The Paint Shop of the Future

www.durr.com

Welcome to a whole new world of painting

The Paint Shop of the Future

Welcome to a whole new world of painting.

FLEXIBILITY SUSTAINABILITY INNOVATION EFFICIENCY QUALITY

Modular Flexible Scalable

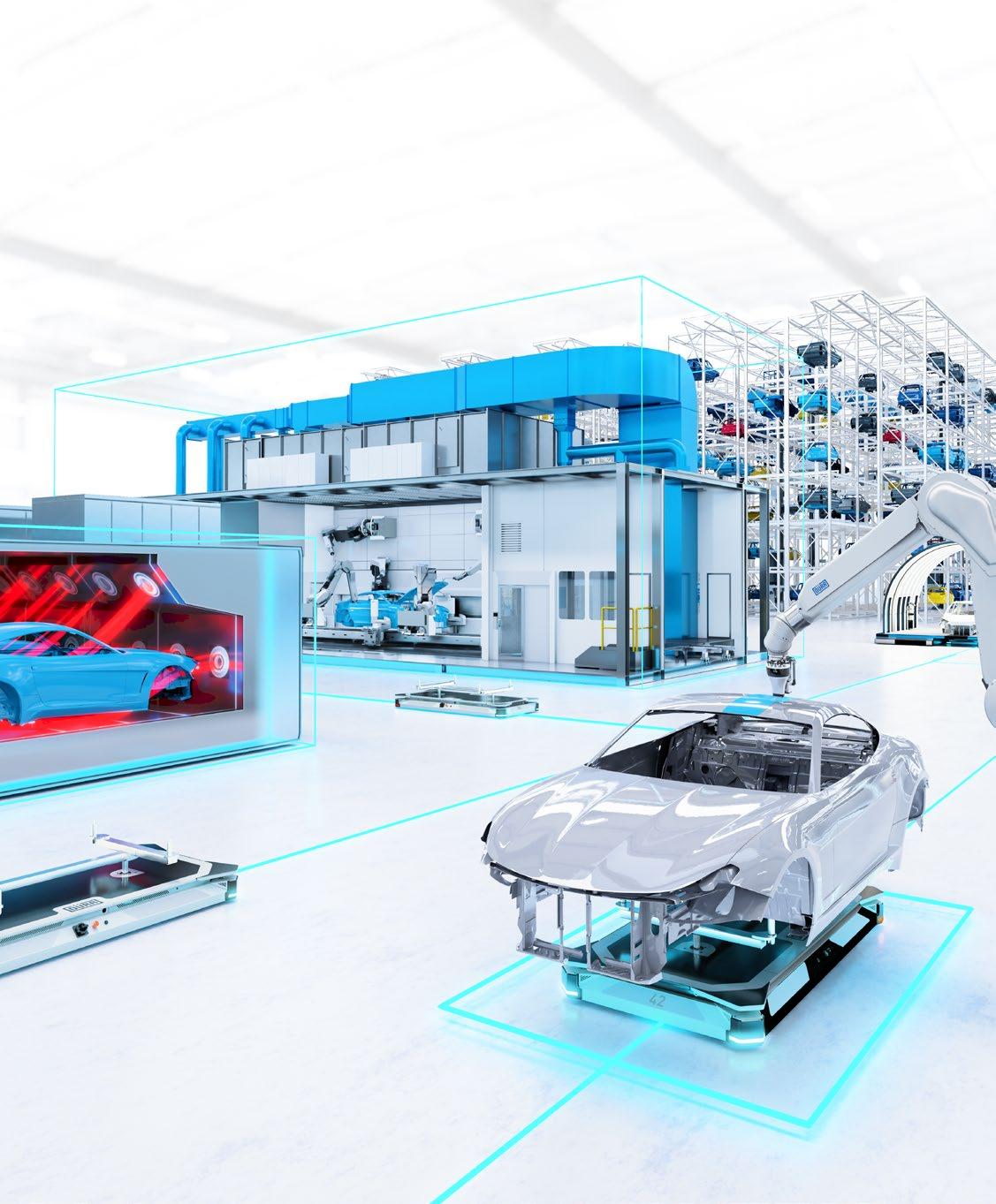

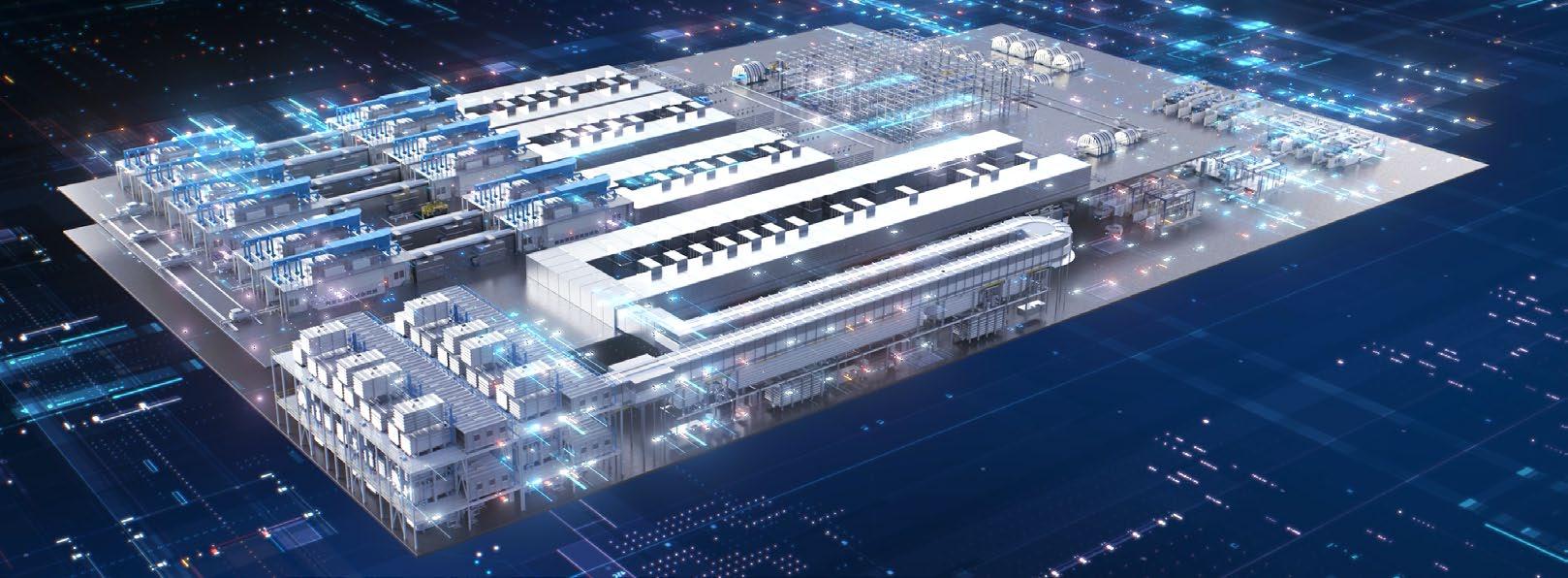

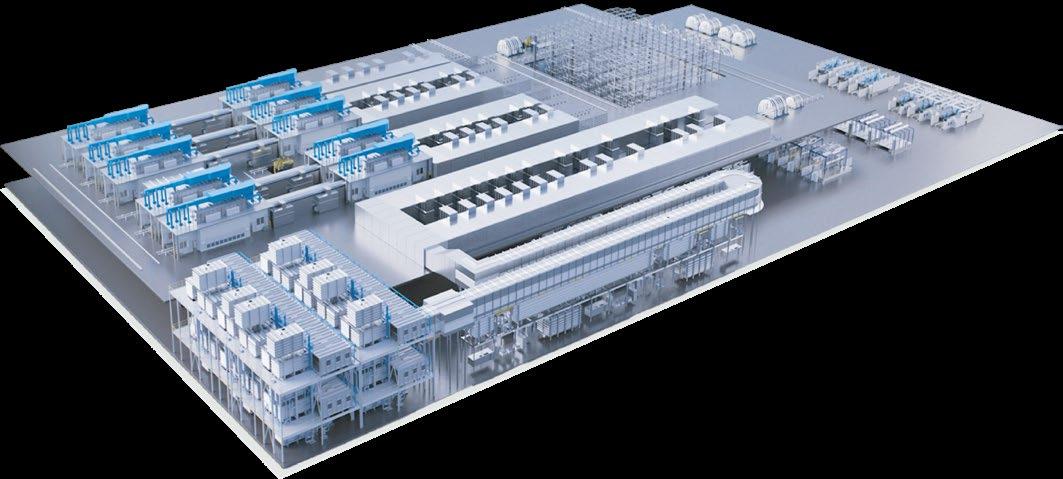

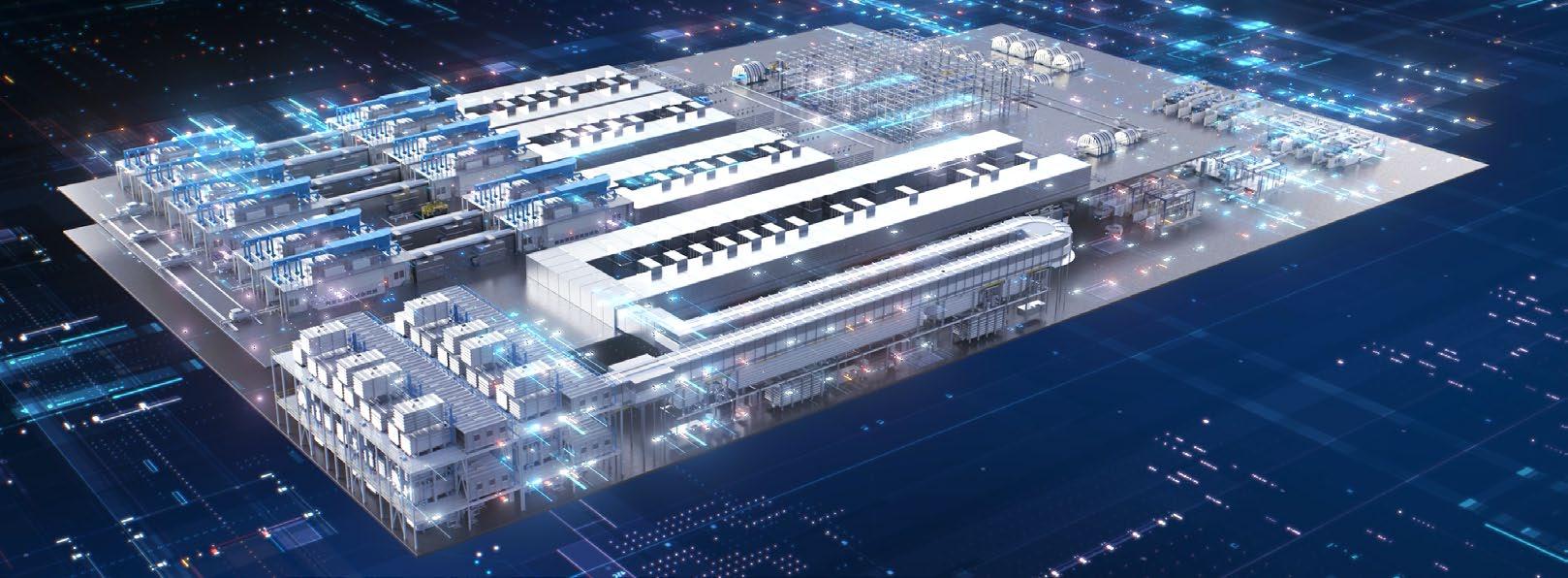

The future won‘t happen all by itself. It’s always based on what we already know today. A classic paint shop layout is enormous, taking up a lot of space with tons of equipment. Once built, it takes great effort to change the layout. Dürr‘s answer is The Paint Shop of the Future - flexible, scalable and efficient across all processes.

This paint shop stands for sustainability and optimized, digitally supported processes.

These innovations make clear: we can create a new layout - the layout of The Paint Shop of the Future. Modular. Flexible. Scalable. Because tomorrow‘s efficient production starts today.

WITH THE PAINT SHOP OF THE FUTURE, YOU CAN

Easily integrate new vehicle models

Adapt production capacities to meet market demand

Achieve high process efficiency

Implement sustainable production requirements

3

The Paint Shop of the Future: flexible and

scalable.

