T GE

How to make metal powders. Part 2: Understanding water atomisation and water atomised powders In the Winter 2021 issue of PM Review, we introduced the first instalment in our four-part series on metal powder atomisation, in which two masters of atomisation, Joe Strauss and John Dunkley, introduced the fundamental principles of atomising technology and atomised powders. Now, in the second instalment in the series, they explore one of the most widely used metal powder production methods – water atomisation. This long-established technology is used to produce a vast range of metal powders for many industrial applications, including press and sinter PM and MIM, and is now making inroads into metal AM.

General attributes of water atomisation As outlined in our introduction ‘How to make metal powders. Part 1: An introduction to atomisation, process fundamentals and powder characteristics,’ published in the Winter 2021 issue of PM Review, materials in the form of powder constitute a substantial volume of many metals, ranging from ~0.1% to nearly 50% of global production of different alloys. Probably the majority of metal powders by mass are produced by water atomisation. This is a long-established process whose origins are unclear, but the preparation of iron and steel shot goes back over a century, and high-pressure water atomisation was perhaps originally developed for non-ferrous metals. The great Dr W D Jones of FW Berk Chemical, later Powder Metallurgy Ltd, did pioneering work in the 1940s and 50s that led to the first stainless steel and self-fluxing nickel alloy powders. Since then, plants

© 2022 Inovar Communications Ltd

have grown from the initial 100–200 kg for high alloys to 2–5 t units for pig iron in the 60s, then progressed to arc furnaces for 10 t, 20 t and 60 t ladles of steel, and now include units up to 110 t for iron powder serviced

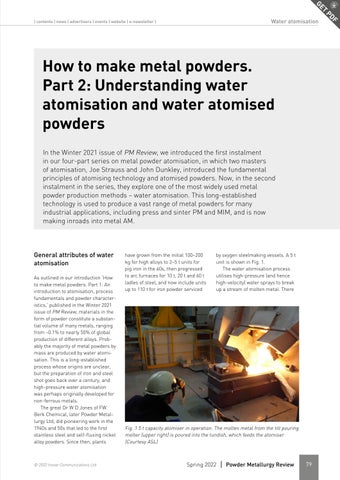

by oxygen steelmaking vessels. A 5 t unit is shown in Fig. 1. The water atomisation process utilises high-pressure (and hence high-velocity) water sprays to break up a stream of molten metal. There

Fig. 1 5 t capacity atomiser in operation. The molten metal from the tilt pouring melter (upper right) is poured into the tundish, which feeds the atomiser (Courtesy ASL)

Spring 2022

Powder Metallurgy Review

79

F PD

Water atomisation

| contents | news | advertisers | events | website | e-newsletter |