A new line of nanotechnology conversions for corrosion classes C3H - C4H - C5M

DOLLCOAT RS 103 is the first product in a new family of surface conversions for high-performance processes. It gives pre-treated surfaces extremely high-quality protection and corrosion resistance, whatever the nature of the paints used.

MAIN FEATURES

Multimetal no rinse product to be used at room temperature.

Applicable with nebulisation modules, through traditional recirculating or immersion nozzles.

Excellent pre-cataphoresis treatment.

REGISTRATI ORA

ESPOSIZIONE

CONFERENZA

TECHFOCUS

Esplora le più recenti tendenze e tecnologie nel mondo della pittura e dei rivestimenti, mentre stringi preziose connessioni con i leader del settore.

Paint & Coatings: il luogo dove l’ispirazione, l’apprendimento e le opportunità di networking si incontrano per trasformare il tuo business!

Unisciti a Noi per l’Aperitivo di Paint & Coatings!

Quando

Il primo giorno dell’evento, 22 ottobre 2024

Ora Dalle 17:00

Dove

NH Milano Congress Centre

POLYMER ACADEMY

sponsorizzato da

Coatings for Emboss’ Three-Dimensional Cladding Surfaces

Hard and Sustainable Non-stick Coating Revolutionises Shaping Processes In Injection Moulding and Die Casting

The HP series is specifically designed to uniform the thickness of powder applied on all parts of the painted support.

CARATTERISTICHE

La serie HP è pensata specificatamente per uniformare lo spessore di polvere applicata su tutte le parti del supporto verniciato.

Pulverit S.p.A. Italia

Via Carlo Reale, 15/4

20157 Milano-Italy

Tel +39 02 376751

email: pulverit@pulverit.it

Reduction between 15% and 30% of the powder required to paint the support. The HP series considerably reduces the “orange peel” effect due to the accumulation of powder in the parts adjacent to the critical points and minimizes the accumulation effect on the edges.

CARATTERISTICHE

Riduzione tra il 15 % e il 30% della polvere necessaria a verniciare il supporto. La serie HP riduce notevolmente l’effetto “buccia di arancia”

dovuto all’accumulo di polvere nelle parti adiacenti ai punti critici e minimizza l’effetto di accumulo sui bordi.

Pulverit Polska Sp. z o.o. ul. Strefowa 16

43100 Tychy-Polska

Tel. +48 32 329 14 11

email: biuro@pulverit.pl

Pulverit Deutschland GmbH Im Wert 3

73563 Mögglingen- Deutschland

telef.: +49 7174 7193000 email: info@pulverit.de

Pulverit Iberia s.l.u. c/ Caravis, 28, 1º 3ª 50197 Zaragoza Tel. +34 607163259

email: iberia@pulverit.it

ADVANCEMENTS

Evolution on Design: Kenosistec’s PVD Technology for Elegant, Durable, and Sustainable Finishes 90

ROAD TO 2050

Ice Cream Spoons and Golf Tees: Completely Absorbed by Nature 116

102

FOCUS ON TECHNOLOGY

Raising the Bar of Quality: Sirio Galv’s New Liquid Coating Plant for High-End Furniture and Lighting Accessories

146

SUCCESS STORIES

Delco Trailers Revolutionises Its Trailer Finishing Process with a New Automatic Coating Line

FOCUS ON TECHNOLOGY

Luxe Perfil: The Experts in the Impossible Rely on the New PrimeCoat® A109 Pre-Treatment Product’s High Performance

EcodePure: the Road to Water Recycling and Zero Discharge

SUCCESS STORIES

ItalMesh Clads the New Burger King in Rovereto with Perforated and Painted Aluminium Panels

SUCCESS STORIES

RIPOL in Bayreuth: Innovation and Avant-Garde Design 122

SUCCESS STORIES

PAN-DUR Paints Refrigeration

Equipment with Dürr’s EcoPaintJet –Without the Need for Masking

126

ROAD TO 2050

Ahead of Regulation for More Environmentally Friendly Coatings

130 HIGHLIGHT OF THE MONTH

The Evolution of Vernici Caldart: an Italian Success Story Through Fifty Years of Innovation 134 ANALYSIS

The Choice: The Ecological Transition and the HangOn Green Effect

142

150

HIGHLIGHT OF THE MONTH

Defil Srl: Innovation in Industrial Filtration

ROAD TO 2050

Olea FP: a Natural, Sustainable Option for the Paints & Coatings IndustryFrom Waste Stream to High-performance Functional Powders

154

UCIF INFORMS

Corporate Cybersecurity: a Shared Commitment to Digital Security

156

COLOUR STUDY

The Irresistible Charm of Pink

160 MEETING THE INDUSTRY

The strength of Europolveri products does not derive from the sole mixture of carefully selected raw materials, but rather from the people who study, model and formulate powder coatings thanks to more than 40 years of experience, and provide customers with the best solutions on the market A clear corporate philosophy and a shared vision have allowed to supply a vast range of products for three generations With more than 1000 products available in stock and over 40,000 already formulated, Europolveri offers infinite solutions to customer requests

Alessia Venturi Editor-in-chief Direttore Responsabile

Have you ever reflected on the difference between planning and designing, between a project and its development?

It is the same as between dream and reality.

Dreaming, like planning, belongs to a creative, imaginative, detailed, and inspirational phase with unrealistic but visionary traits. It connects the subject with reality, the designer with the issue to be addressed.

Reality, like the design activity, is the construction phase, the realisation of the idea – of the dream, to be more precise – with less vivid colours, with the sacrifice of a few details, and with the necessary compromise between what is feasible and what is not.

In architecture and design, therefore, planning refers to the creative thinking behind a project, the visionary approach intended to guide the subsequent realisation, whereas design refers to the technical process by which an idea is transformed into a tangible product, such as a building or an object.

Bridging the gap between a project and its development requires having all the technologies and materials, including finishes, needed to translate an idea into reality.

This is the most challenging phase for designers, who sometimes lack the necessary technical information on materials and their performance.

That is where CMF (Colour, Materials, Finish) comes in, a field focussing on the chromatic, tactile, and decorative identity of products and environments. Over the years, CMF experts have worked with designers on the one hand and manufacturers of materials and finishes on the other hand, to promote knowledge sharing, training, and collaboration to bring the design world, more inclined to breaking down limits, closer to the industrial one, constantly dealing with technical and scientific limits.

Since its inception in 2010, ipcm® has had the metal architecture sector, including architects and designers, among its preferred targets, providing it with precise information about any innovation in the world of surface finishing materials – in other words, what constitutes the skin of a product, the interface between an object and the environment.

This special Aluminium issue of ipcm® features a series of articles and success stories on the peaks of innovation achieved in the surface treatment of aluminium, a material that is increasingly popular in architecture and beyond.

As in previous years, ipcm® is also a media partner of the most important platform dedicated to the aluminium sector, the international trade fair Aluminium in Düsseldorf (Germany).

We will gladly meet you among the stands to discuss the most significant issues, trends, and developments in the industry.

Gianmaria Guidi,

Germedia

Srl – Brescia, Italy gianmaria.guidi@germedia.it

Unfortunately, and increasingly often in the coating industry too, our society fails to anticipate and avoid the loss of knowledge, skills, and expertise levels. In 1974, Kaufman called this phenomenon “the obsolescence of skills”, referring to the lack of up-todate knowledge or proficiency a worker needs to continue to perform their current or future job properly. More and more often in our professional activities, major problems arise precisely from the failure to compensate for physiological information asymmetries between contractual parties, which can no longer be adequately compensated due to a lack of specific technical expertise. In recent decades, market

dynamics have favoured economic and financial aspects to the detriment of investment in technical training, taking it for granted that the necessary technical elements were simply ingrained in the common consciousness. The case described below attempts to refocus attention on a calculation method that helps define the economic impact of paint products in a coating project.

