ANALYSIS

Accelerating Wind Turbine Blade Circularity This is an abstract of the report jointly prepared by Marylise Schmid from WindEurope, Nieves Gonzalez Ramon and Ann Dierckx from Cefic and Thomas Wegman, EuCIA1 sustainability-platform@windeurope.org

1

The complete report is available at the following link: https://windeurope.org/data-and-analysis/product/?id=86

A

s the wind industry continues to grow to provide renewable

wind turbine blades, including technologies, processes, waste flow

energy across the globe, we are committed to promoting a circular

management, reintegration in the value chain and logistics.

economy which reduces environmental impacts throughout product

Today around 85 to 90% of wind turbines’ total mass can be recycled

lifecycles. To this end, WindEurope (representing the Wind Energy

[1], [2], [3]. Most components of a wind turbine have established

Industry), Cefic (representing the European Chemical Industry) and

recycling practices. However, wind turbine blades are more challenging

EuCIA (representing the European Composites Industry) have created

to recycle due to the composite materials used in their production.

a cross-sector platform to advance approaches for the recycling of

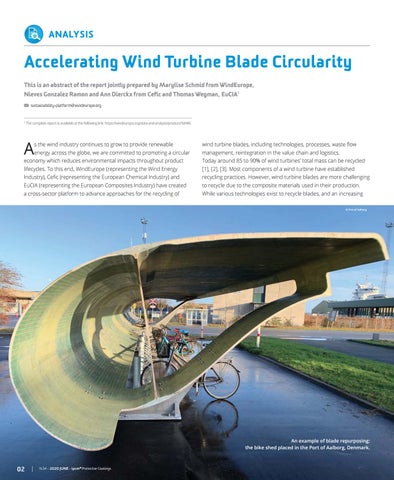

While various technologies exist to recycle blades, and an increasing © Port of Aalborg

An example of blade repurposing: the bike shed placed in the Port of Aalborg, Denmark.

02

N.34 - 2020 JUNE - ipcm® Protective Coatings