BRAND-NEW

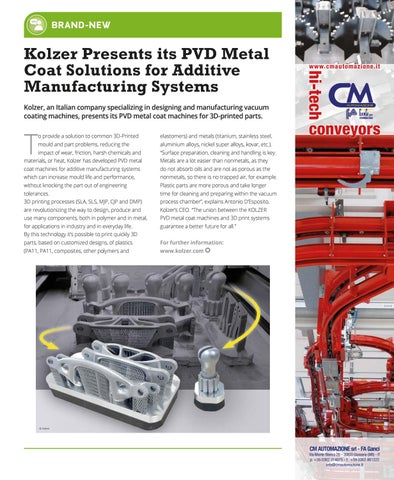

Kolzer, an Italian company specializing in designing and manufacturing vacuum coating machines, presents its PVD metal coat machines for 3D-printed parts.

T

o provide a solution to common 3D-Printed

elastomers) and metals (titanium, stainless steel,

mould and part problems, reducing the

aluminium alloys, nickel super alloys, kovar, etc.).

impact of wear, friction, harsh chemicals and

“Surface preparation, cleaning and handling is key.

materials, or heat, Kolzer has developed PVD metal

Metals are a lot easier than nonmetals, as they

coat machines for additive manufacturing systems

do not absorb oils and are not as porous as the

which can increase mould life and performance,

nonmetals, so there is no trapped air, for example.

without knocking the part out of engineering

Plastic parts are more porous and take longer

tolerances.

time for cleaning and preparing within the vacuum

3D printing processes (SLA, SLS, MJP, CJP and DMP)

process chamber”, explains Antonio D’Esposito,

are revolutionizing the way to design, produce and

Kolzer’s CEO. “The union between the KOLZER

use many components, both in polymer and in metal,

PVD metal coat machines and 3D print systems

for applications in industry and in everyday life.

guarantee a better future for all.”

www.cmautomazione.it

hi-tech

Kolzer Presents its PVD Metal Coat Solutions for Additive Manufacturing Systems

conveyors

By this technology it’s possible to print quickly 3D parts, based on customized designs, of plastics

For further information:

(PA11, PA11, composites, other polymers and

www.kolzer.com

© Kolzer

CM AUTOMAZIONE srl - FA Ganci

Via Monte Bianco 20 - 20833 Giussano (MB) - IT p. +39.0362.314075 - f. +39.0362.861222 info@cmautomazione.it