Practical coverage or consumption calculation criteria Every coating project requires a thorough feasibility analysis that considers various factors and constraints, e.g. time-related,

technological, regulatory and, last but not least, economic. In particular, this article analyses paint coverage as a cost item directly affecting the coating project’s economic factor.

To reach a coating treatment’s expected performance and durability as defined in the design phase, it is necessary to achieve and maintain the specified dry film thickness (DFT) value. That ensures the coating acts as a protective barrier, preventing corrosive agents such as water, salts, and oxygen from reaching the metal surface. Insufficient DFT can indeed leave vulnerable areas, exposing the metal to corrosion. In contrast, adequate DFT increases the coating’s resistance to mechanical and chemical stress, prolonging its service life and protective action and reducing the need for frequent maintenance and repairs. A sound coating project should also use the appropriate terminology to define the desired DFTs, also considering that, in the context of coating treatments, nominal quantities translate into actual measures conditioned by wide tolerances, which are absolutely necessary and unavoidable.

Various international standards can be used to determine the dry or wet thickness of a coating. This article focuses on dry thicknesses as an objective parameter for qualitatively evaluating the applied cycle. The coating work can be divided into two main macro-phases: design and execution. In the design phase, the designer defines the coating’s nominal dry film thickness (NDFT), the required sampling plan, and the

measurement tolerances (e.g. +/- 20%). In the execution phase, the applicator applies the coating and strives to meet and maintain the set standards, initially measuring the applied wet film thickness (WFT) and then checking the final dry film thickness (DFT) achieved after the polymerisation step.

It is important to emphasise that the terminology and acronyms used to define the desired values are not universal but strictly depend on the technical regulations adopted by the designer. For example, in ISO 2808 and ISO 19840, the acronym DFT may refer to two different measurements, one of which rules out surface roughness after shot blasting. These differences are of fundamental importance when calculating the coverage of a coating treatment.

To achieve the specified NDFT, the applicator must calculate the coverage of the products that make up the coating system by taking into account at least the following aspects:

The theoretical coverage of a paint product (fig. 1), considering its dry solid by volume (S.V.) and the possible dilution required for its application, which increases the value of volatile organic compounds (VOCs) and decreases the DRV, with a direct impact on the final DFT.

The correction factor for shot-blasted surfaces, which takes into account the fact that part of the paint is deposited within the surface irregularities, creating a so-called “dead volume” (fig. 2). Although such

volume is filled by the product, it does not contribute to the effective protection of the substrate, as it does not increase the thickness of the dry film covering the exposed areas. Therefore, it is crucial to consider this correction factor when calculating product coverage, as it directly affects the effectiveness of the protection provided by the coating treatment. Ignoring the dead volume could lead to underestimating the amount of paint required to achieve the necessary degree of protection.

The necessary overconsumption factor (NOC), representing an amount of paint product that does not disperse into the environment but rather is deposited on the surface to ensure compliance with the required NDFT values (fig. 3): such overconsumption is not due to the applicator’s lack of skill but is an unavoidable discontinuity in the coating process. Any application method inevitably generates variations in the thickness of the organic film deposited on the surface. Therefore, a larger volume of paint must always be applied to ensure compliance with the minimum DFT value defined in the sampling plan.

The loss factor due to the geometry of the object to be coated mainly affects spray application operations, but it should be considered that, to a lesser extent, it can also affect brush or roller application ones, depending on the complexity of the part’s geometry itself.

The loss factor due to overspray affects spray application and can be

influenced by various elements, such as the distance from the surface, the complexity of the part’s shape, the presence of air currents, the type of atomisation used, and the spray pressure set by the operator.

Any advance estimate cannot be exact and must be confirmed or denied after completion of the process. However, since it is necessary to calculate the economic impact of paint consumption at the quotation stage, it can be useful to resort to computational formulas using theoretical correction coefficients. If a company is consistent in using these formulas and in subsequently verifying the theoretical coefficients initially applied, it will be able to reduce its error margins, thus consolidating its position in the market with a high level of qualitativeeconomic competitiveness.

The theoretical coverage of a paint product expressed in square metres (m2) per litre (l) applied is generally determined using the following formula:

On the other hand, a paint product’s consumption expressed in litres per square metre applied is determined using the following formula:

Where:

TC = Theoretical Consumption

SV = Solid by Volume, the percentage of product remaining on the surface after evaporation of the solvent

DFT = Dry Film Thickness, the required thickness expressed in microns. The formula assumes ideal conditions and does not take into account factors such as overconsumption, dead volume, or losses due to overspray that may reduce the product’s actual coverage.

Dead volume correction coefficient

The correction coefficient for the dead volume (fig. 2) is essential to compensate for the loss of paint product that is deposited within surface irregularities and, therefore, does not contribute to effective protection.

This coefficient helps estimate the actual amount of paint required to

For decades, Radial has been designing, building and installing tailor-made coating plants for metals, plastics and wood. Our systems are the ideal choice for those who desire a cutting-edge turnkey solution.

achieve the desired result.

ISO 19840, in accordance with ISO 8503-1, provides guidance on how to apply this coefficient. Table 1, provided by these standards, simplifies the practical application of this coefficient, allowing the product coverage calculation to be adapted by considering surface discontinuities and their associated losses.

DFT sampling plan. In this article, specific guidance is given according to the geometry of the part to be treated, leaving the reader to adapt the coefficient according to their past and future experience. This factor reflects the actual paint amount deposited on the treated surface, and although it relates to geometry, it does not directly imply the loss of material due to the part’s geometry itself, which will be treated separately. To distinguish these two coefficients, we will use here the acronym NOC followed by the type of object geometry.

NOC for linear geometry:

Linear geometry refers to large, flat-surfaced sheets, profiles, and tubular structures where the spray paint application does not involve frequent direction changes. This application process allows the operator to maintain a constant dispensing position over at least 90% of the surface to be treated. The stripe coating technique is not mandatory, and if used, it should be limited to a maximum of 5% of the total surface area.

Therefore, in the case of a shot-blasted surface, it is necessary to define its type of surface profile and consequently increase the NDFT of the first layer by the correction value.

NOC correction coefficient

As this article introduces a new factor to balance the interests of all parties involved in a coating project, the following considerations will be based on empirical data collected experimentally during inspection activities (fig. 3). It should be noted that this factor is affected by multiple conditions, such as the type of application process, the complexity of the object geometry, the method used, and the tolerances indicated in the

NOC for complex geometry:

Complex geometry refers to sheets, profiles, and tubes assembled to form complex structures. In such cases, the spray application of the paint product requires numerous changes of direction, preventing the applicator from maintaining a constant dispensing position over more than 50% of the surface to be treated. Stripe coating is necessary but should cover a maximum of 15% of the surface.

NOC for intricate geometry:

Intricate geometry refers to sheets, profiles, and tubes assembled to form intricate structures. In such cases, the spray application of the

with a complete service that includes system design manufacturing, installation, technical support and chemicals

paint product requires numerous and frequent changes of direction, preventing the applicator from maintaining a constant dispensing position over the entire surface to be treated. Stripe coat application is therefore necessary and should cover more than 15% of the surface.

Table 2 also provides values for roller and brush application.

Actual paint loss correction coefficient

The actual paint loss must be related to transfer efficiency (TE), which represents the amount of applied paint that actually reaches the surface to be coated (figs. 4 and 5). Two main factors influence such efficiency: the object’s geometry and the application method. Based on the previous definitions, we will use the term “loss” similarly to the acronym NOC, to differentiate the required correction coefficients (table 3).

Loss for linear geometry:

This refers to large, flat-surfaced sheets, profiles, and tubular structures where the spray paint application does not involve frequent direction changes, allowing the operator to maintain a constant dispensing position over at least 90% of the surface to be treated. Under these conditions, almost all the applied paint is deposited on the surface. However, factors such as the type of atomisation technology, the distance from the surface, the geometry of the workpiece, the presence of air currents, and the delivery pressure set by the operator can affect the final result.

