BRAND-NEW

SPECI AL AUTOMOTIVE

High-quality Surfaces in Automotive Interiors

C

This technology enables the efficient production of coated components with tremendous design freedom in regard to appearance and haptics. Today plastics dominate the automotive interior. Components are typically injectionmolded from a thermoplastic and then, in a second step, coated on a coating line at a different location to create the desired appearance and haptic properties.

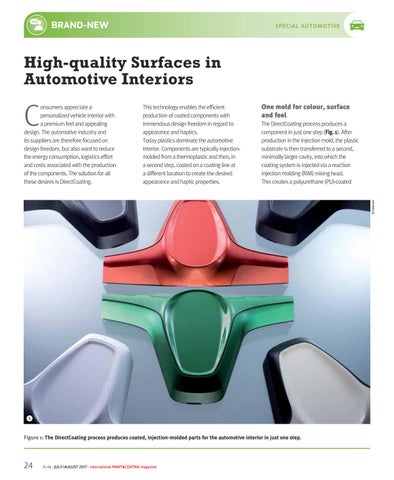

One mold for colour, surface and feel The DirectCoating process produces a component in just one step (Fig. 1). After production in the injection mold, the plastic substrate is then transferred to a second, minimally larger cavity, into which the coating system is injected via a reaction injection molding (RIM) mixing head. This creates a polyurethane (PU)-coated

Š Covestro

onsumers appreciate a personalized vehicle interior with a premium feel and appealing design. The automotive industry and its suppliers are therefore focused on design freedom, but also want to reduce the energy consumption, logistics effort and costs associated with the production of the components. The solution for all these desires is DirectCoating.

1

Figure 1: The DirectCoating process produces coated, injection-molded parts for the automotive interior in just one step.

24

N. 46 - JULY/AUGUST 2017 - international PAINT&COATING magazine