetheless, consumer awareness keeps putting pressure on reaching further. Today, OEM in both the general and the automotive industry need to monitor the entire value chain in terms of sustainability. One essential question to be investigated has been to establish numbers on the energy consumption and the energy losses in a coating line. The idea that Petter Törefors, CEO at HangOn and the whole team started out with was to understand in depth what the energy consumption in a coating line really looks like. To achieve this, they conducted a thorough study in five different standard powder coating line set-ups, assisted by surface treatment expert Anders Jansson,

Meyer & Hjort AB. What the study rather surprisingly revealed was that regardless of how many workpieces you fill the line with, the energy consumption is constant up to between 80 and 90 percent. For example, increasing the goods flow times five per hour with HQChanging instead of regular hooks, will only increase the total energy consumption with 18 percent.

On HangOn website you can compare the numbers of different coating cost calculations in standard scenarios in five standard coating lines. You can also fill in the blanks with your own numbers if you like, to check the facts – a great way for validation of the numbers your own coating facility.

Using the energy wisely by increasing hanging density

No matter what, there will be energy losses in the outer surfaces, ventilation, and heat leakages through openings. So you need to be smart and use the energy wisely: by hanging the pieces in a more efficient way you can cut your costs up to 75 percent if you count the cost of energy consumption per coated piece. Hanging the goods is mainly a task that is handled on the workshop floor, but this matter should be addressed all the way up to management. Because the question of hanging density makes a big difference, not only on reducing costs and increasing profit, but it definitely makes a difference in reducing energy consumption and

07 international PAINT&COATING magazine - NOVEMBER/DECEMBER 2022 - N. 78 ANALYSIS

© HangOn

©

thereby contributing to a greener coating industry. What is really important for the decision makers to understand is that you can actually cut costs up to 48 percent on the coating process as a whole, going from 0,28 kWh per coated product down to 0,07 kWh per coated product if you choose to increase the hanging density.

A Green Effect with an enormous hidden potential

Let’s give an example of calculation.

A medium sized automatic coating line with a conveyor speed of 2 m/min, a conveyor length of 293 metres and a piece size of 3000 x 600 x 1500 mm (LxWxH) that transports about 850 kg goods per hour uses about 470 kWh/hour. Of this consumption, the pre-treatment stage uses about 200 kWh, the drying oven about 85 kWh, the powder application around 40 kWh and the curing oven 145 kWh.

Running the coating line with HQC-hanging and a density of 3550 kg per hour of painted goods instead would use 580 kWh per hour. A full year of running a medium sized coating line in 3-shift with daisy-chain hanging, amounts to about 2,5 million kWh per year. With dense HQC-hanging you can paint the same amount of goods while using about 800,000 kWh per year.

Numbers that make a huge difference on the last line of accounting with energy prices skyrocketing all over Europe.

The energy saved by this would be enough to supply 170 average EU households with energy for a whole year. And if you take this further to a global scale, there is an enormous hidden potential to save energy and make the coating industry greener.

This is what HangOn calls “the double Green Effect”.

Real numbers in real life

Realizing that the numbers might sound overly positive, HangOn brings the Swedish company Skeppshult as a real-industry example.

08 N. 78 - NOVEMBER/DECEMBER 2022 - international PAINT&COATING magazine

HangOn

© HangOn

© HangOn

Skeppshult is one of Sweden´s most well-known bicycle brands that has taken capacity utilization to a whole new level. All manufacturing has been done in their own workshop in southern Sweden since 1911, and to make their production even more sustainable they wanted to increase efficiency in their coating process with special hangers. In one specific coating job they went from 54 pcs/hour to 180 pcs /hour with the new solution developed by HangOn.

For Skeppshult the green effect was summed up in 66% energy savings and a total coating cost savings of 53%. In another of Skeppshult´s coating job they went from 216 pcs/hour to 864 pcs with the new solution, resulting in 75% energy savings and a total coating cost savings of 63%. This industrial application shows exactly what the Green Effect is all about: lowering your energy consumption and increasing your profit by increasing the hanging density in the coating process.

Reduced energy consumption of utmost importance

As previously stated, going green and prioritizing matters of sustainability is an important goal for all manufacturing industry, with increased customer awareness and continually strengthened

requirements from all European governments, all by the lead of EU regulations. From February 10 to March 16 earlier this year, the team at HangOn made a market study which garnered responses from 250 participants in 11 countries, representing a wide range of regions, company sizes, coating processes and professional roles. This study shows that the impact of issues concerning sustainability in the coating industry is significant. 85% agrees that sustainability is important to their company.

The same number of respondents agrees that issues related to energy consumption will become more important over the next five years. So, what are, according to the respondents, the most important means to improve sustainability?

Reduced energy consumption is deemed as the most important factor, followed by reduced powder consumption, and reduced chemical and pre-treatment usage.

Increasing hanging density – an easy step to undertake And when it comes to the most important means to reduce energy consumption, a majority of the respondents agree that the secret lies in

ANALYSIS www.trasmetal.net

pre-treatment | spray applications | electroplating | vertical & horizontal plants | enameling | aluminium | white goods | automotive | general industry

eosmarketing.it

over 60 years of experience in surface finishing lines

ACE

cataphoresis and liquid spray applications

increasing line utilization, such as maximizing the number of coated items per hour.

To improve the coating line utilization, increasing hanging density is the most important factor, according to 30% of responders. This is a fairly easy step to undertake, compared to other costly investments, when pressured to become more sustainable while still delivering profits. At the HangOn production site in Hillerstorp, Sweden, efforts are continually made to reduce their own energy consumption, ranging from developing more energy efficient production processes to installing solar cell panels and LED lighting.

“Improving the efficiency in our customers’ coating lines is by far the biggest impact we can make for sustainability”, Petter Törefors says.

HangOn conducted a life cycle analysis (LCA) on all the hooks produced for the Swedish market. Everything was counted in, from the energy consumption when the steel was made to the energy consumption in the process where the hooks are used. The numbers on the left show the result. “That´s why it is so important for us at HangOn to do everything we can to provide our customers with sustainable solutions that can reduce their energy consumption”, Petter Törefors says.

10 N. 78 - NOVEMBER/DECEMBER 2022 - international PAINT&COATING magazine

or

© HangOn © HangOn © HangOn

Click or scan the QR code to get further information on HangOn Green Effect campaign Click

scan the QR code to see HangOn CCC Coating Cost Calculation

ALIT Technologies Presented the Dosing and Application System Drizzling

During the trade fair Aluminium, that took place from 27th to 29th September 2022 in Düsseldorf (Germany), ALIT Technologies has showcased its new dosing and application system for the passivation of metal components Drizzling. As it is extremely compact and easy to install, it allows to apply a constantly fresh and contamination-free passivating solution to the products.

