15 minute read

Decarbonizing Pulp and Paper Industry

The Transformative Potential of Gene-Edited Low-Lignin Trees

By Sanjay Wahal, PhD

The pulp and paper sector is a significant contributor to global industrial greenhouse gas (GHG) emissions, largely due to the energy- and chemically-intensive process of lignin removal during pulping. Recent advances in CRISPR-based gene editing – particularly in fast-growing species such as poplar – offer a transformative opportunity to reduce the sector’s environmental footprint. Here, we will review key breakthroughs in the development of low-lignin trees, examine their industrial integration in Kraft and Sulphite pulping processes, and analyze the commercialization barriers and ecosystem trade-offs involved. Modeling results indicate that widespread adoption of gene-edited, low-lignin feedstocks could reduce pulping-related GHG emissions by 20–50%, lower chemical and energy consumption, and deliver cost savings exceeding $6 billion annually. Furthermore, these innovations could accelerate the transition toward integrated biorefineries and circular bioeconomy models, aligning with corporate ESG goals and regulatory climate targets.

Pivotal Juncture Towards Sustainability

Every year, paper mills generate millions of tons of chemical waste and more than 150 million tons of greenhouse gas emissions1. The pulp and paper industry is at a pivotal juncture in its sustainability journey. One of its largest environmental challenges – removing lignin from wood to extract cellulose – is also among the most energy- and chemically-intensive processes in industrial manufacturing1

Lignin – a complex biopolymer that binds a tree’s fibers, provides structural rigidity or integrity in wood but complicates cellulose extraction during pulping due to its recalcitrance to degradation. Wood typically consists of about 25% lignin. Traditional delignification processes, particularly in Kraft and Sulphite pulping, use alkali solutions and operate under high temperatures and pressures – conditions that demand substantial energy, chemicals and contribute heavily to pollution and carbon emissions1.

CRISPR-based gene editing offers a promising solution. It enables the design of trees with lower lignin content, improving pulping efficiency and reducing processing and chemical costs while significantly lowering the carbon footprint of paper production2. Poplar trees, widely used in plantations for papermaking due to their fast growth and favorable characteristics, have emerged as a promising candidate in this breakthrough research2-7

Why Lignin Reduction Matters

Lignin is essential for the structural integrity of wood, yet its removal is critical for isolating cellulose fibers during pulping operation. High lignin content increases reliance on harsh chemicals such as sodium hydroxide and sodium sulfide, escalates energy consumption, and significantly contributes to GHG emissions. Furthermore, lignin impairs carbohydrate recovery – making the carbohydrate-tolignin (C:L) ratio a key metric for pulping efficiency determinant of pulping efficiency or pulp yield. A higher C:L ratio correlates with increased pulp yield, reduced energy and chemical use, and a more sustainable process3,4.

CRISPR-Edited Poplars: Mechanism and Breakthroughs

Engineered poplars developed using CRISPR-Cas9 have demonstrated remarkable improvements in lignin reduction and pulping efficiency. In recent studies, these gene-edited trees achieved up to a 50% reduction in lignin content, a 228–239% increase in the cellulose-tolignin (C:L) ratio, and pulp yield improvements of up to 40%4. These genetic modifications also led to 20–31% reductions in GHG emissions during pulping, while improving the syringyl-to-guaiacyl (S/G) lignin ratio, a key factor in enabling easier delignification and fiber extraction4–6.

