Š Spra yVision

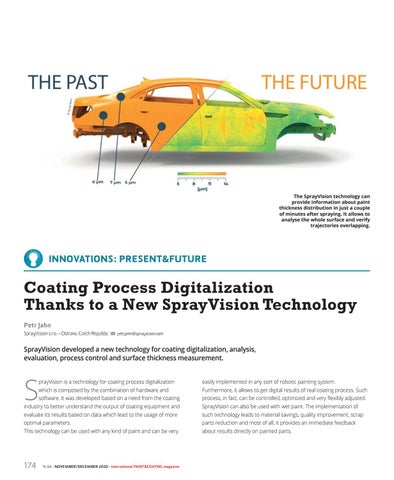

The SprayVision technology can provide information about paint thickness distribution in just a couple of minutes after spraying. It allows to analyse the whole surface and verify trajectories overlapping.

INNOVATIONS: PRESENT&FUTURE

Coating Process Digitalization Thanks to a New SprayVision Technology Petr Jahn SprayVision s.r.o. – Ostrava, Czech Republic

petr.jahn@sprayvision.com

SprayVision developed a new technology for coating digitalization, analysis, evaluation, process control and surface thickness measurement.

S

prayVision is a technology for coating process digitalization

easily implemented in any sort of robotic painting system.

which is composed by the combination of hardware and

Furthermore, it allows to get digital results of real coating process. Such

software. It was developed based on a need from the coating

process, in fact, can be controlled, optimized and very flexibly adjusted.

industry to better understand the output of coating equipment and

SprayVision can also be used with wet paint. The implementation of

evaluate its results based on data which lead to the usage of more

such technology leads to material savings, quality improvement, scrap

optimal parameters.

parts reduction and most of all, it provides an immediate feedback

This technology can be used with any kind of paint and can be very

about results directly on painted parts.

174

N. 66 - NOVEMBER/DECEMBER 2020 - international PAINT&COATING magazine