15 minute read

Surface Roughness Of Stainless Steel Wires Coated with Titanium Dioxide after Exposure to Oral Medium

By Homa Farhadifard,

Abstract

Advertisement

Introduction: Orthodontic wires as a most important orthodontic component are affected in the oral cavity. This study is investigated the effect of clinical application of titanium dioxide coating on reducing the surface roughness of orthodontic wires after exposure to the oral environment.

Methods: In this clinical study, 16 patients participated in the aged range 12–25 years. A titanium dioxide coating layer was deposited on 0.018΄ stainless steel orthodontic wires by physical vapor deposition method. Scanning electron microscopes was done to check the accuracy of coating. The coated wires assigned to one arch and the opposite arch received an uncoated wire as control. After one month of intraoral exposure, wires were removed from the patient’s mouth and 10 mm of the wire was cut from the distal of canine to the mesial of premolar bracket. The AFM analysis was used to scanning the surface of the wires.

Result: Man-Whitney test showed that the mean surface roughness of coated and uncoated wires in Ra number (Z=-2.53, p=0.011) and Rq number (Z=-2.638, p=0.007) was significant difference among the two groups. Wilcoxon test showed there was no difference between the mean surface roughness in the maxilla and in the mandible in each group (p>0.05).

Conclusion: According to the results of this study, modifying the surface of orthodontic wires with titaniumdioxide reduces their surface roughness.

Keywords: Orthodontic wire, Titanium dioxide, Atomic force microscopy, Surface roughness

Introduction

Orthodontic treatment is one of the most effective methods to correct the position of the teeth. One of the most important orthodontic components of fixed appliance therapy is orthodontic wires, which control tooth movement (material). In the oral cavity, orthodontic wires are affected by the salivary flow and fluids and foods consumed temperature fluctuations and forces caused by the chewing process and orthodontic appliance, which results in the creation of friction and biological corrosion. These conditions affect the performance of orthodontic components and can lead to changes in microstructure, surface topography and mechanical properties.6,7 It is important for clinicians to identify these substance changes and evaluate their clinical behavior.

An important item related to the effective sliding mechanics of teeth by orthodontic wires is surface roughness, which can be associated with several clinical factors, including bacterial accumulation, friction, biocompatibility, color stability, health and aesthetic (scalo). There is a positive relationship between corrosion, wire surface roughness, and ion release in the oral cavity environment (Firas Elayyan). Increased surface roughness increases the frictional forces due to the strengthening of the contact surface between the bracket and the wire, which leads to a 50% reduction in effective orthodontic forces and reduces the quality of orthodontic treatment, especially in situations where we need to correct more than 2 mm (David Normando). On the other hand, surface roughness and irregularities of surfaces increase the tendency of orthodontic wires to corrode, and the release of ions following corrosion is a worrying source of side effects on the human body that affect the oral mucosa, immune system, and its biological function and can cause allergies and systemic disorders (ghasemi, amini).

Coating orthodontic appliances using nanotechnology is one of the available methods to change the surface properties, including reducing surface roughness (material). Nanotechnology and the materials science and engineering are less than 100 nanometers in size. By improving the mechanical and physical properties of materials, this technology has revolutionized the fields of medicine and dentistry in the fields of diagnosis and treatment. In the past decade, the use of nano-oxide films has been considered, and among them, titanium dioxide has gained attention due to its specific properties. Titanium dioxide is an inorganic white substance that is thermally stable, non-flammable, has low solubility and is chemically neutral.

There are various methods for measuring the level of surface roughness, which have the disadvantage of being invasive and the possibility of damage to the surface during scanning. Therefore, the demand for noninvasive and non-destructive methods based on optical methods is increasing. Atomic force microscopy (AFM) is the most suitable tool for measuring surface topography that can provide three-dimensional information of surface morphology without direct interference.

According to what has been said about the importance of surface roughness and its effects, this study investigated the effect of clinical application of titanium dioxide coating on reducing the surface roughness of orthodontic wires after exposure to the oral environment.

