As the world‘s leading manufacturer of high-performance corrosion protection systems DÖRKEN consistently focuses on sustainability and environmental protection. In line with the current developments around the possible PFAS ban, we already offer our main products completely PFAS-free.

You can rely on innovative solutions that combine maximum performance and ecological responsibility.

Contact us.

Dörken Coatings GmbH & Co. KG . Wetterstrasse 58 D-58313 Herdecke . Telephone +492330 63243

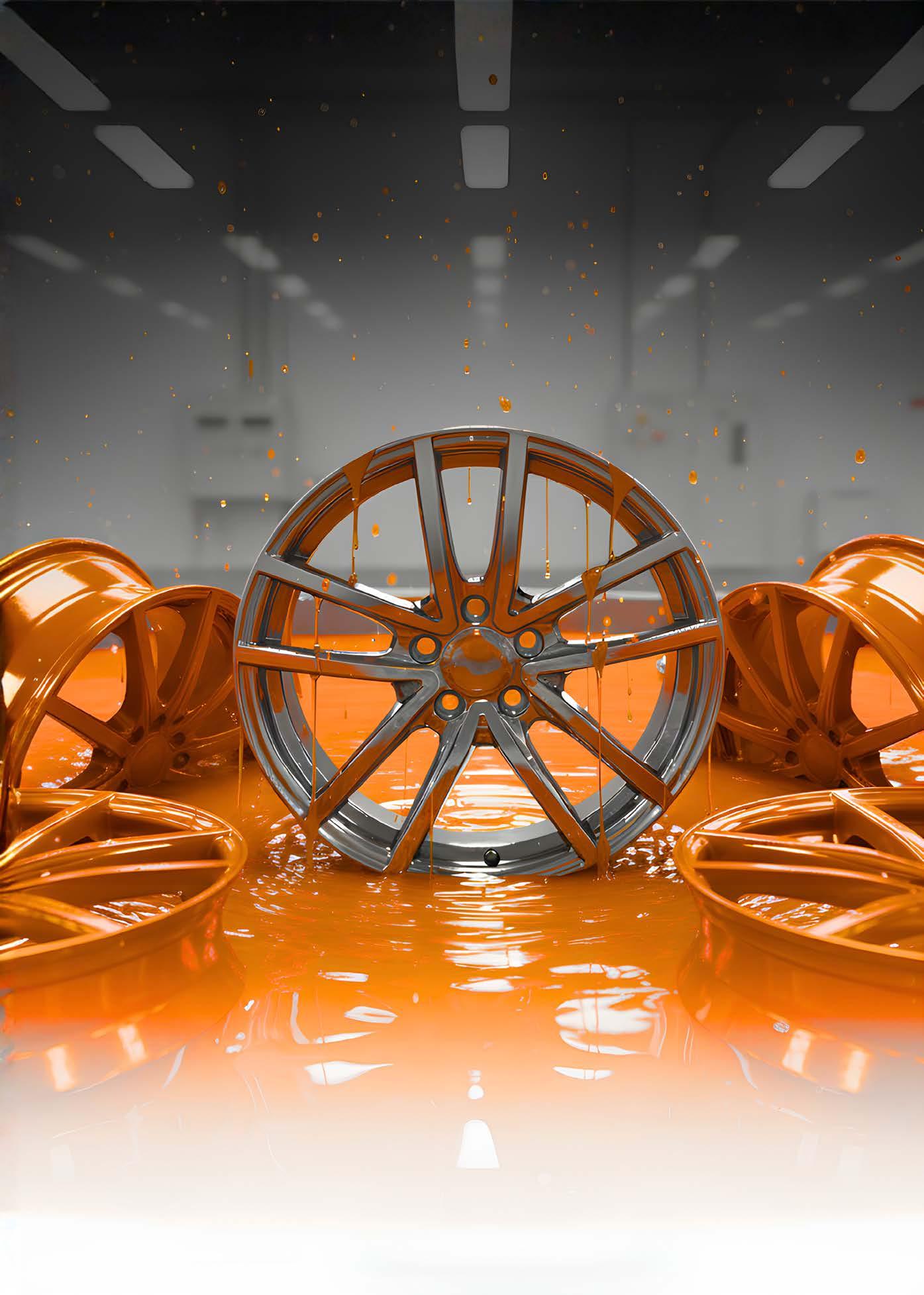

Bespoke durability: DKC optimises pre-treatment to meet new market demands

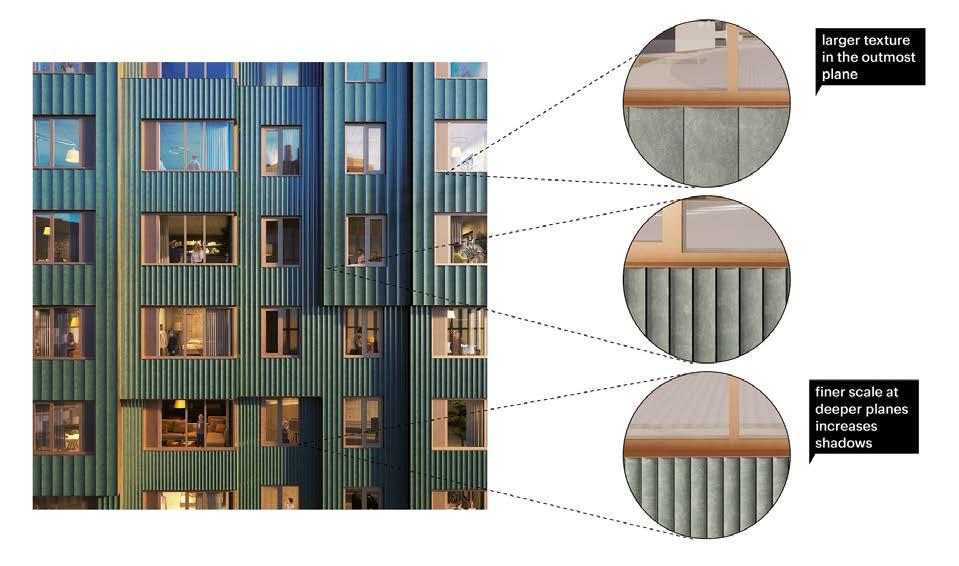

Textured, glossy, and decorative finishes for the Enterprise Research Campus in Boston

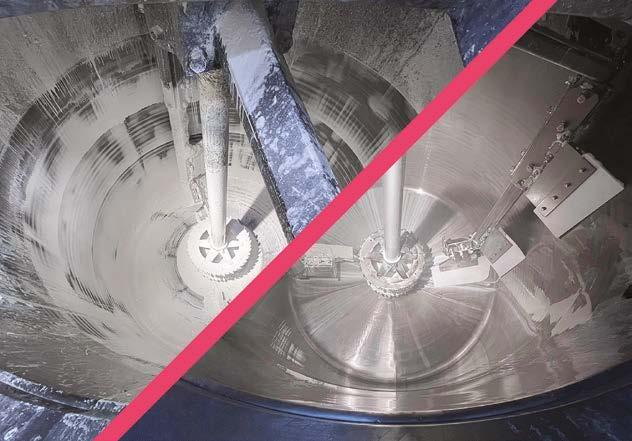

Safety, efficiency, and traceability: the value of automatic tank cleaning according to Basca

Bocciolone Antincendio chooses all-electric power for its first coating plant

Automation for spraying hydraulic cylinders: the Bicelli and Lesta case

A cutting-edge, flexible application system promoting the sustainable development of Rimorchi Bertoja

The evolution of water-based industrial coatings: a new high-performance DTM polyacrylic finish

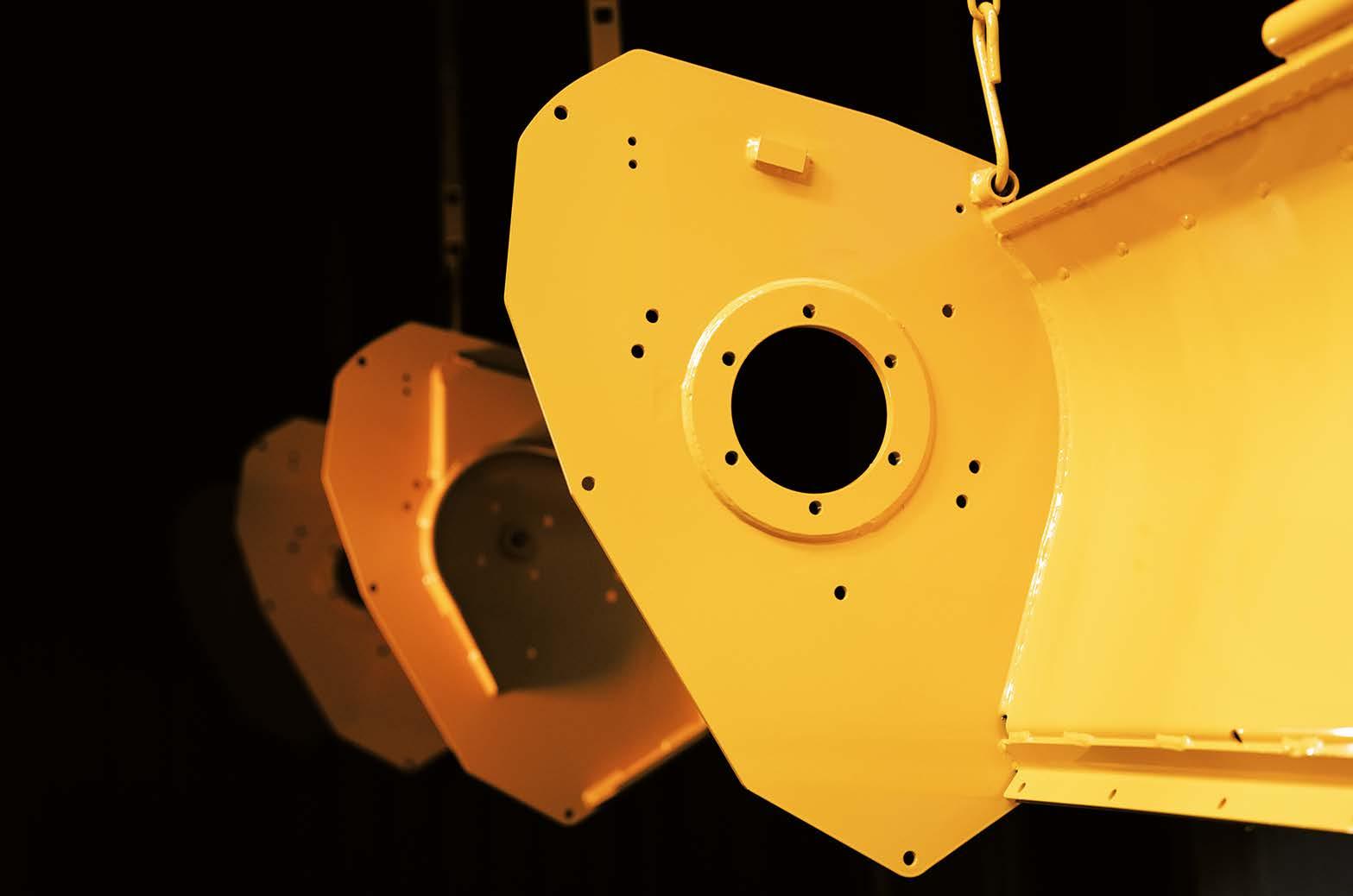

In its coating contracting hub, Argos Surface Technologies’ partnership with its powder supplier consolidates its presence in the ACE sector

Quarry and construction site vehicles require high-performance coatings and maximum colour customisation

FTALON: polyester polyols in high-performance coatings for the ACE and industrial machinery sectors

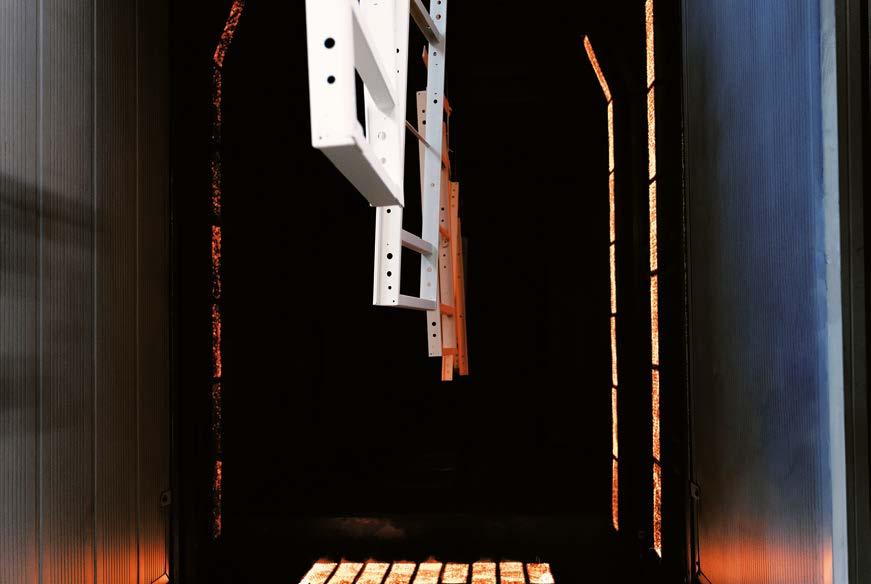

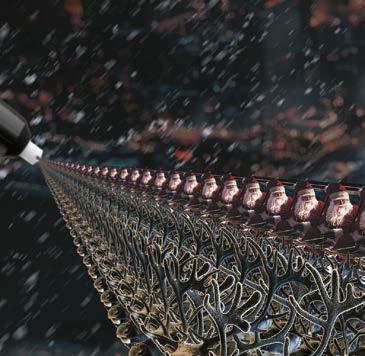

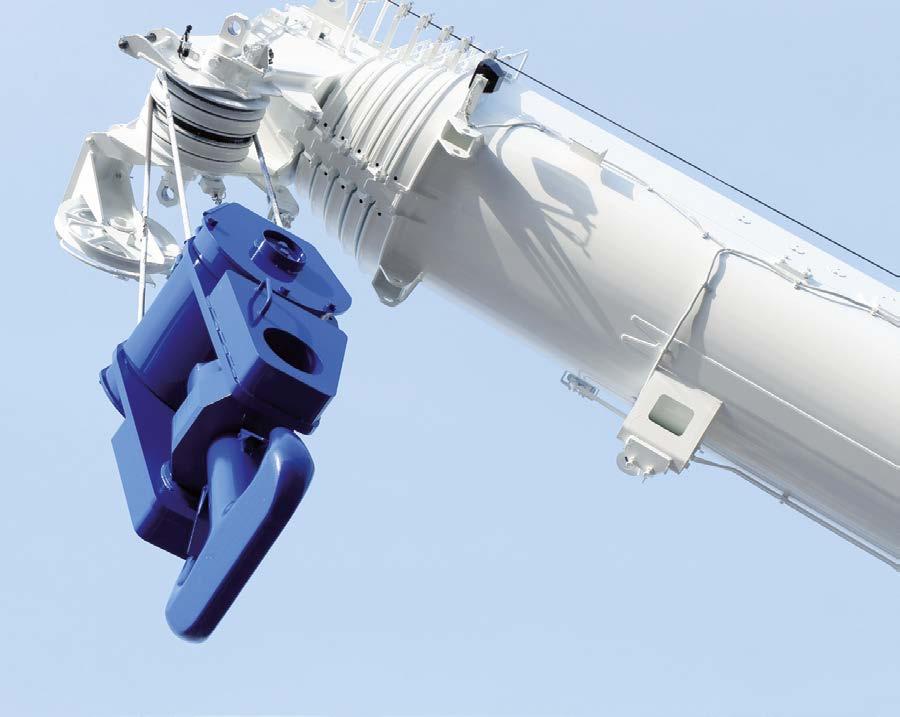

Efficient coating solution powers complex crane production

Energy efficiency and high performance: the keys to a new coating plant for discs intended for agricultural machinery

