| contents page | news | events | advertisers’ index | contact |

Investing in Additive Manufacturing

To invest or not to invest: Understanding the business cases for entering the Additive Manufacturing arena With such intense levels of interest in Additive Manufacturing, the pressure for businesses to adopt the technology can be high. Expectations, however, need to be managed and the business opportunities and challenges need to be understood. As Onno Ponfoort and Chris Krampitz explain, the dilemmas for any company looking to move into this arena range from fully understanding the advantages that the technology presents to ensuring that those tasked with the project, as well as potential customers, have the necessary technical training.

Additive Manufacturing is at the heart of the digital manufacturing revolution. Being able to produce individualised, tailored products, on demand and on location, spurs the imagination of everyone, children and adults, the technologically savvy and business professionals alike. But is the impact of AM indeed as great as some reports may suggest? This article looks at the potential impact of AM on the various stages in the value chain. It also addresses some key areas of development that need to be tackled before more wide spread use of AM can be expected.

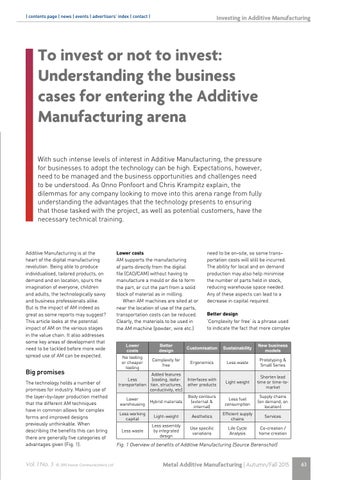

Big promises The technology holds a number of promises for industry. Making use of the layer-by-layer production method that the different AM techniques have in common allows for complex forms and improved designs previously unthinkable. When describing the benefits this can bring there are generally five categories of advantages given (Fig. 1).

Vol. 1 No. 3 © 2015 Inovar Communications Ltd

Lower costs AM supports the manufacturing of parts directly from the digital file (CAD/CAM) without having to manufacture a mould or die to form the part, or cut the part from a solid block of material as in milling. When AM machines are sited at or near the location of use of the parts, transportation costs can be reduced. Clearly, the materials to be used in the AM machine (powder, wire etc.)

need to be on-site, so some transportation costs will still be incurred. The ability for local and on demand production may also help minimise the number of parts held in stock, reducing warehouse space needed. Any of these aspects can lead to a decrease in capital required. Better design ‘Complexity for free’ is a phrase used to indicate the fact that more complex

Lower costs

Better design

Customisation

Sustainability

New business models

No tooling or cheaper tooling

Complexity for free

Ergonomics

Less waste

Prototyping & Small Series

Interfaces with other products

Light weight

Shorten lead time or time-tomarket

Added features Less (cooling, isolatransportation tion, structures, conductivity, etc) Lower warehousing

Hybrid materials

Body contours (external & internal)

Less fuel consumption

Supply chains (on demand, on location)

Less working capital

Light-weight

Aesthetics

Efficient supply chains

Services

Less waste

Less assembly by integrated design

Use specific variations

Life Cycle Analysis

Co-creation / home creation

Fig. 1 Overview of benefits of Additive Manufacturing (Source Berenschot)

Metal Additive Manufacturing | Autumn/Fall 2015

63