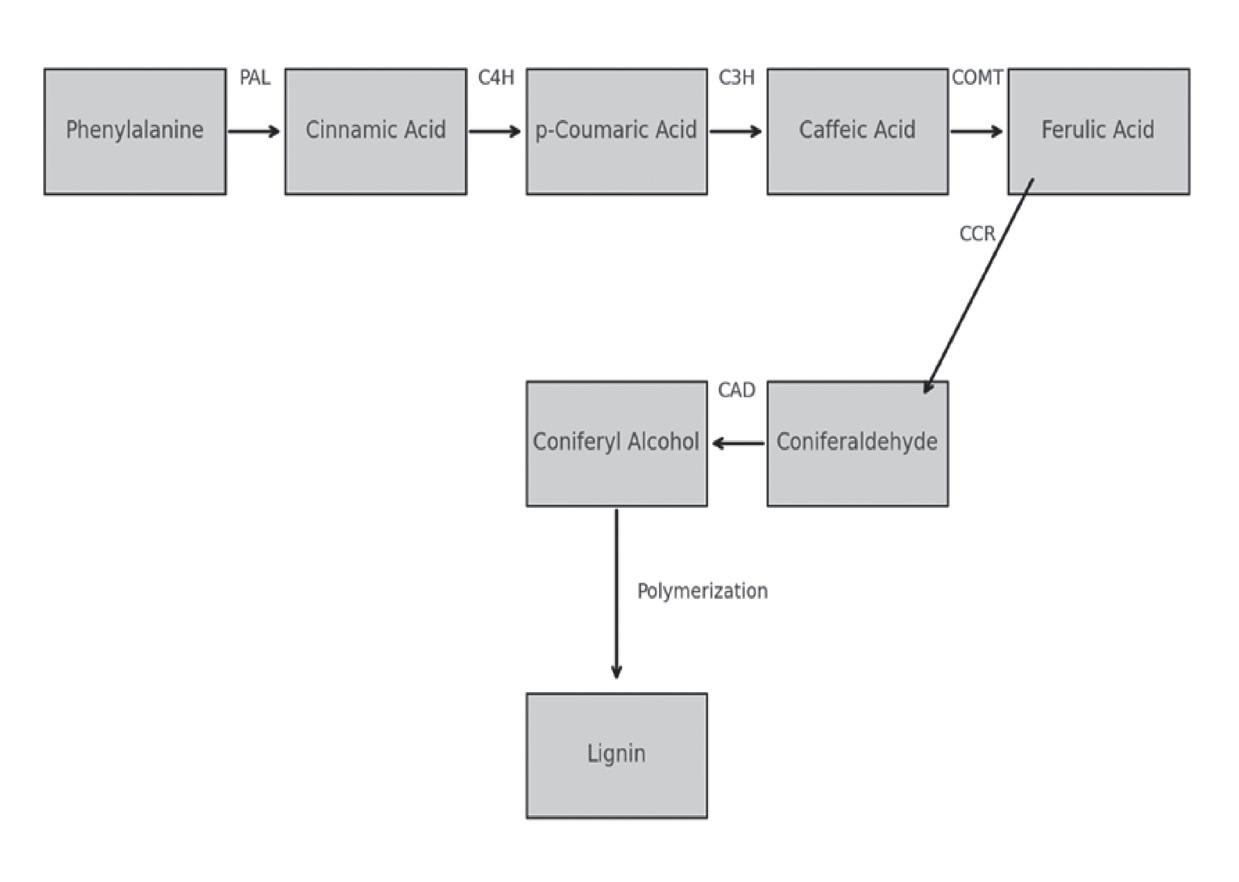

These results stem from innovative work at North Carolina State University, where researchers combined CRISPRCas9 gene editing with machine learningbased optimization to explore over 69,000 design strategies. The editing focused on key genes in the lignin biosynthesis pathway, including 4CL (4-coumarate: CoA ligase), CCR (cinnamoyl-CoA reductase), and C3’H (p-coumaroyl shikimate 3’-hydroxylase)2,4 By multiplexing edits across three to six gene targets, the researchers effectively circumvented compensatory mechanisms that often limit the impact of single-gene edits.

The improved C:L ratios not only enhance pulping efficiency but also support greater glucose recovery during saccharification, opening up pathways for integrated biorefinery development. Figure 1 provides a schematic overview of the phenylpropanoid pathway, illustrating the metabolic steps converting phenylalanine into lignin monomers, focusing on enzyme targets such as PAL (phenylalanine ammonia-lyase), C4H (cinnamate 4-hydroxylase), C3’H (p-coumaroyl shikimate 3’-hydroxylase), COMT (caffeic acid O-methyltransferase), CCR (cinnamoyl-CoA reductase), and CAD (cinnamyl alcohol dehydrogenase) – involved in lignin biosynthesis and edited via CRISPR-Cas9 to achieve these breakthroughs7–9

Multiplexed CRISPR edits to these genes enable reductions in total lignin content, improved S/G monomer ratios, and enhanced cellulose-to-lignin ratios –thereby improving pulping efficiency and downstream sugar recovery.