Materials and Methods:

In this study, 32 wires placed in patient’s mouth during four weeks (16 coated wires and 16 uncoated wires) and divided randomly in each patient’s jaws. Eight coated wires in the maxilla and eight coated wires in the mandible were placed. The uncoated wires were placed in the opposite jaw as control group in the same patient.

At selected times the wires were removed from the patient’s mouth (after four weeks of intraoral exposure). The wire was cut from the distal of canine to the mesial of premolar and separated (10 mm) and removed by water and cotton rolls and placed in small tubes for sampling, then the samples were transferred to the laboratory and the surface roughness of each piece of wire was calculated with an AFM microscope. This study was blind for evaluator of surface roughness in the samples.

Preparation and coating of wires:

In this study, the physical vapor deposition (PVD) was used to coat the wires. For this purpose, the first step was to get a suitable metal surface, so any covering layer or crust such as grease and dirt from the surface of the wire was removed by alcohol and then the wires entered the coating stage:

1. Ultrasonic cleaning in ethanol and acetone bath for 15 minutes,

2. Ultrasonic cleaning in water–NaOH solution for 20 minutes,

3. Rinsing with distilled water for 15 min.

An E-gun thermal method at 5,000 W and 1 Å/ second was used for coating the wires with a 100 mm layer of TiO2. Vacuum-chamber pressure was 0.00002 mbar before the start of the coating process and 0.00005 mbar during coating. The chamber temperature was set at 300°C.