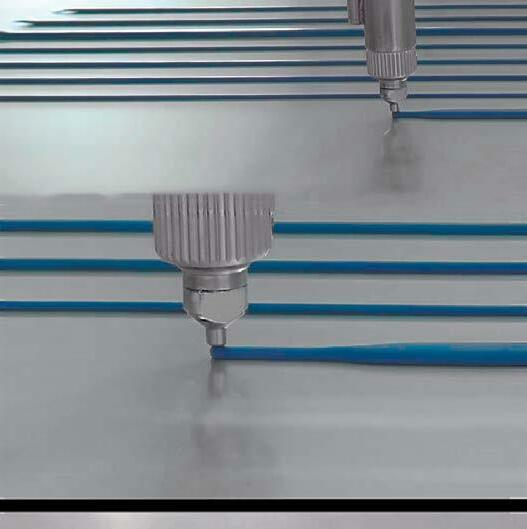

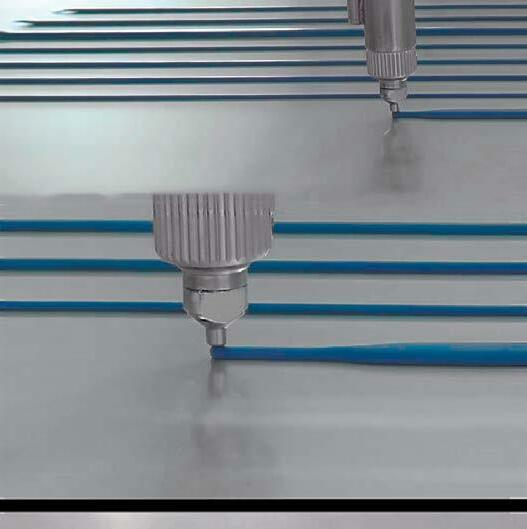

Drizzling is a complete dosing system capable of automatically managing the mixing of demineralised water coming from a feed tank with the exact quantity of passivating chemical product, thus obtaining an optimal and always fresh solution to be dispensed directly on the surface of metals. The use of special atomizing nozzles and compressed air enables the Drizzling system to homogeneously produce and distribute a fine and light mist of passivating solution that completely envelops the product, even in 7-meter vertical lines for aluminium profiles. It can be combined with chrome-free chemicals, including titanium and polymerbased ALFICOAT 748/3 from ALUFINISH GMBH & Co. KG, in order to guarantee excellent results in the passivation process both in terms of corrosion protection and paint adhesion.

For further information: www.alit-tech.com

12 N. 78 - NOVEMBER/DECEMBER 2022 - international PAINT&COATING magazine BRAND-NEW

Drizzling is an innovative process for the application of chrome-free passivation products for all metals.

© ALIT Technologies

AkzoNobel Aerospace Showcased ITA Airways Chromate-Free Metallic Livery at MRO Europe

AkzoNobel Aerospace Coatings showcased the innovative metallic blue coating, with a chromate-free primer, used in ITA Airways’ new livery at MRO Europe in London. The event took place from 18 to 20 October.

The livery consists of a deep metallic blue overlaid with pearl, stylized icons representing Italy’s artistic heritage, the Italian tricolour used on the fleet’s rudders, and the white and red gold of ITA Airways’ logo. A replica of ITA’s livery coating system was displayed on AkzoNobel’s exhibition stand.

The base coat-clear coat system included Aerobase Special effects, and Aviox Clearcoat UVR. ITA chose the system because of its high performance and the uniform coverage and appearance, which can be achieved with just one coat.

“The team at ITA approached us looking for a partner to help bring their marketing idea to life. Together we created a stunning livery in the colour of the jerseys of the Italian national sporting teams. The beautiful metallic blue honours sporting legends such as Paolo Rossi – hero of the 1982 World Cup – whom the ITA planes are named after. And at AkzoNobel we look forward to a long and continuing partnership of innovation”, said Edoardo Sorvillo, AkzoNobel Sales Manager Italy & Poland.

At its stand, AkzoNobel also previewed its new natureinspired interior colour collection, including the 2023 Colour of the Year, Wild Wonder.

For further information: https://aerospace.akzonobel.com/en

BRAND-NEW

© Malcom Nason

AkzoNobel showcased the innovative metallic blue coating used in ITA Airways new livery at MRO Europe, which took place from 18 to 20 October in London. The company also previewed its 2023 Colour of the Year – Wild WonderTM.

Anton Paar Is Celebrating a Century of Activities

The global company Anton Paar GmbH is celebrating its 100th anniversary. For 100 years, Anton Paar has combined highprecision technology with scientific curiosity. The company is now an international player in the fields of density, concentration, rheometry and CO2 measurement and several leading companies worldwide rely on its technical know-how and instruments for chocolate, beer, wine and soft drink production and pharmaceuticals, cosmetics and cell phone display manufacturing. Anton Paar’s analysers and laboratory instruments are used to prepare, produce and test materials down to the nanometer range. They perform material characterisation, including scratch and indentation testing, XRD, gas adsorption analysis, powder rheometry, particle size analysis, X-ray scattering and microwave synthesis. They then allow to examine the unique liquid crystals found in LCD screens, thermometry, optical imaging and medicine. For this reason, they are used by research departments to characterise nanomaterials in final products

in electronics, packaging, paints, coatings, inks, fabrics and cosmetics. In addition, in 2021 the company launched its brand-new automated multipurpose powder X-Ray diffractometer XRDynamic 500, delivering best-in-class resolution/signal-to-noise ratio out-of-the-box. “Talent, commitment and inner cohesion, in both successful and difficult times, have always distinguished us and our company. With these attributes, we are confidently entering the second century of our history,” has stated Friedrich Santner, the CEO of Anton Paar. The company has been owned since 2003 by the non-profit organisation Santner Private Foundation, which is focused on science and research projects and the prevention of drug addiction. Anton Paar GmbH, which operates in more than 110 countries around the world, has now 45 sister companies and sales subsidiaries and 50 sales partners.

For further information: www.anton-paar.com

14 N. 78 - NOVEMBER/DECEMBER 2022 - international PAINT&COATING magazine BRAND-NEW

Founded in 1922, Anton Paar has now become an international provider of analysers and laboratory instruments.

©

©

Anton Paar

Anton Paar

Axalta Launched the Halogen-Free Flame Retardant Plascoat ® PPA571 FR

The new thermoplastic anti-corrosion solution developed by Axalta does not contain halogen constituents such as chlorine or bromine.

The manufacturer of powder and liquid coatings Axalta has recently announced that it has launched the flame retardant Plascoat® PPA571 FR, a new thermoplastic anti-corrosion solution specifically developed to protect buildings and save human lives in the event of fires. The coating, that can be applied in several environments on steel, iron and aluminium substrates, is fire-resistant and act as a barrier to additional damage caused by the spread of flames. Plascoat PPA571 FR offers also protection against sun, salt and sea water, as well as impact and sand abrasion resistance. In addition, the flame retardant does not contain a halogen constituent, such as chlorine or bromine, helping to eliminate the presence of toxic fumes and their associated negative environmental impact.

Thanks to its fire-retardant and low toxicity properties, Axalta’s Plascoat PPA571 FR is compliant with British Standard 476, EN 45545-2 European Railway Standard for Fire Safety, British Standard 6853, International Maritime Organization FTPC standard and UL 94 -Tests for Flammability of Plastic Materials for Parts in Devices and Appliances.

“As a business, we develop solutions in response to the coating requirements of every project, no matter how harsh the environment, which is made possible by our extensive expertise across thermosetting, thermoplastic, and liquid product technologies acquired over more than 150 years,” has commented Meindert Crapts, the business development and product manager for the Thermoplastic division at Axalta.

“Plascoat® PPA571 FR delivers proven flame retardant capability to help minimise the spread of fire. Not only does this reduce any potentially catastrophic impact on humans and property, Axalta’s specially developed Halogen-free composition eliminates any further negative environmental impact stemming from the use of chemicals. Our focus is on delivering high performance coating solutions that provide unrivalled protection, while respecting the planet and meeting the stringent sustainability requirements of customers around the world.”

For further information: www.axalta.com/plascoat

15 international PAINT&COATING magazine - NOVEMBER/DECEMBER 2022 - N. 78 BRAND-NEW

© Axalta

©

The Powder Coatings Market in North America is Expected to Cross USD 3.4 Billion By 2027

According to a recent study from market research firm Graphical Research, the North America Powder Coatings Market size is projected to reach a valuation of US$ 3.4 billion by 2027.

The market research firm Graphical Research1 has released a study in which it analyses the powder coatings market in North America. According to the report, the share is likely to grow steadily in the next years: it is estimated that its market size will be valued at $3.40 billion by 2027, thanks to growing technological breakthroughs and

1 https://www.graphicalresearch.com/industry-insights/2032/north-america-pow der-coatings-market

a wide range of applications, such as in the automotive, architecture, agriculture, construction, earthmoving equipment, oil & gas and general metal sectors.

Since the industrialization activities are growing at a strong rate both in the United States of America and in Canada, the firm reports that all the related industries will witness new potential growth opportunities.

16 N. 78 - NOVEMBER/DECEMBER 2022 - international PAINT&COATING magazine MARKET CLOSE UP SPECIAL ISSUE ON ACE & OFF ROAD VEHICLES

Adobe Stock

In addition, the powder coatings market outlook in North America will allegedly be positively affected by the strong presence of several international brands involved in the development, formulation, production and commercialization of thermoplastic and thermoset resins for powder coatings, including PPG Industries, Somar Corporation, Axalta Coating System, AkzoNobel N.V., Asian Paints, BASF, Kansai Paints, RPM International, The Sherwin-Williams Company, AkzoNobel N.V. and Dupont Coating & Colour Technologies Group.

There are several benefits of using powder coatings, such as high-quality finish, great efficiency, easy availability of different varieties, reduced clean up and ease of application. The two most significant drivers for the adoption of these products are the increased market demand for sustainable solutions

and enhanced performance expectancy. As a matter of fact, powder coating is then considered to be a long-term solution for a wide range of industrial coating applications.

The trends strengthening the regional industry potential are expounded below.

The metallic substrates are witnessing a robust use of powder coatings

Metallic substrates are being highly demanded in a variety of sectors, such as medical, agriculture, architecture and construction. One of the main reasons for it is that powder coatings offer a durable and attractive finish to many components that are commonly used in these sectors.

The application of powder coatings on metal substrates captured a share worth around $840 million in North America alone during 2020. The manufacturers and distributors of these products are projected to hold a share worth of $3.2 billion by 2027, as reported by Graphical Research, since powder coatings are being extensively used to coat a variety of metals, including bronze, brass, aluminum, titanium and copper as well as different types of steel, such as stainless, galvanized and anodized.

Thermosetting powders will be highly employed for automotive and transportation components

The well-established automotive and transportation sector in Canada and the United States is likely to offer lucrative market growth prospects to powder coating manufacturers in the following years, according to the research.

Powder coating has gained popularity as one of the most common methods for finishing automotive parts, due to its long-lasting and robust finish and smooth and corrosion-resistant texture. The need for an environmentally benign alternative to solventbased paints was a significant driving force behind the development of sustainable powder coating materials.

Thermoset resins, such as polyester, epoxy, acrylic, polyurethane and epoxy polyester – that are also used for lightweight industrial components – are

then finding robust use in the automotive sector for parts such as springs, chassis, engine blocks, headlamp reflectors, wipers, horns, door handles, wheel rims, radiator grills, bumpers and other metallic structure and interior components.

The COVID-19 pandemic had an overall adverse effect on the North American powder coatings industry, as the automotive market witnessed a massive decrease in revenues during the first half of 2020: there has been a sharp decline in the number of people purchasing vehicles due to the strict lockdown and movement restrictions imposed by governments and local authorities in order to contain the spread of the virus, which eventually led also towards a negative impact on the production of and demand for powder coatings. However, the region is now experiencing a notable rise in the demand for automobiles due to the growing per-capita income of the population,

on luxury cars and bikes. These vehicles require a strong and protective coating to keep scratches and dust at bay and offer an elevated appearance, which will augment the demand for powder coating services.

The North America powder coatings market share from the automotive and transportation segment, which was worth around $425 million in 2020, is now expected to grow steadily in the near future and the market size from thermoset resins is now expected to observe 5.5% CAGR through 2027.

Coatings for non-metal substrates also projected to rise

The market share from the non-metal substrates, such as composites, glass and wood plastic layer – which are expected to be high demand in the near future – accounted for $110 million in 2020 and it is also estimated to observe a significant growth over the next five years.

18 N. 78 - NOVEMBER/DECEMBER 2022 - international PAINT&COATING magazine

& OFF ROAD VEHICLES

MARKET CLOSE UP SPECIAL ISSUE ON ACE

© Adobe Stock

Merck Commissions Fully Automated Unit for Digital Colour Measurement

Merck commissioned its first fully automated unit for the digital colour measurement of its pigment products. The unit was commissioned in Gernsheim, Germany, the company’s largest pigments production site, where about 560 people work. “We have invested tremendously in recent years to expand our pigment production capacities,” said Jeff White, Head of the Surface Solutions business unit within the Electronics business sector of Merck.

“In September 2021, a second production line for effect pigments based on silicon dioxide was launched in Gernsheim – an investment of nearly € 28 million. We are now increasingly investing in automating and digitalizing our production processes. The investment of nearly € 10 million in a unit for the automated and digital colour measurement is only one example of how we are further advancing the digitalization of our production processes within Surface Solutions.” With this investment, Merck aims at improving the colour reliability of

its pigment products. To date, quality control of colour pigments has mainly been manual and was highly dependent on the perception of the human eye. With the new, fully automated process, Merck will measure the colour values digitally and thus generate extremely reliable colour measurement values that can be validated by customers. This will also improve reproducibility of the pigments and, consequently, consistently high product quality worldwide. Following Gernsheim, colour measurement units are to be introduced in the coming months at additional Merck pigment production sites in Onahama (Japan) and Savannah, Georgia (USA). This falls within the company’s goal of advancing the quality of products and processes through automation and digitalization.