SPRAY BOOTHS WATER SLUDGE REMOVAL

RESIN DEMINERALIZATION SYSTEMS

REMEDIATION OF CONTAMINATED SITES

BIOLOGICAL SYSTEMS BATCH TREATMENTS

PHYSICAL-CHEMICAL SYSTEMS

ADSORPTION FILTRATION

REVERSE OSMOSIS

MEMBRANE SYSTEMS

EVAPORATORS

BIOGAS BIOMASS SYSTEMS

OIL SEPARATORS

DESANDERS

DESALINATION SYSTEMS

PYROCHAR

OTHER SYSTEMS

CHEMICALS

Loss for complex geometry:

This refers to sheets, profiles, and tubes assembled to form complex structures, where the spray application of the paint product requires numerous changes of direction and prevents the applicator from maintaining a constant dispensing position over more than 50% of the surface to be treated. In these circumstances, part of the paint is not deposited on the surface due to the geometry of the workpiece, which facilitates the dispersion of the applied product. Additional factors, such as the type of atomisation technology, the presence of air currents, and the dispensing pressure set by the operator, can further aggravate dispersion.

Loss for intricate geometry:

This refers to sheets, profiles, and tubes assembled to form complex structures, where the spray application of the paint product requires continuous direction changes and prevents the applicator from maintaining a constant dispensing position over the entire surface to be treated. In this situation, a significant amount of paint is not deposited correctly on the surface due to the highly complex geometry of the workpiece, which facilitates the dispersion of most of the applied product. Additional factors, such as the type of atomisation technology, the presence of air currents, and the dispensing pressure set by the operator, can further aggravate dispersion.

For computational calculations related to a spray coating project on a structure with linear or intricate geometry and a “coarse” roughness

profile, in order to achieve an NDFT of 200 microns with a paint product (PP) with 80% DRV, the following calculation scheme is suggested as per the two examples

Conducting a thorough preliminary economic analysis is essential to ensure durable coating results. The project variables and their correction coefficients should be discussed and agreed upon in specific meetings between the customer and the contractor.

Corrective factors such as the necessary overconsumption, if not adequately considered, can have significant economic consequences. These costs cannot be overlooked in the design phase nor entirely attributed to the applicators, assuming unrealistic execution skills. All the parties involved should consider and concretely agree on the mentioned correction factors to meet the required treatment performance standards.

Dr. Gianmaria Guidi has over thirty years of experience in the industrial and corrosion protection coating sector. Over the years, he has specialised in the management of technical-legal disputes and is regularly registered with the Official Register of Court-Appointed Experts (C.T.U.) of the Italian Ministry of Justice, further enhancing his previous NACE and FROSIO certifications.

Everything stated and reported here is intended for the benefit of the industry.

EXAMPLE 1

Total NDFT adjusted by the coefficients =

Project NDFT adaptation scheme

Values in µm

NDFT as per design 200

Dead volume correction factor (for the primer only) + 40

NOC correction factor (intricate geometry =40%) + 80

Actual paint loss correction factor (intricate geometry =50%) + 100

Total NDFT adjusted by the coefficients = 420

Theoretical and

Increase over theoretical consumption + 110%

Let‘s talk about powder coating. A technology that is proven since decades and actually, it‘s just getting started with FLOWSENSE. FLOWSENSE? It‘s a software masterpiece and a bunch of small sensors that do big things: Consistent powder output from the first to the last workpiece. Reliability, measured in real time. Put quality on repeat!

The new ALIT-Service Branches in Serbia and Portugal will bring high-quality paint-stripping services closer to its clients.

The chemical paint stripping company ALIT Technologies has recently proudly announced the opening of its first two international branches in Portugal and Serbia, under the brandname ALIT-Service. The expansion testifies the beginning of a new chapter for the Italian business, that is willingly to spread its paint stripping services to new global markets.

“ALIT-Service represents an innovative and strategic initiative, which is set to transform the landscape of industrial paint stripping. What makes our service unique is its bold and personalised approach, exclusively using top products to meet the diverse needs of customers worldwide”, has stated Loris Rossi, the CEO of ALIT Technologies. With the introduction of ALIT-Service, the company then further expands its already extensive range of offerings, in order to bring high-quality services closer to its clients. As a matter of fact, the new openings aim to bridge geographical gaps and meet the growing demand for contract

paint stripping services in regions not yet covered by its distributors. However, the new branches in Portugal and Serbia are just the start of an ambitious expansion project: ALIT Technologies plans to open many more strategic locations around the world. According to the company, its expansion is not only a sign of ambition but also a concrete commitment to supporting economic growth and sustainable development in local communities, creating new jobs and providing increasingly in-demand services.

“With this revolutionary initiative, ALIT Technologies embraces change, redefines industry standards and opens the doors to a new and exciting chapter of global success, demonstrating our vision for a future where innovation and excellence are fundamental pillars,” has concluded Rossi.

For further information: www.alit-tech.com

The acquisition of Monarch Chemicals will strengthen the market position of Brenntag globally.

Brenntag has recently acquired Monarch Group Holdings, a British distributor of chemicals for several industries, including paints and coatings.

“The team at Monarch have built a great product and service offering for their broad customer and supply partner base, and we look forward to growing and expanding that offering together. Brenntag gains expertise, infrastructure, as well as expanded liquid and powder blending capabilities with this transaction. With our acquisition strategy, we expand our last mile service operations to bring a broader portfolio of products and value-added services to customers, supported by our regional supply chain services within our global network. With this extended offering, all our customers in the UK can benefit going forward,” has stated Russel Argo, Regional President Brenntag Essentials EMEA.

“We take great pride in the level of service and support we can offer our supply partners and customers. Our independence made us flexible, but joining Brenntag, a truly global distributor, will give us the scale and network we can use to grow our business and better serve our customers with a wider range of products and services,” has added Jon Hill, Managing Director of Monarch.

For further information: www.brenntag.com

Eurotherm solves every problem concerning painting processes, creating complete lines for the entire process.

Our structure is organized and flexible and able to satisfy the most demanding requests.

Customers who turn to Eurotherm are customers who, despite knowing the “painting process”, want to improve production by adopting highly customized technical solutions.

Employees 205 Plants realized in 2023

(IT)

(FR) Sigmaringen (DE) Brussels (BE) Other locations

Eurotherm S.p.A.

T +39 011 98 23 500 | M info@eurotherm.eu

Eurotherm France S.A.S.

T +33 6 76 72 48 65 | M france@eurotherm.eu

Eurotherm Oberflächentechnik GmbH

T +49 7571 92795 10 | M germany@eurotherm.eu

Eurotherm Benelux Srl T +33 6 47 44 96 27 | M dekergorlay@eurotherm.eu

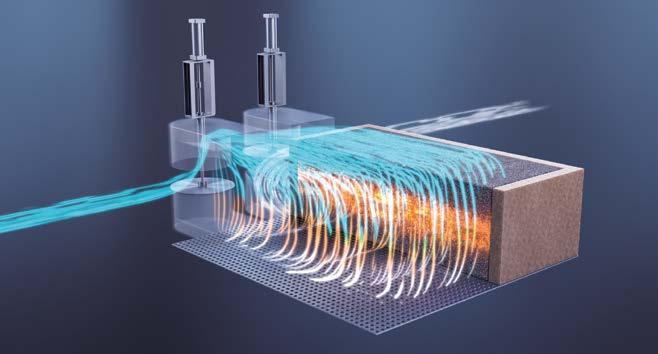

The upcoming coating system from Dürr will enable Airbus to paint the rear centre tank of the A321XLR aircraft with enhanced energy efficiency and reduced carbon emissions.

The German engineering company Dürr has taken on its most significant individual project to date for the Airbus Group’s division, Premium AEROTEC. The project involves constructing a state-of-the-art paint shop in Augsburg (Germany) for coating the new rear centre tank of the Airbus A321XLR, crucial for the aircraft’s longrange capability, extending its reach by 8,700 kilometres.