SEM Analysis

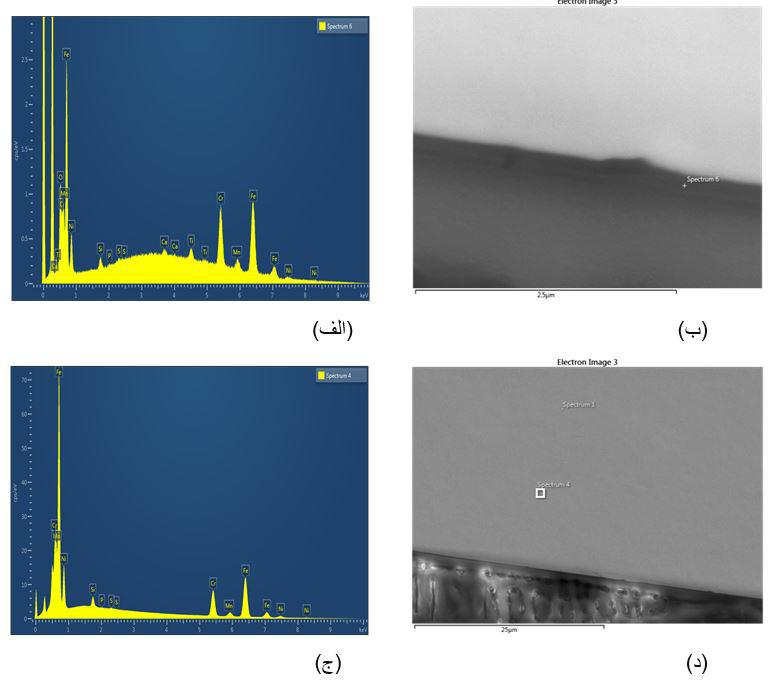

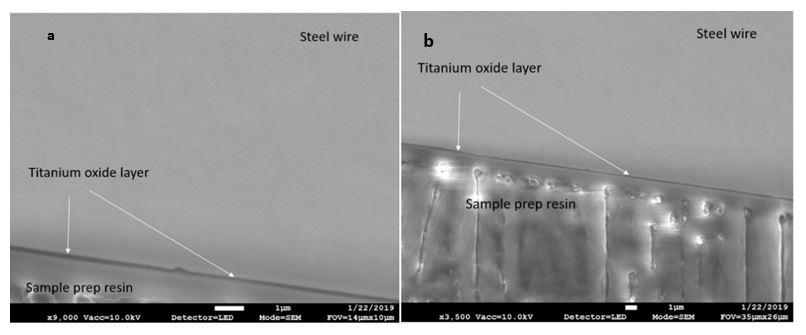

To check coating quality and integrity, one of the wires was randomly selected. The sample was first glued between two silicon wafers with a mixture of super glue and Bakelite (for conductivity). After the adhesive had dried, the sample was ground using P800, P100, and P2400 sandpaper to obtain a uniform cross-section. Then, a smooth cross-section of the sample was prepared using a (Leica EM TIC 3X, Sweden (ion mill) instrument. To check the accuracy of coated orthodontic wires, a wire was randomly selected. This study was performed by Scanning Electron Microscopes (SEM) (JEOL JSM7800F Prime) at Chalmers university of technology in Sweden (Figure 1). EDS analysis method was also used to analyze and detect the chemical elements in the coating layer (Figure 2). mandible) did not follow a normal distribution. Therefore, nonparametric Wilcoxon test was used to compare that among the groups (p<0.05). This test also showed that there was no difference between the mean surface roughness in the maxilla and in the mandible in each group.

In addition to these comparisons, the mean surface roughness of coated and uncoated wires in Ra number was investigated by Man-Whitney test, and it was observed that there was significant difference among the two groups (Z=-2.53, p=0.011). The test also showed that there was a significant difference in the mean surface roughness of coated and uncoated wires in Rq number (Z=2.638, p=0.007).

AFM Analysis Results:

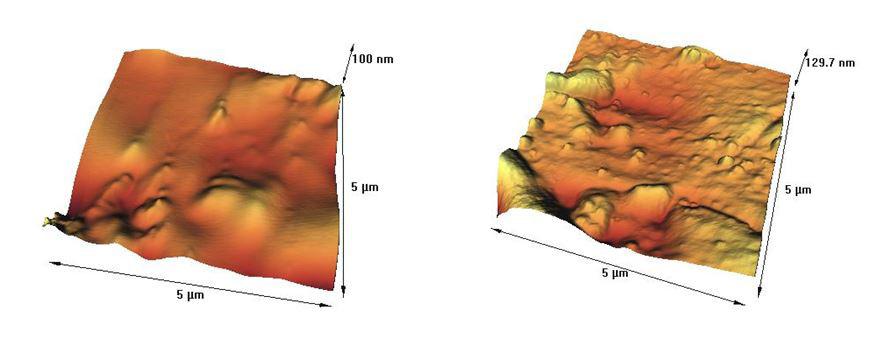

Typical AFM of uncoated and coated stainless steel orthodontic wires surface is presented in Figure 3. According to Kolmogorov–Smirnov test the surface roughness values in the studied groups, (with and without titanium oxide layer in the maxilla and in

Orthodontic wires are one of the most important components of conventional orthodontic appliances. The surface roughness of orthodontic wires is a crucial factor in determining the effectiveness of directed tooth movement on the wire. It was shown that surface properties affect both the performance and biocompatibility of orthodontic wires. In addition, surface topography can alter the aesthetics, corrosion, plaque accumulation, and performance of orthodontic components, and above all, surface roughness affects the coefficient of friction. The use of an efficient method to change the levels of orthodontic appliques to improve performance in the oral cavity has been made possible by the introduction of nanomaterials. The use of nanoparticles to reduce the frictional forces between two metal surfaces has been emphasized as excellent solid phase lubricants. The presence of nanoparticles on the modified surfaces acts as a spacer and reduces the number of surface irregularities that are in contact with each other, leading to a lower coefficient of friction.

This study aimed to evaluate the property of TiO2-coating to reduce the surface roughness of orthodontic wires and the results showed that coated orthodontic wires have significantly less surface roughness. Although there are few studies on the impact of TiO2-coating on the surface roughness of orthodontic stainless steel wires in the literature, a number of studies have reported data that are close to ours:

Ghasemi et al. investigated the antimicrobial effect, friction, and surface roughness of orthodontic brackets coated with silver nanofilm and titanium oxide. The brackets were coated with vapor deposition method with 60- and 100-µm films of silver and titanium oxide. The results showed that all 4 groups of coated brackets had reduced surface roughness and bacterial growth. These outcomes are in agreement with our study.

