6 minute read

Depestele and Fibroline Collaborate to Produce Innovative and Sustainable Flax UD Tapes

Over the last few years, Fibroline, a technology provider, and Depestele, a major actor in the natural fiber industry, collaborated on a significant project. Its aim was the development of new range of sustainable flax UD tapes, an innovative product that can lead to breakthrough innovations, and allow Depestele to diversify its activities and enter the composites market as a semi-product supplier. This flax UD tape has many advantages in both its sustainable and its mechanical characteristics.

As Europe’s leading private flax producer, Depestele transforms 80,000 tons of flax every year. It is a French familyowned business that has been processing linen since 1850, and which owns three production sites in Normandy, where the company originates from. The group collects flax from all over the area, as well as from the Île-de-France and Brittany regions, in collaboration with over 900 farmers. The Depestele Group has also joined BPI’s Coq Vert community as part of its commitment to energy transition and environmental preservation. It has dedicated its innovation center to flax reinforcements in order to enter composites markets. Flax fibers have great mechanical characteristics, with comparable specific tensile strength as glass (for the same weight), and higher specific stiffness. They have also demonstrated great acoustic and damping properties, with great capacities to absorb sound or vibrations. All of these make them a relevant eco-friendly alternative to glass fibers in composite industry, as flax benefits from a lower carbon footprint. These rovings can be used to reinforce various polymeric matrixes to produce innovative flax UD tapes. These are well suited for different applications, in sectors such as aeronautic, transportation or sports for instance.

The Combination of High-Performance Fiber and Eco-Friendly Technology

In order for this semi-product to be efficient, the processing method of roving into tape has to preserve all of its mechanical properties. Depestele also made an effort in the selection of its production conditions to ensure the conservation of its eco-friendly characteristics. To this end, the company requires a clean technology process to impregnate its flax roving.

And here comes Fibroline. It is a world leader of ecofriendly impregnation technologies based out of Lyon, France, with more than 50 patents worldwide. Fibroline has developed dry powder impregnation solutions, which consist in the distribution of any form of powders into porous structures thanks to the use of high intensity alternating electric fields. Its R&D team has unique know-how with dedicated knowledge for various industries. The combination of Depestele’s knowledge in flax reinforcements and Fibroline’s impregnation capacity was key to the success of this project.

The Key Strategic Advantages of Dry Impregnation Solutions

Dry powder impregnation solutions benefit from several key strategic advantages that grant them capacity to respond to Depestele’s project needs for the impregnation of flax roving in the preservation of both its mechanical characteristics as well as its sustainable attributes. Fibroline solutions indeed allow to overcome some of the limitations of the conventional impregnation solutions such as comingling, extrusion or solvent based impregnation method.

Where commingling reinforcements with thermoplastic filaments typically results in heterogeneous material, dry powder impregnation allows to impregnate in an extremely homogenous way, which ensures good mechanical properties. By repulsing the particles, this process makes them occupy all of the available space within the given material. It also allows to deposit powder particles with a very wide range of resin ratios. This leads to a near-perfect control of targeted mechanical characteristics, which is a particularly adapted feature for composite materials.

Another key advantage of dry impregnation is its capacity to process at lower temperature and pressure compared to other solutions such as extrusion, which in turn grants capacity to avoid flax degradation. Indeed, as the polymer is already located inside the material, it does not need to flow across the whole reinforcement.

Furthermore, dry impregnation solutions benefit from key sustainable attributes. As opposed to solvent-based solutions, these technologies by nature do not require solvents. They have therefore significantly less VOCs emissions. This leads to quality of products’ improvement with the removal of unsafe volatiles which can be a key benefit both to workers during manufacturing process, as well as for specific applications in dealing with ever more constraining regulations.

Similarly, as opposed to water-based solutions, Fibroline’s process does not require any consuming step for water evaporation, resulting in significant energy savings and decrease in processing time. It is particularly advantageous for flax processing considering its high rate of humidity absorption.

Finally, Fibroline’s solution also allows for versatile semi-products, as this process can impregnate several kinds of polymers. This flexibility is a key success factor for the development of a wide range of products, and the Fibroline dry impregnation is equally efficient with classical thermosetting resins such as Epoxies and polyesters, with thermoplastic such as PLA or PA11 or PHA. All these tapes are particularly adapted to processing with systems like filament winding or automated fiber placement (AFP), widely used in aeronautic, sports, wind energy or transportation.

A Wide Variety of Products with Low Environmental Impact

To achieve the required performances, Fibroline benefits from significant knowledge garnered over time with various projects. The company has developed and patented its own technology portfolio to offer several impregnation solutions with specific characteristics, adapted to the needs of different markets. In this specific case of roving materials impregnation, Fibroline recently patented and introduced to the market the Y-Preg technology. Within its portfolio, Y-Preg is a dry impregnation solution that is perfectly suited to impregnate yarns, braids, or rovings and can process several bobbins at once.