Alpego doubles down on coating: an advanced twin plant to support growth

ACE manufacturers turn cost of

into competitive

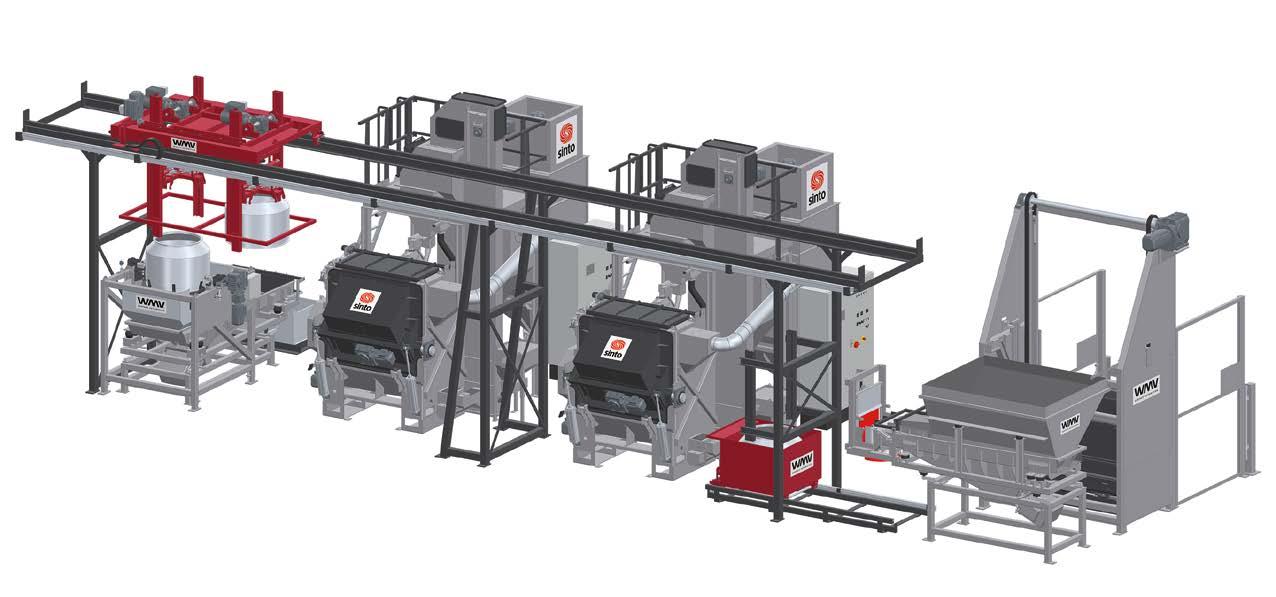

New WMV cleaning system: greater efficiency in blasting

Customisation and flexibility as winning features in the world of filtration

First collaboration between Dürr and Thanh Cong Group

Total Finishing Supplies expands its range to meet market demands

The right filter for every stage of filtration

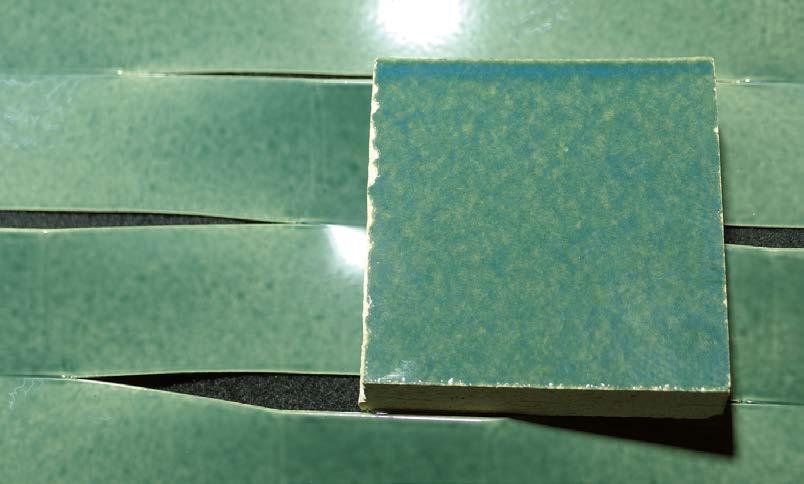

A new line of nanotechnologic conversion for corrosion classes C3H – C4H – C5M

DOLLCOAT GP 107 based on graphite engineered by

Multimetal no rinse product to be used at room temperature

Compatible with any plant and applied by spraying, deep immersion or by nebulization modules

Excellent pre-cataphoresis pretreatment

150 ROAD TO 2050

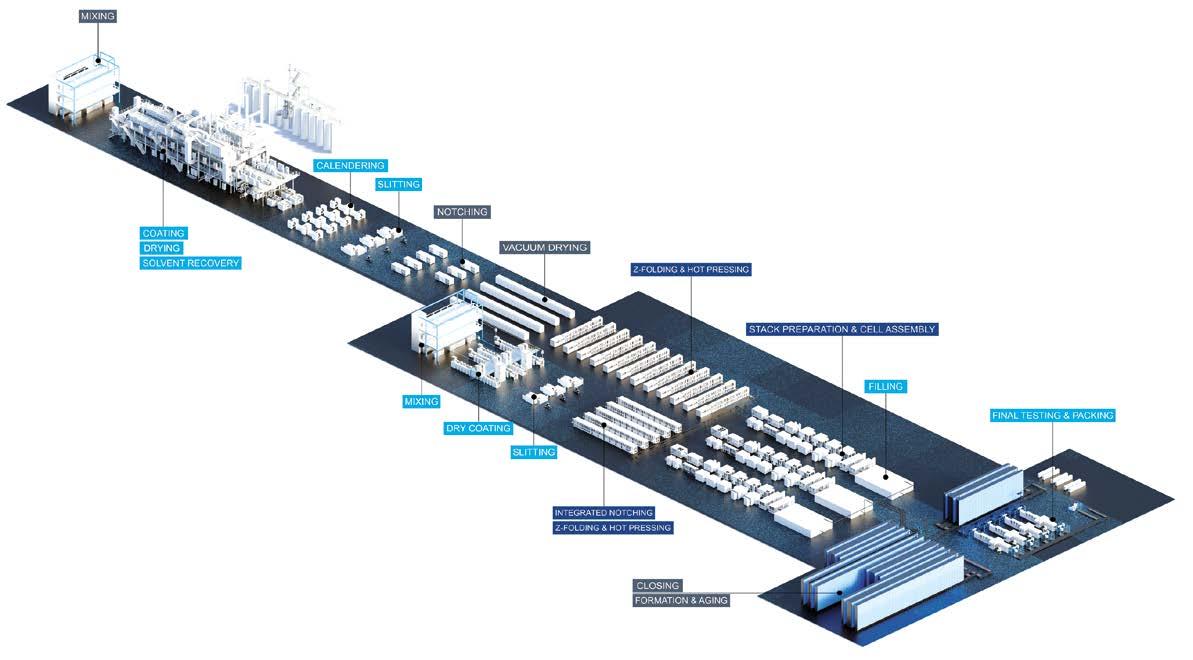

Dürr and GROB present new concept factory for battery cell production

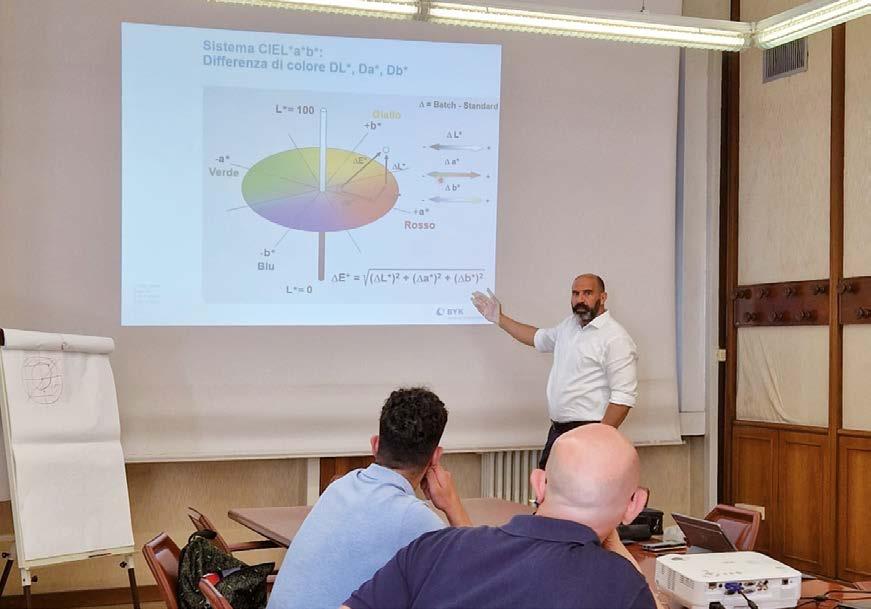

154 COLOUR STUDY

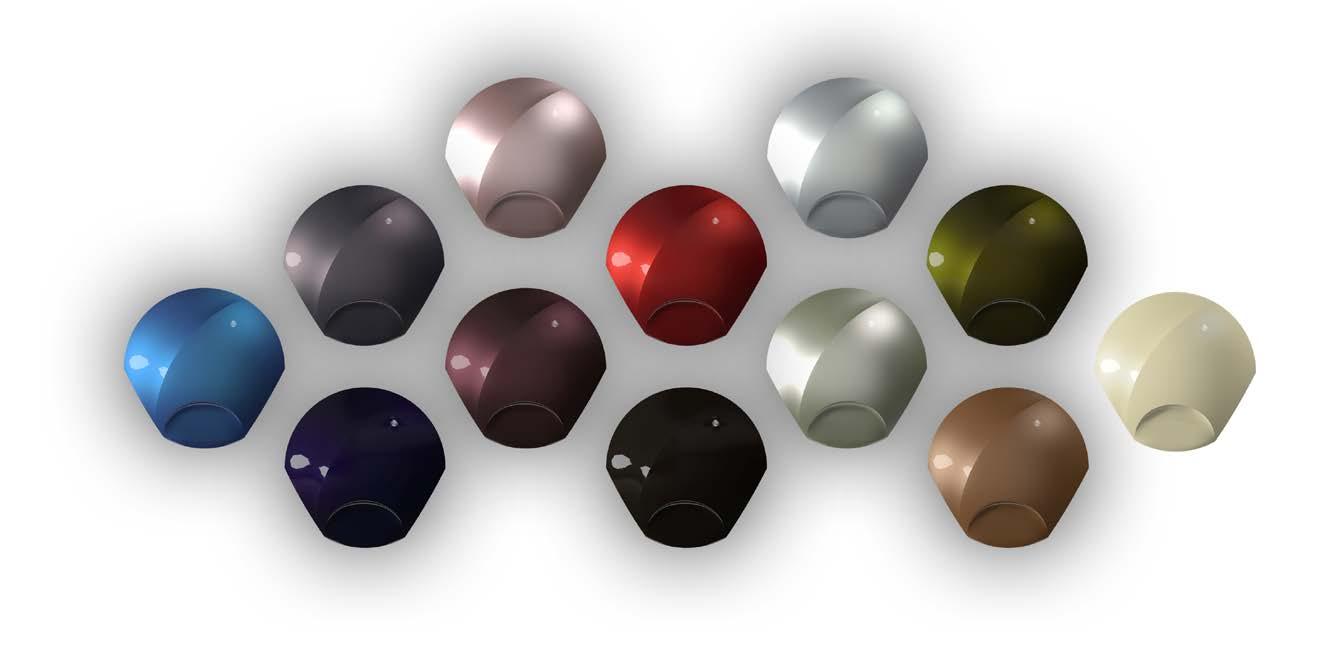

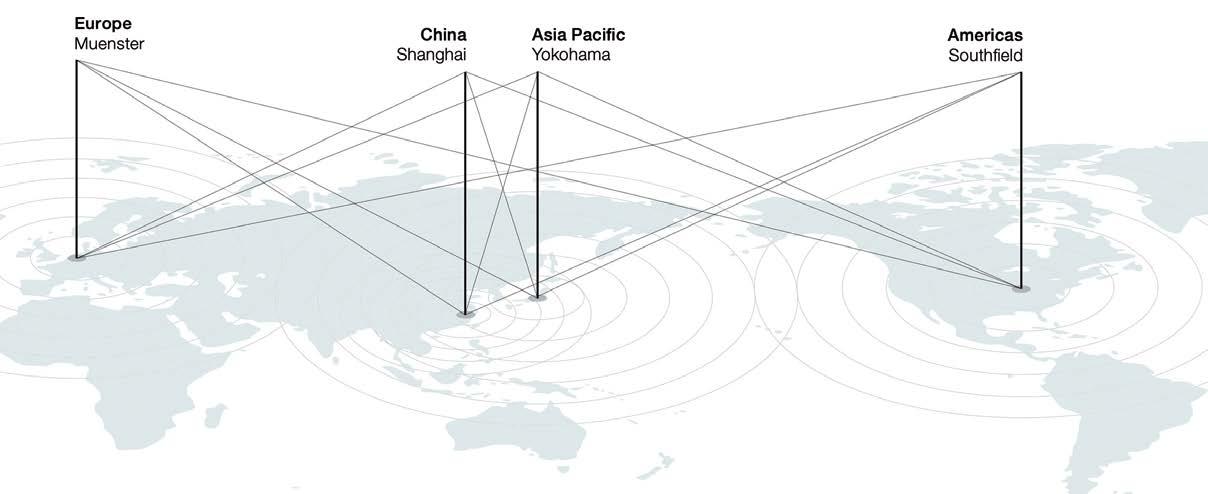

DRIVING THE PROXY: BASF Coatings unveils 2025-2026 Automotive Color Trends® collection