Keerthi et al. studied the effect of titanium dioxide coating on the surface roughness of nickeltitanium wires and its influence on Streptococcus mutans adhesion and enamel mineralization. The results showed that Streptococcus mutans adhesion was significantly reduced in the coated wires as compared with the uncoated wires (p=0.001). Also, TiO2- coating on nickel-titanium orthodontic wires reduced their surface roughness.30

Musavi et al. studied the effect of coating on the surface roughness of orthodontic wires on 25 wires including NiTi Memory wire as a control group, Orthocosmetic Elastinol, Perfect, Imagination, EverWhite. Significant differences existed between uncoated and coated wires regarding surface roughness values of NiTi (p<0.01), being higher for the uncoated wires. In our study, wire coating was associated with a reduction in surface roughness, which was consistent with the results of this study, and both studies recommended orthodontic wire coating to achieve less surface roughness.

Many studies have identified kerogen as a factor in increasing the surface roughness of wires after placement in patients’ mouths. From the results of these studies, it can be concluded that the surface roughness of coated wires related to their kerogen is less likely to be lower.23,31 On the other hand, Chois et al. showed that the friction force increases with increasing surface roughness between the wire and the brackets.22 Therefore, less surface roughness of TiO2 coated stainless steel wires can apply a more balanced force to the teeth during treatment and be effective in achieving the desired orthodontist treatment.

In the present study, PVD method was used to cover the wires. Surfaces coated using PVD method have excellent abrasion resistance, friction-coefficient reduction, excellent adhesion, and stability in different environments which shows the superiority of this method over other methods.33,32

Radio Frequency magnetron sputtering method was used in the study by Keerthi et al. for the coating process, which is performed at a lower temperature than the vapor deposition method, and therefore applicable for coating nickel-titanium wires that lose structural memory at high temperatures. Other controversial aspects of the Radio Frequency magnetron sputtering method include its applicability to a wide range of materials and the simplicity which layer thickness can be controlled by the sputtering method. The sputtering method makes controlling the layer thickness very simple. The bombardment of the surface with high-energy ions, which causes surface damage, is one of the method’s drawbacks.33, 34

An important issue regarding the application of nanomaterials in human samples is their biocompatibility. The toxicity of nanoparticles is directly related to their size.35 In this study, the application of nanotechnology is in the form of a nanoscale coating made by PVD and its corrosion is much less than that of TiO2, which naturally occurs on titanium implants. In addition, the oral exposure limit of TiO2 in the age range of 7–69 years is 1.6 μg/kg, which considering the characteristics mentioned so far, the release of some of it in saliva is not important.27

Mollabashi et al., showed that the survival rate of L929 fibroblast cells in the stainless steel orthodontic wires surface coated with TiO2 thin film was 90.3%±9.5% and for the uncoated-wire group 86.6%±8.1%. There was not a significant difference between the coated-wire and control group.

Measurement of titanium concentration in saliva samples also revealed that there was no substantial difference in the amount of titanium released in saliva before and after the wire was inserted in the mouth for various periods of time in all four groups of patients involved in the study.

Fatani et al. assessed the biocompatibility of titanium dioxide–coated brackets on the human gingival fibroblast (HGF) cell line with MTT assays in vitro. All coated brackets had higher OD values, which indicated that the survival rate of HGF cells around the coated brackets was higher than that of uncoated brackets.28

Suggestions:

1. There is an important issue about coating applainces. The durability and longevity of titanium oxide coating is not yet clinically determined. The importance of the effect of reducing surface roughness by titanium dioxide coating on other orthodontic appliances, including brackets, is overshadowed by their clinical application. If the time-dependent effect is desired, the simultaneous use of coated wires and brackets (taking into account the absence of subtle changes in dimensions) is recommended.

2. The present study did not perform heavy mechanotherapy when the wires were inserted into the patient’s mouth, leading to mechanical deterioration of the wire coating. However, further studies are needed to investigate the mechanical stability of the titanium dioxide coating under mechanical loading during the treatment.

Conclusion:

According to the results of this study, modifying the surface of orthodontic wires with TiO2 reduces their surface roughness.