The paint shop will be a turnkey system, incorporating cutting-edge technology to enhance energy efficiency and reduce emissions. Notably, it will feature an all-electric exhaust purification system, marking a first for Premium AEROTEC’s facilities. This system, based on regenerative thermal oxidation, promises to significantly minimise CO2 emissions.

Advanced surface protection and energy efficiency

The project will cover the entire coating process, from pretreatment to sealing and painting. The new paint shop will include sealing, cleaning and painting booths, as well as surface and leak testing areas. High standards for corrosion resistance and diffusion will ensure that the tank surfaces withstand extreme conditions without corroding. Moreover, to achieve these high standards while maintaining energy

The fuel tank integrated into the fuselage of the Airbus A321XLR is the key component in transforming the former short- and medium-haul planes into the new long-haul version.

efficiency, Dürr is implementing a component-specific air ducting system. This system reduces the amount of air needed for conditioning – thus lowering energy consumption. The energy recovery systems will also recycle up to 65% of the energy from the exhaust air, further enhancing efficiency.

Sustainable pollutant removal

Premium AEROTEC’s commitment to sustainability is underscored by its adoption of Dürr’s Oxi.X RV all-electric exhaust purification system that operates without an open flame, resulting in very low nitrogen oxide emissions. In addition, it is designed to run on green electricity, eliminating additional CO2 emissions.

Dürr’s Oxi.X RV system also includes a Sorpt.X CD unit that concentrates the exhaust air streams to enhance economic efficiency, reducing the volume and increasing the solvent concentration. This allows the downstream Oxi.X RV unit to be smaller and operate without additional heating energy, optimising the cost-benefit ratio.

For further information: www.durr.com

The exhaust air is purified with a flameless Oxi.X RV in accordance with the principle of regenerative thermal oxidation (RTO).

Lechler Tech water-based CAM-compliant products offer high performance, reduce environmental impact thanks to low VOC emissions and guarantee quality finishes in compliance with European regulations.

Lechler Tech offers solutions that meet its customers’ needs without compromising the health of the planet. Choosing waterbased products complying with CAM (Criteri Ambientali Minimi

- Minimum Environmental Criteria) is an important step towards a more conscious future. The features and benefits of Lechler Tech’s CAM-compliant water-based products include as follows:

• Reduced VOC emissions: water-based products have lower emissions of Volatile Organic Compounds (VOC), helping improve air quality and reducing environmental impact.

• Safety: water-based products are generally less toxic and safer to handle than solvent-based products, protecting the health of operators and end users.

• High performance: besides ensuring a reduced environmental impact, Lechler Tech’s products provide excellent performance in terms of durability, resistance, and finishing quality.

• Regulatory compliance: being CAM-compliant means being in line with current European building regulations (Green Public Procurement), which facilitates access to tenders and contracts.

• Compliance with international protocols BREEAM/LEED/WELL: compliance with CAM allows accessing LEED/BREEAM/WELL certifications.

These water-based products have passed the EN 16516 low-VOC emission test required by IAC GOLD in accordance with EN 16000 and are CAM approved, which means they are totally free of HEAVY METALS, with low or no VOC EMISSIONS, and with controlled VOC CONTENT.

Lechler Tech’s water-based products guarantee high-quality finishes on a wide range of metal and plastic substrates. They offer remarkable versatility, allowing for the creation of glossy, matte, pastel-coloured, and even metallic/micalised effects and textures.

For further information: www.lechler.eu

©

Redox One Coat from AkzoNobel Interpon is a powder coating designed to protect metal surfaces from corrosion and UV damage, all while streamlining production time and reducing costs.

The Czech shelving systems manufacturer

Trestles has turned to international paints and coatings supplier AkzoNobel for a quality and durable powder coating, opting for Redox One Coat.

“In the gates and fences sector in particular, there are many companies we compete against, most of whom have more experience than us. To stand out from the competition we need to have the best quality, and since Redox One Coat can be applied to both stainless steel and zinc steel, we are able to deliver the quality our customers are looking for at the price they are willing to pay. In salt spray tests, Interpon Redox One Coat performed the best in protecting our products against corrosion. We also tested it on different steel surfaces, as well as some Beta products we currently have on trial, with excellent results. We wanted to be sure the product would perform, even

in rain or snow, and since using Redox One Coat there have been no complaints,” has stated Daniel Molnár, Procurement Manager at Trestles.

Technically, Interpon Redox One Coat enables Trestles to reach corrosion protection up to C4M and high UV durability in a single coat which requires only a base chemical pre-treatment, while traditional powder coatings require a primer layer for corrosion protection followed by a topcoat for gloss and UV protection. In addition, Trestles offers its product in four colours: Anthracite Grey, Jet Black, Moss Green and Blue/Grey.

“We are looking to increase our production and Interpon Redox OneCoat will help us.

A single coat application will have a positive impact on reducing the time and cost of production and will help keep us competitive. AkzoNobel not only has the products and

colours we need, but its people are also very friendly and flexible to work with. The technical support it provides is certainly one of the reasons why we continue to be one of the most important manufacturers in the entire European Union,” has added Daniel Molnár.

“Businesses like Trestles need simple, effective solutions to get the job done with high quality but quickly, easily and at a lower cost. With Interpon Redox OneCoat we’ve removed the need for a second process for the same job, saving on powder, energy and labour and maximizing productivity while delivering desired quality. It’s helping Trestles to be competitive in a new market, and further improve their business performance,” has added Sanal Limoncuoglu, Commercial Director South and East Europe of AkzoNobel Powder Coatings.

“In a competitive market, Trestles is offering customers a new portfolio of fencing systems, and recognises that quality is key. We demonstrate this quality with what is visible at first glance - the powder coating system of the Interpon Redox One Coat series from AkzoNobel,” has concluded Pawel Nowak, CEO of Trestles.

For further information: www.interpon.com/us/en

BYK-Gardner has appointed its new President and CEO, Dr. Jörg Krames.

The global measuring instrument manufacturer BYK-Gardner, headquartered in Geretsried, Upper Bavaria (Germany) and part of the ALTANA Group, welcomes its new Managing Director, Dr. Jörg Krames. As a trained mechanical engineer with a doctorate in chemical engineering, Jörg Krames takes over the global management of the company with its foreign representatives and around 350 employees. BYK-Gardner is a leading supplier in the field of measuring instruments. The testing and measuring instruments objectively assess the quality of colour, gloss and appearance as well as the physical properties of paint and plastic products. Last year, the company acquired measuring instruments for non-destructive, high-precision coating thickness measurement.

Jörg Krames previously spent 15 years at ECKART, also an ALTANA Group company, as Vice President Global Key Account and responsible for Business Line Management Coatings. Prior to that, he worked for BASF Coatings as Director Key Account in Japan and Germany for leading car brands such as Toyota and Volkswagen. His main goals are to drive forward the brand perception of the premium measuring instrument manufacturer and to drive forward the digitalization of business processes. Looking ahead to the upcoming generational change, transformation projects and the continuous development of employees are among the focal points of his business

strategy to strengthen BYK-Gardner as the market leader. “We are delighted to have found a managing director in Jörg Krames within our own ranks, who not only has excellent professional expertise, but is already very familiar with the ALTANA Group,” said Dr. Jörg Hinnerwisch, BYK Executive management and ALTANA Management Board member. “With his strong focus on customers, technology and innovation, Jörg Krames is continuing to lead BYK-Gardner on the road to success.”

For further information: www.byk-instruments.com

HMG Paints has recently launched Hydrosol, a new range of hybrid coatings designed for the metal fabrication marketplace.

The first product to launch in this range is Hydrosol QD Primer, an alkyd-based, quick-drying primer designed for ultimate versatility and efficiency. In fact, it improves adhesion and moisture resistance, while granting good corrosion protection thanks to the incorporation of modified Zinc Phosphate. This primer is ideal for structural steel, chassis and steel fabrications, and can be applied by using either roller, airless or conventional spray methods.

