INNOVATIONS: PRESENT&FUTURE

SPECIAL ISSUE ON ARCHITECTURE & DESIGN

Scientist at Fraunhofer Institute Develops Coating that Protects Steel from the Penetration of Hydrogen Katharina Hien Fraunhofer Institute for Mechanics of Materials IWM - Freiburg, Germany

katharina.hien@iwm.fraunhofer.de

Lukas Gröner of the Fraunhofer IWM, MikroTribologie Centrum μTC, has developed a coating that effectively protects steel from the penetration of hydrogen. The barrier effect of this so-called MAX-phase layer is 3500 times greater than that of untreated steel.

R

egeneratively produced hydrogen is an

steel components that virtually prevent

The development process

environmentally friendly energy carrier,

the penetration of atomic hydrogen, and

In a vacuum chamber, Gröner first deposited

which can be used as fuel in cars or to

succeeded in producing thin MAX-phase

very precisely alternating layers of aluminium

generate electricity and heat in fuel cells. It can

coatings2 that protect steel very well against

nitride, an aluminium-nitrogen compound,

also be mixed with natural gas and used in

corrosion and hydrogen embrittlement.

and titanium on a steel surface using physical

gas-fired power plants to generate energy.

“MAX-phases have amazing properties

vapor deposition (PVD).

However, atomic hydrogen often induces

because they combine characteristics of both

This sandwich structure, which is only about

brittle behaviour in metals at high

ceramics and metals”, explains Gröner.

three micrometres thick, was then heated to

temperatures, which can lead to component

In fact, MAX-phases, like ceramics, are

form a very thin MAX-phase layer of titanium, aluminium and nitrogen (Ti2AlN).

failure.

insensitive to attack by oxygen and very

To provide a solution to this issue, in his

heat-resistant, but unlike pure ceramics, they

doctoral thesis physicist Lukas Gröner

are not brittle, so they do not break. Moreover,

deposition of titanium and aluminium nitride

developed and tested special coatings for

they are electrically conductive like metals.

in such a way that parallel Ti2AlN platelets

1

92

N. 65 - SEPTEMBER/OCTOBER 2020 - international PAINT&COATING magazine

© Fraunhofer Institute for Mechanics of Materials IWM

© Fraunhofer Institute for Mechanics of Materials IWM

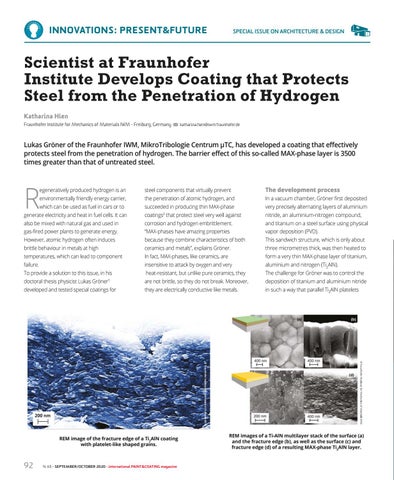

REM image of the fracture edge of a Ti2AlN coating with platelet-like shaped grains.

The challenge for Gröner was to control the

REM images of a Ti-AlN multilayer stack of the surface (a) and the fracture edge (b), as well as the surface (c) and fracture edge (d) of a resulting MAX-phase Ti2AlN layer.