References:

1 Wahl N. Orthodontics in 3 millennia. Chapter 1: Antiquity to the mid-19th century. Am J Orthod Dentofacial Orthop. 2005 Feb;127(2):255-9. doi: 10.1016/j.ajodo.2004.11.013. PMID: 15750547.

2 Naidu, Shyamala, and Anand Suresh. “EVOLUTION OF ORTHODONTIC APPLIANCES-THEN AND NOW!!!.” International Journal of Dental and Health Sciences (2018): 319329.

3 Phulari, B. S.: History of Orthodontics. 2013: publisher: JP Medical Ltd.

4 Corruccini RS, Pacciani E. “Orthodontistry” and dental occlusion in Etruscans. Angle Orthod. 1989;59(1):61-64.

5 Nour Eldin Tarraf, Darendeliler M. Ali, Present and the future of digital orthodontics,Seminars in Orthodontics,Volume 24, Issue 4,2018,Pages 376-385,

6 Bichu, Yashodhan & Alwafi, Abdulraheem & Liu, Xiaomo & And0rews, James & Ludwig, Björn & Bichu, Aditi & Zou, Bingshuang. (2022). Advances in orthodontic clear aligner materials.Bioactive Materials. 22. 10.1016/j.bioactmat.2022.10.006.

7 Ahmed Mohammed Alassiry,Clinical aspects of digital threedimensional intraoral scanning in orthodontics – A systematic review,The Saudi Dental Journal,2023,

8 Hong K, Kim WH, Eghan-Acquah E, Lee JH, Lee BK, Kim B. Efficient Design of a Clear Aligner Attachment to Induce Bodily Tooth Movement in Orthodontic Treatment Using Finite Element Analysis. Materials (Basel). 2021 Aug 30;14(17):4926. doi: 10.3390/ ma14174926. PMID: 34501017; PMCID: PMC8433704.

9 Macrì M, Murmura G, Varvara G, Traini T and Festa F (2022) Clinical Performances and Biological Features of Clear Aligners Materials in Orthodontics. Front. Mater. 9:819121. doi: 10.3389/ fmats.2022.819121

10 Madariaga ACP, Bucci R, Rongo R, Simeon V, D’Antò V, Valletta R. Impact of Fixed Orthodontic Appliance and Clear Aligners on the Periodontal Health: A Prospective Clinical Study. Dent J (Basel). 2020 Jan 2;8(1):4. doi: 10.3390/dj8010004. PMID: 31906577; PMCID: PMC7175220.

11 Muro MP, Caracciolo ACA, Patel MP, Feres MFN, Roscoe MG. Effectiveness and predictability of treatment with clear orthodontic aligners: A scoping review. Int Orthod. 2023 Apr 20;21(2):100755. doi: 10.1016/j.ortho.2023.100755. Epub ahead of print. PMID: 37086643.

12 Bilello G, Fazio M, Amato E, Crivello L, Galvano A, Currò G. Accuracy evaluation of orthodontic movements with aligners: a prospective observational study. Prog Orthod. 2022 Apr 11;23(1):12. doi: 10.1186/s40510-022-00406-7. PMID: 35399128; PMCID: PMC8995220.

13 Ren L, Liu L, Wu Z, Shan D, Pu L, Gao Y, Tang Z, Li X, Jian F, Wang Y, Long H, Lai W. The predictability of orthodontic tooth movements through clear aligner among first-premolar extraction patients: a multivariate analysis. Prog Orthod. 2022 Dec 30;23(1):52. doi: 10.1186/s40510-022-00447-y. PMID: 36581703; PMCID: PMC9800677.

14 Tartaglia GM, Mapelli A, Maspero C, Santaniello T, Serafin M, Farronato M, Caprioglio A. Direct 3D Printing of Clear Orthodontic Aligners: Current State and Future Possibilities.

Materials (Basel). 2021 Apr 5;14(7):1799. doi: 10.3390/ma14071799. PMID: 33916462; PMCID: PMC8038630.

15 Maspero C, Tartaglia GM. 3D Printing of Clear Orthodontic Aligners: Where We Are and Where We Are Going. Materials (Basel). 2020 Nov 18;13(22):5204. doi: 10.3390/ma13225204. PMID: 33217905; PMCID: PMC7698787.