For further information: www.merckgroup.com/en

20 N. 78 - NOVEMBER/DECEMBER 2022 - international PAINT&COATING magazine BRAND-NEW

Merck announced the commissioning of its first fully automated unit for the digital colour measurement of its pigment products. ©

Markus Mink

Sierra Aluminum and SAT Partner for a Fully Automatic Anodizing Line in North America

Sierra Aluminum and SAT have announced that, in July 2022, the companies have signed a joint agreement to design, produce and install a fully-automatic anodizing line in the North American production site of Sierra.

Sierra Aluminum – which is a division of Samuel, Son & Co. – is a vertically integrated aluminium extrusion mill providing both standard and custom products for several sectors. In order to identify the best solutions for its needs, Sierra had chosen to visit several production and operational plants throughout Europe.

It has then witnessed the advantages offered by the technologies of SAT (Surface Aluminium Tech), an Italian company part of the American group Graco Inc., and decided to request a Fully Automatic Anodizing line. “SAT was the most reliable partner for a highly automated solution which allows us to maintain strict control of all the process parameters,” has stated Robert Smith, the director of Manufacturing and Growth Strategy at Sierra Aluminium.

The anodizing line has a high degree of automation, resulting from the

close synergy between software and hardware internally developed by SAT. The automatic management of the whole process will guarantee a high level of productivity with a reduction of downtime, fine-tuned dosing of chemical products, constant monitoring and thermoregulation of the process tanks.

“Thanks to the customized Supervision Software, it will be possible to constantly check and collect all data from the working tanks, and then link this information to each anodic bar. In this way at the end of the process every load will be accompanied by a specific and thorough production history. We’re very proud to announce this new partnership between SAT and Sierra for this first SAT Anodizing Line in North America. We are sure this collaboration represents a fundamental step for both companies and I really look forward to seeing the line in operations,” has declared Andrea Trevisan, the CEO of SAT.

For further information: www.sataluminium.com/en

21 international PAINT&COATING magazine - NOVEMBER/DECEMBER 2022 - N. 78 BRAND-NEW

The new line developed by SAT will provide high level of productivity with a reduction of downtime.

© SAT

The European Coatings Association CEPE Voted

David Beckford into its Board of Directors

The European Coatings Association CEPE has recently announced that the managing director of Pronto Paints David Beckford has been voted into its Board of Directors. Beckford also joined the board of the British Coatings Federation in 2011 and served as president of the organisation from 2018 to 2020.

“It is an honour to serve on the European coatings association’s board, and I’m really looking forward to contributing to the important work we have ahead of us to continue to influence chemical regulations in the EU and UK and to promote the positive contribution of the coatings sector to society. I want to champion the voice of the smaller companies, as well as be the link between BCF and CEPE on the challenging topic of Brexit”, has stated Beckford.

“Given the interconnected supply chains, and significant overlap of membership, the UK paint industry continues to have an excellent relationship with the European coatings association, CEPE, and

I’m delighted David has stepped up to represent the UK”, has also commented Tom Bowtell, the CEO of the BCF.

Beckford received 2,673 votes in favour, 3 abstentions and 0 votes against. The result was announced by Roald Johannsen, the vicepresident of PPG Automotive Coatings EMEA and president of CEPE, during the General Assembly of the association that took place in Madrid on 30th September 2022. The United Kingdom was represented by the BCF Board member Geoff Mackrill, owner of Teal and Mackrill Paints.

“It is fantastic to continue to have representation from the UK on the CEPE board, and from an SME company. We welcome David to the board and wish him every success”, has concluded Johannsen.

For further information: www.cepe.org

22 N. 78 - NOVEMBER/DECEMBER 2022 - international PAINT&COATING magazine BRAND-NEW

David Beckford is also a member of the board of the British Coatings Federation.

© CEPE

Evonik Expands the Production Capabilities for ACEMATT ® Matting Agents in Asia

Evonik is expanding the production capacity of its ACEMATT® precipitated matting agents at its manufacturing facility in Taiwan.

Evonik is increasing the production capacity of its ACEMATT® precipitated matting agents at its manufacturing facility in Taiwan. Capacity expansion is expected by the second half of 2023 and will allow Evonik to meet the growing demand for matting agents in the Asian region.

“The capacity expansion of our leading matting agents in Taiwan further emphasizes our commitment to the growing markets in Asia and to all our regional and multi-national customers,” says Maximilian Morin, Head of Industrial & Transportation Coatings at Evonik Coating Additives. “We are continuously expanding our position as

a truly global partner for our coatings customers by offering the same high-quality products from manufacturing locations in multiple regions. In times of rising logistical challenges, such an investment will also directly benefit our partners and customers across the globe by further improving our supply situation worldwide.”

ACEMATT® matting agents manufactured in Taiwain will have the same properties as the products currently manufactured at Evonik’s manufacturing plant in Bonn, Germany.

For further information: www.evonik.com

BRAND-NEW

www.rostirolla.it

COMPLETE SOLUTIONS for HANGING and MASKING

© Evonik

The “Ask an Expert” Column

Kevin Biller kbiller@chemquest.com

Even for this last column of the year, there are still many questions for our expert Joe Powder from coaters around the world.

Hi Joe,

I have a technical question to ask. I hope you have the answer. I read some non-technical articles mentioning powder coating on wood. How is it can be done because wood is a non-magnetic material?

Have a good day!

Dr. Jinwen Zhang Washington State University

Hello Dr. Zhang, Electrostatics and not magnetism is used to deposit dry powder onto a substrate. Nevertheless, this is still a good question. Most wood has surface characteristics that allow electrostatic deposition of powder onto its surface. In some cases, like MDF (medium density fibreboard), the “wood” needs to be preheated to allow moisture to migrate to the surface of the board. This moisture provides enough conductivity to deposit the charged powder.

One of the challenges to coat wood is having a powder coating chemistry that cures at low temperatures. If the cure temperature is too high the wood emits volatiles that ruin the coating appearance.

The powder coating industry has developed chemistries and processes that allow MDF to be coated commercially. Please let me know if you would like to know more about these chemistries.

Best regards, Joe

Dear Joe, I hope that you and your family are well. Long time no see. How is your business?

I have a question, regarding Qualicoat Class 1 approval. For polyester-TGIC powder coating the gloss should not be less than 50% after 1000 hours Xenon Arc exposure. I want to know if a powder based on a standard polyester-TGIC resin will pass this test (approximately equivalent to 1 year Florida). Or do we need another type of polyester resin for Class 1 or no?

My pleasure will be hearing from you.

Regards, Mohammed Seddighian Tehran, Iran

24 N. 78 - NOVEMBER/DECEMBER 2022 - international PAINT&COATING magazine

ASK JOE POWDER

Hello Seddighian, All is well here. We celebrated our daughter’s birthday this past weekend. It was a wonderful day. I hope you and your family are well. And our business is doing well – we are now part of ChemQuest and continue to grow each year.

A standard architectural grade TGIC-polyester will meet the Qualicoat Class 1 specification. Qualicoat Class 1 basically requires a powder coating finish to maintain colour and gloss after one year exposure to a south Florida climate.

The specification also requires chemical resistance, so it is important to confirm mortar and sulfuric acid resistance performance. In addition, it is important to select your polyester resin from a reputable supplier. Furthermore, make sure that the pigments and additives in your formula are weather resistant.

Some waxes are not UV durable. Keep in mind that many organic pigments will fade from one year Florida exposure. So, choose you additives and pigments wisely.

Please let me know if you have any further questions and have a pleasant rest of your day. Kind regards, Joe

Dear Joe, What is the best way to measure weatherability and the cheapest way? QUV, Xenon Arc or Solarbox? I want to get a machine for my laboratory. What is your suggestion? Best regards, Ozlem Ekinci Kaseri, Turkey

Hooks & CE Hooks

From the in-stock small and thin hook to the special hook Ø30 with EU certification and loading capacity calculation, for both small and heavy parts to be coated.

HOOKS

& CE HOOKS

COMPLETE SOLUTIONS FOR HANGING AND MASKING

www.rostirolla.it

Atlas Ci4000 Xenon Arc Weather-Ometer - Figure Courtesy of Atlas Material Testing Technology.

Hello Ozlem,

The very best way to ascertain resistance to outdoor conditions is natural exposure (this is expensive and takes years). The second-best weathering simulation technique is exposure to concentrated sunlight through the use of solar reflectors and water mist and is commonly known as EMMAQUA or equatorial mount with mirrors for acceleration and water (ISO-877 and ASTM D4141). This technique utilizes real solar energy but because the energy is concentrated by mirrors the duration is significantly reduced. A factor of 10 to 12 times faster is claimed. ASTM D4141 testing requires the careful measurement of the UV light a surface is exposed to. The amount measured is then compared to historical data of Florida exposure and correlated to the number of months of typical exposure. This is also very expensive.

Next best technique is Xenon Arc Weatherometer (ASTM D6695 and ISO 16474-2). For artificial tests the wavelengths of xenon arc emission best simulate sunlight. These cabinets are relatively expensive to buy and costly to operate.

Next in relevance is QUV (ASTM D4587 and ISO-11507). This is tried and true, but not as representative of sunlight as the tests described above. I would use 340-A lamps as the shorter wavelengths (UVB-313) are selectively too damaging to polyester resin molecular backbones. QUV cabinets are much less expensive than Xenon Arc units. I bought a used one for less than $2000. New ones cost around $10,000 to $12,000. You may want to consider building a rack and exposing test panels at your own facility as well. Hope this helps. Joe

26 N. 78 - NOVEMBER/DECEMBER 2022 - international PAINT&COATING magazine ASK JOE POWDER

QUV lamp outputs vs. natural sunlight - Figure Courtesy of Q-Lab Corporation.

Magical Pow erd

4 0 Y e a r s o f A d v a n c e d S o l u t i o n s f o r M e t a l S u r f a c e s T r e a t m e n t

4 0 y e a r s o f t a r g e t e d g o a l s , p r e c i s e c h o i c e s a n d c o n t i n u o u s e ff o r t d e v e l o p i n g h i g h l y p e r f o r m i n g a n d i n n o v a t i v e p r o d u c t s F o r E u r o p o l v e r i t h i s anniversary represents only the first step in the taken direction. Today the main challenge is to plan the future with a constantly evolving growth s t r a t e g y a n d g r e a t c a r e a n d s e n s i t i v i t y t o t h e e c o l o g i c a l e n v i r o n m e n t a l c o n t e x t

EUROPOLVERI S.p.A. Sandrigo (VI) Italy Ph. +39.0444.750643 Fax +39.0444.750653 FILIALI/Branch Office: Cernusco sul Naviglio (MI) Ph +39 02 92148001 Erbusco (BS) Ph +39 030 7704158 DEPOSITO/Depot: Iori Colori, Reggio Emilia Ph.+39.0522.327248 info@europolveri.it - www.europolveri.it Z a n o l o C d A 0 3 2 2

HIGHLIGHT OF THE MONTH

A Return to its Roots Turned Towards the Future: SAMES KREMLIN Becomes Sames

Edited by SAMES Meylan - France

SAMES KREMLIN, a company specializing in manufacturing coatings application technologies, will become Sames. The aim of this name and logo change is to better reflect the corporate values focused on innovation and environmental protection.

On Monday 03 October 2022, the multinational company Sames Kremlin announced its rebranding. A new logo, a new corporate image, and - above all - a new name: Sames.

The decision to rethink its image is due to the desire to better reflect its corporate values aimed at innovation and environmental protection, in order to respond to the technological and environmental challenges of its customers and partners around the world.

Founded in 1925, the French company has been expanding throughout the globe, specializing in solutions for the application of coating for the most diverse industrial markets.

With the acquisition of iNTEC in 2020, Sames Kremlin has also further strengthened its presence in the sealing sector as well.

The purpose of this rebranding is to make customers feel that Sames is much more than a supplier of technologies and equipment for industrial coating. It is in fact a partner focused on three fundamental values:

• The human factor, in order to improve together;

• Innovation, to achieve the excellence and flexibility to satisfy each customer;

• Sustainability, to protect the environment while beautifying the world.

28 N. 78 - NOVEMBER/DECEMBER 2022 - international PAINT&COATING magazine

The new SAMES identity

Sames took advantage of the new corporate identity to convey in a more convincing way its business philosophy focused on providing added value to its customers through efficient and eco-sustainable solutions, keeping faith with its motto: Simply Applying Most Efficient Solutions, which is the acronym of SAMES. This rebranding concerned the simplification of the logo, which emphasises the synergy of the sectors in which Sames operates and its know how with a minimal style and softened shapes. The new corporate image maintains the iconic phosphorus green colour - to symbolize attention to the environment - while combining shades of blue that accentuate its technical expertise and passion for innovation.

New name, same quality

By transforming its identity, Sames mobilizes around a single vision: unite people, protect the environment, and beautify the world.

The company will keep its portfolio and services unchanged: this means that Sames will continue to design, produce and distribute manual guns, coating robots, pumps, dosing units and all the other technologies that have distinguished its offer in almost a century of activities.

Sames will also continue to distribute its products for sealing, protecting and beautifying materials through its historic product ranges:

• Sames Intec for high viscosity extrusion;

• Sames Kremlin for conventional spraying;

• Sames Nanocoat for rotating bell spraying;

• Sames Inocoat for powder coating;

• Sames Services for turnkey projects and services.

HIGHLIGHT OF THE MONTH DO YOU KNOW HOW TO SAVE UP TO 75 % ENERGY WHEN DRYING SLUDGE? WE ALREADY DO. HARTER GmbH | +49 (0) 83 83 / 92 23-0 | info@ harter-gmbh.de | harter-gmbh.de # GENTLE # EXHAUST FREE # ENERGY-SAVING # PROCESS-SAFE

© SAMES

Paint it Black: Behind the James Webb Space Telescope’s Signature Colour

Chelsea Gohd Space.com

Chelsea Gohd Space.com

As the agency explained in its new YouTube series “Elements of Webb,” the James Webb Space Telescope’s radiator is painted black to absorb heat. Just like how black asphalt gets hot in the summertime, objects that are black are generally hotter as they absorb all wavelengths of light and convert it into heat (comparatively white objects reflect light and do not absorb heat).