Moreover, the first user who are adopting the Hydrosol QD Primer are identifying several benefits, including increased coverage compared to competitor products and improved efficiency in application. This is thanks to volume solids of Hydrosol QD Primer which stands at 55% in comparison to approximately 40% for competitor equivalents.

“Our new Hydrosol QD Primer represents a significant advancement in protective coatings and is a testament to the work done by our Research & Development team to bring innovations to the market. This product not only meets the high-performance standards our customers expect from us, but also aligns with our commitment to environmental sustainability. It is the first piece of the jigsaw in our Hydrosol brand, with a variety of exciting products set to join this range in the near future,” has stated Paddy Dyson, Marketing Manager of HMG Paints.

The second to be launched will be the Hydrosol Compliant DTM, a Direct-to-Metal that can be applied directly to bare or primed metal surfaces. This technology is PG6/23 11 Compliant and ideal as a single coat primer finish for stillages, skips, containers, agricultural and construction equipment and machinery. It has lower VOCs in comparison to solvent based equivalent products and it is available in a wide range of colours, including RAL & BS.

For further information: www.hmgpaint.com

The new X-SMART PRO Automatic Dispenser from Fast & Fluid Management combines repeatability and durability.

Fast & Fluid Management has recently presented the new X-SMART PRO Automatic Dispenser, specifically engineered to provide unparalleled repeatability and with a robust design which is tailored for demanding environments. By leveraging an advanced piston pump technology, it delivers precise colour dispensing, crucial for achieving consistent results required in various industries.

The automatic paint dispenser enhances the previous X-SMART series with a durable metal case and an upgraded brush, ensuring optimal cleaning operations. In addition, it also introduces additional safety features – including a front door sensor that guarantees operators safety without compromising functionality.

“In the fast-paced world of industrial tinting, precision and durability are not just simple requirements, but the foundation upon which businesses can build their reputation. So, recognising the challenges faced by different locations across the globe, the X-SMART PRO Automatic Dispenser is engineered to deliver both speed and robustness, crucial for maintaining continuous and reliable operation. Its steel-armoured design ensures it can withstand the rigors of heavy usage, making it an ideal solution for businesses looking to reduce downtime and enhance operational efficiency”, has declared the company.

For further information: https://emea.fast-fluid.com

From Turin to Cassino (Italy): the degreaser CONDORINE SG 576 N developed by Condoroil Chemical, already used in the bumper cleaning line of the Stellantis plant in Turin-Mirafiori, has now also been implemented in the Cassino site’s production line, with considerable savings in energy and water consumption.

Energy saving, ecology, and low environmental impact have always been key elements for the Stellantis Group. With this in mind, about a year ago, Condoroil Chemical began testing its degreaser CONDORINE SG 576 N for integration into the final cleaning phases of plastic components.

Product features

CONDORINE SG 576 N is a one-component low-foam detergent, active even at room temperature. Its use ensures considerable energy savings and lower water consumption compared with traditional products. The almost total absence of foam and the innovative features of its formulation also

reduce dragging issues, thus minimising the progressive pollution of post-cleaning rinsing baths.

A successful project

The project was developed in collaboration with the Painting Process Engineering PPE Materials Approval team at Turin-Mirafiori, where the product is now used in the cleaning phase of the bumper production line, confirming the positive outcome of the preliminary tests carried out. All the quality requirements imposed by Stellantis for product approval were met from the outset, as well as the considerable savings predicted during the design phase.

The benefits for the customer included as follows:

perfect cleanliness of the treated components;

considerable energy savings by applying the product at room temperature;

lower product consumption;

lower water consumption, including for rinsing. An 80% reduction in demineralised water consumption was observed in the final rinse phase (from 500 l/h to 100 l/h).

From Turin to Cassino: implementing CONDORINE SG 576 N Afterwards, CONDORINE SG 576 N was presented to the Plastic Unit of the bumper production and coating department at the Stellantis plant in Cassino (Frosinone), where a two-component solution was used that required a working temperature of at least 55 °C, like almost all current plastic degreasers. Now, by working at room temperature, they achieved considerable savings without any compromise on the quality of results. The implementation of this product in the Cassino plant was possible thanks to the Process Improvement team, which played a vital role in the early start-up phases and continues to closely monitor the regular production process.

For further information: www.condoroil.com

Zuccarelli, Condoroil’s Industrial Coating Sales

The new Gossau-based facility features expanded production areas, advanced testing labs and eco-friendly systems, allowing Gema to enhance its manufacturing capabilities and increase production capacity.

The powder coatings application systems supplier Gema has recently relocated to a new facility in Gossau (Switzerland). This move underscores the company’s commitment to advancing manufacturing capabilities and boosting production capacity.

The new Gossau facility boasts spacious office environments, state-of-the-art meeting rooms and modern technological infrastructure. It features a high-bay warehouse and expanded production areas, enhancing operational efficiency. Additionally, the facility includes a sophisticated test and

customer application laboratory with advanced coating lines, enabling more effective and practical coating tests.

Demonstrating its commitment to sustainability, Gema’s new location is equipped with photovoltaic systems for energy generation and a brine/water heat pump system for heating, highlighting the company’s dedication to environmentally friendly practices.

For further information: www.gemapowdercoating.com/en/

Leading companies rely on vacuum distillation systems for the sustainable treatment of industrial wastewater.

Do you want to benefit from a zero liquid discharge production with VACUDEST aswell?

Just contact our Experts!

KANSAI HELIOS Italy and Weilburger Coatings Italia continue their successful course together.

After KANSAI HELIOS announced the successful acquisition of Weilburger Coatings in May 2024, Weilburger Coatings Italia and KANSAI HELIOS Italy have started to identify and leverage initial synergies. This strategic integration not only expands the production capabilities in Italy but also reinforces KANSAI HELIOS’s position as a system supplier on the market. With local production of both –industrial powder and liquid coatings – the company's expertise and service offerings are now stronger than ever. Additionally, the strategic locations of the production units and the enhanced storage facilities in Bergamo ensure greater flexibility and more efficient supply chains. From now on KANSAI HELIOS Italy and Weilburger Coatings Italia will combine their expertise and strengths to serve the Italian market with a unified approach.

Over the past few years, KANSAI HELIOS Italy has experienced significant growth through strategic investments and continuous improvements on its powder coatings production locations in Riese Pio X (Treviso) and Tezze sul Brenta (Vicenza). The company expanded its production capabilities by adding new production lines and upgrading existing facilities with state-of-the-art equipment. Advanced systems are being implemented to enable paperless production and full product traceability, enhancing both, efficiency and sustainability. Focusing on innovation and sustainability, KANSAI HELIOS Italy is developing new products such as low-temperature cure powders and formulations using recycled or natural raw materials. Their unwavering commitment to excellent customer service is evident in their efforts to ensure maximum product availability, short delivery times, and continuous technical assistance. With 22 different quality approvals, KANSAI HELIOS Italy became a preferred partner for the industry. Weilburger Coatings Italia has also made significant strides in recent years, driven by strategic investments and ongoing improvements. The company specializes in industrial liquid coatings and operates from a state-of-the-art production site in Sotto Il Monte, Bergamo.

The company has been focusing on expanding its infrastructure with projects like the implementation of new warehouses, enhancing both, storage and logistics capabilities. This expansion supports their strategic goal of serving diverse industries including houseware, stoves and heating appliances, railway vehicles, the eyewear industry, small items and zippers, aluminium packaging, and coil and foil sectors.

Weilburger Coatings Italia is committed to quality and sustainability, holding certifications such as ISO 9001-2015, ISO 14001-2015, and ISO 45001-2018. With the acquisition of Weilburger Coatings Italia, KANSAI

HELIOS is significantly expanding its presence in Italy. The strategic alignment of the two companies will not only expand the presence of KANSAI HELIOS in Italy, it also broadens the production capabilities and most of all, strengthens its position as a system supplier. Now, with two central hubs, KANSAI HELIOS offers a comprehensive range of industrial coatings: the Bergamo site for liquid coatings and the Treviso and Vicenza sites for powder coatings, architectural coatings, and car refinishing.

