BRAND-NEW

SPECIAL PaintExpo

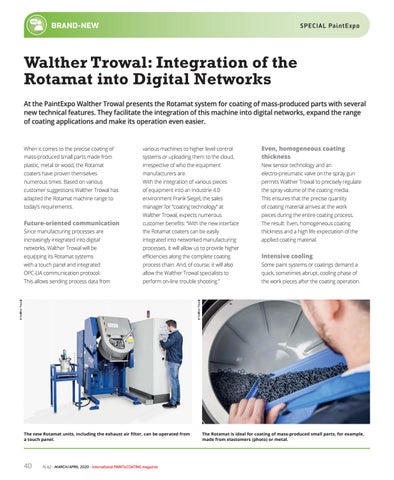

Walther Trowal: Integration of the Rotamat into Digital Networks At the PaintExpo Walther Trowal presents the Rotamat system for coating of mass-produced parts with several new technical features. They facilitate the integration of this machine into digital networks, expand the range of coating applications and make its operation even easier.

systems or uploading them to the cloud,

Even, homogeneous coating thickness

plastic, metal or wood, the Rotamat

irrespective of who the equipment

New sensor technology and an

coaters have proven themselves

manufacturers are.

electro-pneumatic valve on the spray gun

numerous times. Based on various

With the integration of various pieces

permits Walther Trowal to precisely regulate

customer suggestions Walther Trowal has

of equipment into an industrie 4.0

the spray volume of the coating media.

adapted the Rotamat machine range to

environment Frank Siegel, the sales

This ensures that the precise quantity

today’s requirements.

manager for “coating technology” at

of coating material arrives at the work

Walther Trowal, expects numerous

pieces during the entire coating process.

Future-oriented communication

customer benefits: “With the new interface

The result: Even, homogeneous coating

Since manufacturing processes are

the Rotamat coaters can be easily

thickness and a high life expectation of the

increasingly integrated into digital

integrated into networked manufacturing

applied coating material.

networks, Walther Trowal will be

processes. It will allow us to provide higher

equipping its Rotamat systems

efficiencies along the complete coating

Intensive cooling

with a touch panel and integrated

process chain. And, of course, it will also

Some paint systems or coatings demand a

OPC-UA communication protocol.

allow the Walther Trowal specialists to

quick, sometimes abrupt, cooling phase of

This allows sending process data from

perform on-line trouble shooting.”

the work pieces after the coating operation.

© Walther Trowal

various machines to higher level control

mass-produced small parts made from

© Walther Trowal

When it comes to the precise coating of

The new Rotamat units, including the exhaust air filter, can be operated from a touch panel.

40

N. 62 - MARCH/APRIL 2020 - international PAINT&COATING magazine

The Rotamat is ideal for coating of mass-produced small parts, for example, made from elastomers (photo) or metal.