158 SPECIALIZED TRAINING

Training, innovation, and growth: ipcm® Academy in 2025 and its prospects for 2026

162 UCIF INFORMS

The Data Act and its impact on Italian manufacturers of finishing equipment: challenges and opportunities

164 MEETING THE INDUSTRY

188 CASE STUDY

Figros: symbiosis between maximum production flexibility and eco-friendliness in the vibratory finishing of components for fashion accessories

196 ADVANCEMENTS

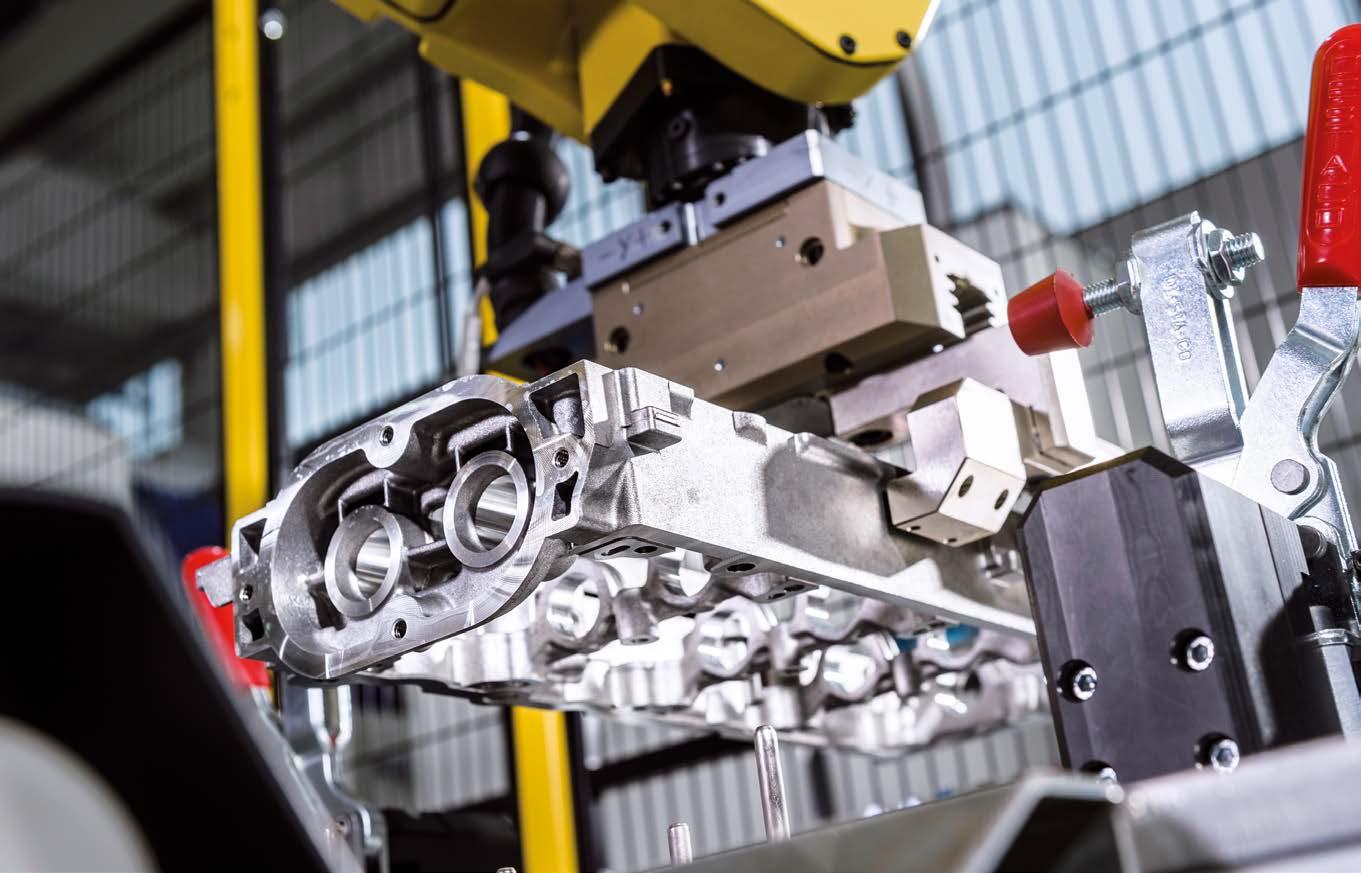

From robotic deburring to autonomous production

200 CASE STUDY

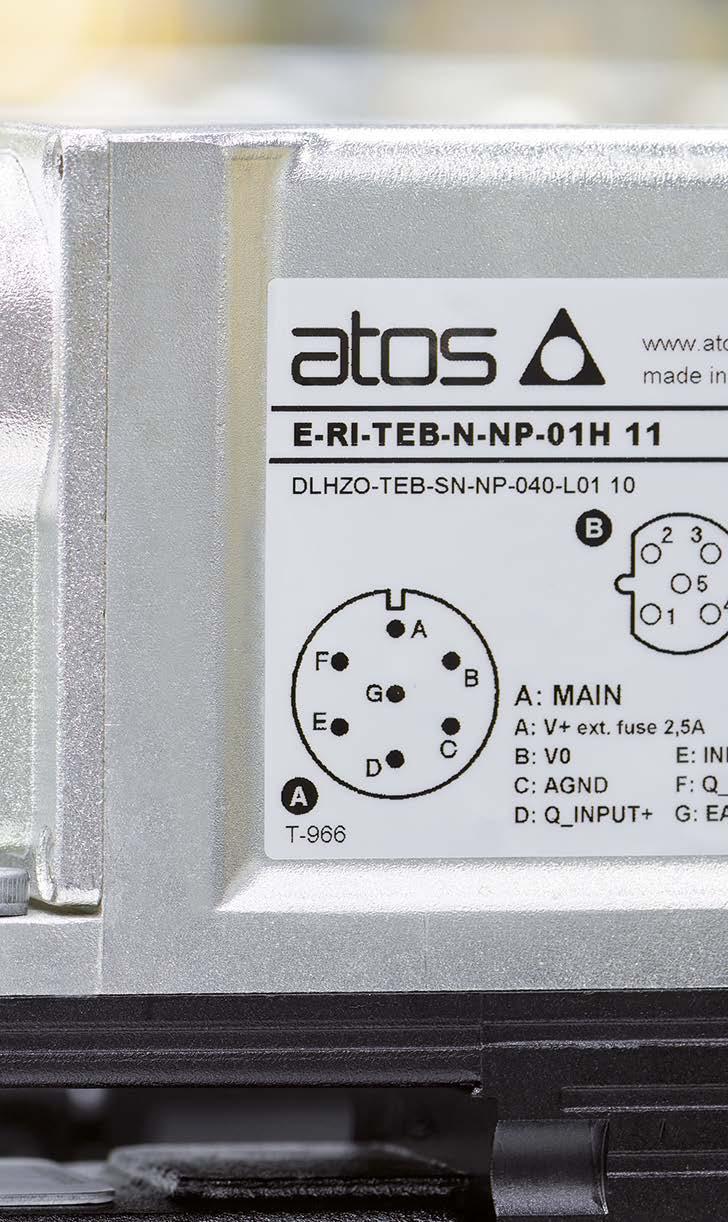

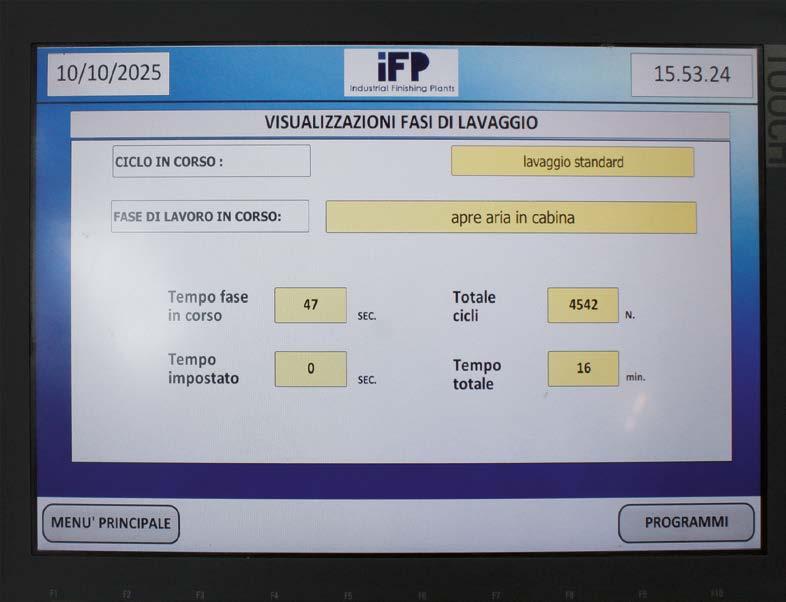

Atos upgrades cleaning to speed up its operations and secure the high quality standards of its electrohydraulic components

206 HIGHLIGHT OF THE MONTH

Innovation and sustainability in industrial cleaning: Fismet’s closed-loop multipurpose plant

210 MEETING THE INDUSTRY

179 ICT - INDUSTRIAL CLEANING TECNOLOGIES

180 CASE STUDY

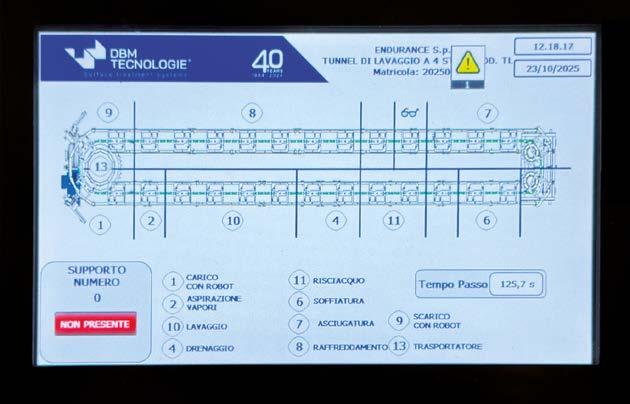

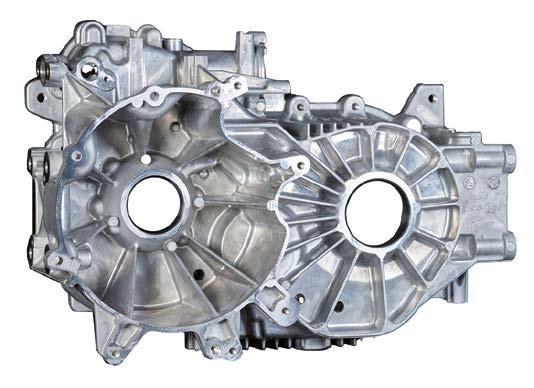

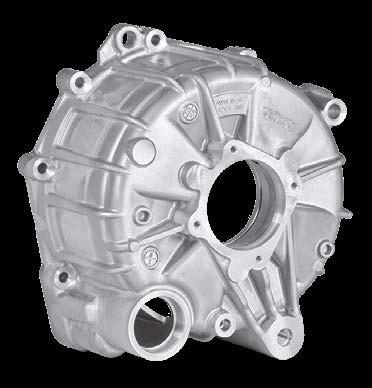

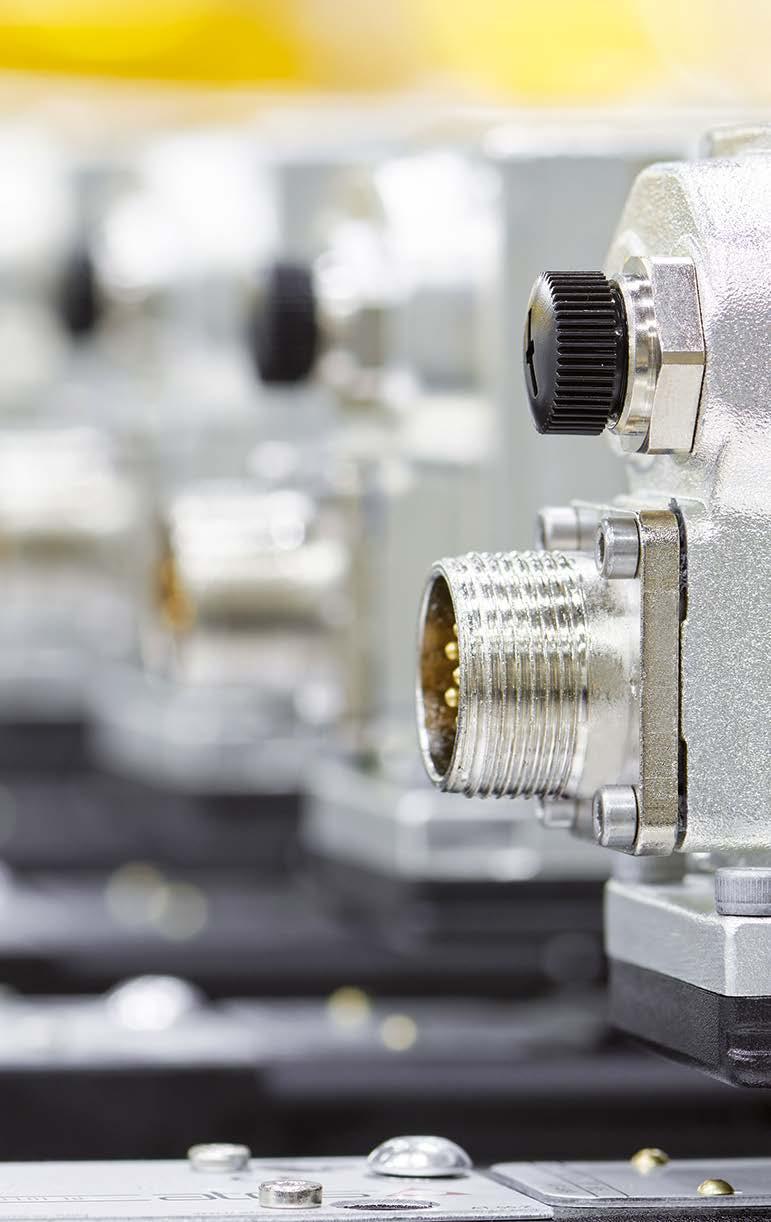

High-performance cleaning at the heart of Endurance’s electric conversion efforts

Since it was founded in 1988, HUBO Automation has always focused the attention to the market needs and to the technological evolution. This allowed the company to establish itself as a leader for the industrial automation and painting. Thanks to the experience of the technical staff and to the continuous investment in new technologies, HUBO is able to satisfy dynamically the requests of a wide range of industries.