Bine Pangršič, Managing Director of KANSAI HELIOS Italy, assures: “We want to fully utilize the expertise of the Weilburger Coatings team for our customers and confidently place our industrial coatings business in the hands of our colleagues in Bergamo. Weilburger Coatings Italia will thus become the hub for industrial liquid coatings in Italy - also for KANSAI HELIOS products, which of course will be retained. Weilburger Coatings Italia will only take over the trading part and act as a local service partner

with its experts for liquid coatings together with the well-known sales representatives for liquid coatings from KANSAI HELIOS, who will move to Bergamo. This means that the usual contacts will remain.”

By joining forces and focusing on their core businesses, KANSAI HELIOS Italy and Weilburger Coatings Italia are set to improve performance by leveraging synergies and maximizing efficiency. The integration of Bergamo’s production site into the KANSAI HELIOS network offers, for example, extended warehouse options, enabling the relocation of goods from the Piacenza hub to Bergamo and thus closing the offices there.

Zoran Boras, Managing Director of Weilburger Coatings Italia, adds:

“The strategic locations of our production units and the well-developed warehouses at all sites provide a solid foundation for future growth. This setup allows us to maintain greater flexibility and higher storage capacities in the long term, with the opportunity for further expansion in the future. This move, set to be completed by March 2025, aims to keep day-to-day business unaffected, ensuring no impact on deliveries. Additionally, the proximity of the warehouses to production facilities offers seamless logistics and quicker response times.”

The expanded capabilities and enhanced service offerings underscore the company's dedication to being a full system supplier aligned with customers’ wishes and needs. Italy remains one of the strategic markets for the KANSAI HELIOS Group, and this acquisition further extends the offer and strengthens the approach as a system supplier. By joining forces with Weilburger Coatings, KANSAI HELIOS is now stronger than ever on the Italian market, providing a robust platform for innovation and growth.

The two companies are one of the major suppliers of integrated coating systems, including liquid, powder, cataphoresis technologies, gelcoats as well as adhesives and sealants. Together they run three production sites in Italy. For powder coatings one in Riese Pio X (Treviso), with a production of around 7500 tones of thermosetting powder coatings and one in Tezze sul Brenta (Vicenza) with a production of around 2500 tones of thermoplastic powders. The liquid coatings production is located in Sotto Il Monte, Bergamo, where around 2500 tons of coatings are produced. Both companies are members of KANSAI HELIOS, which is part of KANSAI PAINT, one of the world's leading manufacturers of paints, varnishes and coatings.

Interview with Matthias Haarer, Managing Director of Eisenmann GmbH – Böblingen, Germany

Alessia Venturi, Editor-in-Chief of the ipcm® magazines, interviewed Matthias Haarer, Managing Director of Eisenmann GmbH, whose name has always been associated with customised, efficient solutions and the highest quality in industrial coating technology.

Eisenmann is a rapidly growing company. Since the GmbH was founded in October 2020, the number of employees at its headquarters in Böblingen (Germany) has risen from 100 to 190. In addition, there are 40 employees in its branches in Puebla (Mexico) and South Carolina (USA).

At its headquarters in Böblingen, the company pools all its core competencies: research & development, engineering, project management, quality assurance, service, and sales. Eisenmann also operates a technical centre with 8,000 square meters for pre-assembly, logistics, spare parts storage, and research & development. Via business partners (licensees) in China, India, and Spain, and own subsidiaries in Turkey, Italy, USA, Mexico and Saudi-Arabia, the German company maintains reliable business relationships in these markets.

Eisenmann GmbH plans to achieve a total operating performance of over 100 Mio. Euro in 2024, counting on a broad product portfolio and customer base in different industrial field, from the automotive (historically, the company’s core business) and wheels industries to the agricultural and construction equipment, down to the general industry as far as coating of metals and plastics by using dipping, powder and wet application techniques is concerned.

Mr. Haarer, can you offer our readers a concise portrait of Eisenmann GmbH?

“The 2020 founded Eisenmann GmbH is focused on the successful further development of its business unit Paint & Assembly Systems with more than 1,000 patents which include all key products such as E-Shuttle 200 & 300, Vario-Shuttle XL, Vario-Loc, Vario-Mover (AGV), E-Cube and over 2,000 painting systems installed all over the world, of which around 90 are attributable to the alloy wheel sector, a field in which Eisenmann has been a pioneer”.

Modular, energy-efficient dry separation system E-Cube.

What does the brand Eisenmann represent today?

“The brand Eisenmann represents customised, efficient solutions, and the highest quality in industrial coating technology. We offer a worldwide proven and extensive portfolio of coating systems in the metal,

automotive, and wheels industries, including conveyor technology for final assembly.

Having over 2,000 painting systems installed worldwide means that more than 60 million car bodies have been equipped in the PT-ED area with Eisenmann patented technologies, like the conveyor systems for dip coating of the E-Shuttle series or the rotating dip system for higher payloads, VarioShuttle XL. With the new course of the company, we are able to support our customers worldwide with reliable service and spare parts management (24/7). The aim is to ensure that the systems retain their value for as long as possible, so that our customers can reliably achieve their individual production targets and the highest quality. Our expertise also includes the analysis of modernisation measures and the creation of innovative and sustainable retrofit concepts for existing systems”.

What does it mean to customise a paint shop?

“Customers requirements are extremely variable, even within the same industrial field. Each painting system is based on individual planning and

design, it is tailored to the customer’s requirements and is therefore unique. They vary in their complex interplay of process steps and the conveyor systems adapted to them. All our products and solutions are based on the experience we have gained from a wide range of projects in different industries around the world. And it is on this expertise that we will continue to focus on in the future”.

Company culture: how can you define that of Eisenmann?

“Transparency and corporate responsibility, appreciation and tolerance, commitment and genuine practice, boldness, openness to something new, resource-consciousness, and sustainability in focus: these are Eisenmann corporate values. Today, more than 230 employees work every day to ensure the success of our clients. Highly specialised designers combine their many years of engineering experience with fresh ideas from highly qualified young talents. As a result, our product range and services are continually evolving. Our operations have been characterised by agility and the ability to innovate, as well as reliability and ambitious collaboration within the team.

But living our values in our working environment also contributes to customer satisfaction and a good working atmosphere. We work constructively together, keep our promises, and meet our deadlines. This has resulted in a high level of loyalty among our employees and trusting relationships with our partners and suppliers. This is something we are proud of”.

Can you briefly outline Eisenmann product portfolio & services?

“Our technologies provide consistent quality standards throughout the whole process, from pre-treatment to final assembly. What sets us apart is our solution-oriented and customercentric approach, which is always geared towards changing market requirements. Our aim is to develop permanently relevant system concepts that can be optimally integrated into existing processes and open new potential in painting for our customers.

Our product portfolio includes:

Conveyor systems for pre-treatment and

cataphoretic dip coating (PT/E-Coat), for example VarioShuttle XL, E-Shuttle 200, and E-Shuttle 300;

Conveyor systems for the whole coating process, like the VarioMover (Automated Guided Vehicle), VarioLoc, Monorail systems, classic skid conveyor systems, Power & Free-Systems for different payloads (Inverted Power & Free, circular and spindle conveyor) for effective and individual usage in general industries / metal industries as well as the automotive industry;

Various drying systems (most compact and resource-saving: E-SmartOven);

E-Cube, RE-Cube /Dry separation system for collection and disposal of overspray;

Solutions and application technology for automated handling.

The new founded business unit Robotics adds to this wide range of technologies”.

What is the new business unit Robotics about?

“There are high expectations on product

quality and quantity, as well as on production processes and health aspects: precision, positioning accuracy, effectiveness, speed, and ergonomics are becoming increasingly important. A clever combination and safe co-operation between man and machine are indispensable and common practice today. That’s why we are working on reliable concepts for new systems and – also very important – ideas for retrofitting or converting existing paint shops.

Based on a standardised software architecture with uniform operating concepts, we enable the use of robots and application technologies from leading manufacturers.