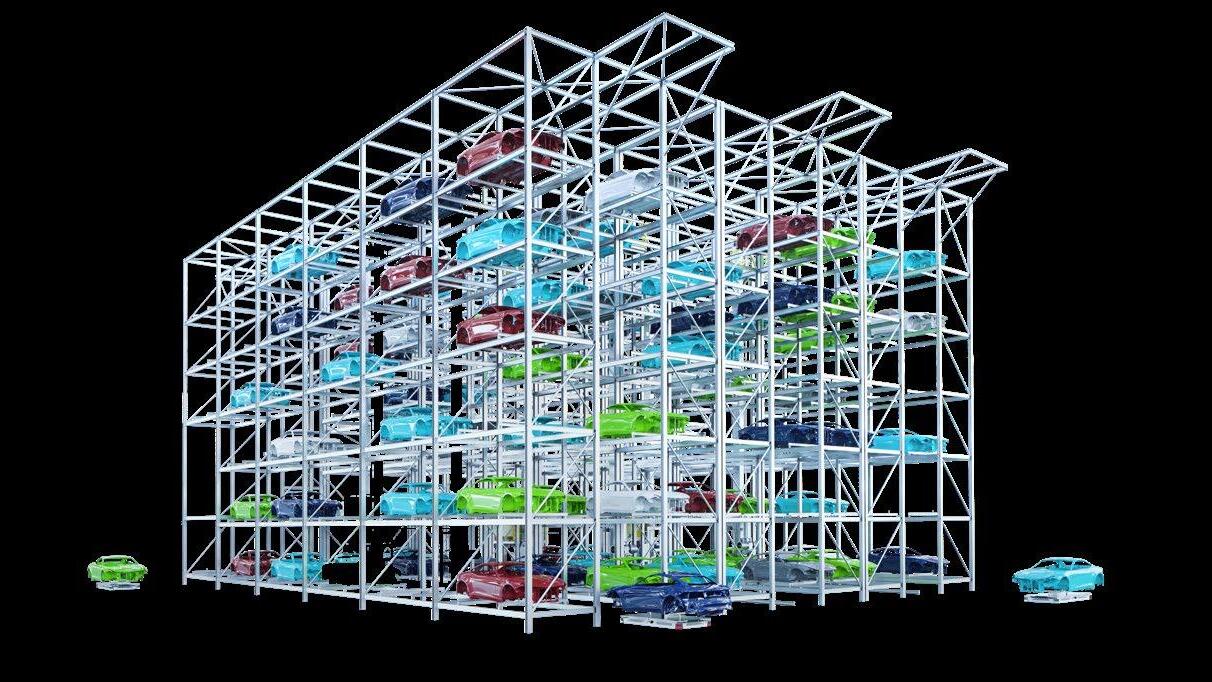

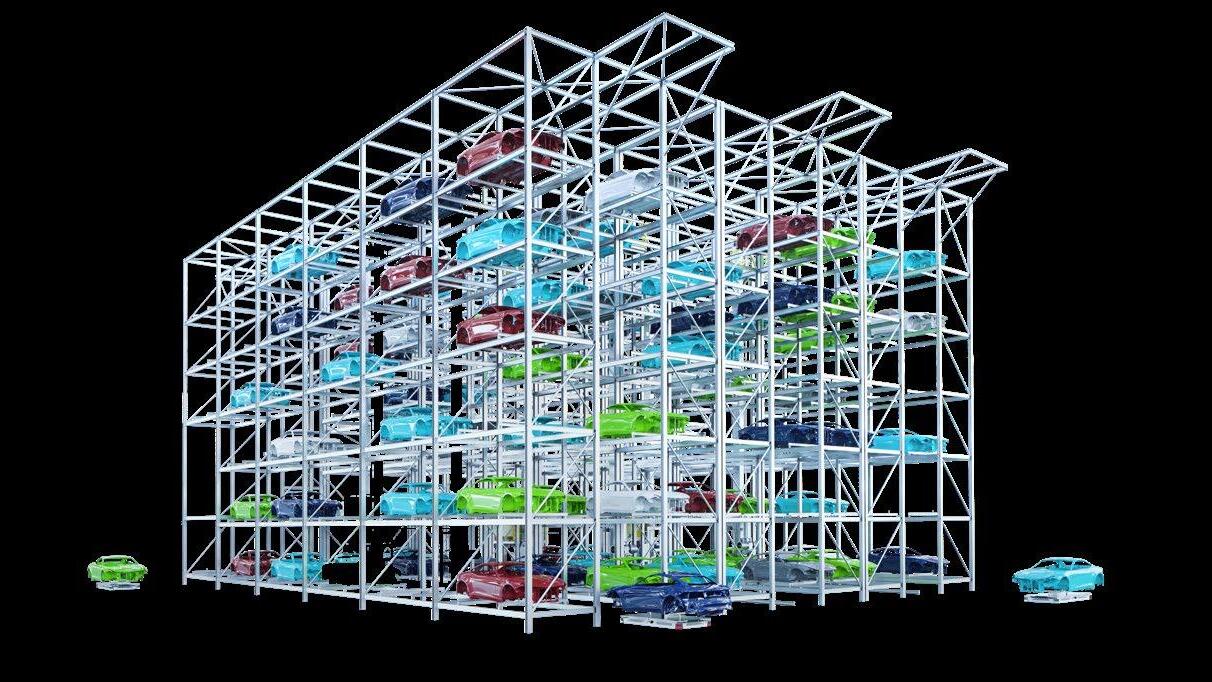

CENTRAL HIGH BAY WAREHOUSE

A critical step in making The Paint Shop of the Future as flexible as possible is to convert fixed low-level storage areas into one central high-bay storage area across all process levels.

This saves space and, with the right supervisory controls, enables the most efficient body selection and sequencing. The bodies can be stored at any time in the storage area, which is only a short distance away and be retrieved at a scheduled time for the next process.