HUBO core business is the painting division. The wide range of automation solutions fully meets any need of automatic painting; in addition, the combination of special systems can satisfy particular requests and can guarantee a flexible and reliable painting system from all points of view.

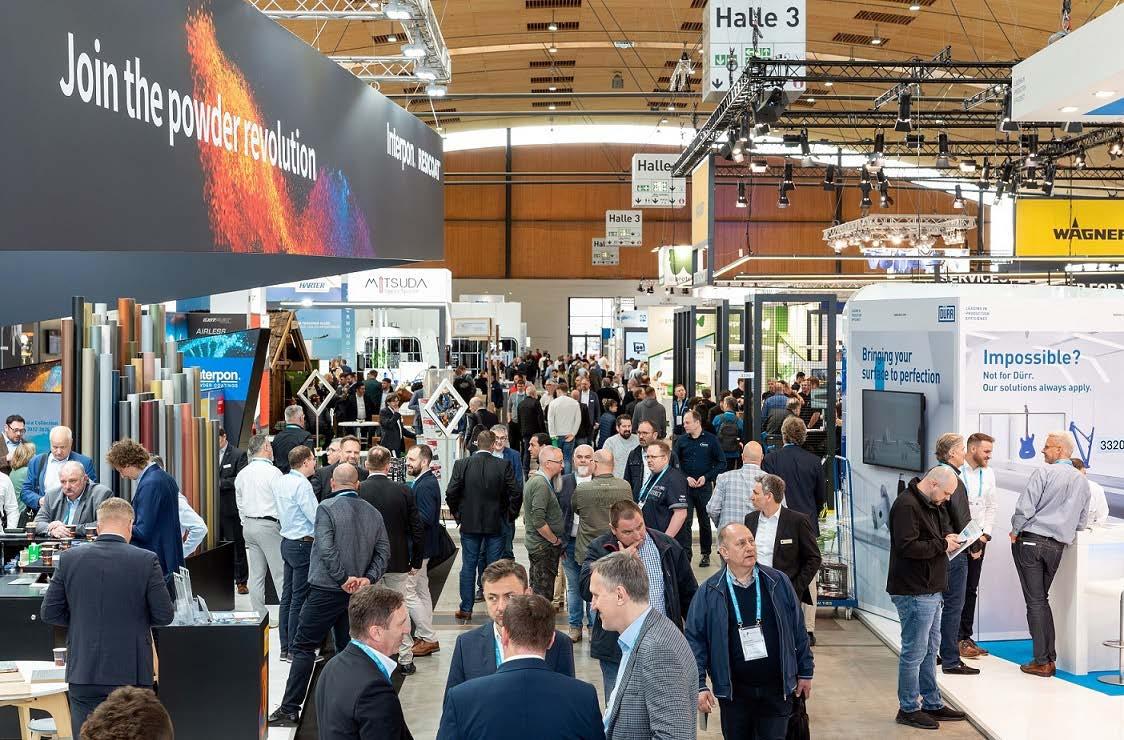

When there is no compromise to be made on a powder coating finish, architects need look no further than AkzoNobel’s Interpon D2525 Anodic powder coatings range. It delivers the stunning look of anodized aluminum and unbeatable resistance to weathering, all within a solution that reduces energy consumption, increases productivity and reduces carbon footprint.

Available in a striking selection of matt and metallic-effect finishes, from shiny golds and soft silvers to steely blues and earthy bronzes, matching every mood and style. The ideal alternative to anodized aluminum for windows and facades, the finish delivers excellent color and gloss retention. Formulated with Interpon D Low-E technology to support sustainability goals by curing at a lower temperature or faster speed, the range is pushing the boundaries of sustainable solutions in powder coatings.

Your imagination starts with our finish.

interpon.com

Alessia Venturi Editor-in-chief Direttore Responsabile

Efficiency.

After resilience, which escaped the realm of physics to gain popularity in the early 2000s, dominating the everyday vocabulary of almost everyone until it became meaningless, efficiency is today’s new watchword in any field: industrial, productive, social, family-related, educational, philosophical. Making the best use of available resources to achieve a goal – this is the word’s literal meaning – is the cornerstone of Industry 4.0. The mantra for the industry to be sustainable. The imperative for a society that demonises any waste, especially of time, in favour of performance.

This approach translates into the search for ever-increasing technological content, both in everyday life and in the economy.

In recent years, from manufacturing and logistics to agri-food to chemicals, every industrial branch has seen a growing trend towards the research and adoption of more and more advanced technologies, with the primary objective of improving operational efficiency, performance, and profitability while eliminating human error, the unexpected, and chance.

The implementation of digital systems, smart sensors, advanced automation, and data analysis platforms now enables real-time monitoring of processes and performance, reducing waste and downtime, improving product quality, and optimising resource utilisation. Technologies such as artificial intelligence, machine learning, collaborative robotics, and the Industrial Internet of Things are turning traditional activities into predictive and adaptive processes that anticipate problems and respond quickly to changes in demand. Even in the ACE (Agriculture, Construction, and Earthmoving equipment) industry, which is widely covered in the pages of this issue of ipcm®, the last for 2025, the focus on technology is getting stronger: drones that map the land and give operators instructions, planting and cultivation machines that combine several work steps in one, sensors and decision support software based on AI, and digital imaging solutions generating information that was previously only available to humans are just some of the innovations and trends presented at Agritechnica, the world’s leading trade fair for agricultural technology, which took place in Hanover (Germany) from 14 to 20 November.

It is undeniable that efficiency is part of progress and that, thanks to it, we can produce better, live better, consume less, and be more sustainable. However, it is equally true that eliminating error through standardised procedures can sometimes stifle innovation. Scientific and technological discoveries often arise from the unexpected, from experiments that exceed expectations, from mistakes. Embracing failure as a learning opportunity is crucial for progressing, finding creative solutions, developing new knowledge, adapting, and evolving.

Our wish for ipcm®’s readers in 2026 is to reserve a little space in our daily lives and business procedures for the unexpected and for beauty – values that perhaps contrast with efficiency, yet remain deeply human, fulfilling, and inspiring.

Happy holidays and a happy 2026 to you all!

Richiedi la versione in italiano a info@ipcm.it

Robert Kramer Director, The ChemQuest Group, Inc. rkramer@chemquest.com

Effectiveness (OEE) can drive operational excellence through a deep analysis of the main causes of productivity loss and common performance management mistakes, in order to optimise efficiency and business profitability.

The goal of operational excellence is to continuously improve a company’s end-to-end operations, including production facilities as well as business functions, enabling the organization to achieve high performance while maintaining agility and responsiveness. Optimal operations support your company’s competitive advantage while driving long-term profitable growth.

Operational areas to focus on can range from process optimization and capacity/production issues to expansion planning, supply chain, and even environmental health and safety. One ripe target for improvement in many organizations is overall equipment effectiveness (OEE), which compares your operation’s ideal performance to its overall real performance. Minor improvements in operations OEE can make a major difference to overall total productive maintenance (TPM), the goal of which is to maximize your equipment’s efficiency and minimize downtime. OEE is a quantifiable way to evaluate how well your equipment, people, and processes are working by measuring:

Availability: Available time divided by uptime

Performance: Production/output speed and consistency

Quality: Number of defects.

OEE uses these data points to determine a percentage of good production time for each asset. The resulting OEE scores enable you to identify and address opportunities for improvement.

Several common factors related to the previously noted availability, performance, and quality cause equipment productivity loss in manufacturing. Identifying and focusing on the most common losses in an organization creates a clear path to improving the OEE score and optimizing efficiencies.

Working to reduce availability loss due to equipment failures or setups/ adjustments protects against preventable unplanned downtime while minimizing unplanned stops. Equipment failure accounts for any significant period in which equipment is scheduled for production but is not running due to failure (i.e., unplanned stoppage or downtime). Some common examples of equipment failure include machine breakdowns, improper setup, and unplanned maintenance. From the broader perspective of unplanned stops, additional causes might include a lack of operators or materials, the process being choked by upstream

equipment, or downstream equipment causing blockages. Proven control plans should be put in place to reduce or eliminate equipment failure.

Setup and adjustments account for any significant period in which equipment is scheduled for production but is not running due to changeovers or other adjustments to equipment. Some common reasons for setups and adjustments might be product-to-product equipment modifications, product changeovers not being optimal, or unplanned maintenance. Production schedulers should target customers’ satisfaction as well, meeting on time and full delivery related to production and efficiency costs where production campaigns are maximized. It is important to reach an equilibrium, if possible, between the service level that you provide to the customer and the associated costs. Be sure to take into consideration the overall impact on the production scheduling and planning aspect, especially with changeovers.

Addressing performance loss that results from idling and minor stops, as well as reductions in speed, prevents small stops and slow cycles from accumulating. When we consider idling and minor stops, we generally include short (under 5 minutes) stops that occur while the operator resolves an issue without the help of maintenance. While short in duration, the root causes of these types of stoppages are often chronic, which can make operators somewhat blind to the full impact. Some examples of idling and minor stops might be raw material disruptions, plugged transfer lines, incorrect operator parameters or work instructions, improper calibrations, or design issues. Sometimes, the operator may need to locate ancillary equipment that is not stored in the right place or isn’t easily accessible. While performance-related issues may appear small in magnitude, they add up when multiple occurrences happen. Most companies not embedded in a robust continuous improvement culture tend to ignore the full impact of these types of issues. While these stops might be only a few minutes in a single duration, they accumulate and can make a significant difference over the course of your production cycle. Another factor in performance loss is reduced speed. Also known as slow cycles, reduced speed includes anything that keeps the process from running at its theoretical maximum speed (sometimes referred to as ideal run rate or nameplate capacity). Causes can include poor maintenance, substandard raw materials, limited ancillary equipment, poor environmental conditions in the plant, operator inexperience, or general lack of operator training.

Every day, everywhere, you deserve to breathe clean air.

Minimizing quality loss in the form of process defects and lower yield reduces the number of unusable products produced during steady

production. Process defects can account for defective material produced as off-spec batches or from startup until steady-state production is reached. This includes scrap material as well as material that must be reworked, since OEE measures quality from a first-pass yield perspective. Examples of common process defects include lot-to-lot raw material variation, incorrect equipment settings, or operator or equipment handling errors. In addition to process defects impacting OEE, the increased inspection needed as a result of poor quality results in added costs as well as potentially inferior or out-of-spec product reaching the customer. Best practice is to eliminate the defects altogether, as this will help the cost situation while providing a better product for the end customer. Reduced yield accounts for material loss due to poor processing results and suboptimal finished product output. Examples of reduced yield include suboptimal changeovers, incorrect settings on a new product run, equipment that requires warmup cycles, or poor operator training. Yield losses can have a significant impact on a company’s profitability, depending on the associated costs, especially when taking into consideration the raw material price increases of the last few years. Using a first-time-right mindset by increasing the first-pass yield saves time and hence costs. For example, think in terms of the goal of zero yield loss: It would be ideal if each one pound (or one unit) going into your process results in one pound (one unit) out of your process. This would represent 100% yield (fairly unrealistic).

Let’s say you determine your yield is at 90%. What are the drivers of that 10% in yield losses? You might investigate and discover a root cause that represents 2% (e.g., a poor metering system), another that’s 1% (e.g., container damage that occurs during material handling), another few that are 0.5% each (e.g., air loss during mixing or stagnant inventory). All of these small issues can add up to a significant number in terms of losses. When you understand where the 10% comes from, you can take steps to make improvements. Look first at the issues that have the biggest impact. Once those have been addressed, target issues with obvious (ideally, simpler) solutions.

Fully understanding OEE in terms of your company’s operations, as well as the ideal steps to take when making improvements, can be quite a complicated process. A few common OEE mistakes to avoid are highlighted below:

The true value of OEE comes from understanding the underlying losses and acting accordingly.

Many companies confuse the two and end up creating slower targets. While useful for planning purposes, they don’t help optimize potential.

Overemphasizing OEE on the shop floor

Too much pressure will result in potential poor behaviour. It’s best to instead provide extensive training on the positive behaviours that impact the underlying common losses to OEE.

Keep OEE data collection simple. Having too many reason codes creates confusion for the operators, which can prevent them from doing their jobs effectively. Instead, “Collect less and do it well.”

Unless processes are the same at your various sites, you can potentially put operators in a position to fudge data or at a minimum demotivate them due to unjust comparisons. For example, the complexity of parts/ product produced, as well as the number of production changeovers, are often inherently different between two facilities. It is unfair and indeed counterproductive to attempt to hold both sites accountable to the same metrics.

Excluding changeovers

Changeover time is lost production time, so it is important that reducing changeover time is given the utmost attention. Think of an auto race such as Formula 1, where the pit crew changes the tires with lightning-fast speed. Time is truly of the essence to ensure optimal productivity.