Our expertise covers all process and applications technologies for:

Seam sealing from bottom;

Seam sealing from top;

Insulating spray;

Cavity preservation;

Material handling”.

What is Eisenmann focus when developing new technologies?

“Economic and ecological sustainability, as well as a focus on energy efficiency, are crucial drivers for all developments. Beside this, we want to offer flexibility, user-friendliness, and easy-integration of the different systems. This is why we have founded the new Robotics BU. Automotive paint shops are massive installations packed with painting technologies, and are energy- and resource-intensive.

Energy-wise, the painting stage is the most intense when it comes to the whole manufacturing process of a car body. Among the various technologies we have developed in this regard, it is worth mentioning the new dry separation system RE-Cube, which uses pyrolysis for a costand energy-effective dry separation of the overspray.

The changeover from wet separation to dry separation of the overspray was already pushed by energy issues. Now that dry separation is well proven and widely used,

we developed the new RE-Cube system from the expertise gained with the two generation of our proprietary E-Cube technology. RE-Cube stands for REcycling Cube and that is the key point. It is a cube with a shell of sheet metal and only the filter parts inside the cube are made of card box. The idea behind is to pyrolyze the card board cube in a pyrolysis oven at 450 °C, using the heat generated by this process for other areas of the paint shop, for example to heat up the ovens or the PT tanks. This is a CO2 neutral process, since you eliminate the need for logistics and transportation and you balance the CO2 emitted during the pyrolysis with the CO2 saved for heating up other stages of the painting process. It is circular economy at its best!”

You mentioned ATLAS, Eisenmann sustainability concept to improve the energy and resource balance. Can you explain this approach in details?

“A paint shop is very resource-intensive. We are

aware of our responsibilities and try to design our products in a way that reduces harmful emissions and conserves resources such as electricity and water. All key ideas and technical approaches that can improve the energy and resource balance are based on the firmly anchored sustainability concept ATLAS that is observed by our employees. ATLAS stands for Advanced Technology for Lowemission Application and Sustainability. We do not want to just place a slogan for sustainability, we really want to live this programme in terms of product categories. An easy example of this is the drying technology in an automotive paint shop. We have developed very efficient smart ovens, able to adapt the drying process to the type of car body entering the oven. We call these ovens “smart” because, in combination with our smart conveyor technologies, like the VarioLoc or the Vario Mover (our own AGV system), they do have the intelligence to direct the warm air individually and precisely to the respective components of the car body by means

of an optimised control of the swivel nozzles. There are many other examples of technologies developed by Eisenmann that comply with the ATLAS approach. In the PT/ED area with the patented Vario-Shuttle XL, a rotating conveyor system for dip coating, even heavy bodies of up to 2,000 kg can be coated with consistently high flexibility, manoeuvrability and efficiency. This meets a new common demand from our customers, which are manufacturing car bodies becoming bigger and bigger every day, in line with the SUV and E-Mobility trend. It is funny, but electrical car bodies are sometimes heavier than those of traditional cars!

To sum up, ATLAS is not just theory put on a web-page: it is a concept, we live it and our products realise it”.

As last question, can you set out briefly what the prospects of the company are?

“Eisenmann is currently planning a new building and will move to its own premises in the neighbouring town of Gärtringen in 2026. This step emphasises the stable growth of Eisenmann GmbH.

A new building offers us the greatest possible flexibility in terms of modern and energy-efficient construction. We go back to the ATLAS

concept: the careful use of valuable natural resources not only determines our actions in the development of our technologies. It is also important to us to consistently realise these goals when designing a modern working environment that optimally meets our needs and also provides an adequate presentation framework for our customers’ investment projects.

We are building a new pre-assembly hall of about 7,000 sqm that will accommodate logistics, testing devices and equipment, the R&D area, and the pre -assembly of our own proprietary products. Besides the pre-assembly hall, a new headquarter building of around 3,500 sqm will accommodate from 250 up to 300 employees.

As I said, this step emphasises somehow the positive development of our new company; sometimes, we need to remind ourselves that it is not just four years that we are back in the business, we did not start from scratch: with a new headquarters we combine the heritage and the future. The investment for the new building will amount to 20 –30 million Euro. The new location in Gärtringen also offers scope for future expansion. We would like to continue to develop as an attractive employer in the region and to create additional jobs”.

via E De Nicola, 18 - I-20090 Cesano Boscone (MI) Italy - tel +39 0255210608 www.ravarinicastoldi.it - dive@ravarinicastoldi.it

Kevin Biller kbiller@chemquest.com

Dear Joe,

What makes one powder fluidize better than another?

Jason Smith Denver, Pennsylvania

Hi Jason,

This is an excellent question. For a powder coating to perform well, many physical and chemical properties must be aligned. Fluidization performance is one of the critical physical properties necessary to successfully apply a powder coating. Fluidization involves incorporating a volume of air into a quantity of powder to prepare it to be transported from the feed hopper to the application gun. This mixture of air and particles not only helps transport the material but also enhances the delivery of electrostatic charge to the individual particles as they exit the spray gun. Particle size distribution (PSD) is the primary factor that influences fluidization. Powder coatings are comprised of a range of different-sized particles, from about 1.0 micron upwards to around 100 microns. The best fluidization occurs within the heart of this range, typically 20-60 microns. Fines (< 10 microns) tend to agglomerate and impair fluidization. Coarse particles (> 100 microns) are difficult to fluidize because of their relatively high mass. Hence, the best fluidizing powder coatings possess tight particle size distributions. This means a minimal level of fines and also a minimum of coarse particles. If you employ a reclaim system to capture and recycle oversprayed powder, this can be a factor in fluidization. The best-suited particles are preferentially deposited on the parts you coat. And as you can surmise, the fines and coarse particles populate the overspray. Reintroducing

overspray into your virgin powder feed will affect fluidization. This increase in fines and coarse particles may require adjustments to your fluidization process. How do you avoid this problem? The best strategy is to use high-quality powder coating from a reputable powder manufacturer. The most reliable suppliers have well-controlled grinding processes that yield relatively narrow PSDs. Narrow PSDs deliver high first-pass transfer efficiency and hence less overspray to contend with.

A secondary factor that contributes to poor fluidization is moisture.

“Wet” powder is very difficult to fluidize and transport through a powder application system. High levels of moisture are usually due to poor storage and handling of powder coating inventory. Powder should be stored in an air-conditioned environment and open bags/containers should be avoided. In addition, you should be careful to avoid introducing “cool” powder into a warmer, moister environment. The cool powder will act as a desiccant and absorb the ambient moisture. It is wise, as you move powder from storage to the application area, to allow it to acclimate to the ambient application environment before opening the package.

Thank you for the question. Best regards, Joe

We currently are planning on using cold-rolled 304 stainless square tubing for our instrument housings, and the tubing comes slightly oxidized and slightly pitted. We are looking to provide the customer a finish for the housing that looks professional and prevents it from going back to the way we received it.

We were looking at possibly painting, powder coating, polishing, or plating the housing, but I am leaning towards powder coating as a cost-effective means to protect the housing. The environment the instrument will be in ranges from -40°C to +100°C and is occasionally dusty, oily, and near sea water (not touching or emerged). Given that the tubing is 304SST, I know adhesion is the big problem. Can you recommend the proper way to prepare the surface of a 304SST material? Details on the type of degreaser to the type of grit (non-ferrous) or chemical (i.e., silane), to the primer type so that UV and sea salt corrosion will not affect the housing for up to 10 years would be greatly appreciated.

