S P E C I A L O N A L UMINIU M FOR M E TA L A RC HI TE C TURE A ND I ND US T RIAL DESIGN

BRAND-NEW

Colourful, Functional, Customized: Qualisteelcoat Approved Anti-Corrosion Systems

T

he phenomenon of corrosion is

Structural deterioration, maintenance and

commonly associated with metallic

replacement of parts subject to corrosion

materials. Metal corrosion can

have a significant impact on costs.

ECO-STEELCORR painting systems: Qualisteelcoat approvals

be defined as a degradation process

A study by the WCO (World Corrosion

ECOPOLIFIX has been providing with

under certain environmental conditions.

Organization) in 2017 calculated that the

anticorrosive primers ECO-Primer O195

Corrosion indicates a natural and

costs related to corrosion are around

for many years. These, in combination

irreversible process of slow and continuous

2.5 trillion dollars/year and that it

with suitable Top-coats, such as the

consumption of a material, which results in

affects 3–4 % of the PIL of industrialized

Qualicoat-approved polyesters of

the deterioration of the characteristics or

countries. The same study also estimates

the various Helios powder coating

physical properties of the material initially

that a reduction of 875 billion dollars

series, offer a very high protection

involved. Durability, functionality and safety

per year of these costs is potentially

against corrosion. The Qualisteelcoat

are the most important and required

possible through: harmonization of

specification adopts parts of the

features of metal materials and structures.

regulations and standards, training of the

ISO 12944 standard that can also be

Thus, the protection from corrosion of

various professional figures and through

applied to powder coating.

metal artefacts is a necessary requirement

the use of appropriate anti-corrosion

The Qualisteelcoat approvals of the

for the steel construction industry.

technologies.

ECO-STEELCORR systems are the

© shutterstock_Marino Bocelli

result of the research and work of the ECOPOLIFIX laboratory in synergy with the HELIOS TBLUS laboratory in Ljubljana for the numerous physical and instrumental tests performed on the samples over the years. All ECOPOLIFIX’s staff in Italy and in the whole Helios Group in Europe are engaged in the continuous search for solutions that the market today solicits and requires in terms of quality, durability and warranty levels, making its trading partners available to the knowledge and synergy of a global group. For further information: www.ecopolifix.it and www.helios-powdercoatings.com

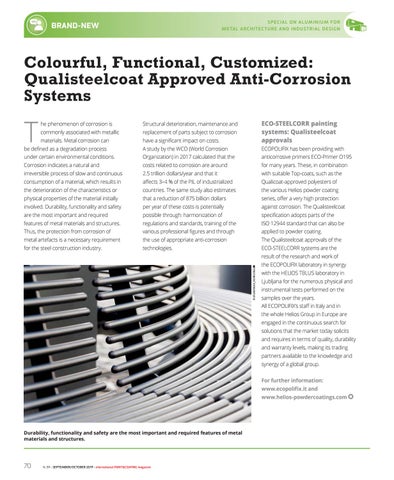

Durability, functionality and safety are the most important and required features of metal materials and structures.

70

N. 59 - SEPTEMBER/OCTOBER 2019 - international PAINT&COATING magazine