BRAND-NEW

Tikkurila Protects Steel Structures of the World’s Largest Indoor Ski Centre

T

he world’s largest indoor ski

the roof structures, will comprise of

anti-corrosive Temacoat Primer and

centre is under construction at

150 components and weigh about

high-solids polyurethane topcoat

Lørenskog, Norway, approximately

500 tonnes. The complex has been

Temathane PC 50. The combination

20 kilometres east of Oslo. The

designed by Norwegian Halvorsen &

provides excellent weather and

six-story skiing complex houses a

Reine AS and the opening is scheduled

abrasion resistance for steel, stainless

downhill ski slope over 500 meters

for early 2020.

steel, aluminium and zinc surfaces.

long and a suspended cross-country

Over 60 companies are involved in

ski track. Tikkurila partners with Ruukki

building the EUR 105 million ski centre.

High-performance protection

Construction in providing the steel

Ruukki Construction, a subsidiary

The quality standards for the ski

structures for the site.

of SSAB, is in charge of designing,

centre’s steel structures and protective

The ski centre has a snow-covered

manufacturing and installing the steel

coatings are very high. The minimum

area of around 40,000 square meters,

frame and load-bearing sheets.

structural steel grade was S355, but

which is the equivalent of five football

The steel structures are manufactured

certain structures of longer span

pitches. The downhill ski slope,

in Ruukki’s Peräseinäjoki and Oborniki

distances required S550 high-strength

equipped with three ski lifts, will be

units, where they are also coated

steels. Protective coatings had to meet

accompanied by a cross-country ski

with Tikkurila’s polyurethane system

corrosivity category C3-H according to

track. The ski track, suspended from

TP131. The paint system includes

EN 12944-2.

© Tikkurila

“These standards are exceptionally high for indoor steel structures. All outside structures had to be galvanized steel”, explains Mika Jäsperlä, Design Manager of Ruukki Construction. “In protective coatings, we must consider not only the final purpose of use, but also logistics. An element made for indoors has to withstand varying weather conditions during transport, such as overseas shipping. Our epoxy primer gives steel structures excellent chemical and abrasion resistance and our polyurethane topcoat protects them from the weather and ultraviolet radiation. This ensures, that the final structures fully match the architects’ vision”, says Mikko Soini, International 1

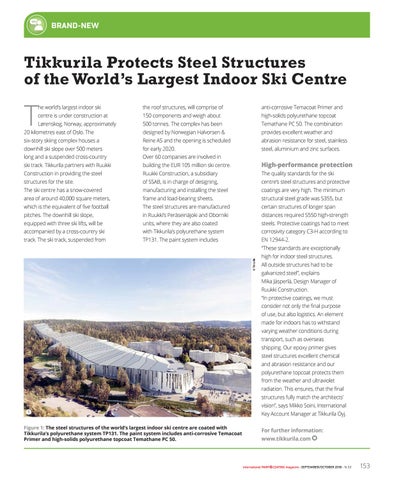

Figure 1: The steel structures of the world’s largest indoor ski centre are coated with Tikkurila’s polyurethane system TP131. The paint system includes anti-corrosive Temacoat Primer and high-solids polyurethane topcoat Temathane PC 50.

Key Account Manager at Tikkurila Oyj. For further information: www.tikkurila.com

international PAINT&COATING magazine - SEPTEMBER/OCTOBER 2018 - N. 53

153