T GE Advances in the PBF-LB of Ni 718 and Mo

Euro PM2021: Advances in the processing of nickel alloy 718 and molybdenum by Laser Beam Powder Bed Fusion A technical session in the programme of the virtual Euro PM2021 conference, organised by the European Powder Metallurgy Association (EPMA) and held October 18-22, 2021, focused on issues related to the processing of nickel-base alloys and refractory metals by Laser Beam Powder Bed Fusion (PBF-LB) Additive Manufacturing. Dr David Whittaker reviews four papers that address microstructure control, lattice optimisation and chemical postprocessing parameters for IN718, and the AM of molybdenum.

Vol. 8 No. 1 © 2022 Inovar Communications Ltd

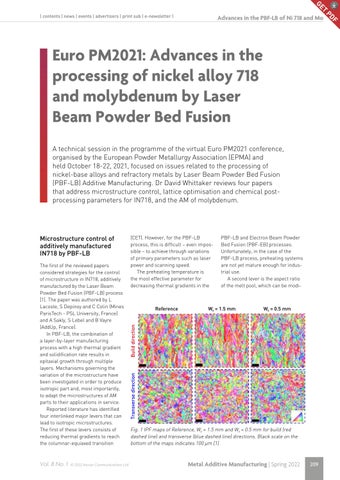

Reference

PBF-LB and Electron Beam Powder Bed Fusion (PBF-EB) processes. Unfortunately, in the case of the PBF-LB process, preheating systems are not yet mature enough for industrial use. A second lever is the aspect ratio of the melt pool, which can be modi-

Ws = 1.5 mm

Ws = 0.5 mm

Build direction

The first of the reviewed papers considered strategies for the control of microstructure in IN718, additively manufactured by the Laser Beam Powder Bed Fusion (PBF-LB) process [1]. The paper was authored by L Lacoste, S Depinoy and C Colin (Mines ParisTech - PSL University, France) and A Sakly, S Lebel and B Vayre (AddUp, France). In PBF-LB, the combination of a layer-by-layer manufacturing process with a high thermal gradient and solidification rate results in epitaxial growth through multiple layers. Mechanisms governing the variation of the microstructure have been investigated in order to produce isotropic part and, most importantly, to adapt the microstructures of AM parts to their applications in service. Reported literature has identified four interlinked major levers that can lead to isotropic microstructures. The first of these levers consists of reducing thermal gradients to reach the columnar-equiaxed transition

(CET). However, for the PBF-LB process, this is difficult – even impossible – to achieve through variations of primary parameters such as laser power and scanning speed. The preheating temperature is the most effective parameter for decreasing thermal gradients in the

Transverse direction

Microstructure control of additively manufactured IN718 by PBF-LB

Fig. 1 IPF maps of Reference, Ws = 1.5 mm and Ws = 0.5 mm for build (red dashed line) and transverse (blue dashed line) directions. Black scale on the bottom of the maps indicates 100 μm [1]

Metal Additive Manufacturing | Spring 2022

209

F PD

| contents | news | events | advertisers | print sub | e-newsletter |