All in all, this increases overall plant availability. In combination with intelligent IoT solutions, the paint shop of the future can adapt to any desired production scenario.

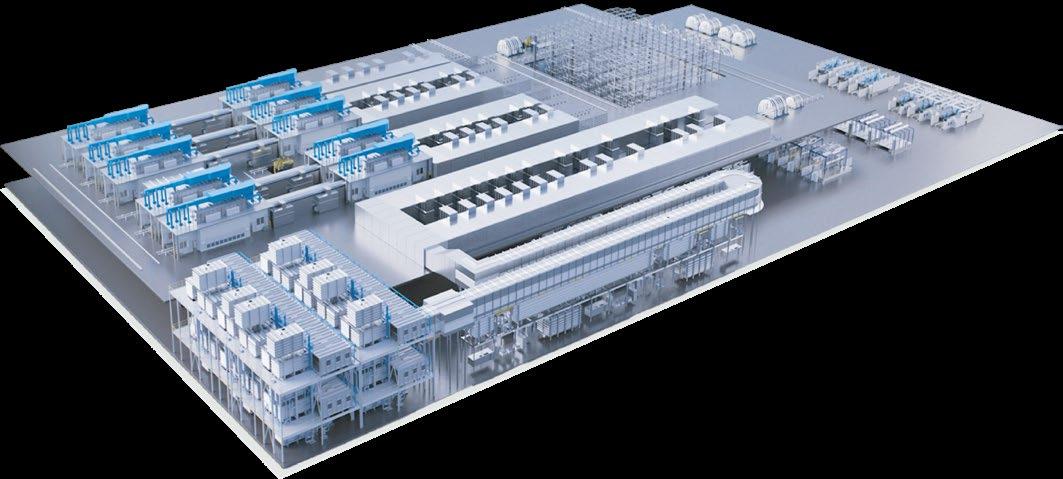

LAYOUT

Dürr‘s paint shop of the future enables the highest levels of production flexibility. The Paint Shop of the Future breaks away from the traditional layout used in the automotive industry and relies on a modular concept.

The bodies are now painted in parallel boxes rather than on a line. In the paint shop, in the seam sealing area and in the rework booths. These scalable boxes are ideal for a variety of component sizes and applications.

