7 minute read

DESIGNERPrada in Space

New Textile Partnerships Forged in the Commercialization of Space

By Adrian Wilson, International Correspondent, IFJ

For decades, the uncharted exploration of space was largely the domain of government-led organizations, most notably the USA’s NASA. Now, private companies backed by entrepreneurs such as Jeff Bezos (Blue Origin), Elon Musk (SpaceX), and Richard Branson (Virgin Galactic) are now rapidly changing the game.

One result among others is the emergence of non-traditional partnerships to enhance many products for space travel, including the extra-vehicular mobility unit (EMU) spacesuits worn by astronauts for spacewalks.

The hybrid EMU spacesuit currently used on the International Space Station consists of a composite hard upper torso and a soft lower torso assembly, allowing for a wider range of movement and including body seal closure, waist bearing, and leg sections. A liquid cooling and ventilation garment is worn underneath the pressure suit to help regulate body temperature and remove waste gases, and a primary life support system (PLSS) provides oxygen, manages carbon dioxide, and regulates temperature.

Breaking the Mold

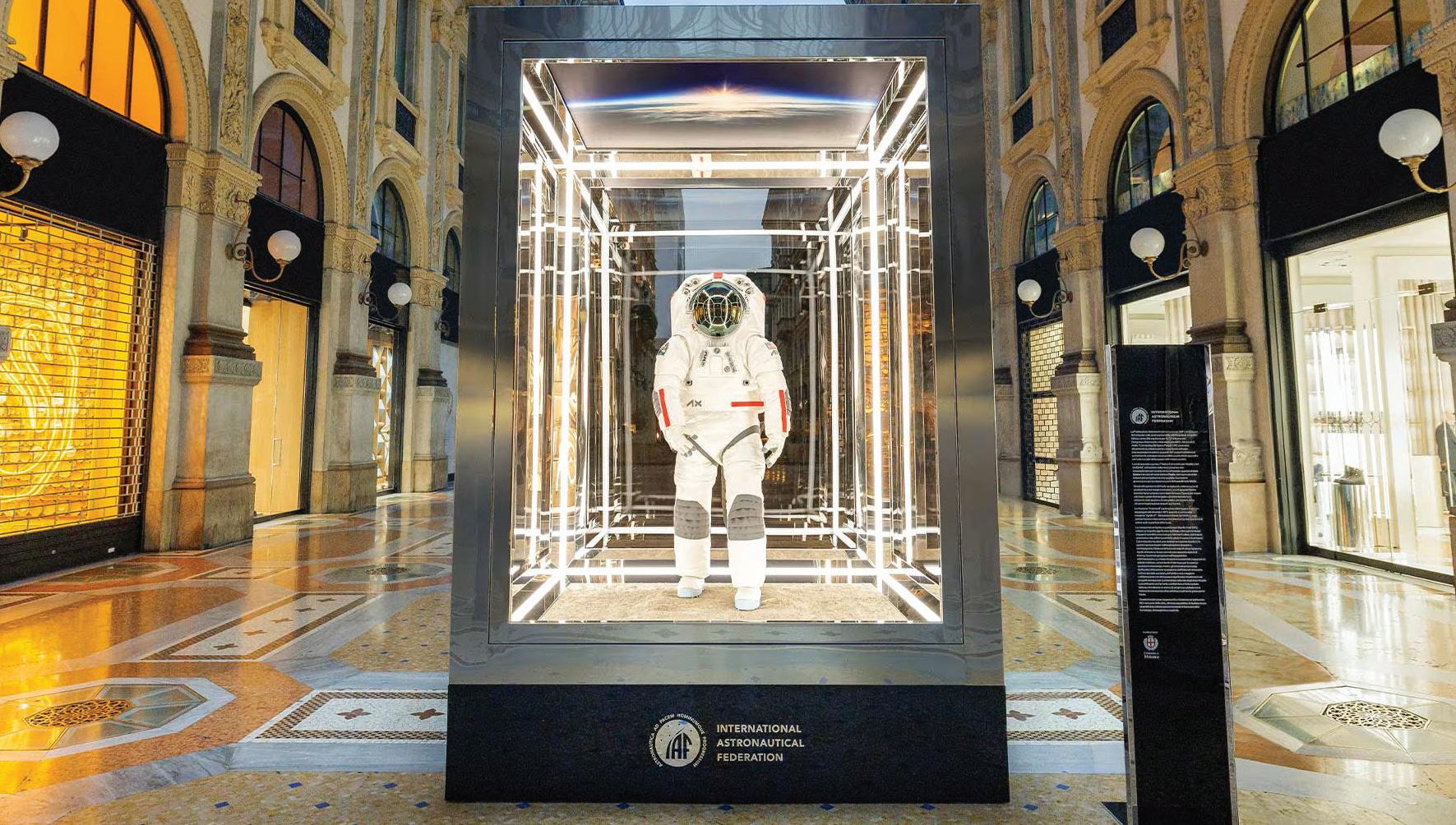

In October last year, however, Houston, Texas-headquartered Axiom Space unveiled its Axiom Extra-vehicular Mobility Unit (AxEMU) in Milan, which its says breaks the mold in terms of design and functionality (seen on p. 18).