16 Lee, S.Y., Kim, H., Kim, HJ. et al. Thermo-mechanical properties of 3D printed photocurable shape memory resin for clear aligners. Sci Rep 12, 6246 (2022). https://doi.org/10.1038/s41598-02209831-4

17 Tartaglia GM, Mapelli A, Maspero C, Santaniello T, Serafin M, Farronato M, Caprioglio A. Direct 3D Printing of Clear Orthodontic Aligners: Current State and Future Possibilities. Materials (Basel). 2021 Apr 5;14(7):1799. doi: 10.3390/ ma14071799. PMID: 33916462; PMCID: PMC8038630.

18 Shivapuja P., Shah D., Shah N., Shah S. Direct 3D-Printed Orthodontic Aligners with Torque, Rotation, and Full Control Anchors. No. 10,179,035. U.S. Patent. 2019 Jan 15

19 Jindal P., Juneja M., Siena F.L., Bajaj D., Breedon P. Mechanical and geometric properties of thermoformed and 3D printed clear dental aligners. Am. J. Orthod. Dentofacial. Orthop. 2019;156:694–701.

20 Prasad S., Kader N.A., Sujath G., Raj T. 3D printing in dentistry. J. 3D Print. Med. 2018;2:89–91.

21 Caruso S, Caruso S, Pellegrino M, Skafi R, Nota A, Tecco S. A Knowledge-Based Algorithm for Automatic Monitoring of Orthodontic Treatment: The Dental Monitoring System. Two Cases. Sensors (Basel). 2021 Mar 7;21(5):1856. doi: 10.3390/ s21051856. PMID: 33799930; PMCID: PMC7961518.

22 Strunga M, Urban R, Surovková J, Thurzo A. Artificial Intelligence Systems Assisting in the Assessment of the Course and Retention of Orthodontic Treatment. Healthcare (Basel). 2023 Feb 25;11(5):683

23 Mohammad-Rahimi H, Nadimi M, Rohban MH, Shamsoddin E, Lee VY, Motamedian SR. Machine learning and orthodontics, current trends and the future opportunities: A scoping review. Am J Orthod Dentofacial Orthop. 2021 Aug;160(2):170-192.e4. doi: 10.1016/j.ajodo.2021.02.013. Epub 2021 Jun 5. PMID: 34103190.

24 Maspero C, Abate A, Cavagnetto D, El Morsi M, Fama A, Farronato M. Available Technologies, Applications and Benefits of Teleorthodontics. A Literature Review and Possible Applications during the COVID-19 Pandemic. Journal of Clinical Medicine. 2020; 9(6):1891. https://doi.org/10.3390/jcm9061891

25 Ismaeel Hansa, Steven J. Semaan, Nikhilesh R. Vaid, Donald J. Ferguson,Remote monitoring and “Tele-orthodontics”: Concept, scope and applications,Seminars in Orthodontics, Volume 24, Issue 4,2018,Pages 470-481,ISSN 1073-8746, https://doi.org/10.1053/j. sodo.2018.10.011.

26 Gan, N., Xiong, Y., & Jiao, T. (2016). Accuracy of Intraoral Digital Impressions for Whole Upper Jaws, Including Full Dentitions and Palatal Soft Tissues. PLoS ONE, 11.

27 Pattamavilai S, Ongthiemsak C. Accuracy of intraoral scanners in different complete arch scan patterns. J Prosthet Dent. 2022 Mar 4:S0022-3913(22)00046-4. doi: 10.1016/j.prosdent.2021.12.026. Epub ahead of print. PMID: 35256181.

28 Aly P, Mohsen C. Comparison of the Accuracy of ThreeDimensional Printed Casts, Digital, and Conventional Casts: An In Vitro Study. Eur J Dent. 2020 Mar;14(2):189-193. doi: 10.1055/s0040-1705243. Epub 2020 Apr 20. PMID: 32311750; PMCID: PMC7274830.