OEE typically only measures the productivity aspects of production assets (both equipment and manpower). However, it can also have a positive impact on capital expenditures (CapEx) when processes are running optimally.

For example, operating more efficiently allows companies to delay further investment in CapEx, which frees up cash. The resulting monetary resources might be better served in more profitable areas of the business — or even by not being spent at all, which only bolsters the company’s balance sheet and supports your initiative’s positive impact on the bottom line.

Backed by AkzoNobel’s global network and science-based carbon reduction targets, the launch of the IONOMY ecosystem marks a bold step towards helping the entire value chain address decarbonisation, modernisation, and resilient growth.

AkzoNobel Coil & Extrusion Coatings has launched the industry’s first consultancyled, not-for-profit partnership dedicated to make energy curing a viable and scalable solution for coil coaters and integrated steel manufacturers worldwide. The initiative, called IONOMY™, brings together experts in technology and solutions, including materials, curing, systems integration, software and hardware. The IONOMY ecosystem unites leading specialists to help businesses overcome the challenges of adopting energy curing, providing guidance from diagnostics and road mapping to line redesign and longterm optimisation. “It isn’t just about making a tweak to the process. Energy-curing is a complete reimagining and transformation of how coating lines are designed, operated, and optimised. We see the enormity of the challenge through our customers’ eyes, and this is why we have created the IONOMY ecosystem,” has stated Sebastien Villeneuve, Transformation Manager, Coil Coatings, AkzoNobel Coil & Extrusion Coatings. The name IONOMY combines ‘ionisation’ and ‘economy’. Ionisation highlights the critical role energy plays in triggering the cold curing process, which is central to renewable energy curing. Economy reflects the significant business benefits of energy curing, including reduced energy costs, faster throughput, improved sustainability, and long-term profitability.

The IONOMY ecosystem comprises:

AkzoNobel Coil & Extrusion Coatings –initiator of IONOMY and a global leader in coil coating solutions.

PCT Ebeam and Integration - supplier of innovative and reliable ebeam systems for coil lines.

IST METZ GmbH & Co. KG – leader in UV and LED curing systems.

Globus Srl – specialist in coating systems and machine engineering for coil.

NOVACEL SA – global leader in processing and protective films for innovative materials.

Despite the availability of energy-curable products, adoption in the coil coating industry has been slow, largely due to the complexity of transition. Many businesses remain uncertain about how to adapt operations to seize the renewable energy-curing opportunity.

“We’ve been guided by the values of collaboration, innovation, and sustainability to step forward and help our customers unlock change. No one company can deliver this kind of transformation alone, which is why the IONOMY ecosystem is built on collaboration to guide the industry into its next chapter. Our aim is to help coil coaters embrace the more efficient and sustainable future that’s within reach. Together, we’ll make renewable energy curing not just possible, but practical and profitable for all coil coaters and steel processors who will be free to adapt, innovate and compete on a new level,” has commented Chris Bradford, Market Director, Coil & Packaging Coatings, AkzoNobel.

For further information:

https://coilcoatings.akzonobel.com/us/ ionomy-redefining-coating-technology

Airbus highlighted Chemetall’s exceptional delivery record and longstanding role as a reliable partner within its supply chain.

The Surface Treatment global business unit of BASF Coatings, operating under the Chemetall brand, has once again been honoured with the prestigious Airbus Supply Chain & Quality Improvement Programme (SQIP) Award. The recognition marks the tenth consecutive year that Chemetall has received Airbus’ highest supplier accolade, underscoring its consistently strong delivery performance and product quality throughout 2024. The award ceremony took place at Airbus Headquarters in Toulouse (France), where the aerospace manufacturer celebrated its topperforming suppliers. Through the SQIP initiative, Airbus seeks to elevate its strategically important suppliers to world-class standards in quality and delivery performance—an increasingly crucial factor as production rates continue to rise. Chemetall, a certified and established supplier to the aerospace sector, provides Airbus with Naftoseal® aircraft sealing compounds and Ardrox® corrosion protection solutions, among other technologies, all designed to meet the stringent demands of the global aerospace industry. “We are very proud to receive the prestigious Airbus SQIP accreditation, which is the highest recognition for suppliers for their quality performance for the tenth year in a row. It is a testament to our commitment to deliver innovative and high-performing solutions across the whole value chain of the aerospace industry, from manufacturers to maintenance, repair, and overhaul companies of aircraft and aircraft engines. I want to thank Airbus for their trust and close collaboration for many years and promise that you can always expect more from us,” has stated Frank Naber, Senior Vice President Global Surface Treatment at BASF Coatings. “We are very pleased to have met the requirements of the Airbus SQIP programme again. This is a great team effort by all aerospace colleagues in Quality, Production, Technical and Laboratory

Support, Supply Chain, and Customer Service, who all contribute to delivering this high level of performance. We will continue to make every effort to ensure sustained excellence in delivery performance and quality for our customers and to work closely with Airbus to further improve our performance in the future,” has added Guillaume Larrieu, Global Key Account Manager Airbus at Chemetall.

For further information: www.chemetall.com

CUSTOM BUILT Engineered finishing systems: Blast, Pretreatment, Conveyors, Booths, applicators, robotics, and ovens.

Total Finishing Systems is a leading designer and integrator of high-quality and complex industrial finishing systems Whether you need an in-depth process analysis or require finishing equipment and components, our equipment exceeds expectations and our innovation and automation is industry leading

This launch positions Dürr CTS to be faster, more focused, and more influential in shaping sustainable industrial practices worldwide.

Dürr CTS, a global leader in air pollution control and noise abatement, has officially begun operations as a standalone company. Formerly the Clean Technology Systems (CTS) division of the Dürr Group, the company is now entering a new phase, focusing on advancing environmental technologies and driving sustainable growth in industrial production. With more than 60 years of experience in air pollution control, noise abatement, and decentralised power generation, Dürr CTS aims to make industrial production cleaner, quieter, and more efficient. Its technologies assist manufacturers across sectors such as automotive, chemicals, and energy production to meet stringent environmental and efficiency standards.

Regenerative thermal oxidisers (RTOs) from Dürr CTS purify exhaust air containing solvents and odours, achieving purification levels of over 99.8%, and helping to minimise emissions in industrial processes. Since November 2025, Dürr CTS has been majority-owned by Stellex Capital Management, which holds a 75% stake, with Dürr AG retaining a 25% minority share.

The company’s independence enhances its agility and entrepreneurial spirit, allowing it to respond more swiftly to market demands and invest in forward-looking technologies.

The global shift towards cleaner manufacturing continues to accelerate, driven by tighter emissions targets and the need for more efficient use of energy and resources. Dürr CTS addresses these challenges by combining deep process expertise, advanced engineering, and a strong customer focus. Working closely with clients worldwide, the company designs and implements systems that ensure environmental compliance while optimising plant performance.

“As a standalone company, we can build on our established strengths in air pollution control, noise abatement, and waste heat recovery while accelerating innovation in future-oriented technologies. Our strong R&D foundation enables us to further advance solutions such as CO2 capture and thermal energy storage which are key enablers of sustainability in modern industrial production,” has stated Sebastian Baumann, CEO of Dürr CTS.

Dürr CTS employs around 1,300 people across 12 countries and generated annual revenues of over €400 million in 2024. Its global network of engineering, manufacturing, and service locations ensures close customer support and rapid response capabilities.

For further information: www.cts-durr.com/en

The deal, combined with BASF’s earlier divestment of its decorative paints business, values the company’s entire Coatings division at €8.7 billion, reflecting an implied 2024 EV/EBITDA multiple before special items of approximately 13x. BASF will retain a 40% equity stake in the business and is expected to receive around €5.8 billion in pre-tax cash proceeds at closing.

BASF and global investment firm Carlyle, in partnership with the Qatar Investment Authority (QIA), have reached a binding agreement to transfer BASF’s automotive OEM coatings, automotive refinish coatings, and surface treatment businesses, collectively known as BASF Coatings. The enterprise value of the transaction has been set at €7.7 billion, with closing expected in the second quarter of 2026, subject to customary regulatory approvals.

BASF Coatings operates globally, providing innovative and sustainable coatings for automotive OEMs, automotive refinish, and surface treatments for metal, plastic, and glass across multiple industries. The business, which has a presence in Europe, North America, South America, and Asia Pacific, generated sales of around €3.8 billion in 2024.

Carlyle will work closely with BASF Coatings’ management to support future growth by investing in commercial capabilities, innovation, and organisational structure, enhancing customer focus. Carlyle brings extensive experience in industrial and chemical carveouts, having previously invested in Axalta, Atotech, and Nouryon.

“We are delighted to partner with Carlyle, whose sector expertise, carve-out capabilities and collaborative approach will help position BASF Coatings for longterm success. By retaining an equity stake, we are showing our belief in Coatings’ future value creation and upside potential. The passion, expertise, and customer focus of our Coatings team is what makes this business outstanding,” has stated Markus

Kamieth, Chairman of the Board of Executive Directors of BASF SE.

“The transaction announced today opens a new chapter of opportunity for BASF Coatings, building on today’s success and shaping an even stronger future,” has commented Anup Kothari, member of the Board of Executive Directors of BASF SE and responsible for the Coatings division.

“BASF Coatings is an exceptional platform with leading technologies, a world-class management team, strong customer partnerships, and a truly global footprint. We see compelling opportunities to leverage our global platform to support the business becoming an established independent leader. This transaction exemplifies Carlyle’s ability to execute complex carveouts in partnership with leading global corporates,” have added Martin Sumner, Global Head of Industrials, and Tanaka Maswoswe, Partner at Carlyle.

“QIA is pleased to partner with Carlyle to support the next phase of BASF Coatings’ continued growth. This investment aligns with QIA’s approach of investing in industry leaders and is testament to our belief in the long-term resilience of German businesses,” has concluded Mohammed Al-Sowaidi, CEO of QIA. BASF has assured that business continuity for customers will be maintained throughout the transaction process and that employee representatives will be involved in accordance with legal requirements and local practice.

For further information: www.basf.com

FreiLacke is investing in future-proofing its Döggingen operations, consolidating technical capabilities, and enhancing customer interaction – signalling growth and a commitment to both technology and sustainability, further reinforced by the continuity of the company’s management vision ensured following the retirement of Hans-Peter Frei.

FreiLacke has officially commenced construction of its new Product Technology Centre (PTC) with a ceremonial groundbreaking at its Döggingen site (Germany). The three-storey building, which will house cuttingedge laboratory and application technology, is expected to be ready for occupation in early 2027. The PTC is set to become the technical hub of the company. It will feature spacious development laboratories, a modern technical centre, and a central training facility where customers can receive handson training and experience FreiLacke’s coating systems using the latest application technologies.

The new building reflects FreiLacke’s response to increasing demands in product development and customer support. By consolidating technical centre operations previously spread across multiple buildings, the PTC will provide additional office and laboratory space and alleviate current capacity constraints, while efficiently accommodating the growing need for customer training. Covering approximately 550 m² per floor, the three-storey building, including a technical annex, will mirror the design of FreiLacke’s administrative building. It will be fully accessible, featuring an elevator and a link to the existing laboratory building, which will also be made barrier-free. Sustainability has been central to the planning process, with the PTC to include:

State-of-the-art, energy-efficient building services incorporating heat pump technology.

Energy integration with existing buildings to minimise additional consumption.

Compliance with current ecological standards.

Through this development, FreiLacke underscores its long-term commitment to the future by investing in the continued expansion of the Döggingen site, strengthening innovation through cutting-edge laboratories and advanced application technologies, and enhancing customer collaboration and support with a centralised, hands-on training centre.

In parallel with this investment, FreiLacke has announced a forthcoming change in management that underscores the company’s stability and forward-looking vision.

After 36 years of service, Hans-Peter Frei will retire at the end of 2025, stepping down as Managing Director, Executive Board Member, and Head of Technical Disciplines. Dr. Rainer Frei will assume responsibility as sole Managing Director, ensuring continuity in the family-owned company’s leadership.

In addition, Stefan Kienzler, who has overseen production since 2018, has been appointed to the management board as Head of Technology Division, joining Dr. Rainer Frei, Roland Bäurer, and Hans-Peter Frei until the end of 2025.

The management transition has been designed to guarantee continuity, stability, and consistent strategic direction, reinforcing FreiLacke’s role as a reliable global partner for advanced industrial coating solutions.

For further information: www.freilacke.com

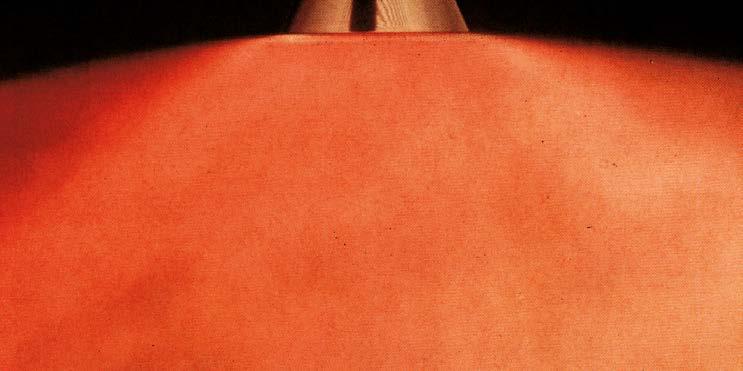

NASA and Boeing teams at the Michoud Assembly Facility have implemented an improved technique for priming the Space Launch System (SLS) core stage fuel tank ahead of applying its signature thermal protection foam.

NASA technicians have introduced a refined method for preparing the Space Launch System (SLS) fuel tank - the core stage - ahead of applying its well-known thermal protection system (TPS) coating.

Although the rover shown is not bound for Mars, it is supporting development of the rocket that will send astronauts around the Moon. At NASA’s Michoud Assembly Facility near New Orleans, Boeing teams have enhanced the priming process used on the SLS cryogenic fuel tank.

The rocket’s distinctive orange spray-foam layer regulates the temperature of approximately 733,000 gallons (2.8 million litres) of liquid hydrogen and liquid oxygen propellants, stored at minus 423 F and minus 297 F (minus 253 C and minus 183 C) during pre-launch operations.