The AxEMU was developed in close collaboration with Italian luxury fashion brand Prada and will be used for NASA’s

Artemis III mission, which aims to put humans back on the Moon for the first time since 1972, scheduled for mid-2027.

Axiom is keeping details of the materials and construction techniques employed in its creation strictly under wraps, but reports that Prada’s expertise has enabled advanced technologies and sewing methods to marry functional demands with an aesthetically appealing white outer layer, providing astronauts with an increased level of comfort while improving material performance.

New Pathways

“Our elite teams have redefined spacesuit development with the AxEMU,” said Axiom president Matt Ondler. “The Axiom Space-Prada partnership has set a new foundational model for cross-industry collaboration, further expanding what’s possible in commercial space.”

“Going beyond our limits reflects the spirit of the Prada brand,” added Lorenzo Bertelli, Prada’s chief marketing officer. “I’m very proud of the result which is just the first step in a long-term collaboration with Axiom Space.”

Visual Inspiration

Prada’s design and product development team collaborated with Axiom Space engineers to recommend customized materials and features that will both protect astronauts against the unique challenges of the lunar environment and visually inspire future space exploration.

This program epitomizes how the commercial space industry is enabling non-traditional partnerships to enhance space exploration.

The AxEMU has undergone extensive testing and simulations with a wide range of astronauts and engineers at Axiom Space, SpaceX and NASA facilities. Testing was conducted underwater to simulate the lunar environment with an unoccupied spacesuit at NASA’s Neutral Buoyancy Laboratory and reduced gravity simulations at NASA’s Johnson Space Center.

Now nearing its final development stage, the AxEMU has already completed a successful pressurized simulation with design and product development team collaborated with Axiom Space engineers to recommend customized materials and features that will both protect astronauts against the unique challenges of the lunar environment and visually inspire future space exploration.

Artemis III partners – NASA, SpaceX, and Axiom Space – marking the first test of its kind since the Apollo era. It continues to undergo further testing prior to its critical design review phase.

Space Race

Rivalry between the governments of the USA and the former-USSR in the so-called ‘Space Race’ spurred on both countries to great achievements within the relatively short period between 1957 and 1969.

Less than ten years after the USSR’s Yuri Gagarin became the first human to travel to outer space in 1961, Neil Armstrong and Edwin Aldrin stepped onto the surface of the Moon for the USA on July 20, 1969.

The period up to Apollo 11’s triumph provided a driver for the rapid development of many technologies, including new fibers and textiles.

Kevlar and Nomex

Notably in this respect, Kevlar paraaramid fibers were invented by DuPont in 1965, followed by Nomex meta-aramid fibers in 1967.

In addition to adding strength and protection to spacesuits, Kevlar has, over the years, been adopted for spacecraft shields designed to protect against micrometeorites and space debris, especially on the International Space Station.

A parachute made of Kevlar was included on the Galileo probe to Jupiter and research and development is ongoing to explore new applications, including 3D-printed shields for aerospace repair. Kevlar is further used in honeycomb structures for light, tough and durable spacecraft components.

Nomex was also a crucial component of the Apollo program, especially in the creation of spacesuits. It was used in both NASA’s thermal micrometeoroid EMU and its ACES pressure suit, providing protection against fire and extreme environments.

Nomex Felt Reusable Surface Insulation (FRSI) was also used on the Space Shuttle Orbiter to protect critical parts from high temperatures during reentry. FRSI covered various areas like the upper wing surfaces, upper payload bay doors and the aft fuselage.

Further applications for Nomex have been in the airbags for the Mars Path-finder and Mars Exploration Rover missions, providing protection during landing, and also in the Galileo atmospheric probe and the Cassini-Huygens Titan probe.

Apollo 1 Tragedy

While the Apollo 11 mission is rightly celebrated as the ultimate achievement in this period, it was the tragedy of Apollo 1 in 1967 that first led to a wave of urgently required innovation in science and engineering. During a launch rehearsal on January 27th of that year, a fire destroyed the spacecraft’s cabin and killed the three crew members aboard.