29 As of July 2020, iTero scans have been used in more than 5.5 million restorative case scans, including crown, bridge, and custom implant cases and more than 24.0 million iTero orthodontic case scans. Data on file at Align Technology, as of July 22nd, 2020. https://www.digitalplatform.me/references

30 Intraoral Scanner Reviews from IDS 2021 + IOS Market Update https://instituteofdigitaldentistry.com/news/intraoral-scannerreviews-from-ids-2021-ios-market-u pdate/

31 Schmalzl, J., Róth, I., Borbély, J. et al. The impact of software updates on accuracy of intraoral scanners. BMC Oral Health 23, 219 (2023). https://doi.org/10.1186/s12903-023-02926-y

32 García-Sanz V, Bellot-Arcís C, Hernández V, Serrano-Sánchez P, Guarinos J, Paredes-Gallardo V. Accuracy and Reliability of Cone-Beam Computed Tomography for Linear and Volumetric Mandibular Condyle Measurements. A Human Cadaver Study. Sci Rep. 2017 Sep 20;7(1):11993. doi: 10.1038/s41598-017-12100-4. PMID: 28931867; PMCID: PMC5607232.

33 Anuraj Singh Kochhar, Gurkeerat Singh, Harshita Gupta. Applications of Cone Beam Computerized Tomography in Orthodontics: A Mini Review. On J Dent & Oral Health. 3(3): 2020. OJDOH.MS.ID.000565.

34 Venkatesh E, Elluru SV. Cone beam computed tomography: basics and applications in dentistry. J Istanb Univ Fac Dent. 2017 Dec 2;51(3 Suppl 1):S102-S121. doi: 10.17096/jiufd.00289. PMID: 29354314; PMCID: PMC5750833.

35 ALIGN TECHNOLOGY LAUNCHES NEW INVISALIGN SYSTEM INNOVATIONS FOR ORTHODONTIC AND RESTORATIVE DENTAL TREATMENT PLANNING WITH INTEGRATION OF CBCT INTO CLINCHECK TREATMENT PLANNING SOFTWARE Mar 18, 2022, https:// investor.aligntech.com/news-releases/news-release-details/aligntechnology-launches-ne w-invisalign-system-innovations

36 Alsufyani NA, Al-Saleh MA, Major PW. CBCT assessment of upper airway changes and treatment outcomes of obstructive sleep apnoea: a systematic review. Sleep Breath. 2013 Sep;17(3):91123. doi: 10.1007/s11325-012-0799-7. Epub 2013 Jan 24. PMID: 23344828.

37 Kapila SD, Nervina JM. CBCT in orthodontics: assessment of treatment outcomes and indications for its use. Dentomaxillofac Radiol. 2015;44(1):20140282. doi: 10.1259/dmfr.20140282. PMID: 25358833; PMCID: PMC4277443.

38 Intraoral X-Ray Imaging Market Size, Status, Demand and Global Outlook- Danaher, Sirona Dental, Carestream, Gendex, Owandy Radiology, TPC Advanced Technology, Digital Doc, https://www. digitaljournal.com/pr/news/xherald/intraoral-x-ray-imagingmarket-size-status-dema nd-and-global-outlook-danaher-sironadental-carestream-gendex-owandy-radiology-tpc-advanc edtechnology-digital-doc

39 Hung K, Yeung AWK, Tanaka R, Bornstein MM. Current Applications, Opportunities, and Limitations of AI for 3D Imaging in Dental Research and Practice. Int J Environ Res Public Health. 2020 Jun 19;17(12):4424. doi: 10.3390/ijerph17124424. PMID: 32575560; PMCID: PMC7345758.

40 Petrescu SM, Țuculină MJ, Popa DL, DuȚă A, Sălan AI, Voinea Georgescu R, Diaconu OA, Turcu AA, Mocanu H, Nicola AG, Dascălu IT. Modeling and Simulating an Orthodontic System 41 Tamer İ, Öztaş E, Marşan G. Orthodontic Treatment with Clear Aligners and The Scientific Reality Behind Their Marketing: A Literature Review. Turk J Orthod. 2019 Dec 1;32(4):241-246. doi: 10.5152/TurkJOrthod.2019.18083. PMID: 32110470; PMCID: