2 minute read

NOTES TECH

Green Theme Technologies and Golden Long John Integrate

Textile Dye and Finishing Technologies

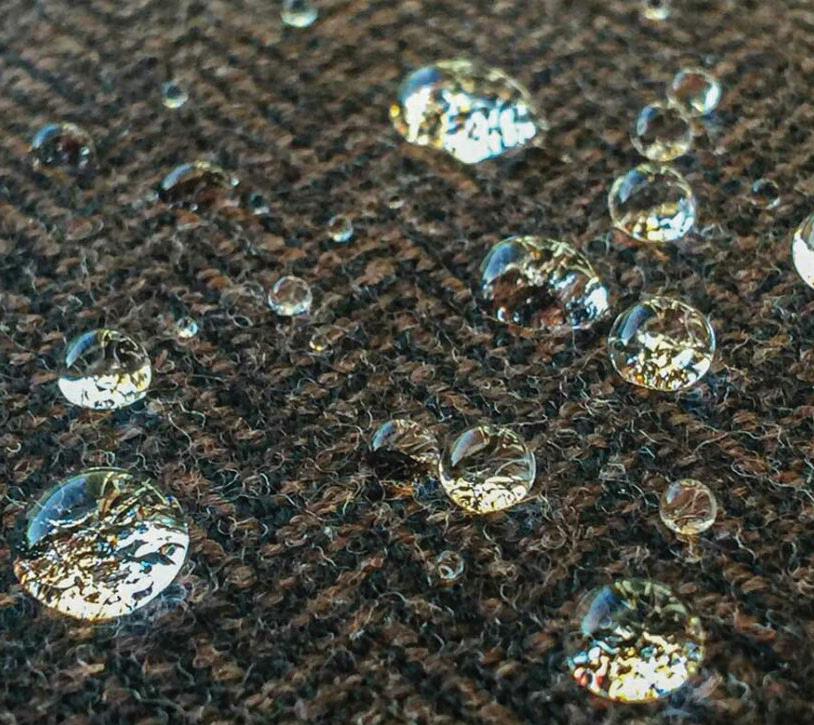

Green Theme Technologies (GTT), creators of the waterless and PFAS-free EMPEL ® textile finishing platform, has teamed up with Golden Long John to promote the next generation of cleaner and more efficient fabric dye and finishing processes.

The textile manufacturing industry generates trillions of gallons of wastewater each year. Traditional textile dyeing and finishing rinses chemical dyes and water repellency onto fabrics. Post-production toxic water is then dumped into rivers and oceans.

Last year, Golden Long John, a major textile supplier of the global footwear industry, introduced GTT’s EMPEL® finishing platform in their Vietnam factories. Their partnership has led to the combination of their two industry leading technologies, the EMPEL® high-performance water-repellent finish and Golden Long John’s direct dye process.

“We believe, cleaner IS better and this is a big step forward for the fashion and textile industries,” said Martin Flora, President of GTT Business Development. “Similar to GTT’s EMPEL® application, Golden Long John applies dye chemistry directly onto fabrics. Better performance with much less pollution is our vision for the future.” www.greenthemetech.com

Vidalia Mills Introduces Innovative Digital Tracker

Cotton Products

American textile company Vidalia Mills based in Vidalia, Louisiana, has implemented a technologically advanced digital tracking system that asks the industry to reconsider how companies trace cotton products throughout the supply chain. This technology, unprecedented within textile manufacturing, guarantees full accountability for all the products Vidalia Mills creates.

The digital tracker, embedded into the cotton fibers themselves, enables Vidalia Mills to monitor the journey of their products from the initial stages of cotton cultivation to the final finished goods.

By integrating this advanced tracking system, Vidalia Mills aims to provide its customers with complete assurance regarding their cotton products’ origin, quality, and sustainability. Vidalia Mills’ digital tracking system is now available for all its cotton products, including its signature artisanal canvas and denim fabrics. Customers can access detailed information about the origin and journey of their clothing by scanning a unique QR code on the garment’s label.

The digital tracking information will be readily available for each product, providing customers with a comprehensive understanding of the item’s journey from seed to shelf. www.vidaliamills.com

Lenzing Nonwovens Expands Its LENZING™ Lyocell Dry Fiber Portfolio

Lenzing Nonwovens, a leading supplier of regenerated cellulose fibers, announced the expansion of its LENZING ™ Lyocell Dry fiber portfolio with two new cellulosic fibers – a fine dry fiber that delivers strength and softness, and a coarse dry fiber which provides enhanced liquid and air flow. These two innovative products enable customers to confidently broaden their use of LENZING’s wood-based and biodegradable fibers into a wider range of applications while maintaining exceptional performance.

All LENZING ™ Lyocell Dry fibers within the family (standard, fine, and coarse) have hydrophobic properties which ensure efficient liquid management suitable for extensive nonwoven applications.

The new LENZING ™ Lyocell Dry fine fiber can produce nonwoven fabrics with higher density compared to LENZING ™ Lyocell Dry standard fiber. With up to 30% more cellulosic fibers in the same space, customers can create strong and soft nonwoven products. These fibers are suitable for use in hygiene applications such as diapers or sanitary pads.

The new LENZING™ Lyocell Dry coarse fiber creates fabrics that are more open due to its extended fiber diameter, and thus increasing the pore sizes between the fibers in the fabric. This allows for more air or liquid to flow through the material. It is particularly suitable for the acquisition and distribution layer in hygiene products and is also being explored for industrial filtration applications.

“By offering a diverse range of hydrophobic cellulosic fibers from fine to coarse, which are not plastic according to the EU’s Single-Use Plastics Directive (SUPD),” said Monique Buch, Executive Vice President Nonwoven at Lenzing AG, “our customers can use alternative fibers for a wider range of applications whilst delivering superior performance.” www.lenzing.com