FOCUS ON TECHNOLOGY

SPECIAL ISSUE ON ARCHITECTURE & DESIGN

A FOX System for In-Line Pre-Anodising and a C-Expert Booth: Alural’s Future-Proof Technical Choices Alessia Venturi ipcm ☺ ®

Flash oxidation as an additional pre-treatment step for aluminium profiles to ensure even longer outdoor durability has been a topic of debate for some ten years now. Another debated aspect is the difficulty of coating such profiles’ increasingly complex shapes, which prove that their developers take little account of the technical peculiarities of finishing operations when designing new parts. In this article, we show how Alural, one of the largest aluminium coating contractors in the world, has tackled (and solved) these technical issues with the cooperation of its plant engineering partner SAT.

W

ith 2 production sites, 350 employees, and a production

specialisation, and excellent service are the mission of this company

capacity of 9,250,000 m2 of painted material and 660,000

with 35 years’ experience in the aluminium treatment market,

m2 of anodised metal, Alural is one of the largest aluminium

continuous technological innovation is what has made Alural a leader

finishing contractors in the world. Active in several European

in its field. It continuously invests in new production and process

countries, it offers a complete service to extruding and plant

technologies and in new plants, while at the same time exchanging

engineering firms: powder coating with various types of pre-treatment

information and knowledge both within its Group – it was acquired by

processes, wood-effect finishes, and anodising, but also storage, order

Reynaers Aluminium in 2011 – and within the associations to which it

management, packaging, and logistics. Whereas high quality, high

belongs. © ipcm

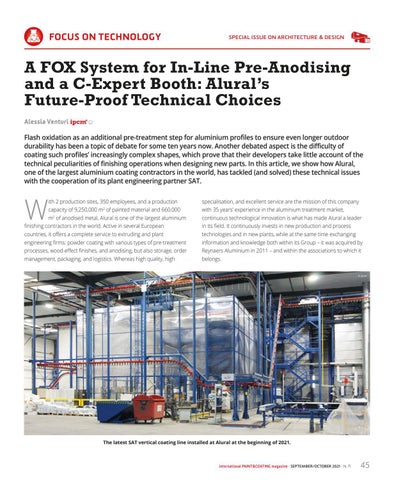

The latest SAT vertical coating line installed at Alural at the beginning of 2021.

international PAINT&COATING magazine - SEPTEMBER/OCTOBER 2021 - N. 71

45