5 minute read

Embracing Hemp for a Sustainable Tomorrow with Harper Hygienics S.A.

By Jakub Wojtaszak, Head of Strategic Innovation Projects and Technology Development

For over three decades, Harper Hygienics S.A. has carved a legacy of prioritizing evolving environmental trends and innovation to meet customer demands responsibly. Our journey has been driven by a commitment to ecoconscious innovation, and our latest endeavor underscores that dedication. Together with SIA iCotton, we are embracing hemp – a powerful, sustainable fiber – as a cornerstone of our new product line, offering an eco-friendly alternative in nonwovens, wipes, pads, and liners. This effort, supported by cutting-edge research and collaboration with global fiber leaders like Bast Fibre Technologies Inc. (BFT), represents our commitment to meeting consumers’ growing demand for environmentally responsible products.

reaching maturity in around 100 days. Moreover, hemp produces more fiber per acre than cotton or flax, reducing the environmental strain while ensuring a reliable supply chain, and boasts natural resistance to bacteria and UV rays. Its cultivation supports soil health, increases water retention, and promotes biodiversity.

In addition to environmental benefits, hemp fibers are durable, antimicrobial, and breathable, with significant water absorption capabilities and softness. These properties make them excellent for various applications, from dry and wet wipes, facial cleansing products to sanitary pads and liners.

Our commitment to hemp’s sustainable properties is evident in our collaboration with BFT, where we selected sero™ for its unique properties and environmental benefits, offering an alternative to conventional cellulose fibers.

The Power of Partnership in Eco-Innovation

At Harper Hygienics, we understand that meaningful innovation requires collaboration. By working closely with BFT, the developers of the groundbreaking sero™ hemp fiber, we can harness hemp’s full potential to create products that are sustainable, high-quality, and beneficial for both our customers and the planet. BFT’s dedication to regenerative agriculture, minimal chemical use, and adherence to sustainability certifications like Oeko-Tex Standard 100 and USDA Certified Biobased Product further underscores the alignment of our goals. This partnership reflects a shared commitment to natural, plastic-free fibers that enable our products to biodegrade safely without contributing to microplastic pollution. With hemp’s sustainability benefits, the ability to make specific fiber blends, and BFT’s fiber engineering, we are making strides towards a greener future, starting with a novel platform: Hemplace™.

Our Hemplace™ platform brings vertical integration between Harper Hygienics and iCotton, allowing us to produce unique carded-spunlace nonwovens with hemp blends. This platform provides unmatched flexibility in creating materials that are up to 100% hemp or blended with other fibers like viscose, lyocell, cotton, and even banana fiber (based on our know-how). Hemplace™ offers products that meet customers’ needs, ensuring that every product layer is sustainable and precisely tailored to performance requirements.

Why Hemp? An Eco-Friendly Choice for Many Product Categories

Hemp is fast becoming a top choice for sustainable products, and for good reason. Compared to cotton, which requires substantial water, pesticides, and land, hemp is naturally hardy and highly resource efficient. Hemp needs only minimal irrigation, does not rely on pesticides and grows rapidly,

Addressing Market Demand Through Hemplace™ and sero™

Through Hemplace™, we provide products that maintain the quality and reliability our consumers expect while significantly reducing our environmental impact. Utilizing multilayer carding-spunlace technology, Hemplace™ allows us to create fabrics with hemp fiber compositions ranging from 10% to 100%, available in weights up to 250 GSM, meeting different consumer preferences and product requirements.

An essential milestone was successfully building the know-how for blending hemp with other fibers like viscose and lyocell. The resulting materials maintain tensile strength, absorbency, and a pleasing tactile quality without additional chemical treatments. Hemplace™ fabrics are engineered to integrate seamlessly with our converting processes, underscoring the technological strength behind this innovation. This versatility allows us to create product textures and characteristics that were previously difficult to achieve in sustainable materials, such as nonwoven surfaces that balance softness and durability.

Moreover, our approach aligns with BFT’s “2R” mission –replace synthetic fibers and repair the planet. Hemp’s rapid growth cycle and high CO₂ sequestration capacity make it an ideal solution for capturing carbon and rebuilding the soil. Moreover, BFT’s production method avoids harmful chemicals, prioritizing alkaline oxidation instead of the chemically intensive processes seen in cotton or viscose production. This ensures that sero™ hemp fibers maintain their natural integrity while requiring fewer resources.

Challenges and Opportunities

While the benefits of hemp are clear, integrating it into mainstream product lines poses challenges. Consumer awareness and acceptance of hemp products are steadily growing, especially in regions like the EU and the USA, but misconceptions around hemp’s properties remain a hurdle. Educating the market about the advantages of hemp – its sustainability, performance, and hypoallergenic qualities – is crucial to wider adoption. Additionally, scaling up hemp-based products requires ongoing investment in R&D and production infrastructure.