I look forward to your reply, Christopher Filoon, Pennsylvania

Hi Christopher,

This is an excellent question, and it is very wise to explore all your options before committing to a new process. Powder coatings are a very good finish for stainless steel if the process is designed and maintained properly. The key is in the cleaning and metal pretreatment process that precedes application of the powder. The process you should consider for powder coating starts with media blasting. A high-quality medium such as aluminum oxide will suffice. Follow the blasting with a wellcontrolled alkaline degreasing step to remove any residual oils, process fluids, and handling contaminants. It is also important to keep your blast media clean. Next, I suggest a passivation step to remove any iron-based residues on the stainless surface, as well as the possible presence of residual sulfides. Trace amounts of either contaminant can act as sites for subsequent corrosion. Passivation of stainless steel typically involves immersing the part in a nitric acid bath, although nitric acid/ sodium dichromate or citric acid solutions can also be used. The concentration of acid can range from 20-50% by volume. ASTM A380 describes standard practices for passivating stainless steel. After thoroughly drying the parts, it is wise to powder coat the passivated surface as soon as possible. Chemically pretreated surfaces have a finite shelf life before they begin to degrade. Using a highquality powder coating precludes the need for a primer coating. Meeting the durability required in the environments you describe requires the powder coating to be applied at a reasonable thickness as specified by the powder coating supplier; 6580 microns are usually sufficient for an outdoor application. It is also critical to ensure that the coated parts see enough temperature and time to complete the cure to the powder coating chemistry. When a powder supplier quotes a recommended bake, they are referring to the time at or above the stated temperature that the part has reached. It is therefore important to factor in the heat-up time needed to reach the bake temperature. As for ensuring acceptable coating performance in the field, I can recommend a couple of practical tests. I suggest that you prepare a few test pieces that have been

run through the entire cleaning/passivation/coating/ curing process and perform the following tests: Simple “X” crosscut dry adhesion. Cut a 40 mm by 40 mm “X” into the coating with a sharp blade. Apply a strong tape such as 3M 2517 or Permacel #99 and pull sharply. The coating should exhibit no loss of adhesion. A similar test can be done with a “crosshatch” as described in ASTM D3359. This entails a perpendicular series of cuts that create a grid. Nevertheless, the simple “X” crosscut test is usually sufficient to determine if adhesion is acceptable.

Hot water immersion adhesion. Place the coated samples evaluated in the adhesion test described above into a 75°C water bath for 24 hrs. Remove and allow them to dry, then recheck tape adhesion. The coating should show little or no loss of adhesion. I would confirm these test results with a 500-hrs Salt Fog test (ASTM B-117). Place the scribed test parts in the corrosion chamber and evaluate every 250 hrs. Most powder coatings pass 1,000-hrs Salt Fog resistance, and 500 hrs is what I consider a minimum benchmark.

Good luck with identifying a finishing technology that provides the necessary cost/performance balance. Best regards, Joe

Ilaria Paolomelo ipcm®

Pulsar, a Polish company specialising in the production of safety devices and accessories for alarm systems, was experiencing some problems with its products’ coating quality. To solve these issues, it decided to switch from a manual to an automatic application system by relying on Lesta. The coating robot supplied by this Italian company enabled Pulsar to obtain uniform finishes, improve process repeatability, and minimise manual touch-ups. This change significantly boosted its productivity, allowing it to handle a daily production of up to 2,000 product sets, with a 400% increase in capacity.

In the modern industrial context, coating is a crucial phase that affects not only the aesthetics of products but also their degree of protection and durability over time. Often, when companies need to install a new coating system, they are faced with a fundamental choice between two application methods: manual and automatic. Each brings specific advantages and challenges that can significantly affect the efficiency and overall quality of the end products.

Manual coating offers a high degree of control and adaptability but strongly depends on the operator’s skills and experience. This process makes it possible to work on complex details and flexibly handle unpredictable variables, such as uneven surfaces or changing environmental conditions. However, it may present limitations regarding uniformity and repeatability of results, increasing the risk of defects and variability in the quality of finishes.

On the other hand, automatic coating systems are designed to operate efficiently, ensure greater accuracy and repeatability of results, reduce processing times, and minimise human error. They are particularly advantageous in large-scale production environments, where consistent

results and speed are essential to maintain competitiveness and meet quality requirements.

Pulsar faced this decision, too. Until 2017, it operated with a manual coating plant equipped with two booths, but despite the efficiency of the plant, the results’ quality was not up to expectations: problems with finishing uniformity and quality were compromising the company’s operational efficiency and ability to meet the high standards demanded by its customers.

To solve these critical issues, Pulsar chose to automate the coating application phase by relying on Lesta (Dairago, Milan, Italy) for the supply of a new, six-axis articulated coating robot. Installed within a single coating booth, this works in synergy with the reciprocators: the robot applies paint on the difficult-to-reach surfaces of parts, such as hollow spots, whereas the two reciprocators, each equipped with three guns, coat the flatter surfaces. This innovation has enabled the Polish company to overcome the limitations of the manual process, achieving higher levels of quality and more consistent finishes.

Pulsar: innovation and quality in the production of safety and video surveillance accessories

Since 1994, Pulsar (Łapczyca, Poland) has established itself as a leading

manufacturer of accessories for alarm, access control, and video surveillance systems. Pulsar’s product range is broad and diverse and includes enclosures, power supplies, PoE devices, fire protection systems, transformers, and accumulators. The company has quickly extended its presence to European and Asian markets, consolidating its position through a constant commitment to excellence. “Thanks to a strategy focused on quality and innovation, we have been able to expand into new markets and maintain a leading position,” states Pulsar’s CEO, Krzysztof Tatara.

Today, with over 200 employees and a production site of 8,000 m², Pulsar stands out as a modern and dynamic company, capable of responding flexibly to the global market’s needs. Its success is the result of a carefully curated production cycle in which every stage is designed to ensure high quality standards. “Pulsar uses only the highest quality materials and subjects each product to rigorous controls during all manufacturing stages, from sheet metal processing to coating and from the electrical components’ production and installation to final assembly,” adds Tatara. “In particular, coating is one of the most important steps in our workflow, as it provides each metal part with essential protection. For Pulsar, the finishing cycle plays first of all a functional role and only secondarily an aesthetic one.”

The coating cycle and the booth’s special feature

The coating process is designed to ensure the highest quality and durability of the finished parts while maintaining high production efficiency. “The components are manually loaded by the operator onto the monorail conveyor and taken to the pre-treatment tunnel, where they undergo a degreasing phase, necessary to remove oils and surface residues from the previous processing stages, combined with passivation with iron salts to form a protective layer; a rinse with mains water and further rinse with demineralised water. That is sufficient for Pulsar products intended for indoor use, such as home security systems, which do not require advanced corrosion protection,” notes Łukasz Szczepanik, Sales Manager at Indufinish, the plant engineering company that supplied the coating system.

“The special feature of the pre-treatment tunnel lies in the tanks made of polypropylene, which provides numerous advantages over steel. It is characterised by its high resistance to corrosion, a decisive factor in industrial environments where moisture and chemicals can easily deteriorate steel. Finally, the improved thermal insulation offered by the polypropylene contributes to the greater energy efficiency of the system by maintaining stable temperatures and reducing heat loss,” adds Szczepanik.

After pre-treatment, the operator unloads the workpieces, which then undergo a masking process necessary to prevent certain parts from losing conductivity. They are then placed on special trolleys and transported to the new coating area. “Our products’ hanging precision is crucial as even a shift of a few millimetres can affect their final finishing quality. Therefore, the operator uses laser trackers to position the components correctly on the hooks,” indicates Szczepanik.

The system, equipped with a laser barrier for automatic part contour detection, optimises all the paint application operations. The components are transported into the coating booth at a speed of 1 metre per minute, where the coating process is divided into two stages.

At first, the six-axis articulated robot supplied by Lesta applies the coating in hollow, difficult-to-reach areas using its advanced technology to paint concave surfaces. Subsequently, six reciprocator-mounted guns supplied by PUT Wagner-Service Polska apply the powder on the outer surfaces of the components, which are mostly flat.

“This plant’s key peculiarity,” illustrates Indufinish’s Sales Manager, “is that the robot and the reciprocators coexist in one booth. Unlike other systems where the robot only performs a pre-finishing function, here it is an integral part of the application phase.” Manual post-finishing is performed if necessary, but thanks to advanced robot programming,