The TPS spray foam may not adhere to the tank’s surface if the primer isn’t first applied consistently and in compliance with engineering requirements. Before the protective foam is applied, bare aluminium tank surfaces must be covered with primer. An automated spray system treats most of the 149-foot (45.4-metre) tank, but technicians still manually coat the domed sections to ensure full coverage and adherence.

“Kicking off this project was a bit overwhelming as well as exciting. It’s a challenge to collaborate across different functional groups, using everyone’s unique strengths and perspectives, but rewarding. We had team members familiar with chemical processing, engineering design and requirements, and practical knowledge of applying these concepts for manufacturability. I’m proud of how our Boeing teammates worked together to create a simple yet effective solution to solve such a complicated problem,” has stated Boeing engineer Nick McEvoy.

For further information: www.boeing.com

Engineering specialized in the supply of systems for surface treatment, painting and coating

SYSTEMS LIQUID PAINTING SYSTEMS POWDER COATING SYSTEMS

SELF-LEARNING ROBOTS FOR AUTOMATED PAINTING

SYSTEMS FOR THE TREATMENT OF VOCs EMISSIONS .

Julian Rixrath Evonik Industries AG – Essen, Germany Julian.rixrath@evonik.com

TEGO® Powder Aid C01 enhances corrosion protection and adhesion of powder coatings while eliminating common additive drawbacks, paving the way for superior surface finishes.

Powder coatings are becoming increasingly popular across a wide range of applications thanks to their numerous advantages. They enhance corrosion protection and adhesion, offer broad compatibility with various binder chemistries, and ensure easy processability without significantly affecting rheological behaviour. Moreover, their sustainable growth and environmental benefits make them an ideal solution for modern, eco-conscious coating technologies. Powder coatings are becoming increasingly popular for a wide range of applications due to their numerous advantages. The market for powder coatings was valued at over $13.5 billion in 2022 and is expected to grow significantly, reaching over $20 billion by 2032, with an annual growth rate of more than 6%. This growth is largely driven by the increasing focus

on reducing volatile organic compounds (VOCs). Powder coatings emit negligible VOCs compared to traditional liquid coatings, making them a more sustainable and environmentally friendly option. These coatings come in a variety of finishes and colours and are known for their high durability. This makes them ideal for architectural uses like outdoor stadium seating, window and door frames, as well as furniture applications. With technological advancements in binder and additive chemistries, their use also has expanded into high quality surface finishing, such as heavy construction machinery and even automotive parts, highlighting their versatility and excellent resistance towards harsh conditions.

In addition to environmental benefits, powder coatings also offer a lot of practical advantages. They are cost-effective, require less personal protective equipment, and do not need solvents for cleanup, further reducing their environmental impact. Even the overspray can be recycled in most cases. Powder coatings also allow for thicker application without the risk of running or sagging and do not contain any solvents, which lowers transportation and storage costs.

Commonly used powder coating additives that contain a significant amount of silica can sometimes go hand in hand with several unwanted effects. These include a slight loss of gloss, orange-peel, reduced film flexibility, or even a loss of adhesion. Such issues result in inferior coating quality, where the surface protection might not perform as effectively as intended. This can lead to a lower quality perception of the final product, as the coating may not provide the desired aesthetic or protective properties.

TEGO® Powder Aid C01 uses a novel technology, where modified polyester polymers come into action. This technology creates the desired effects in coatings without the drawbacks of silica containing additives. It may positively impact desired paint film properties, for example providing a smoother surface and improving film flexibility.

TEGO® Powder Aid C01 consists of free-flowing granules that are simply added to the premix before the extrusion process. There is no special handling necessary, as the product is very easy to use and incorporate.

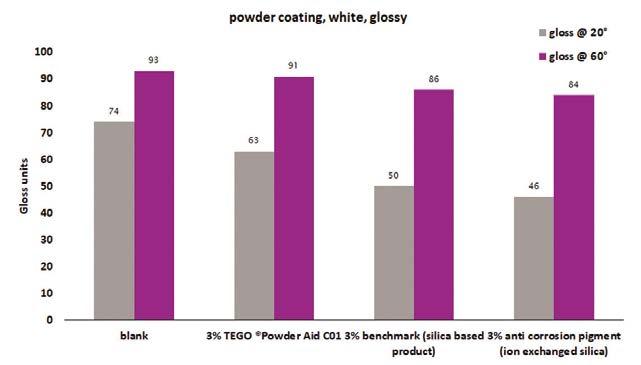

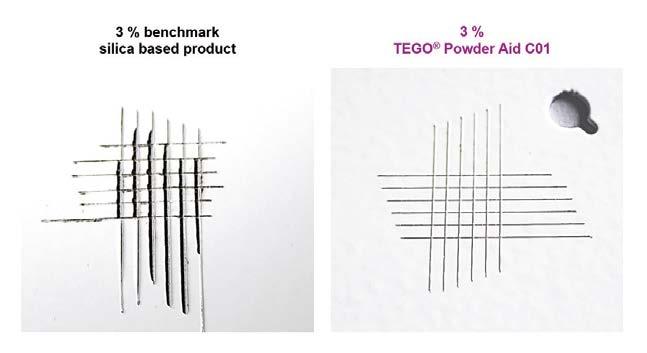

Extended laboratory trials across various binder technologies have shown a significant improvement of results after exposure to a natural salt spray (NSS) test following DIN EN ISO 9227. Figure 1 for example shows a white glossy powder coating (PE/ HAA - 95/5, DFT 85-90µm on zinc-phosphated steel panels) with both 3% and 5% TEGO® Powder Aid C01 after exposure to salt spray for approx. 860h. In addition to the optimized corrosion protection properties, less impact on the gloss level of the coating was observed. Figure 2 shows the gloss levels in 20° and 60° angle, comparing TEGO® Powder Aid C01 to a silica based market standard and a typical ion-exchanged anti-corrosion pigment. Having a look on the influence of adhesion, Figure 3 shows best results in terms of chipping and loss of adhesion, even on the cutting edges of the cross-cut test.

In conclusion, the use of TEGO® Powder Aid C01 can not only increase the corrosion protection properties of powder coatings, but also features best adhesion and surface finish properties.

Giulia Gentile ipcm®

Rostirolla presents its EB eyebolts and CF threaded caps: selecting the correct component helps reduce production waste and optimise the operational flow of the entire coating line.

In the industrial coating sector, attention is often focused on application systems and coating technologies, overlooking the crucial contribution of small accessories.

The EB eyebolts and CF threaded caps developed by Rostirolla - a company with over twenty years of experience in the production of hooks, frames, trolleys, masking systems, and accessories for painting processes - provide a simple yet effective solution to improve the quality of the final coating. These elements allow workpieces to be hung and supported during painting while simultaneously masking the areas that must remain uncoated.

Correct selection and use of these components reduce the risk of rejects caused by non-compliant coating results.

Technical features of eyebolts (EB)

Eyebolts are fastening elements whose head forms a closed or partially closed loop, allowing attachment via hooks, carabiners, or suspension wires. They are the ideal solution when the available attachment point is a

threaded hole already present on the workpiece. EB eyebolts are made of galvanized steel and available with standard metric threads M3, M4, M5, M6, and M8.

Advantages for coating

Allow hanging the part while minimising contact points with fixed supports.

Perform a masking function: the eyebolt can be removed after painting without leaving imperfections if the hole is subsequently used for final fastening.

Offer versatility of use on workpieces with different geometries.

Best practices

Before hanging, verify that the component can support the weight of the workpiece (both static and dynamic loads).

Avoid overtightening to prevent thread deformation; follow the supplier’s instructions.

Threaded caps (screw caps) are galvanized steel plugs that screw onto threaded studs on the workpiece to create a temporary suspension point and protect the thread from paint. The standard version is compatible with M3, M4, M5, M6, and M8 studs or threads.

Advantages

Mask the thread, preventing paint from filling it and compromising subsequent assembly or coupling.

Quick to install and remove, and suitable for reuse.

Make sure the thread on the part is a normal "ISO metric" type;

Some components do not use standard metric threads (e.g. lighting, hydraulics). Do not force the accessories into place as this could damage the thread.

Whether using EB eyebolts or CF threaded caps, it is essential to verify the load capacity and material of the attachment point, as safety must always come before convenience. Reusability and thermal resistance should also be evaluated according to the specific coating cycle.

Before loading and hanging the parts, it is therefore necessary to:

check that the part can bear the weight and stresses;

select EB for threaded holes and CF for threaded studs;

verify material and thermal compatibility;

run a pilot cycle to ensure defect-free results;

establish post-coating quality control procedures.

Rostirolla keeps both products in stock in the most common metric threads (M3–M8) and can also supply customised variants upon request. The company’s service offer includes technical consulting for product selection, just-in-time supply, customised hanging kits, and solutions to minimise contact defects and optimize line efficiency.

“Accessories should never be underestimated,” states Pierluigi Rostirolla, who manages the company together with his brother Simone. “EB and CF are small investments that substantially improve both the aesthetic quality and productivity of the coating line. Rostirolla provides a complete range, stock availability, and technical support to integrate these solutions into any coating system.”

Edited by Defil Srl Sesto San Giovanni (Milan) – Italy info@defil.it

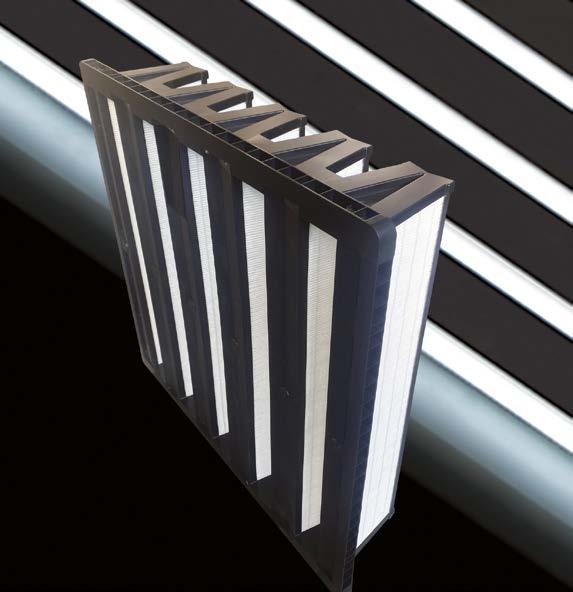

In the HVAC and air treatment sector, continuous innovation is essential to meet the growing demands for energy efficiency, environmental sustainability, and costeffectiveness. DEFIL’s K Series DIE filter stands out among the solutions that are revolutionising the way air is filtered as a concentrate of technology and functionality, designed to be a cutting-edge response to today’s indoor air handling challenges.

The strength of the K Series DIE filter lies in its compact design, with approximately half the depth of conventional rigid pocket filters. This feature is not only aesthetic but also strategic, since it significantly optimises the space inside filtration systems, making installation possible even in small or already packed spaces.

This is particularly useful for retrofitting existing systems, where the size of traditional filters often limits their application, and for designing new, more compact and lightweight air handling units.

However, reducing the size does not mean compromising on performance. On the contrary, measuring 592 x 592 x 150 mm, the K Series DIE filter provides an airflow rate of 3400 m³/h with an initial pressure drop of 120 Pa, and it guarantees high standards of filtration of particulates, allergens, fine dust, and other harmful particles

thanks to high-quality materials and advanced design technologies. Its ability to maintain optimal airflow, coupled with superior filtration efficiency, ensures advanced functionality without losing energy efficiency.

The K Series DIE filter is extremely versatile, effectively adapting to a variety of environments and filtration requirements. It is particularly suitable for:

replacing both rigid and flexible pocket filters: a quick, straightforward, and minimally intrusive upgrade compared to traditional filters, thanks to its compact and easy-to-install design;

coating, sandblasting, and laser/plasma cutting systems: thanks to its high efficiency, it can be the ideal solution for filtering exhaust air or an excellent intermediate stage before higher filtration;

HVAC and air treatment systems in general: ideal for commercial, hospital, and industrial settings where air quality is a key factor for people’s health and well-being;

public buildings and healthcare facilities: thanks to its ability to capture fine particulates and pathogens, it enhances indoor safety and health measures;

industrial process plants: wherever accurate and reliable filtration is required, especially in critical environments or those that must comply with strict regulations.

In addition to a compact design, this filter offers numerous benefits that make it a worthwhile long-term investment:

increased service life: its robust construction with high-quality materials ensures reliable and stable operation over time, thus reducing maintenance costs and downtime.

A longer service life also means limited waste disposal and a lower environmental impact.

energy savings: thanks to optimised airflow and low pressure drop, it promotes an efficient use of ventilation units, helping to reduce energy consumption and CO2 emissions.

These advantages translate into lower operating costs and increased sustainability over time.

DEFIL’s K Series DIE filter is a true innovation in the industry. Its compact and lightweight design, combined with high performance and superior energy efficiency, makes it an ideal solution for the most demanding applications.

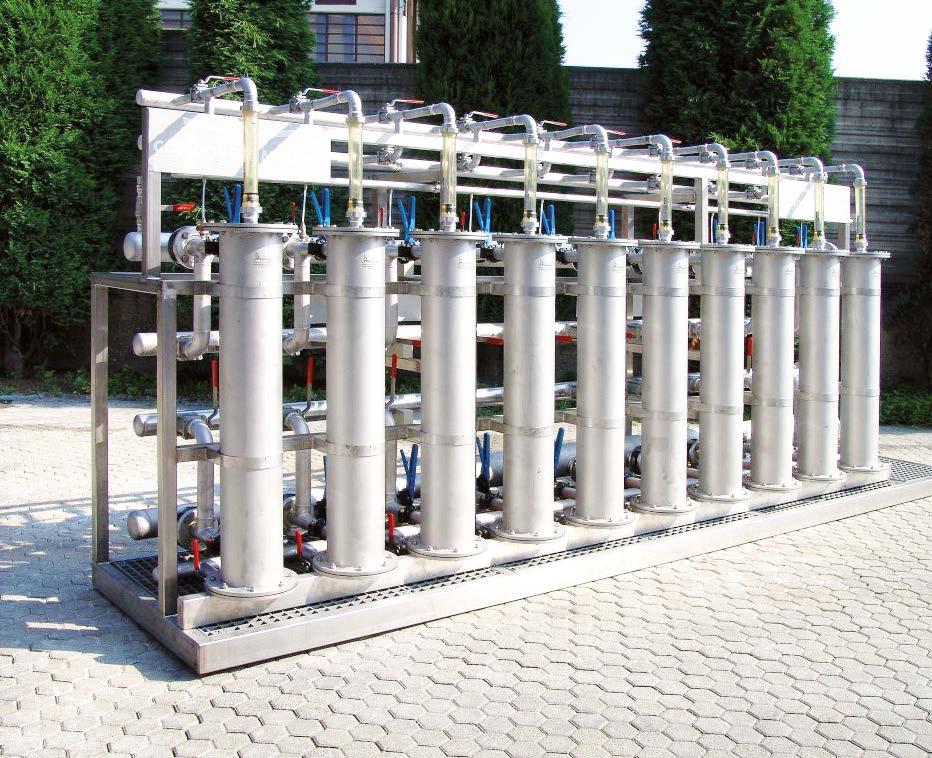

In 2025, SAITA Srl celebrates 45 years in business: a journey built day by day thanks to the expertise, passion, and commitment of everyone who has been, and continues to be, part of it. From a small company founded to provide support to wastewater treatment systems in the provinces of Padua and Vicenza, SAITA is now a well-established international player in the industrial wastewater treatment and recycling sector.