Instead of fixed cycle times, there are requirement-based process times. It is easy to integrate new vehicle models at any time.

Eco ProFleet - DRIVERLESS TRANSPORT SYSTEM

To link processes flexibly, we replace permanently installed conveyor technology wherever it makes sense. Our highly versatile EcoProFleet automated guided vehicles (AGVs) can be used in many areas. They can approach the boxes individually and adapt to the assignment, work type and processing time, increasing efficiency because the absolute time a body spends in the paint shop is reduced to the necessary minimum.

The DXQcontrol system is responsible for the AGVs and optimal car body selection and sequencing.

FLEXIBILITY

EcoProWet PT

The new pretreatment system: Flexible. Compact. Scalable.

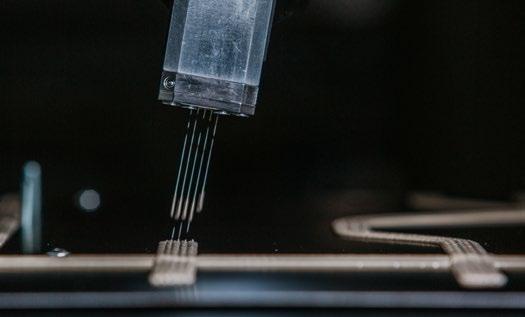

EcoSealJet Pro

The variable sealing applicator.

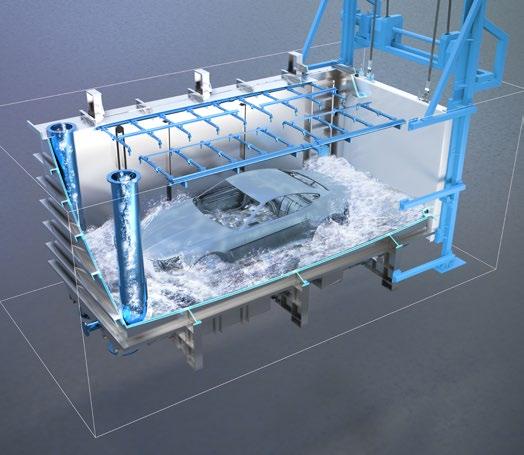

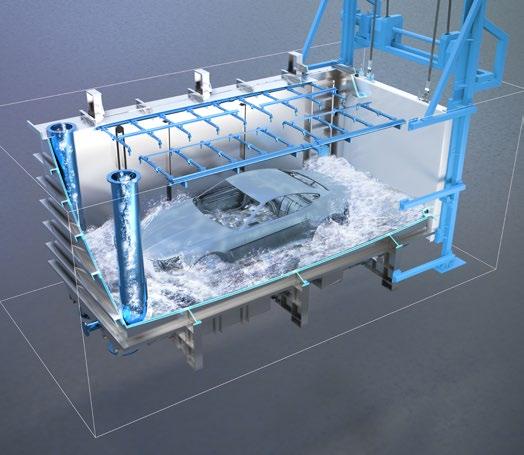

In vehicle painting, pretreatment with basic cleaning and dip coating requires the most space, mainly because the tanks are designed for the largest car body dimensions and longest process times.

That’s why process efficiency is the key to pretreatment. EcoProWet PT is a new, modular pretreatment system based on standardized chambers instead of a series of dip tanks. The EcoProWet PT system floods instead of dips to clean the body.

To do this, we replace the long line with a vertical process based on a box concept. This is not only more flexible but saves a lot of space. It‘s how we optimize plant construction for scalability, sustainability and availability.

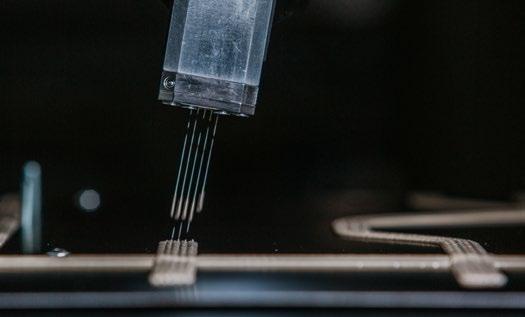

The seam sealing stations are already highly automated. However, sealing is still done manually in hard-to-reach areas of the car body.

Our EcoSealJet Pro bridges the final gap in vehicle sealing automation. It is highly precise and sustainable!

Its precision applies to hard-to-reach areas, for example, in the engine compartment or headlight units. The applicator also significantly eliminates the need for manual work for tasks where the automated PVC sealing systems have problems with unique contours, drilled holes, bolts and other obstacles.

The needles activate individually depending on the robot‘s speed and the amount of sealant to apply the material to the car body with consistent precision and quality. The applicator is highly versatile because it can adjust to the application distance and angle.

Each needle can apply the paint in jets or single drops through the application nozzles. The highly flexible applicator offers seam geometries of different thicknesses and widths, which have highedge definition and are free from overspray every time.

No sealing material is wasted, and the individual needle activation prevents material duplication at the seam joints. This system uses less material, prevents waste and reduces the frequency of equipment cleaning.