Webb engineers use this principle to keep the telescope cool. Webb essentially has two sides, a hot side

and a cool side, which are separated by the spacecraft’s sunshield. The cool side is where its highly sensitive scientific instruments reside, and sunshield blocks any heat from the sun from reaching those instruments. The cool side “even has a radiator to keep it extra cool,” NASA multimedia specialist Sophia Roberts said in the video. That radiator and everything except Webb’s bright gold mirrors are black on that side, she explained. Now, this black paint is important not only because black objects absorb heat well, but also because they emit heat well, Roberts

noted, adding that objects painted black are highly emissive (a measurement of how well something radiates heat).

To ensure that the black paint used on Webb did the best job possible at soaking up and radiating heat away from the telescope’s instruments, NASA used a special ultra-black paint made by Ball Aerospace called Ball Infrared Black (BIRB).

Webb’s cold side is about minus 388 degrees Fahrenheit (minus 233 degrees Celsius). So, why do Webb’s instruments need to be so cold?

30 N. 78 - NOVEMBER/DECEMBER 2022 - international PAINT&COATING magazine HOW IT’S COATED ?

NASA’s James Webb Space Telescope has to stay super cool to observe the cosmos. How does it beat the heat? Black paint.

© Adobe Stock

Webb observes primarily infrared light, which we humans perceive as heat. If the telescope is too warm, that heat could interfere with observations. Since the scope’s instruments naturally create heat as they work, Roberts noted, Webb has to be proactive about cooling off. This is why, in addition to shielding the instruments from solar rays with the sunshield, Webb also has a radiator — painted with BIRB — that helps to keep things as chilly as possible.

Webb arrived at its final home in space on Jan. 24 after a month of traveling nearly 1 million miles (1.5 million kilometres) through space. By observing in infrared from this distant vantage point, scientists hope that Webb will be able to peer back at some of the earliest moments in the universe’s history, detecting the heat from the earliest stars and galaxies to ever exist.

The James Webb Space Telescope at a glance

The James Webb Space Telescope (sometimes called JWST or Webb) is an orbiting infrared observatory that will complement and extend the discoveries of the Hubble Space Telescope, with longer wavelength coverage and greatly improved sensitivity. The longer wavelengths enable Webb to look much closer to the beginning of time and to hunt for the unobserved formation of the first galaxies, as well as to look inside dust clouds where stars and planetary systems are forming today.

Say goodbye to masking

Overspray-free paint application with EcoPaintJet

Revolutionary precision in automatic application brings efficiency to product customization. Dürr’s solution EcoPaintJet applies sharpedged paint lines on surfaces, pushing the limits for efficient and resource-saving coating: No overspray, no more masking of your product. www.verind.it

HOW IT’S COATED ?

Scan or click the QR Code to watch the Elements of Webb’s episode on James Webb Space Telescope’s painting

Merck Effect Day 2022: Back to the Future

Edited by the ipcm® editorial team

After a long forced hiatus due to the pandemic, the Merck Effect Day event returned with a look at the future of special-effect and functional pigments for the paints, inks, and plastics industries.

Merck’s traditional annual event – the Merck Italia Customer Day dedicated to customers and partners, during which Merck, a leading German multinational company in the electronics, healthcare, and life science sectors, presents its new products and future colour trends in various application fields – went back to being held in person on Monday, 19 September at the Alfa Romeo Museum in Arese (Milan, Italy).

For the over eighty participants, it was an opportunity to learn about the latest special-effect and functional pigments offered by Merck in the coating, plastic, and printing fields and to meet company representatives

who are experts in their respective sectors. In the historic as well as technological setting of the Alfa Romeo Museum, the day’s activities explored not only new colour trends but also Merck’s demonstration tools, including the innovative M-Box, and some technical aspects related to the application of different pigments and the formulation of paints, printing inks, and plastic colouring products.

In particular, the morning’s agenda included the following topics: sustainability according to Merck, illustrated by EMEA senior regional marketing manager Fabio Carati; the M-Box concept, presented to customers and designers for the first time in Italy by Dominik Eisend, the

The new special-effect colours for the automotive sector.

The packed hall of the Alfa Romeo Museum in Arese, just outside Milan, during the Merck Effect Day 2022.

32 N. 78 - NOVEMBER/DECEMBER 2022 - international PAINT&COATING magazine

HIGHLIGHT OF THE MONTH

© ipcm © ipcm

senior design manager of Merck’s Surface Solutions | Automotive Coatings division; the Eco-Inspired by Nature project for a more sustainable approach to packaging design and production; the technical aspects of product formulation with Merck pigments and the FCN (Food Contact Notification) requirements; an in-depth look at the new special-effect pigments of the Xirallic family, called Safari NXT, with their lively and elegant shades; and a look at the latest colour trends from the world of decorative cosmetics, always a source of inspiration for the industry as well. “There are five guidelines for guaranteeing the sustainability of products,” stated Laura Zanini, decoratives account manager at Merck, in her report titled “Eco-Inspired by Nature”, “namely designing for recycling, designing for reuse, replacing plastics with bioplastics, favouring the use of mono-materials, and increasing the products’ recycled plastics content. Collaborating with five industrial partners specialised in different stages of cosmetic packaging production (from masterbatch to tube production, from snap closures and cosmetic products manufacturing to laser marking), we created a shower gel packaged in lighter, mono-material tubes that are therefore easier to recycle and have an indelible laser-marked closure. Merck pigments from the Iriotec® 8000 Series were used for laser marking and Colorstream® pigments were used for tube colouring.”

The morning continued with the presentation of the M-Box, “a design tool that goes beyond conventional marketing tools that only display beautiful colours, thus becoming a curated design collection that incorporates Merck’s special effects and functional

solutions,” explained Dominik Eisend. “It focuses on three trending stories (CO2 Footprint Driven Design, Phygital World, and Off to New Worlds) which allow realising creative ideas and solutions by offering valuable support and guidance for design in the automotive and industrial sectors, thanks to Merck’s experience but also to the collaboration of external partners.”

After lunch, the day continued with a Colour Forecast workshop for the plastics industry, an analysis of Merck’s e-Shop, and the presentation of the City Lights – Urban Colour Story collection (already the subject of an in-depth report published in ipcm® at the beginning of 20221), the first special-effect pigment toolbox specially developed for powder coatings formulators, inspired by the play of light and shadow in the most modern urban contexts.

“It is the first tool specifically designed and developed by Merck for the powder coating industry,” stated Stefano Corrado, Coatings Account Manager at Merck. “It was inspired by six modern cities with the most fascinating urban contexts and it aims at reproducing the nuances of colour at the most evocative times of day, that is, from dusk to dawn. City Lights brings to life the play of light and shadow in the nights of New York, Chicago, Copenhagen, Frankfurt, Vancouver, and Vienna. We have created twentyeight new colours for this toolbox: we have selected seven special-effect pigments from our product series

1 From an interview with Laura Zanini and Stefano Corrado, Merck Group - Darmstadt, Germany, City Lights in Merck’s New Powder Coatings with Special-Effect Pigments, in ipcm Vol. XIII no. 73, January-February 2022, pp. 18-21.