Industrial Implications and Comparative Analysis:

Kraft vs. Sulphite Pulping

Kraft pulping, accounting for approximately 80% of global wood pulp production, benefits greatly from low-lignin inputs (trees) due to its high chemical intensity and scale1. Compared to traditional feedstocks, low-lignin trees can reduce the carbon footprint of kraft pulping by 20–31%, significantly increase pulp yield by up to 40%, and enable cost-effective retrofit of existing mills1,4. Additionally, lignin valorization pathways – such as conversion to biofuels or high-value chemicals – are more viable in kraft systems3. In contrast, Sulphite pulping already partially solubilizes lignin, offering only marginal yield improvements and facing economic limitations due to niche applications and higher recovery costs1. The lower-value lignosulfonates generated in this process also limit its appeal for lignin valorization1

1: Schematic of lignin biosynthesis (phenylpropanoid) pathway highlighting key gene targets (e.g., PAL, C3’H, COMT, CCR, CAD) edited via CRISPR-Cas9.

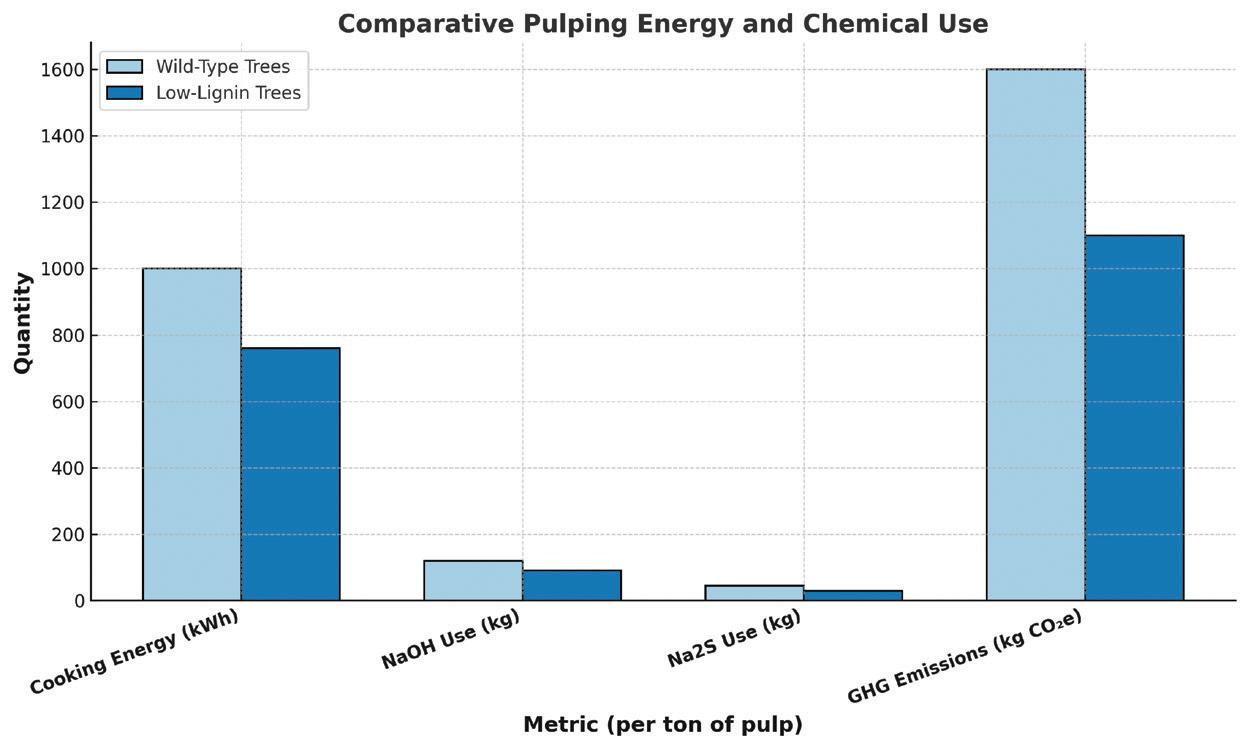

Energy, Chemical, and Environmental Gains from Low-Lignin Trees vs. Traditional Wood Sources

The integration of gene-edited low-lignin trees into kraft pulping processes offers transformative operational advantages. A higher cellulose-to-lignin (C:L) ratio reduces the demand for sodium hydroxide and sodium sulfide by up to 5% for every 1% increase in the C:L ratio1. Concurrently, cooking energy requirements decline by 20–31%, and glucose accessibility improves significantly – rising from 24.8% in traditional wood to 87.2% in low- lignin variants without pretreatment3,4 . This enhanced saccharification enables faster and milder delignification, resulting in improved fiber strength and quality while simplifying downstream biorefinery operations3,10

Low-lignin trees also offer a compelling energy efficiency advantage. Reduced lignin content facilitates shorter cooking times and less intensive chemical treatment, while simulation models indicate an additional 15% reduction in mechanical refining energy1. These operational efficiencies collectively translate into a 20% reduction in greenhouse gas (GHG) emissions per ton of pulp, primarily through decreased fossil fuel use and chemical inputs1.

From a yield perspective, increased C:L ratios can boost pulp output by up to 40%, significantly lowering raw material and processing costs5. These improvements –summarized in Table 1 – could save the U.S. pulp and paper sector over $1 billion annually, while also reducing deforestation pressure by 15–20% globally due to increased yield per tree4,6

Perhaps most consequentially, these feedstocks enable the development of next-generation integrated biorefineries, where high glucose recovery (>87%) without pretreatment supports more energy-efficient and cost-effective biofuel production1,3. Life-cycle modeling suggests a potential 35% improvement in energy return on investment (EROI)

Metric Improvement with Low-Lignin Trees

for biofuel pathways when low-lignin inputs are used11. This is further discussed under the Future Outlook and Adjacent Opportunities section.

The large-scale adoption of low-lignin trees could substantially decarbonize pulping operations. Emissions from recovery boilers and thermal processes would decrease due to reduced lignin combustion and milder processing conditions1. If just 50% of global pulp mills transitioned to gene-edited low-lignin feedstocks, the industry could realize annual savings of $6 billion and GHG reductions exceeding 50 million metric tons of CO₂-equivalent3,11

Lifecycle analysis models employ standard emissions factors for pulp production – typically 1.1–1.4 metric tons of CO₂e per ton of kraft pulp – based on GREET and SimaPro databases12,13 . Modeled emission reductions of 20–31% result from decreased fossil fuel inputs (via lower cooking energy demand), reduced chemical use (notably sodium hydroxide and sulfide), and higher glucose accessibility enabling more efficient saccharification and potential biofuel integration1,4.

Conversion efficiencies reflect validated pilot-scale trials from TreeCo – a spinoff from North Carolina State University (NCSU) and academic groups at NCSU and Brookhaven National Laboratory2,11 Importantly, these figures exclude landuse change benefits, ecosystem service enhancements, or product substitution impacts from lignin valorization, making the modeled climate benefits conservative.

However, achieving this potential will require coordinated investments in seedling supply chains, market pull mechanisms for lignin-derived coproducts (e.g., adhesives, bioplastics), and regulatory alignment on genetically modified biomass2,14. In terms of carbon intensity, pairing these trees with nextgeneration solvents like deep eutectic systems (DES) could lower the carbon footprint of kraft pulping by 35–50%. Furthermore, redirecting surplus lignin to produce bioplastics and adhesives could offset roughly 35% of fossil-derived carbon emissions through product substitution15.

All the savings and benefits are summarized in Figure 2 and Table 1, respectively.

Policy and ESG Alignment

The deployment of CRISPR-edited lowlignin trees directly supports corporate ESG strategies and decarbonization commitments under frameworks such as the Science Based Targets initiative (SBTi) and the GHG Protocol. Scope 3 emissions – particularly from upstream processing in pulp and paper – can account for over 70% of a company’s total footprint in sectors, like packaging, hygiene, and publishing16,17. By reducing chemical inputs and cooking energy requirements, low-lignin trees enable measurable reductions in cradle-to-gate emissions intensity. These reductions can be reported under CDP disclosures, integrated into sustainabilitylinked KPIs, and contribute to Scope 3 abatement targets in line with sciencebased net-zero roadmaps18

In regulatory contexts, the adoption of low-lignin feedstocks supports alignment with emerging global and regional policies. This framework includes the

EU Deforestation Regulation (EUDR), which mandates sustainable sourcing of forest-based commodities, and national bioeconomy strategies that prioritize circular and low-carbon feedstocks19 Additionally, Extended Producer Responsibility (EPR) mandates – particularly in the EU and Asia-Pacific – are driving major paper and packaging producers to decarbonize their supply chains. Genetically enhanced trees that reduce land-use intensity and improve processing efficiency can help companies meet compliance obligations while securing access to preferential procurement and green financing programs.

Trade-Offs and Strategic Considerations

Despite low-lignin trees offering extensive efficiency and sustainability benefits, trade-offs exist. Traditional kraft mills derive nearly half their process energy from lignin combustion; reducing lignin content lowers this internal energy supply. However, the resulting gains in chemical, thermal, and process efficiency typically outweigh this loss. Research has identified reductions in structural stability in some gene-edited poplars trees, as reduced lignin can weaken stems20. Nonetheless, studies indicate that smart editing strategies – such as co-targeting CCR2 and C3H3 – can minimize growth penalties and maintain acceptable levels of biomass productivity.

Biodiversity and Ecosystem Trade-Offs

Concerns around gene flow, ecosystem disruption, and unintended biodiversity impacts are central to the debate on genetically modified trees. Studies by Voelker et al.20 and Hoengenaert et al.9 have documented reductions in stem stiffness and field growth variability in modified poplars, raising ecological stability concerns. To address this, several institutions – including the University of British Columbia, FuturaGene, and Canadian Forest Service partners – are advancing long-term risk assessments, examining soil microbiomes, pollinator interaction, and reproductive containment strategies10,21,22

Mitigation measures include sterilityinducing gene edits, geographic containment, and post-release monitoring23 Regulatory review processes in jurisdictions such as the U.S., Brazil, and China increasingly mandate ecological impact studies over multiple generations, reinforcing a precautionary approach to deployment19,24. Though uncertainties remain, current evidence suggests that with thoughtful design and oversight, ecological risks can be minimized.

Additionally, early studies at MIT suggest the need for long-term monitoring to detect potential ecological interactions and trophic effects25. Genetically engineered trees also raise ecological and public concern. Media coverage and advocacy groups have drawn attention to potential biodiversity risks and unintended consequences of releasing modified trees into the environment23,26.

Commercialization Outlook: Emerging Players and Progress

TreeCo: Pioneering CRISPR-Edited

Trees

TreeCo, a biotechnology startup founded by researchers from North Carolina State University, is at the forefront of developing low-lignin trees using CRISPR gene-editing technology. Their approach combines CRISPR with machine learning to target multiple genes responsible for lignin biosynthesis, aiming to produce trees with reduced lignin content and improved carbohydrate-to-lignin ratios. Currently, TreeCo has achieved promising results in laboratory settings, including up to 50% reduction in lignin content and significant increases in pulp yield. However, they are in the early stages of commercialization, with plans to initiate field trials to assess the performance of these genetically edited trees under realworld conditions.

Arauco: Integrating Biotechnology into Forestry Operations

Arauco, a major forestry company based in Chile, is exploring the use of geneediting technologies to develop low-lignin tree varieties. Their research focuses on enhancing wood properties to improve pulping efficiency and reduce environmental impact. While specific details about Arauco’s commercialization timeline are limited, the company has expressed interest in leveraging gene-edited trees to increase productivity per acre and lessen the pressure on natural forests. They are likely in the research and development phase, evaluating the feasibility and benefits of integrating such technologies into their operations.

ArborGen: Advancing Genetically Improved Trees for Industrial Efficiency

ArborGen is a prominent forestry biotechnology company focusing on developing genetically improved trees for commercial forestry. They have been involved in research to alter lignin content in plantation trees, particularly eucalyptus and poplar, aiming to reduce pulping costs and environmental impact. By modifying lignin levels, ArborGen seeks to make the pulping process more efficient and less reliant on hazardous chemicals.

FuturaGene (a subsidiary of Suzano): Scaling Lignin-Modified Trees Through Field Trials

FuturaGene, owned by Brazilian pulp and paper company Suzano, has been conducting field trials of genetically modified eucalyptus trees with altered lignin content. Their research focuses on enhancing wood properties to improve pulping efficiency and reduce environmental impact. FuturaGene’s work represents a significant step toward integrating biotechnology into large-scale forestry operations21.