>360°

the applicator can rotate more than 360 degrees around its own axis

-30% steelwork -20% tank volume -10% space usage -8% energy consumption Flooding

Modular pretreatment system, flexibly expandable. EcoSealJet Pro also applies sealant to hard-to-reach areas automatically. Eliminates masking: variable and precise seam geometry.

instead of dipping with the EcoProWet PT.

INNOVATION

Individual

needle activation ensures

efficient application with low material consumption.

6 7

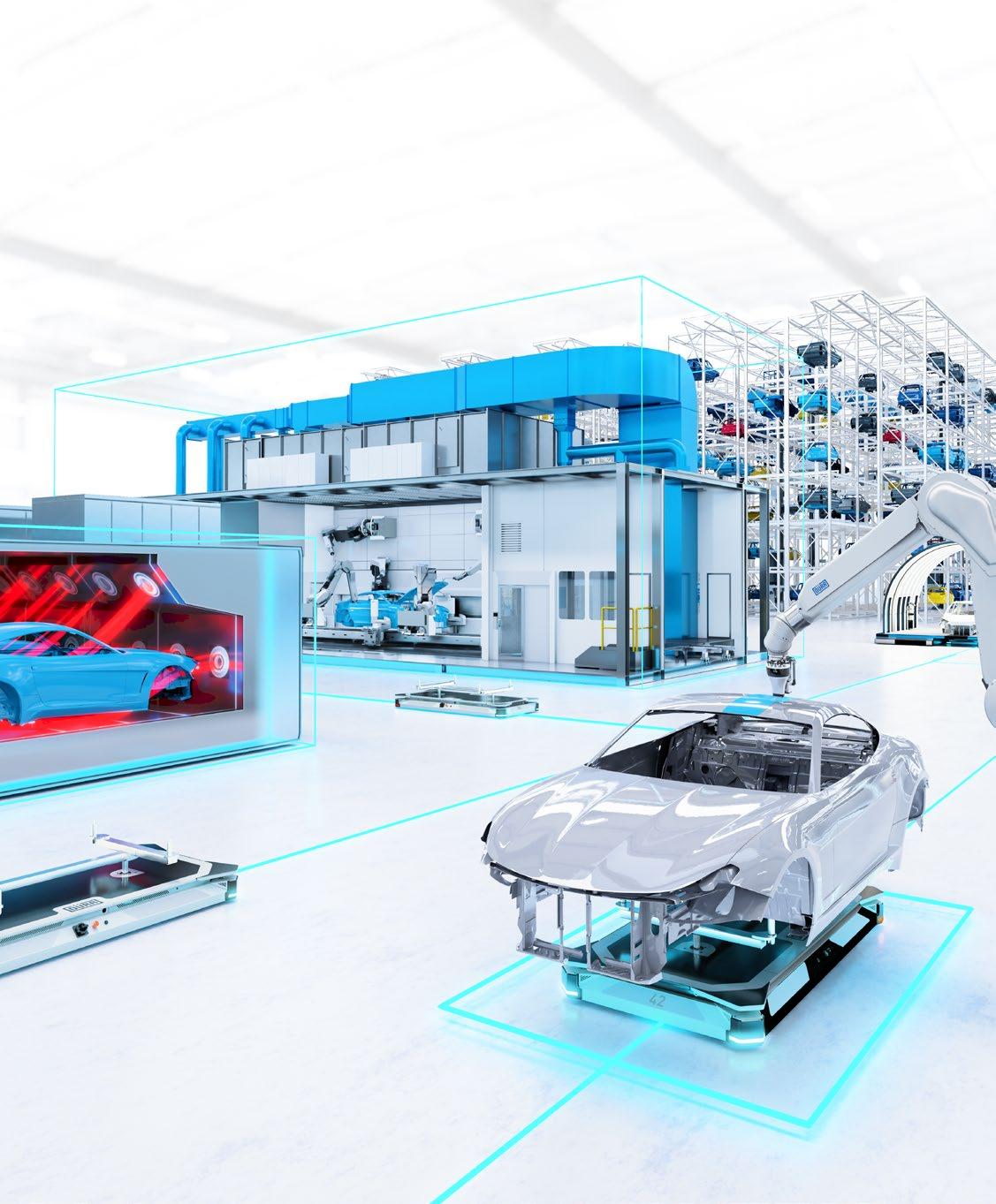

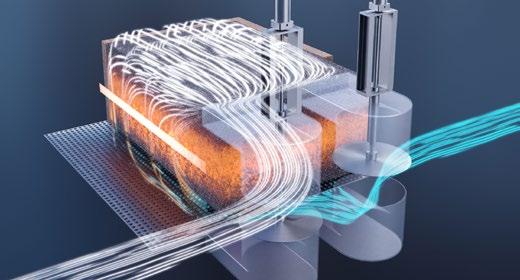

EcoProBooth

One spray booth for all painting tasks.

The changes we have made to the heart of the paint shop, the paint booth, are fundamental: We broke up the lines and introduced a paint box concept. The size and layout of the box are standardized for both the base and clear coats. All common car types - from compact cars to SUVs - can be painted in it. The advantage: the largest body no longer defines the cycle. Each box has the cycle time and process needed for the highest efficiency and quality.