Evelyne Orndoff, of NASA’s Johnson Space Center in Houston, Texas, has delivered inspiring lectures on this period. At the time, she explained, crews wore pressurized suits consisting of multiple layers of polyamide, a fully pressurized helmet, and detachable gloves. Underneath, they wore long cotton underwear and layers of aluminized, biaxially oriented PET films and thin polyester nonwovens for thermal insulation, which were developed for NASA’s previous Gemini program that ran from 1961 to 1968.

The Apollo 1 tragedy highlighted the need for specially-designed protective clothing to be worn by astronauts within a space vehicle, in addition to the pressurized spacesuits developed for them to wear outside in space.

Beta

One of the developments from the intensified research that followed was the first microfiber, a glass fiber called Beta, with a diameter of 3.4 µm, made by Owens Corning of Toledo, Ohio, as the basis for protective outer layers. In order to exploit the assistance of gravity in drawing such a fine fiber, a two-story plant had to be specially built. The effort, however, was worthwhile, because the resulting fiber was non-flammable – even in the oxygenenriched environments encountered inside the Apollo cabins – and had an extraordinary melting temperature in excess of 1,576°F (840°C).

Beta fiber was used extensively in spacesuits for the Apollo program, but unlike Kevlar and Nomex found few commercial market opportunities and its manufacturing plant was closed in the mid-1990s.

Another development at this time was Chromel R, a metal alloy fiber which was woven into special leggings to protect astronauts from hot gases, and later used in the Apollo spacesuit gloves and boots, as well as in abrasion patches on the suit itself. The fiber consists of 74% nickel, 20% chromium, 3% aluminum and 3% iron.

Space Station Comfort

With the development and deployment of its Skylab space station in the 1970s, NASA’s crews began to learn how to live in spacecraft for extended periods. Comfortable clothing was a must, but there was still a need for protection from fire. According to Orndorf, in the oxygenenriched interior of Skylab “practically every material has the potential to be a fuel next to the skin.”

Working with Monsanto (now Bayer) of Creve Coeur, Missouri, NASA responded by developing Durette, a modified aramid with the principal advantage of remaining dimensionally stable at high temperatures. Nevertheless, the fiber still needed to be treated with high levels of flame-retardant (FR) agents, which, being halogen-based at that time, resulted in early versions proving too toxic for use. Eventually, however, Durette was used in the flight suits, boots, and gloves for Skylab, which orbited the Earth between 1973 and 1979.

Space Shuttle Program

In the build-up to the Space Shuttle program at the start of the 1980s, a special double-faced fabric called Ortho was developed for the outer layers of spacesuits. Its front face is constructed from a 400 denier expanded polytetrafluoroethylene (ePTFE) in a split basket weave and its back face consists of a woven combination of 200 denier Nomex and 400 denier Kevlar yarns.

Ortho fabric has high abrasion and wear-resistance, is flame-resistant in oxygen-rich environments, chemicalresistant, and remains flexible at low temperatures. The material’s breaking strength is 230 pounds per inch, its ultimate elongation 60%, and it has an infrared (IR) emissivity of 0.77 and a solar absorption of 0.18.

Ortho fabric has subsequently been used in the EMUs for the International Space Station.

Another fabric developed during this period and also still in use, is Astro Velcro II. Based on conventional hook-and-loop fasteners such as Velcro, NASA’s version is made with Nomex fibers on a glass base fabric. The fabric has high peel and sheer strength and its extra-resilient hook structures are suited for a wide range of fastening applications.

Partnerships

These are just a few of the developments that commercial companies such as Axiom can now draw on from NASA’s rich history of research and development.

“We are pioneering a new era in space exploration where partnerships are imperative to the commercialization of space,” said Russell Ralston, Axiom’s executive vice president of extravehicular activity. “Partnerships build a strong, cohesive team, enabling industry experts to provide cutting-edge technology, specialized products and services to drive innovation. For the first time, we are leveraging expertise in other industries to craft a better solution for space.”

The AxEMU has been designed to provide increased flexibility, performance, and safety, as well as equipped with specialized tools to aid in exploring the lunar south pole. It will withstand extreme temperatures and endure the coldest temperatures in the permanently shadowed regions for at least two hours.

The spacesuit architecture includes life support systems, pressure garments, avionics, and other systems to meet exploration needs and expand scientific opportunities. Astronauts will be able to perform spacewalks in it for at least eight hours.

Adrian Wilson is an international correspondent for International Fiber Journal . He is a leading journalist covering fiber, filtration, nonwovens and technical textiles. He can be reached at adawilson@gmail.com.