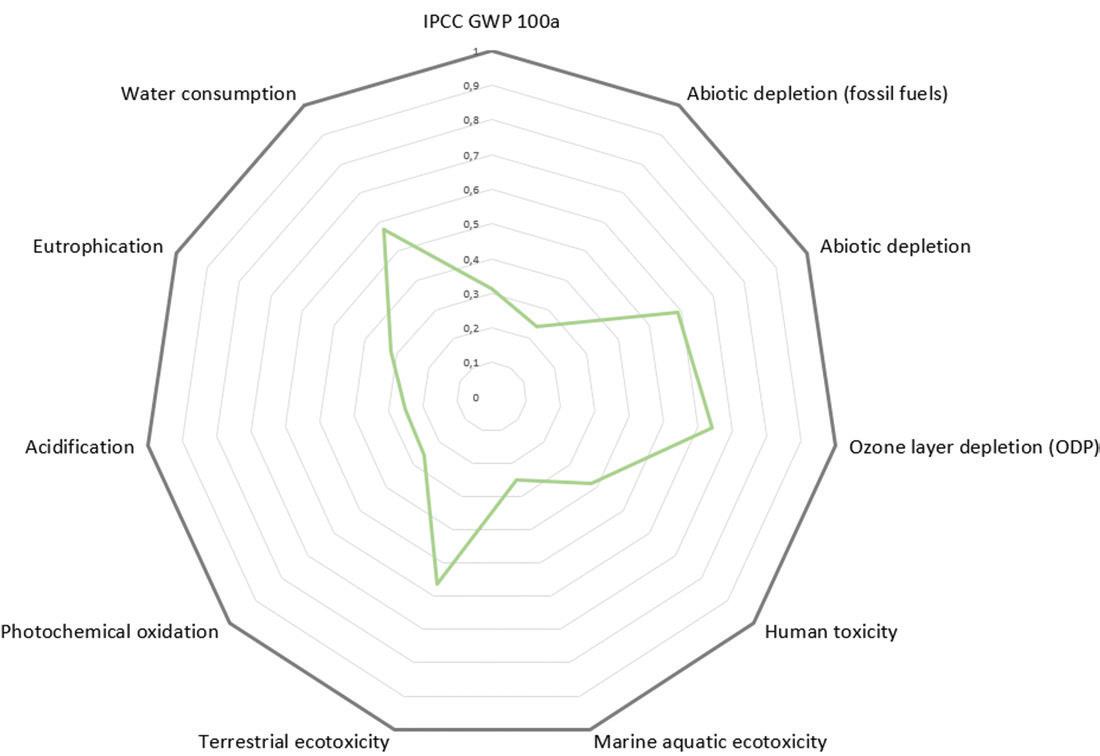

As with all of Fibroline’s technology portfolio, Y-Preg is based on the use of high intensity alternating electric fields, which therefore consumes only little energy and thus reinforces the eco-friendly aspect of the final solution. The graphic underneath shows how Y-Preg Roving is overall much more sustainable than commingled roving, with smaller Life Cycle Analysis (LCA) impact due in part to the drastic reduction of the use of fossil energies in the process.

The reduction in environmental impact in the production of flax UD tapes ought not to deteriorate their mechanical properties, which Fibroline and Depestele achieved to preserve. The materials developed in this project have excellent mechanical characteristics, in addition to their sustainable features. For instance, they have about 22 GPa as modulus and 300 MPa as tensile strength with a flax/nylon 11 with a volume fraction of 60/40, thanks to the long and highly oriented fibers, homogeneous matrix distribution, and low reinforcements degradation. www.fibroline.com

All in all, Fibroline’s dry impregnation solutions responds to Depestele’s needs. Its dry impregnation techniques benefit from several key strategic advantages that allow Depestele to process linen into flax tape of various matrices while preserving its eco-friendly and mechanical properties, in ways that conventional impregnation methods could not have allowed.

With these promising results, Depestele and Fibroline can now foresee promising opportunities for this semi-product. These two partners now look to push this project further, with other turnkey innovations as potential results.

Fibers Are Bringing New Innovations to Major Brands

In the last few years, we have seen graphenebased products commercialized in a wide range of applications ranging from waxes to batteries to plastics, and even concrete.

In textiles and clothing graphene now has a firm footing as a truly innovative new material. Leading this effort is Kyorene® graphene fibers from QS Safety with polyester, nylon, and bamboo-based vis-cose fibers in staple and filament forms.

The graphene in Kyorene® fibers provides three major functional improvements; bacteriostatic, anti-odor, and thermal regulation. These properties are permanent since the graphene is not a coat-ing, but rather part of the fiber itself.

Kyorene® fibers are commercial in applications including underwear, sportswear, socks, denim, jackets, golf and tee shirts, and home textiles.

Another new 2D nanomaterial to enter the textile market is hexagonal Boron Nitride (h-BN) com-monly called “white graphene” and trademarked Kyorene White® by QS Safety. With the same hex-agonal chemical structure as graphene, the fibers have the same benefits listed above and the fiber is white in color which makes it easier to produce white colors and light shades.

One of the leading brands and early adaptor to embrace Kyorene White® was Kontoor (Lee and Wrangler). They have previously used Kyorene® graphene in jackets, denim, and fleece, and now have launched Lee brand shirts and denim jeans under the “Nitro Cool” logo. The main driver in these applications was the thermal regulation (cooling) achieved via the far infrared absorption (heat coming off our bodies) of the h-BN in the fiber.

Brands are always looking for new innovative products that provide permanent consumer benefits and these two new nanomaterials are meeting the need and expanding in the textile market. www.graphene-one.com