MAXIMIZING OEE

What makes this revolutionary? In both the base coat and clear coat zones, interior and exterior painting requires only one booth with the same robots and the same atomizers.

New models can integrate quickly without a rigid line, or booths can shut down if utilization levels are lower.

THE BENEFITS

Standardized spray booths

Easily expanded

Simple retrofitting

Maximum flexibility

Fast maintenance in service booths

No production interruptions

Maximum air recirculation rate, minimal energy consumption

Shortest throughput time per body

One paint booth for all vehicle types.

With “service cubicles” in each corner of the paint booth, we make it possible to clean during the painting process. This allows the system to operate for long stretches without interruption, maximizing overall equipment effectiveness (OEE).

Part of the EcoProBooth is the paint overspray separation system with our latest generation of the EcoDryScrubber: the Big Module. The extremely compact filter kit design is perfect for the paint box concept. The cleaning process is waste-free. Almost 100% of paint particles are bound to powdered limestone and can be recycled.

Compared to classic dry separation, the EcoProBooth reduces energy consumption by 40%.

-40%

energy consumption compared to a classic dry separation system in a line concept

without

to

in the service

INNOVATION

Flexibly expandable EcoProBooth lines. Maintenance

interruptions

production

cubicle.

8 9

EcoBell4 Pro

Faster cycle times, higher capacities, fewer VOC emissions.

4x4

EcoBell4 Pro – 4 colors – 4 main needles –4 color changes – 4 seconds

The EcoBell4 significantly contributes to improving overall equipment effectiveness in the paint shop. The atomizer performs color changes faster than any other high-speed rotary atomizer. Our integrated RFID technology carries out predictive maintenance at the right time.

The Pro versions of the EcoBell4 set standards with the new four-main-needle technology. The patented system needs only four seconds for each color change which reduces paint and solvent consumption, lowers VOC emissions and protects the environment.

Removable external charge systems are another new feature and can be individually combined. Clean electrode rings replace discarded contaminated ones without stopping the line for cleaning.

The EcoBell4 Pro Ux applies the paint in the EcoProBooth. The universal atomizer can accommodate narrow spray jets for the interior, wide ones for the exterior and also metallic paints.

Interior and exterior painting in one booth with the EcoBell4 Pro Ux.

NEW FEATURES

RFID technology for higher system availability

Vibration sensors for permanent condition monitoring of the turbine

Greater accessibility due to 70° atomizer alignment

New magnetic measurement of the rotational speed

Four-main-needle technology for the quickest color changes with the least amount of paint and rinsing agent waste

Universal bell disk/shaping air ring system for BC1 and BC2 (metallic)

Replaceable electrode rings for fast maintenance and cleaning

Interior and exterior painting in one booth with the EcoBell4 Pro Ux

Replaceable electrode rings.

EcoPaintJet Pro

Revolutionary painting technology. High-edge definition and no overspray.

100% efficiency

-30%

energy consumption compared to customary two-tone painting

Revolutionary painting technology: overspray-free painting.

Stripes on the A pillar: customized designs and vertical painting are possible.

THE MORE CUSTOMIZED THE BETTER

When it comes to automotive painting, customers are requesting decorative and contrasting colors more often. And their requirements can now be met fully automatically. Overspray-free painting with the EcoPaintJet Pro was integrated into series production to achieve this.

Decorative stripes on doors, two-tone paint on roofs and, of course, the A, B and C pillars, too. Anything is possible with high-edge definition without overspray applied to an unmasked surface.

Immediately after painting or drying, the special paint can be applied quickly with 100% efficiency. Since the system produces no overspray, a paint overspray separation system is obsolete. The masking process produces no waste, and the cycle wastes no paint.

The EcoPaintJet Pro makes a significant contribution to sustainability with these efficiencies.

INNOVATION

10 11

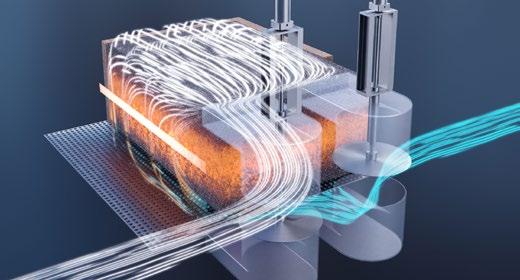

EcoInCure

Innovative car body curing from the inside.

The bodies are transported crosswise, not lengthwise, through the oven.

Electric vehicles are equipped with heavy, bulky sills that protect the battery in the underbody. They usually have a thick aluminum core that is difficult to heat from the outside. With conventional ovens, manufacturers must reduce throughput times, reducing capacity.

EcoInCure, on the other hand, relies on the principle of heating from the inside out. With a variably adjustable temperature, optimized airlock concept and simplified conveyor system, the EcoInCure achieves outstanding results in painting quality and heat-up time.

All Dürr ovens can be heated with the energy sources of the future. Together with an electrically operated air pollution control system, they ensure higher quality and sustainability and thus fewer emissions and a smaller CO2 footprint.

-50 %

less space needed by transporting car bodies crosswise

Oxi.X RV

Flameless exhaust air purification with electric RTO.