SAITA’s story began in 1980, when professionals with strong technical and commercial skills decided to combine their experience to create a company specialised in servicing water purification systems. Originally based in Vicenza, the company moved its headquarters to Limena (Padua) in 1984, where it continued to grow until the inauguration of its current premises in 2006: over 1,000 m² of indoor space, plus 650 m² of carpentry and a further 1,500 m² of the new headquarters, which will be inaugurated by the end of 2025.

Today, with three production facilities in Padua (Italy), the company operates in more than 30 countries, providing plants and technical support to clients across a wide range of industries - from electroplating to painting, chemicals to pharmaceuticals, and even electronics and semiconductors.

Innovation and sustainability at the core

SAITA designs and manufactures all its systems in-house, combining modularity with tailor-made solutions, always integrated into production processes. Environmental sustainability lies at the heart of the company’s mission: reducing the impact of industrial operations and lowering management costs through advanced treatment and recycling technologies.

Its cutting-edge solutions include:

Demineralisers;

Chemical-physical treatment systems;

Vacuum evaporators;

Membrane filtration;

Filtration systems;

UV and ozone disinfection;

Sludge treatment and oil separators;

Zero Liquid Discharge (ZLD) solutions.

The company has also invested in research through SAITA LAB, its in-house laboratory dedicated to analysis, technological development, and staff training.

Over its 45-year history, SAITA has turned challenges into opportunities for growth. A few days ago, the company celebrated this important milestone together with everyone who contributes to its journey every day, renewing its commitment to looking ahead with the same determination. “We would like to thank all those who, yesterday and today, have made this story possible,” has stated SAITA.

For further information: www.saitaimpianti.com/en/

The acquisition reinforces Trasmetal’s growth strategy, aimed at consolidating its leading role in both the Italian and international industrial markets.

Milan-based surface finishing systems leader Trasmetal SpA recently announced that, in July, it acquired a 65% stake in Italtecno Solutions S.r.l., a Modena-based company (Italy) specialising in sustainable technologies for the aluminum industry. Through this transaction, Trasmetal aims to broaden its portfolio of expertise and integrated solutions for its customers—from anodic oxidation plants to extrusion die cleaning lines, from spent soda recovery systems to water treatment facilities— strengthening its position as a leading supplier of aluminum profile finishing systems. “The synergy between the two companies will create new technological and commercial opportunities, leveraging the experience and quality that have always set both companies apart,” has stated the company.

For further information: https://trasmetal.com/en

• Superior coverage and process control for significant powder savings

• Fast, reliable, highly automated color change with visual access

• Advanced automation solutions for reduced manual coating

• High finish quality with advanced charge control and ultrasonic sieving

• Industry 4.0 ready IO links

• User-friendly, connected controls with visual guides and help content

www.nordson.com/powder

ics.eu@nordson.com

Ervin Germany GmbH Berlin, Germany info@ervin.eu

Winter shot blasting challenges - from restart issues to moisture in the abrasive - can be managed effectively with proactive planning and additives like Amapure from Ervin, ensuring consistent performance and protecting equipment.

As the colder months approach, many surface preparation facilities face unique operational challenges that can affect both productivity and equipment reliability. In particular, shot blasting is highly sensitive to seasonal changes. Reduced ambient temperatures, increased humidity, and extended production shutdowns – often associated with holiday periods – can all disrupt otherwise stable processes.

While these factors might seem minor compared to more obvious operational concerns, they can have a disproportionate impact on efficiency, abrasive performance, and the long-term health of critical equipment. Two issues stand out year after year: restarting machinery after extended shutdowns and managing moisture contamination in the abrasive mix. Both can be managed effectively with foresight, planning, and adherence to best practices grounded in technical understanding. This article outlines the key considerations for ensuring winter operations

remain stable, efficient, and safe – keeping both equipment and operators performing at their best during the most demanding months of the year.

It is not uncommon for production facilities to schedule extended shutdowns over the winter period – particularly around December and early January – for holidays, maintenance, or cost-saving reasons.

However, when a blast system sits idle for several days or weeks, the conditions inside the machine and associated infrastructure can change significantly. Dust and abrasive residues settle, moisture accumulates, and seals or bearings may experience slight corrosion or stiffness. When operations resume, these changes can lead to costly start-up issues if left unchecked.

Before powering up, a structured restart procedure should be followed, ideally developed in consultation with the equipment manufacturer or maintenance partner. At minimum, the process should include: Mechanical inspection: verify that blast wheels, impellers, and housings are free from seized or worn components. Check drive belts and couplings for tension and alignment. Any signs of corrosion or abrasive buildup should be addressed before start-up.

Electrical system check: inspect all control panels, sensors, and safety interlocks. Cold, damp conditions can affect cable insulation and connectors, leading to erratic readings or false alarms.

Abrasive and recycling system: empty any standing blast media from the blast pot and conveying systems if not already done before the shutdown. Clumped or compacted abrasive can cause flow blockages, uneven feed rates, or premature wear once the system restarts.

When the time comes to refill the hopper, it is advisable to use a balanced mix of new and reclaimed abrasive. This combination stabilizes operating conditions more quickly and restores the desired particle size distribution. The hopper should ideally be at least three-quarters full before the first run, allowing for consistent flow through the feed system.

If only new abrasive is available, expect a short run-in period while the system reaches equilibrium. During this phase, operators should monitor abrasive flow rate, wheel amperage, and blasting pattern carefully,

adjusting settings as necessary to maintain process consistency. Critical support systems such as airwash separators, sieves, ducting, and dust collectors should also be inspected and cleaned. Dust accumulation in filters can reduce suction efficiency, leading to higher pressure drops and potential contamination of the blast media. Finally, document the restart procedure and assign clear responsibilities to the maintenance and production teams. A short pre-start meeting to review roles and expectations can prevent simple oversights from turning into multi-hour stoppages.

Quick Tip: always plan the restart checklist before the shutdown begins. Identify which components require isolation, cleaning, or lubrication, and ensure the necessary spare parts are on hand. Preparation before downtime saves valuable production hours afterward.

The second major winter challenge is moisture. As temperatures drop and relative humidity rises, the risk of moisture ingress into the abrasive system increases dramatically. This issue often begins subtly – a few damp workpieces, a hopper lid left open during loading, or condensation forming in ducting overnight – but its effects can quickly compound.

Moisture in the abrasive mix causes steel shot or grit to clump together, reducing flow through the feed system. The problem often manifests first as irregular abrasive flow, which leads to inconsistent surface coverage and non-uniform blasting results. Over time, it can escalate into complete blockages within the hopper, elevator, or reclaim system, forcing operators to perform manual cleaning or even complete evacuation of the abrasive.

Beyond flow problems, moisture can also lead to surface quality issues. Wet abrasive impacts the substrate differently, reducing the cleaning efficiency and leaving a surface profile that may compromise coating adhesion. In addition, damp abrasive tends to attract fine dust particles, increasing the load on filter units and accelerating wear. A proactive approach to moisture management is therefore essential. This begins with environmental control – keeping storage areas and feed hoppers as dry and temperature-stable as possible. Covering workpieces stored outdoors, insulating pipework, and ensuring positive airflow through the blasting hall can all help to minimize condensation.

In addition, the use of mineral additives such as Amapure from Ervin, offers a practical, proven method to control moisture within the abrasive itself. These additives act by absorbing residual humidity and oil contamination within the media, maintaining a dry, free-flowing mixture. The benefits extend beyond preventing blockages: operators often report cleaner blasting patterns, reduced dust carryover, and longer filter life.

As Paul Abram, Technical Director at Ervin, explains: “Moisture in the abrasive mix is a hidden winter challenge that can affect both blasting

quality and equipment health. Addressing it early with Amapure makes all the difference.” By maintaining dry, clean, and consistent abrasive flow, facilities can safeguard both performance and the mechanical integrity of their blast equipment.

Quick Tip: store abrasive in sealed, dry containers and avoid leaving hoppers empty overnight. Topping up with a balanced mix of new and recycled abrasive reduces the risk of moisture pockets forming in the feed system.

Even with robust procedures in place, conditions during the winter months can fluctuate rapidly. A system that runs smoothly on a mild, dry day may experience unexpected challenges when humidity spikes or temperatures drop overnight. Continuous monitoring is therefore critical to maintain stability.

Operators should conduct frequent in-shift checks on abrasive flow, blast wheel amperage, and dust extraction performance. Variations in these indicators often reveal early signs of moisture problems or mechanical issues before they escalate. Recording daily readings can also help identify seasonal trends and guide preventive maintenance. Adjustments to airflow and separator settings may be required as ambient conditions change. For instance, cold air tends to be denser, potentially altering the balance between airwash velocity and abrasive fall rate. Small calibration tweaks can help maintain separator efficiency and ensure the correct removal of fines and contaminants.

From a management perspective, documenting the lessons learned each winter creates a valuable knowledge base. Over time, this information evolves into a customized “winter operations playbook” – a reference guide that captures best practices, performance data, and lessons from

previous seasons. Sharing this knowledge across multiple sites can significantly improve company-wide efficiency and reduce learning curves for new operators.

Quick Tip: establish a short daily logbook during the winter season. Record temperature, humidity, and machine performance metrics – these small data points can reveal valuable correlations and support data-driven improvements.

Winter does not have to mean reduced efficiency or increased downtime for shot blasting operations. By focusing on two key areas – controlled restarts after production breaks and proactive moisture management –facilities can maintain consistent performance even under challenging seasonal conditions.

A structured restart plan protects equipment from unnecessary wear, ensures safe operation, and accelerates the return to full production rates. Meanwhile, controlling moisture in the abrasive mix not only preserves surface quality but also extends component life, improves filter performance, and reduces maintenance effort.

Together, these measures embody a proactive approach to process reliability – one that minimizes risk, safeguards output and reinforces operational excellence across the plant.

“Winter need not be a season of reduced performance. With the right preparation, shot blasting operations can remain efficient and reliable all year round,” Paul Abram concludes.

By integrating sound maintenance planning with technical vigilance, operators can turn the challenges of winter into an opportunity to strengthen process discipline and performance resilience across their entire operation.

DISCOVER OUR SYSTEMS

SandenVendo, a global leader in the manufacture of vending machines, is accelerating its sustainability ambitions with the help of Interpon powder coatings from AkzoNobel. The company has reduced energy consumption, waste and associated costs by adopting Interpon Redox One Coat, a high-performance, anti-corrosion solution that requires only a single application.

SandenVendo takes pride in the quality and performance of its equipment, even in more challenging environments where corrosion can be an issue.

The company has been a leader for more than 80 years and built its European manufacturing in Northern Italy in 1965 with the stated aim of ‘designing a sustainable manufacturing system through the entire flow of supply chain, waste recycling and quality control’.

To support this ambition, it began exploring the benefits of Interpon 30 years ago, attracted in part by the absence of any Volatile Organic Compounds (VOCs) making it safer for its workforce to use and recognizing the role that powder coatings could play in delivering on its global sustainability objectives.

Most recently, it started using Interpon Redox One Coat, which achieves all the anti-corrosion performance of the standard Interpon Redox system but in a single application. This helps SandenVendo reduce its energy consumption, waste and associated costs through accelerated production times.

It has recently increased the volume of external vending machines coated with Interpon Redox One Coat from 10% to 40% of total production, and feedback has been entirely positive: “Switching to Interpon Redox One Coat has helped significantly reduce powder consumption, and the business continues to evaluate other powder coating technologies, including Interpon’s low energy (Low-E) which cures at a lower temperature,” says Paola Venesia, Purchasing Manager of SandenVendo Europe. Switching to Interpon Redox One Coat has also helped SandenVendo in becoming certified to ISO 50001, the energy management certification. Greater efficiencies in the powder coating line contributed directly to reducing the overall consumption of electricity and gas throughout the business.

Sanal Limoncuoglu, Commercial Director for South Europe at AkzoNobel Powder Coatings, says the business is proud to support SandenVendo in its sustainability journey: “Interpon Redox One Coat is a great example of how innovative coating technologies can help manufacturers reduce their environmental impact while maintaining high levels of performance and protection. Our collaboration with SandenVendo demonstrates what is possible when shared values around quality, efficiency and sustainability come together.”

In working with Interpon, SandenVendo has benefited from the quality of its products – their colour and durability. It currently manufactures on average 90 pieces of equipment per day, and with a second line shortly to come on stream, expects to increase this number of 130 by the end of 2025. Its vending and coffee equipment is used both indoors and outside, and Interpon used to both coat the casing and some of the internal components. The colours it chooses can be customized for particular clients: “Whenever we have a new colour we always test its performance in a climatic chamber,” Paola continues, “so we can see how it performs over time. Our products are exposed to water, humidity and temperature, as well as the sun, so the colour integrity is important to us. We also test to ensure that the stickers we use adhere to the surface without peeling.”

SandenVendo is on an exciting growth journey. It already delvers to more than 70 countries worldwide and continues to strive to design equipment ‘that improves and inspires the culture and lifestyle of communities around the world’.

Its growth is helped by the partners it chooses: “AkzoNobel is one of our very best suppliers,” Paola concludes. “I believe it is a business that every manufacturer should choose as a partner.”