At Harper Hygienics, we are optimistic about the future. We foresee a steady increase in demand for sustainable products, fueled by growing environmental awareness and regulatory incentives. In partnership with BFT, we are committed to elevating hemp’s role in the global hygiene market, providing products that deliver unmatched environmental benefits without compromising on quality. As we continue our journey, Harper Hygienics remains focused on expanding our eco-friendly product range, setting new standards for sustainability in hygiene and personal care.

Hemp’s Role in a Sustainable Tomorrow

As a company, we aim to be at the forefront of an ecorevolution in hygiene products. By embracing hemp, we

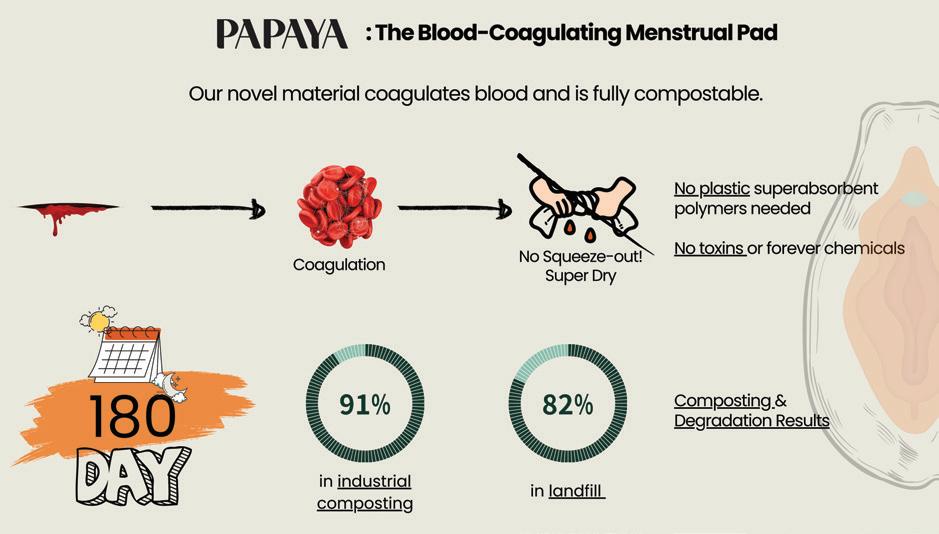

Papaya: Blood-Coagulating Menstrual Pads

Menstrual pads are highly engineered products used by a billion people worldwide.

The primary functional requirements of a menstrual pad are to retain the maximum amount of fluid while keeping the wearer feeling dry. This is typically done by using Super Absorbent Polymers (SAPs) embedded in the core layer of the pad, sandwiched by a wicking top sheet that’s in contact with the skin, and a leakproof bottom layer.

This is far from a perfect solution since when mechanical pressure is applied to the SAP during wear, menstrual fluid will be squeezed out back onto the user. This is solvable by using the blood’s inherent ability to coagulate, which is normally triggered when the body is injured.

Blood-coagulation technology is widely used in products such as blood-clotting bandages but has so far not been used in menstrual products. A suggestion for doing so was recently published by Virginia Tech University and received wide and favorable press coverage.

There are substantial obstacles to doing so. Blood clotting bandages typically clot the blood as close to the user’s skin as possible, since they try to expedite the body’s own healing mechanism and stem the flow of blood. Menstrual pads absolutely do not want to do this.

We want to coagulate the blood within the core of the pad, away from the body, while keeping the core soft for extended wear during a regular day. The solution to this lies are not only meeting today’s sustainability goals but laying the foundation for a future where eco-conscious choices become the norm. As hemp continues to prove its worth in product performance and environmental benefits, we are excited about its potential to transform the hygiene industry. Our goal is clear: to lead with innovative, sustainable solutions that resonate with consumers and protect our planet.

With Hemplace™ and sero™ hemp, we are proud to offer a line of products that embodies the next generation of sustainable hygiene. The future is green, and Harper Hygienics, with partners like BFT, is paving the way. www.harperhygienics.com in fiber and nonwoven technology. We can make a pad that is pliable and dry by integrating the coagulation accelerant into the core layer, rather than presenting it directly against the skin.

Jakub Wojtaszak, Head of Strategic Innovation Projects at Harper Hygienics S.A. – an expert with 10+ years in R&D and Technology Development, has participated in innovative projects like LENZING™ Nonwoven technology and Arvell. His skills span Six-Sigma project management, biological chemistry, and strategic innovation development. Reach him at j.wojtaszak@harperhygienics.com.

In addition to being able to handle large amounts of fluid while staying dry, the process we’ve come up with uses no plastic-based materials anywhere in the pad, which has numerous health and environmental advantages. Our pads are entirely compostable and degrade even in landfill settings. There are other natural-fiber-based pads in the market, but they use the standard absorbance mechanism and are functionally inferior to SAP-based pads.

We, (Papaya) are first-to-market with this technology. We manufacture the pad entirely in-house, including the steps of creating the coagulation-triggering core fabric. www.papayain.com