Living Carbon: Engineering ClimateSmart Trees with Expanded Industrial Potential

Living Carbon is a U.S.-based biotechnology startup developing genetically engineered hybrid poplar trees aimed at enhancing carbon sequestration. While their primary focus is on increasing photosynthetic efficiency and biomass production, their work contributes to the broader field of tree biotechnology, which includes modifying lignin content for various industrial applications23,27

Academic and Research Institutions

Several academic institutions are also engaged in research related to lignin modification in trees:

• North Carolina State University: Researchers have used CRISPR geneediting to breed poplar trees with reduced lignin levels, aiming to make fiber production more sustainable2,4

• University of British Columbia: Scientists have developed genetically modified trees with chemically labile linkages in lignin, allowing for easier breakdown during pulping without compromising tree strength10

These organizations and institutions are at various stages of research and development, contributing to the advancement of gene-edited, low-lignin trees for commercial applications in the pulp and paper industry.

Barriers to Commercialization

Despite their considerable promise, geneedited low-lignin trees face multiple hurdles to commercialization.

Biologically, one of the most persistent challenges is reduced mechanical strength: early-generation modified trees have exhibited up to 62% lower wood stiffness and a nearly 40% reduction in stem strength, thereby increasing their susceptibility to environmental stressors such as wind damage and pests.

Trait instability in field settings is another concern; environmental variability and epigenetic drift can cause partial reversion of the lignin modification, undermining performance across growing cycles. Mitigation strategies include gene stacking, co-editing of compensatory pathways, and multi-year field trials under diverse ecological conditions.

From a technical perspective, the CRISPR editing process in woody perennials presents significant inefficiencies. Fewer than 0.5% of transformation attempts result in viable, stable edits. This low efficiency is due to several factors, including off-target gene activity, somaclonal variation during tissue culture, and the long generation time of trees that delays phenotypic validation. Accelerating the development pipeline will require the use

Barrier Type Challenge

Biological 62% weaker wood stiffness, 40% weaker stems; stress vulnerability

Trait Instability Lignin reversion in field

Technical

<0.5% of CRISPR edits viable; long tree life cycles

Regulatory Biosafety assessments; few GM poplars

Economic $500M–$1B for retrofitting; high propagation of AI-assisted gene target identification, the use of fast-growing surrogate species for early-stage screening, and improvements for in vitro regeneration techniques.

Economic and infrastructural barriers also loom large. Large-scale kraft pulp mills – especially those built prior to the 2000s – may require substantial retrofitting investments to process feedstocks with altered fiber chemistry and lower lignin combustion value. These retrofits are estimated to cost between $500 million and $1 billion per facility, depending on size, geographic location, and integration complexity.

Propagation costs for genetically engineered seedlings are also significantly higher than conventional planting stock, adding to the initial capital burden. Overcoming these constraints will require public-private financing mechanisms, clear regulatory pathways, and lifecycle cost analyses that reflect the long-term energy, carbon, and yield benefits.

Table 2 summarizes various barriers and their mitigation strategies.

Adoption Timeline and Phases

The road to commercialization will likely span two decades, unfolding in distinct phases. Initial laboratory optimization, focused on refining multiplex CRISPR

Mitigation Strategy

Gene stacking, targeted edits to maintain growth

Long-term field trials and stress

AI-driven gene target screening; fast-growing surrogates

Streamlined regulatory pathways; international collaboration

Public-private financing, lifecycle cost editing, is expected to take between two and four years. This effort will be followed by extended field trials over a 10–15-year horizon, aimed at verifying trait stability, stem strength, and resilience under natural conditions. Parallel to this, regulatory approval processes – requiring rigorous biosafety and environmental assessments – are projected to last five to eight years, depending on jurisdiction.

The final phase, commercial scaling, will involve large-scale propagation of successful clones and retrofitting of existing mills to accommodate the new feedstock characteristics. Overall, widespread deployment is not expected before the early- to mid-2040s (Figure 3).

Conclusion

CRISPR-edited low-lignin trees represent a revolutionary advance for the pulp and paper sector, targeting one of its most energy- and emissions-intensive steps: lignin removal. By enabling reductions of up to 50% in sectoral GHG emissions, boosting energy efficiency, and potentially saving billions in operational costs, these trees stand at the intersection of biotechnology, industrial innovation, and climate action. Despite the significant benefits, their successful commercialization depends on overcoming complex biological, technical, regulatory, and economic hurdles.

