T GE Opening the discussion: AM bottle openers

Opening the discussion: How the humble bottle opener demonstrates the importance of requirements in AM Designs not driven by requirements increase the risk of an incomplete solution. This relatively simple statement gets to the heart of how designers need to be approaching AM, particularly when balancing the 'design freedoms' offered by the technology with the reality of viable and profitable production. Through an exploration of the ubiquitous AM bottle opener, John Barnes, Jennifer Coyne and Chelsea Cummings, The Barnes Global Advisors, and Jon Meyer, APWorks, explore how, by focusing on requirements, a data-driven approach ensures fully functional designs that deliver on multiple requirements for the lowest cost.

Vol. 8 No. 1 © 2022 Inovar Communications Ltd

the business case and is necessary and hard. It is harder yet for Additive Manufacturing because AM is still new, so there is perceived risk, which typically drives the ‘cost of change’ conversation. However, it is necessary to consider the other factors and how they contribute to the overall case to adopt AM: • Technical: Form, fit, and function • Commercial: Pricing and quantity

• Aesthetic: Appearance and consistency with the brand of the company or the individual • Environmental: Carbon footprint, waste generation, and end-of-life disposal Clearly, there is a link from the requirements to DFM. DFM helps to ensure the requirements are met given the manufacturing process, which includes the cost targets by considering the entire process holistically. In AM, this includes

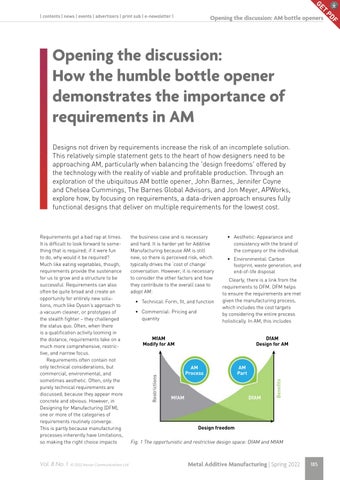

MfAM Modify for AM

DfAM Design for AM

AM Process

MfAM

AM Part

DfAM

Benefits

Restrictions

Requirements get a bad rap at times. It is difficult to look forward to something that is required; if it were fun to do, why would it be required? Much like eating vegetables, though, requirements provide the sustenance for us to grow and a structure to be successful. Requirements can also often be quite broad and create an opportunity for entirely new solutions, much like Dyson’s approach to a vacuum cleaner, or prototypes of the stealth fighter – they challenged the status quo. Often, when there is a qualification activity looming in the distance, requirements take on a much more comprehensive, restrictive, and narrow focus. Requirements often contain not only technical considerations, but commercial, environmental, and sometimes aesthetic. Often, only the purely technical requirements are discussed, because they appear more concrete and obvious. However, in Designing for Manufacturing (DFM), one or more of the categories of requirements routinely converge. This is partly because manufacturing processes inherently have limitations, so making the right choice impacts

Design freedom

Fig. 1 The opportunistic and restrictive design space: DfAM and MfAM

Metal Additive Manufacturing | Spring 2022

185

F PD

| contents | news | events | advertisers | print sub | e-newsletter |