70 years of experience and innovation

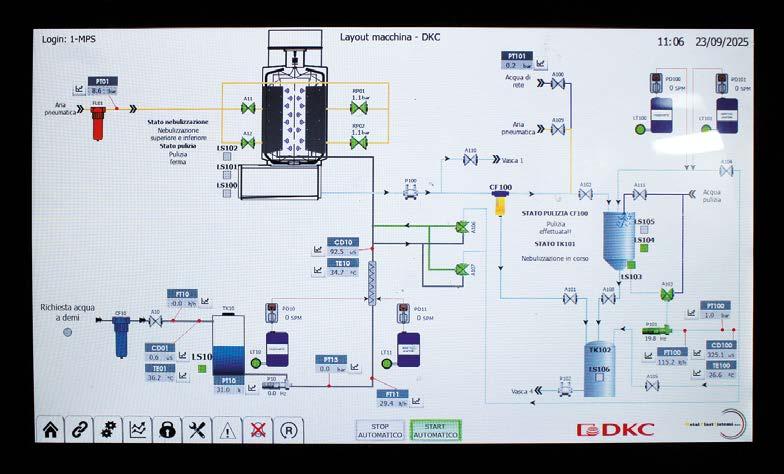

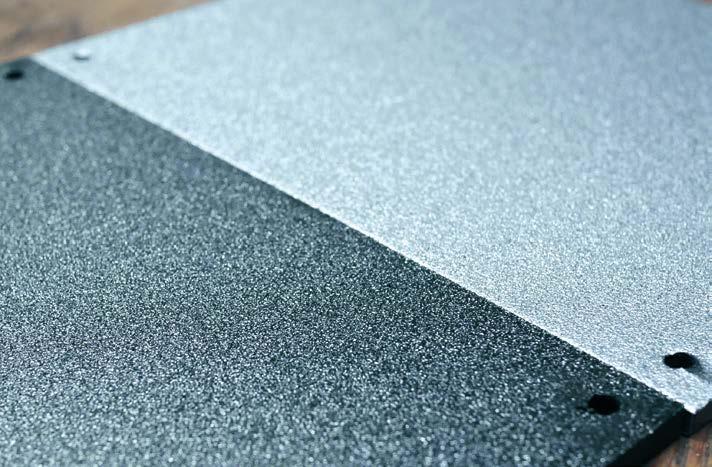

Working with DN Chemicals, DKC Group has revamped its pre-treatment process for cabinets for electrical panels from the RamBlock line, introducing cutting-edge nanotechnology and an automatic atomisation module with customised features, which improves coating adhesion and corrosion resistance up to class C3H–C4H.

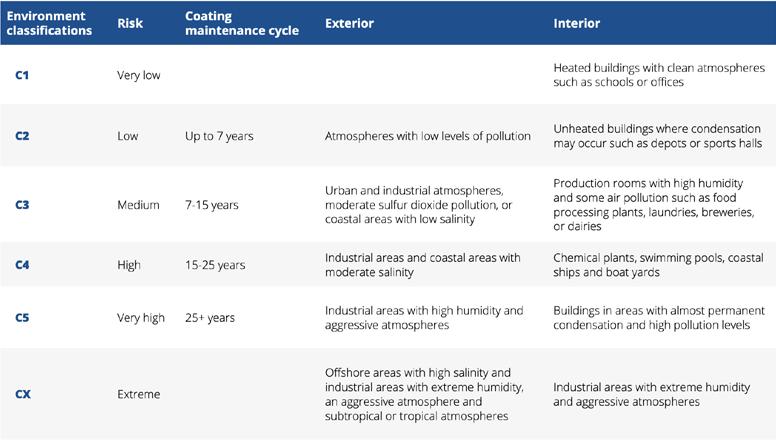

For several years now, the surface treatment market has shown a clear trend: the demand for coatings with increasingly specific levels of durability is growing, even for products not intended for use in harsh environmental conditions or high corrosivity classes. This is a sign of greater maturity within the sector, which today is characterized by a more professional approach and an industrial culture that fosters growth and internationalization.

As a consequence, the R&D departments of surface treatment solution providers are focusing on improving product durability to meet these new requirements, offering flexible and modular systems in terms of investment, operating, and management costs. End users are not always ready to invest in higher performance, creating a gap between what is

requested and the available budget. This is why it is essential to propose the level of performance that best suits the customer’s real needs and the actual use of the products.

This principle was the starting point for the collaboration between the DKC Group, an Italian company recognized worldwide for its extensive experience in the design and production of coordinated solutions for the electrotechnical sector, industrial automation, and e-mobility, and DN Chemicals (Milan, Italy), one of Europe’s leading manufacturers of coating pre-treatment and water treatment chemicals.

The latter, already the supplier of DKC’s coating pretreatment cycle for the RamBlock line, has replaced the silane-based nanotechnology conversion chemical in use with a cutting-edge one from its latest range, aiming to reduce the gap between the corrosion resistance degree guaranteed by DKC (salt spray resistance of 240 hours) and the C4H corrosion class obtained through cataphoresis. In addition, to further strengthen DKC’s role in a constantly evolving market, DN Chemicals also worked closely with the supplier of the fully automated and customised spraying module, contributing the expertise gained on other systems. This collaboration enabled DKC to reduce operating costs and, in the future, to switch from one pretreatment product to another according to customer requirements in just a few seconds and without the need for waste disposal.

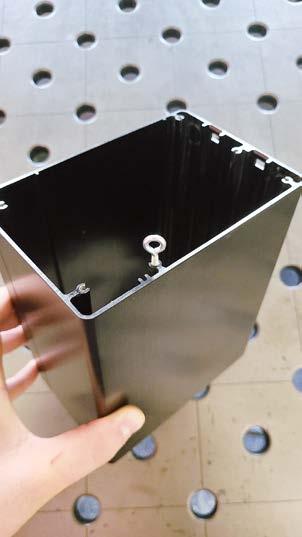

“DKC was founded in 1998 to serve the field of cable management systems. Between 2007 and 2021, the Group consolidated its presence in Italy and Europe through investments in companies with strong technical know-how and well-structured sales networks, which gave shape to the Sistema Italia,” says Michele Oberti, head of DKC’s RamBlock Line Production Unit in Bellinzago Novarese.

“For more than twenty years, we have been a benchmark supplier of a wide range of innovative and efficient solutions for cable protection, energy transmission, storage, and control, industrial automation, and plant engineering. Our offering is primarily aimed at plant manufacturers, system integrators, distributors, installers, designers as well as end users. Our offering includes a broad and coordinated portfolio of solutions. In addition to the Bellinzago Novarese headquarters and two foreign facilities, in Hungary and Romania, dedicated to the RamBlock Line, our Lines include the Combitech and SATI Italia channel, the low-voltage roadside cabinets of the Conchiglia Line, the electrical panel solutions of the Steeltecnica Line, and the metal and plastic cable protection systems of the Cosmec Line. Alongside these, we also offer active products for energy management and distribution developed within the Hercules, RamKlima, RamBatt, Net One, and Energy Lines.”

“Coating is a process that mainly concerns our RamBlock line, distributed among Bellinzago Novarese, Hungary, and Romania, where we produce modular and monobloc metal boxes and cabinets for machine automation, mainly for indoor use,” indicates Oberti. “Durability and corrosion resistance, however, are becoming added-value features of the product, especially for certain specific applications. That is why we explored possible technological alternatives to our existing treatment cycle, looking for ways to improve coating quality and durability without incurring investment and management costs that would make it difficult for the market to recognise us.”

“We needed to find a good compromise between quality and operating costs. It is essential to strike a balance between the level of corrosion resistance actually required and the increase in industrial costs involved in implementing new technologies or processes,” explains Maurizio Bovio from DKC’s production technologies department. “One possible solution was to use cataphoresis to deposit a primer layer and then powder coating: this approach is increasingly common on the market, and some of our competitors had already applied it in the recent past. However, the investment costs for installing cataphoresis systems not only at the Bellinzago site but also at the Hungarian and Romanian ones, which have the same production flow, would have been too high and not justified by actual customer demand.

“At the same time, an essential aspect for us at DKC is avoiding coating delamination because, although we offer a product customisation service, metal cabinets are often drilled and machined by our customers to insert switches or slots. For this reason, paint adhesion to the sheet metal represents one of the most important quality parameters and is highly valued by the market. In light of these considerations, we decided to focus on improving our pre-treatment process by adopting new-generation products. We consulted our long-standing supplier, DN Chemicals, to find a solution that would increase coating adhesion, ensure uniform surface coverage even at the numerous edges and welds, and reach a corrosion class between C3H and C4H.”

• 3D Masks by cutting Silicone

• Max precision

• Multiple materials for multiple uses and industries

• No minimum order quantities

“In our Group’s three metalworking plants, we process hot-rolled carbon steel, mainly in sheets, which is cut, sheared, punched, bent, coated, and finally fitted with seals, as all our panels must be liquid-tight,” illustrates Michele Oberti. “At the Bellinzago Novarese site, we have an automatic coating line with a quick-colour change booth and Nordson HDLV spray guns. Although the standard hue of our products is RAL 7035, we make a dozen colour changes per week because, as we primarily supply the automation market with cabinets installed on board machines, there is often a need to match their colours. We also have some customers who send specific orders calling for special hues.”

“The pre-treatment cycle developed with DN Chemicals a few years ago included phosphodegreasing, two rinses with mains water, one rinse with demineralised water, and a nanotechnology conversion stage using Dollcoat SA116, one of the simplest silane-based nanotechnology products on the market, which can be recirculated and, therefore, applied

by spraying,” says Oberti. “To make a quality leap forward, however, we decided to implement one of DN Chemicals’ newest nanotechnology products, Dollcoat RS103.”

“This product is by no means intended as an alternative to cataphoresis,” says André Bernasconi, the General Manager of DN Chemicals, “but it easily meets the requirements of corrosion class C3H, i.e. 480-500 hours of salt spray resistance with less than 1 mm of delamination from the cut. It is the first (and in a way, the simplest) chemical in our new series, already in use in over twelve industrial plants in Italy and Spain. The development of this new pre-treatment process also required the installation of an atomisation module to enable DKC to follow the evolution of DN Chemicals’ products towards ever-higher quality standards, which require flexible atomisation systems to fully take advantage of their potential.”

“DKC has been extremely active in testing Dollcoat GP107, a nextgeneration nanotechnology product that uses a special graphite

Turn key solutions for industrial wastewater treatment - Design and manufacturing of plants and chemicals for industrial wastewater treatment

Chemical-physical plants - Sludge treatment and compactor systems - Ion exchange demineralization systems and reverse osmosis systems - Oil separators - Filtering systems

Batch type systems - Flotation units - Chemicals and spare parts for water treatment - Technical service, support and maintenance of wastewater treatment plants

We don’t just treat water,we give it a second life. Every drop matters: our ongoing commitment to zero discharge and total water reuse drives every solution we design.

engineered and produced by ENI, for which we have filed a joint international patent,” Bernasconi continues. “The atomisation system installed at DKC’s premises, which is not strictly necessary for applying Dollcoat RS103 as it can also be used in recirculation mode, will enable the Group to switch from one product to another in a matter of seconds, should it decide to implement Dollcoat GP107 to further enhance the corrosion resistance of all or part of its production.”

“The atomisation module ensures greater process control and enables switching from one technology to another without having to dispose of an entire treatment bath. It is the result of a joint development among DN Chemicals, DKC and the system provider, adjusted and customised as different operating conditions arose and always based on experimental data and daily experience,” adds Mara Pege, Laboratory Manager at DN Chemicals. “Compared with the standard version, this module features a tank for collecting any product dripping from the workpieces. From there, this is sent to a second tank equipped with a fluid agitation and semi-recirculation system. Indeed, by analysing the line’s operation, we found that the product was more homogeneous and effective, requiring less replenishment when kept under controlled agitation. This technical measure for product recovery lowered costs by at least 20% compared to initial expectations.”

“This atomisation module has been designed for use with one or more different pre-treatment products – not just RS103 or GP107, but also two-component products, which are the future of the industry,” indicates André Bernasconi. “DKC could ideally switch from one product to another, perhaps one that is more specific to certain types of applications, when it needs to. For example, it could decide to use GP107 only when it requires significantly higher performance than it currently obtains using the standard product, and then quickly return to RS103 or move to a two-component product, while maintaining strict and constant process

control. In fact, the more complex chemical processes become, the more strictly it is necessary to maintain control, both to avoid wasting products and to work exactly within the required parameters.”

Operational and qualitative advantages

“The advantage of this technology is that it allows us to increase corrosion resistance in line with the actual expectations and budget of the market, while maintaining a strong focus on energy consumption, which is a crucial issue for the DKC Group,” says Michele Oberti. “Furthermore, this technological solution is easily replicable at our other sites coating the same products. Another operational advantage provided by the atomisation module is the automation of reactions, with the possibility of setting up a series of actions that the actuators positioned along the pre-treatment line can perform automatically. Clearly, human intervention is still valuable for determining whether any corrections are needed, but most of the work is done by the atomisation module itself, which guarantees consistency and quality, while giving our operators a little more peace of mind.

“Both RS103 and GP107 can be defined as pre-treatment primers. GP107 has proven to promote greater conductivity in the polymer substrate, allowing for significantly superior paint coverage, even in challenging areas from an electrostatic perspective, such as edges; it also ensures better powder coverage by levelling the electric field potential, resulting in greater uniformity in paint application. RS103 is an epoxy modified with POS (synthetic oligomers obtained from silanes) to which additional anticorrosion elements and polymer rheological modifiers are then added; once applied, typically with a thickness of 0.5 microns on sheet metal, it almost creates a veil of epoxy with very special characteristics in terms of mechanical resistance, ideal for the coil and post-forming sectors. In future, we will see the formulation of pre-treatment products with different resins depending on the intended application.”

“Overall, one of the most satisfying aspects of this collaboration was the helpfulness and promptness of DKC, which acted as a true partner to DN Chemicals. Our laboratory provided it with significant support, working

Ervin has been providing customers with the best blasting solutions since 1920. Whatever your needs, we can provide the ideal abrasive and technical support for perfectly clean and prepared surfaces.

Amasteel shot & grit