From a resource efficiency standpoint, low-lignin trees enhance energy efficiency by 20–31% in pulping operations and by more than 3.5-fold in biofuel production relative to conventional wood. Although lignin-derived internal energy is reduced, net gains in processing speed, fiber yield, and chemical use present a compelling trade-off, especially for integrated biorefineries. If adopted at scale, even by 50% of global pulp mills, this technology could prevent more than 50 million metric tons of CO₂-equivalent emissions annually and save the industry over $6 billion per year.

Importantly, the benefits extend beyond pulp and paper. With 87% glucose accessibility – compared to just 25% in wild-type trees – these low-lignin variants are ideally suited for dual-use in pulp and biofuel production.

For fiber producers, paper mills, and bio-based material innovators, geneedited trees offer a path to reshape value chains around sustainability, efficiency, and performance.

Future Outlook and Adjacent Opportunities

The broader impact of low-lignin trees extends well beyond paper manufacturing. One of the most promising avenues is lignin valorization. Instead of being combusted for low-value energy, lignin from engineered trees could be redirected into producing deep eutectic solvents (DES), adhesives, or bioplastics – each with far higher economic and environmental value6

In textiles and nonwovens, high-C:L wood inputs could enable the next generation of bio-based fibers, aligning with growing demand for sustainable materials.

The high saccharification efficiency of low-lignin trees also supports the development of integrated biorefineries, enabling the simultaneous production of pulp and biofuels with improved energy return on investment as shown. Figure 4 shows the system diagram illustrating how low-lignin biomass can simultaneously support fiber production, lignin valorization, and sugar conversion for biofuels.

References

As part of a broader shift toward a circular economy, these trees advance multiple climate targets by reducing waste, increasing resource efficiency, and enabling fossil carbon displacement.

In summary, gene-edited low-lignin trees could become a cornerstone of a

1. Hubbe, M. A. (2021). Energy efficiency challenges in pulp and paper manufacturing: A tutorial review, BioResources, 16 (4), 8567-8639. https://bioresources. cnr.ncsu.edu/wp-content/uploads/2021/10/BioRes_16_4_Review_Hubbe_Energy_Efficiency_Challenges_Pulp__Paper_Manuf_19310-1.pdf

2. North Carolina State University. (2023). CRISPR Poplar Project: Redesigning Trees for Better Pulping Efficiency. NC State News. https://news.ncsu.edu/2023/07/ crispr-poplar-tree/, https://www.the-scientist.com/crispr-trees-could-improvepaper-production-7128, https://www.synbiobeta.com/read/crispr-at-the-root-offorestrys-sustainable-revolution

3. Lu, Y. (2024). CRISPR/Cas9 in Poplar Lignin Biosynthesis: Advances and Future Prospects, Tree genetics and Molecular Breeding. BioPublisher Publishing Platform, 14 (1): 32-42 https://genbreedpublisher.com/index.php/tgmb/article/ html/4011/

4. Sulis, D. B. et al. (2023). Multiplex CRISPR – Editing of Wood for Sustainable Fiber Production. Science, 381 (6654): 216-221. https://www.science.org/ doi/10.1126/science.add4514

5. Liu, Y. et al. (2024). Genome-edited Trees for High-Performance Engineered Wood. Matter, 7 (10): 3658-3671. https://www.sciencedirect.com/science/ article/abs/pii/S2590238524003965

6. Turner, M. Lower lignin for wood efficiency (2023). Nature Ecology& Evolution, 7, 1579 (2023). https://doi.org/10.1038/s41559-023-02175-w

7. Zuin Zeidler, V. G. et al. (2023). Genetic Editing of Wood for Sustainability. Science, 381 (6654): 124-125. https://www.researchgate.net/publication/372343179_Genetic_editing_of_wood_for_sustainability

8. Chanoca, A., de Vries, L. and Boerjan, W. (2019). Lignin Engineering in Forest Trees. Frontiers in Plant Science, 10: 912. https://www.frontiersin.org/journals/ plant-science/articles/10.3389/fpls.2019.00912/full

9. Hoengenaert, L., Reymond, M., de Vries, L., & Boerjan, W. (2025). Transgene‐free genome editing in poplar using CRISPR. New Phytologist. https://nph.onlinelibrary.wiley.com/doi/10.1111/nph.20415