A central component of a sustainable energy concept is flameless exhaust air purification. The Oxi.X RV regenerative thermal oxidizer (RTO) means the system does not rely on fossil fuels. The unique feature of the Oxi.X RV is that the oxidation reaction for cleaning the exhaust air takes place in the ceramic material.

This has two benefits. First, there is no open flame as in conventional combustion processes and no undesirable byproducts, such as nitrogen oxides. Second, the heat bed stores the large quantity of energy generated during oxidation and uses it to keep the process operating.

That means the oxidation process becomes autothermal as soon as the oxidizer reaches its operating temperature. Renewable sources can supply the small amount of electricity needed to bring the system up to its operating temperature.

VOC separation efficiency.

Electric exhaust air purification with 99.7 %

Single-bed, flameless regenerative thermal oxidation.

INNOVATION

< 99.7% VOC separation efficiency. Up to

Innovative

12 13

car body curing from the inside.

Acting responsibly with sustainable processes

The Paint Shop of the Future also means sustainability is our future. Our holistic approach shows how it is possible to use fewer materials and utilities in paint shops and reduce water and wastewater quantities.

≤ 48% fewer VOC emissions

EcoSmart VEC, our software for regulating exhaust and fresh air flow rates, can reduce energy consumption and CO2 emissions by up to 50 percent when the oven is operating under partial load.

In the second step, we can ensure CO2-neutral drying and exhaust air cleaning, for example, by electrifying these process

≤ 50% fewer CO2 emissions ≤ 50% lower energy consumption thanks to our innovative product portfolio

100% plant transparency

Dürr can make a CO2-neutral paint shop that complies with all current and planned local VOC limits a reality today. Resource and process optimization are the key aspects of our planning for all plant areas. From the pretreatment and electrocoating phases to the spray booth and application technology, the oven, the air pollution control system and the work zones - all are complemented by our digital solutions.

We are breaking new ground with the EcoProBooth. We no longer supply air from outside. Instead, we use fresh air from inside the shop. We can reduce the process flow rate and minimize the proportion of fresh air. The EcoProBooth‘s energy consumption is up to 75 percent lower than that of wet scrubbers. Using powdered limestone as a filter medium also improves process sustainability because it is recyclable in the cement industry.

LESS VOC s , LESS CO 2

Our latest innovations in application technology, cleaning equipment and special color paint supply systems enable us to minimize paint and solvent use and then capture them efficiently, resulting in up to 48% VOC emissions reduction. The emphasis is also on preventing consumption in the oven area.

stages and using electricity from renewable sources. DXQenergy.management makes the entire paint shop fully transparent by providing a digital overview of all processes.

All consumption figures are recorded centrally in a single system to immediately identify conspicuous consumption above the nominal value of the paint shop.

SUSTAINABILITY 14 15

DXQ – Digital Intelligence by Dürr

With AI methods for higher OEE.

Dürr bundles its expertise in IT and mechanical engineering to create highperformance, digitally networked manufacturing solutions.

PLANT AND PROCESS EXPERTISE

To obtain a complete overall picture of the plant across all levels, we map individual, plant-specific requirements via individual software modules known as MicroServices.

Our plant and process expertise is our trump card. Coupled with AI methods, we improve three essential aspects of a plant: availability, quality and performance.

In digital production, our DXQ product family supports faster error diagnosis through systematic root cause analysis.

DXQequipment.analytics visualizes critical situations and uses historical data and machine learning to identify long-term trends and patterns.

The DXQplant.analytics software solution gives operators insights into the manufacturing processes. The product correlates recorded quality results with the order data (production number,

derivatives, color, etc.) and process data using artificial intelligence. An extensive database makes it possible to track the causes of defects and define measures.

INCREASING OEE

We optimize throughput times and adjust production planning accordingly with DXQ software. This ensures the long-term availability of the plant, increases the first run rate and significantly improves overall equipment effectiveness (OEE).

EFFICIENCY 16 17

Your partner for successful production

We are at your service. Online and on site.

Dürr’s Services & Solutions customer service offers worldwide support. Dürr is always on-site to help reduce production costs, increase plant availability and guarantee fast technical support.

We are available regardless of if you are dealing with an emergency or planning or implementing a revamp project.

Ramp-up and launch management

Modifications and upgrades

Engineering expertise

Spare parts service

Inspection and maintenance

Service locations all over the world

OUR SERVICE AT YOUR DEMAND

and worldwide DIRECT ACCESS TO OUR SERVICE IN YOUR PLANT CANADA USA MEXICO BRAZIL FRANCE SPAIN BELGIUM UK GERMANY SWEDEN ITALY POLAND RUSSIA TURKEY MOROCCO SOUTH AFRICA CHINA INDIA JAPAN SOUTH KOREA VIETNAM THAILAND MALAYSIA INDONESIA

Anytime

18

Phone: +49 7142 78-0

E-mail: info@durr.com

www.durr.com

Subject to change. The information in this brochure contains only general descriptions or performance characteristics which may vary in actual cases. The requested performance parameters shall be binding only if they are explicitly agreed within the sales contract. © Dürr 2023

Dürr Systems AG

Carl-Benz-Straße 34

74321 Bietigheim-Bissingen