HIGHLIGHT OF THE MONTH

Trends and technical demo-tools of Merck products for plastic and printing applications.

Xirallic® NXT, Pyrisma®, and Colorstream® and created an “urban colour story” for each one of them.”

The day ended with a presentation of Pixel Art, formulation suggestions based on 2023 packaging trends, and a free visit to the Alfa Romeo Museum. The Merck Effect Day 2022 was highly appreciated by the 83 participants: according to 62% of those present, this event should be repeated every year – a further proof of this long-established German company’s experience in studying the most innovative colour trends as well as the feedback received from the market.

The event venue also included an accurate display of the effects and tools presented during the day as a way to enrich the educational and informative experience of participants who, in the breaks between presentations, were able to assess the pigments used with both natural

and artificial light, but above all on three-dimensional and curved shapes, notoriously those that best reveal colour flop and pearlescent effects – a field in which Merck is an industrial excellence.

Feedback from Italian customers, therefore, once again confirmed that the Merck Effect Day is an inspiring, must-attend event:

“…As a technician and not a salesman, I believe in the formula pearlescent pigments = Merck. They’re unbeatable!”

“…It was an exciting and inspirational day. Here’s to the next one!”

“…A great opportunity to see and touch different colour formulations first-hand, which is essential for us designers.”

Merck invites everyone to the next Merck Effect Day and to its booth at the 2023 European Coatings Show next March in Nuremberg, where the special effects company is going to amaze again!

34 N. 78 - NOVEMBER/DECEMBER 2022 - international PAINT&COATING magazine

Stefano Corrado illustrates the special effects of the Safari Xirallic® NXT collection; The Merck Italia team that organised the event; The City Lights, Reset the Future and other demo-tools and applications in coating.

© ipcm

© ipcm

© ipcm

BE WASTEWATER FREE

THE FUTURE OF EVAPORATION

ZLD SINCE 1984 www.eco-techno.it • sales@eco-techno.it

Chery Automobile Relies on 146 State-of-the-art Robots and Intelligent Software from Dürr

Dürr builds Industry 4.0 paint shop for a Chinese car maker in Wuhu, some 185 miles west of Shanghai.

Dürr is building a new, turnkey paint shop for Chinese car manufacturer

Chery Automobile Co. Ltd. for the flexible production of various models and drive systems. The focus is on intelligent networking and tracking all process sequences using a wealth of software solutions from the DXQ product family. Commissioning of the system is planned for 2023 at Chery’s company headquarters in Wuhu.

Chery is China’s top car exporter Car manufacturer Chery was established in 1997 and is China’s top car exporter. According to their figures, Chery has already

sold over nine million vehicles in more than 80 countries and regions. In 2019, the company opened a development and design centre in Raunheim near Frankfurt, Germany, to gain a foothold in the European market.

The Chery’s requirements

Flexibility, scalability, software expertise, high quality, and fast installation are the challenges Dürr faces during the new plant construction in Wuhu, some 185 miles west of Shanghai. Chery sums up its requirements for the new Wuhu plant by stating it wants it to be a “highly intelligent paint shop.” It will paint numerous vehicle categories, from typical bodies to SUVs.

The paint shop is designed to allow future expansion and can also handle two-tone painting. The plant will be ready for operation within eight months and will then complete bodies at a rate of up to 60 per hour.

Extensive ensemble of robots

Dürr is equipping the new paint shop with an extensive ensemble of robots. The 92 painting robots will include 16 EcoRP E043i and four EcoRPL043i. These robots, which are very mobile because of their seventh axis, can easily reach even difficult-to-access places in the body interior. EcoBellCleaner D2 devices clean the high-speed rotary atomizers from the outside within the cycle time. Colour changes and colour channel cleaning inside the atomizer occur in parallel, so the system is ready for the next paint job after 15 seconds. In addition, there are 38 EcoR30L 16i and EcoRS 16i sealing robots responsible for all bonding and sealing processes and four compatible cleaning robots.

Many modules from the DXQ software family

The “highly intelligent paint shop” Chery desires will become a reality in combination with DXQ software products. Dürr will use DXQcontrol for higher-level control of the plant. The software seamlessly tracks the life cycle of each body. The DXQequipment. operation human-machine interface visualizes and monitors individual processes from any device. DXQquality.management connects process monitoring with vehicle details, creating a seamless data record for each vehicle.

36 N. 78 - NOVEMBER/DECEMBER 2022 - international PAINT&COATING magazine SUCCESS STORIES

Dürr

Extremely mobile and precise: the 92 painting robots include 16 EcoRP E043i.

©

And DXQequipment.maintenance logs when individual components like pumps, valves, or filters need to be maintained. In addition, numerous other DXQ portfolio modules will guarantee data-based and fully automated paint shop operation.

Energy efficiency through intelligent air management

In addition to plant flexibility and the networking of all components, energy efficiency is important to Chery. EcoSmart VEC regulates the ovens’ fresh and exhaust air control, which are the biggest energy consumers in the coating process alongside the painting booths. Intelligent air management adjusts the energy supply to the actual need and reduces it in partial-load operation, saving not only energy but reducing CO2 emissions.

For further information: www.durr.com

EcoBellCleaner D2 devices clean the high-speed rotary atomizers from the outside.

© Dürr

FOCUS ON TECHNOLOGY

C.P.C. Group’s Painting Division Relies on Nine Articulated Robots to Coat Carbon Fibre Car Parts

Gabriele Lazzari ipcm®

Operating for more than thirty years in the automotive and racing sectors as a manufacturer of composite components, C.P.C. Group has exponentially increased its production volumes and coating quality degree with nine articulated robots supplied by CMA Robotics, its automation partner for over ten years.

C.P.C. Group is an innovative company that for over sixty years has distinguished itself in the field of prototyping and machining of composite materials for numerous interior and exterior parts of high-end vehicles, such as doors, front and rear wings, bonnets, tailgates, OPT carbon look parts, and complete chassis for various sectors, including automotive, racing, industrial, and aeronautics, thanks to the quality and flexibility of its production. Its parts for highend and racing cars, characterised by high levels of customisation, are certainly the products that most represent its evolution over the years. Starting as a small workshop creating wooden foundry patterns

processed and planed by hand by thirty operators, C.P.C. Group has gradually differentiated and expanded its activities and target markets to become a benchmark partner for many international brands offering Italian-made quality as their distinguishing feature, such as Ferrari, Lamborghini, and Maserati.

Founded in 1958 as Modelleria C.P.C., in the 1990s it was one of the first Italian companies to specialise in the use of 3D design programmes, also equipping itself with 5-axis CNC milling machines and focusing on prototyping and machining of metals and composite materials precisely for the automotive and racing sectors. This now enables it to carry out a

38 N. 78 - NOVEMBER/DECEMBER 2022 - international PAINT&COATING magazine

© C.P.C. Group

complete manufacturing cycle of parts in composite materials with any geometry, working alongside its customers from design to delivery and parts installation on their vehicles. “We now have more than 850 employees working in three plants and a production capacity of 150,000 finished parts per year. This is possible also thanks to our collaboration with CMA Robotics Spa (Pavia di Udine, Udine, Italy), which supplied us with our first articulated painting robot exactly ten years ago. Pleased with the quality and repeatability degree this has guaranteed over time, we recently turned to CMA once again to raise our production speed through the revamping and automation of our new paintshop at the Camposanto (Modena, Italy) production site,” says Fabio Torelli, the director of C.P.C. Group’s Painting Division.

A complete service, from part design to coating “C.P.C. provides a comprehensive service. We listen to requests, we have our technical department design the parts based on the 3D models received from customers, and then we manufacture them by moulding and building them in an autoclave system in our Modena headquarters, which also deals with machining processes: we have an ever-evolving pressing department, five clean rooms for lamination, a large bonding area, and a wide area devoted to trimming. We also have a small paintshop here that has been in operation since the turn of the century. However, the increase in production volumes called for a major

expansion in this area. This is why, in 2011, we inaugurated a new facility devoted to coating, equipped with an articulated robot supplied by CMA Robotics and several manual booths, in Bonporto (Modena), where sixty operators apply the different customised finishes requested by our customers. Over the last decade, however, production has further grown. Therefore, in 2020, we acquired the equipment and personnel of Carrozzeria Nuova G.M., a long-standing industrial body shop founded in 1984, in order to develop our own Painting Division,” adds Torelli.

The Painting Division of C.P.C. Group

As a result, the company set up a Painting Division in Camposanto, with over 200 operators working in three different plants. Its activities started partially in February 2021 and it became fully operational in September of the same year. C.P.C. can now apply both water and solvent-based two-component liquid coatings on up to six car sets per day, using four fully automated lines featuring a floor conveyor: two are for primer application, the other two (built by Tecnofirma S.p.A.) are for top coat and clear coat application. There is also a plant with an overhead ring conveyor for painting small parts for foreign customers. The coated components are subjected to strict visual and dimensional checks by C.P.C.’s laboratory technicians in order to confirm compliance with the parameters agreed upon with the customer and with the project specifications in terms of thickness, gloss, weight, and size.

39 international PAINT&COATING magazine - NOVEMBER/DECEMBER 2022 - N. 78

TECHNOLOGY

FOCUS ON

The surfaces of some carbon fibre components produced by C.P.C. Group.

The quality control department with stations for the visual analysis of parts.

© ipcm © ipcm

“Quality controls carried out with the help of state-of-the-art digital equipment on end products are of paramount importance, because we must always guarantee the best possible result on each individual part,” states Torelli. “This is also the reason why, when we decided to expand our painting division, we relied once again on CMA’s robots.”

The nine CMA robots installed in the new factory

With the exception of five new coating robots, all other devices in the new plant were inherited from Carrozzeria Nuova G.M., which already owned four CMA robots for flame hardening and the application of primers, base coats, and clear coats. This brings to nine the number of articulated robots designed by CMA in use at C.P.C.’s Painting Division.

The coating cycle starts with several surface preparation stages by manual or automatic sanding and cleaning with traditional cloths. C.P.C. Group also installed an automatic spray cleaning tunnel to connect the sanding and painting departments1

Each of the four coating lines includes two 6-axis electronically controlled articulated robots with interpolated trolleys and hollow wrists. As C.P.C. required flexible equipment that can also be adapted to possible future changes in production volumes and part types, the robots are designed to perform spraying operations with both liquid and powder coating products on metal, wood, and plastic surfaces, as well as for the enamelling of sanitary ware and for resin application.

The lines are also equipped with a two-rail floor conveyor, which includes a storage buffer developed on different levels to facilitate loading and unloading; in any case, the robots are also capable of coating parts hooked onto an overhead conveyor with a continuous-flow or step-by-step movement.

1 “A Cleaning Tunnel Suitable for Components with Various Geometries: C.P.C. Group’s Challenge” by G. Lazzari in ipcm® Industrial Cleaning Technologies no. 22.

40 N. 78 - NOVEMBER/DECEMBER 2022 - international PAINT&COATING magazine

© ipcm

The coating robots supplied by CMA Robotics.

© ipcm

The robots’ arms ensure maximum manoeuvrability thanks to a couplings system, perfect pneumatic balancing via the patented smart balance system, and the special light alloys used to build them. Each robot can mount several guns or rotary bells at the same time and integrate perfectly with any airflow and paint control device thanks to its internal control system, which has extremely sophisticated yet user-friendly software and diagnostic tools.

Programming of painting operations is done via the self-learning system, offline, or even through programme self-generation. The operator can also hold the joystick on which a spray gun is mounted without also having to move the robot arm.

“This is an industry first, of which we at CMA Robotics are very proud. It allows creating the required painting programmes even more quickly and conveniently; then, once all the movements have been stored, the robot is able to repeat them faithfully at the same or different speeds. Stored programmes can still be modified in whole or in part by means of the block programming system. It is also possible to adjust both speed and process parameters at any time,” explains CMA sales manager, Marco Zanor.

Coatings give a car more than just long-lasting protection. Brilliant gloss and innovative colors transform contours into dynamics and design into emotion. Lines and curves are united and edges and contours are brought to life. When color and shape come together, and paint evokes passion, it’s because at BASF, we create chemistry.

www.basf-coatings.com

FOCUS ON TECHNOLOGY

We create chemistry that makes lines love curves.

The robot with the Sames rotatory bell atomiser.

© ipcm

A tailor-made project with a complete supply “During the design phase, we studied the needs of C.P.C. Group, analysed the equipment already available to the company, and retrofitted their technology and our new robots accordingly. C.P.C. Group performs a very high quality but highly flexible coating process, with a perfectly calibrated cycle to respect the technical characteristics of composite materials and give them durable, flawless finishes. This is why we developed a project entirely tailored to their specific needs, supplying them with all the technical solutions required to automate their coating operations (i.e. articulated robots, gear pumps, dispensers, applicators, and programme management software), which were then interconnected to the paint management unit set up by Wagner. In addition, the robot applying the clear coat is equipped with a Sames PPH 707 ICWB-M rotary bell atomiser, in order to improve paint transfer efficiency,” adds Zanor. “We have been working with CMA for ten years, namely since when they provided us with an articulated painting robot for our Modena plant: the decision came naturally to rely on them again for revamping our systems and installing new technology. CMA responded quickly to all our requests and met every single need. The investment required was significant but, thanks to their thirty years’ experience and remarkable flexibility, we were able to modernise our technology, optimise costs, and at the same time increase the quality of our coatings and the speed of our production lines,” summarises Torelli.

42 N. 78 - NOVEMBER/DECEMBER 2022 - international PAINT&COATING magazine

© ipcm