10. University of British Columbia (2014), Researcher design trees that make it easier to produce paper. https://www.sciencedaily.com/releases/2014/04/140403142031.htm

11. Brookhaven National Laboratory (2016). Study shows trees with altered lignin are better for biofuels. https://phys.org/news/2016-06-trees-lignin-biofuels.html

12. U.S. DOE Argonne National Laboratory (2023). GREET Model Documentation. https://greet.es.anl.gov

13. Pré Sustainability (2023). SimaPro LCA Software Database. https://simapro.com more sustainable and high-performance fiber economy. While commercialization remains a multi-decade endeavor, early investments and cross-sector collaborations today will be key to unlocking this highleverage decarbonization opportunity.

Sanjay Wahal is the Founder of Decarbonization, LLC, a strategic advisory & consulting firm committed to accelerating low-carbon transitions through innovation in materials, manufacturing, and energy systems, guided by a strong foundation in policy and systems thinking. With over 30 years of executive leadership spanning technology commercialization, advanced materials, and sustainable industrial practices, Dr. Wahal offers a multidisciplinary perspective to climate-focused innovation. He holds a Ph.D. in Chemical Engineering and an MBA in Strategy and Innovation.

14. De Meester, B. et al. (2022). Lignin Engineering in Forest Trees: From Gene Discovery to Field Trials. Plant Communication, 3 (6): 100465. https://www.sciencedirect.com/science/article/pii/S2590346222003029

15. Wilkerson, C. G. et al. (2014). Monolignol Ferulate Transferase Introduces Chemically Labile Linkages into the Lignin Backbone, Science, 344, 90–93. https://doi. org/10.1126/science.1250161

16. SBTi (2023). Science Based Targets for the Forest, Land, and Agriculture (FLAG) sectors. https://sciencebasedtargets.org

17. GHG Protocol (2023). Technical Guidance on Scope 3 Emissions. https://ghgprotocol.org

18. CDP (2022). Supply Chain Emissions Report. https://www.cdp.net/en/research/ global-reports/supply-chain-report

19. European Commission (2023). EU Regulation on Deforestation-Free Products. https://ec.europa.eu/info/law/better-regulation

20. Voelker, S. L., Lachenbruch, B., Meinzer, F. C., Kitin, P., Strauss, S. H., & Gartner, B. L. (2011). Reduced wood stiffness and strength, and altered stem form, in young antisense 4CL transgenic poplars with reduced lignin contents. New Phytologist, 189(4), 1096–1109. https://doi.org/10.1111/j.1469-8137.2010.03572.x

21. FuturaGene. (2012). GM Tree Plantation Research Fact Sheet. Retrieved from https://www.futuragene.com/wp-content/uploads/2019/04/GM-TREE-PLANTATION-RESEARCH-FACT-SHEET.pdf

22. Natural Resources Canada. (2002). Genetically Modified Trees: What is the Canadian Forest Service Doing? Canadian Forest Service. Retrieved from https:// cfs.nrcan.gc.ca/pubwarehouse/pdfs/18459_e.pdf

23. Living Carbon. (2023). Genetically engineered trees stoke climate hope — and environmental fears. https://news.mongabay.com/2023/07/genetically-engineered-trees-stoke-climate-hope-and-environmental-fears/

24. Futurity. (2023). Scientists redesign trees to be easier to turn into paper. https:// www.futurity.org/poplar-trees-crispr-sustainability-wood-fibers-2944552-2/

25. MIT, Dept. of Civil and Environmental Engineering (2009). Testing the Unintended Consequences of Lignin Reduction in Genetically Modified Trees on Trophic Interactions. https://ocw.mit.edu/courses/1-018j-ecology-i-the-earth-system-fall-2009/ c67b6ae95d37958688d8669187367519_MIT1_018JF09_sw_paper2.pdf

26. GeneWatch UK. (2023). GM Trees. Can We? Should We? www.genewatch.org/ uploads/f03c6d66a9b354535738483c1c3d49e4/gm-trees-fin2.pdf

27. Living Carbon, Blog (2023), Our Learnings from Beginning the First ClimateSmart Seedlings to US Markets https://www.livingcarbon.com/post/ourlearnings-from-bringing-the-first-climate-smart-seedlings-to-us-markets