9 minute read

EMERGENCE

Compiled by Caryn Smith, IFN Chief Content Officer

International Filtration News Explores Trending Innovation

IFN highlights significant research from universities and institutions around the world. If you are a part of a project you would like to highlight, email csmith@inda.org. Please write “IFN Emerging Research Submission” in your subject line in order to apply. Please send a completed press release and/or summary of the research as you would want it to be printed, a link to the university online story (if applicable), and all high resolution photographs/charts/graphs, short researcher bio(s). All selections could be edited for length.

Bernal Institute And University Of Limerick

Bernal Researchers

Discover Solution to Eliminate ‘Forever Chemicals’ from Drinking Water

Researchers at Bernal Institute and University of Limerick have developed a new material that can eliminate so-called ‘forever chemicals’ from water.

The research team, working with colleagues from the Technical University of Munich (TUM) in Germany, have discovered a solution to filter harmful chemicals from drinking water.

Per- and polyfluoroalkyl substances (PFAS) are a group of man-made chemicals that have been in use since the 1940s. Due to their ability to resist heat, oil, stains, grease, and water, PFAS have been widely used across a range of industrial and consumer applications, from nonstick cookware and water-repellent fabrics to firefighting foams and industrial processes. However, their chemical stability – key to their effectiveness in these uses – also means they persist in the environment and the human body.

Known as ‘forever chemicals,’ the substances can accumulate in the body via food and drinking water and cause serious illnesses. Prolonged exposure can cause liver damage, tumors and hormonal disorders and they are considered a severe threat to human health.

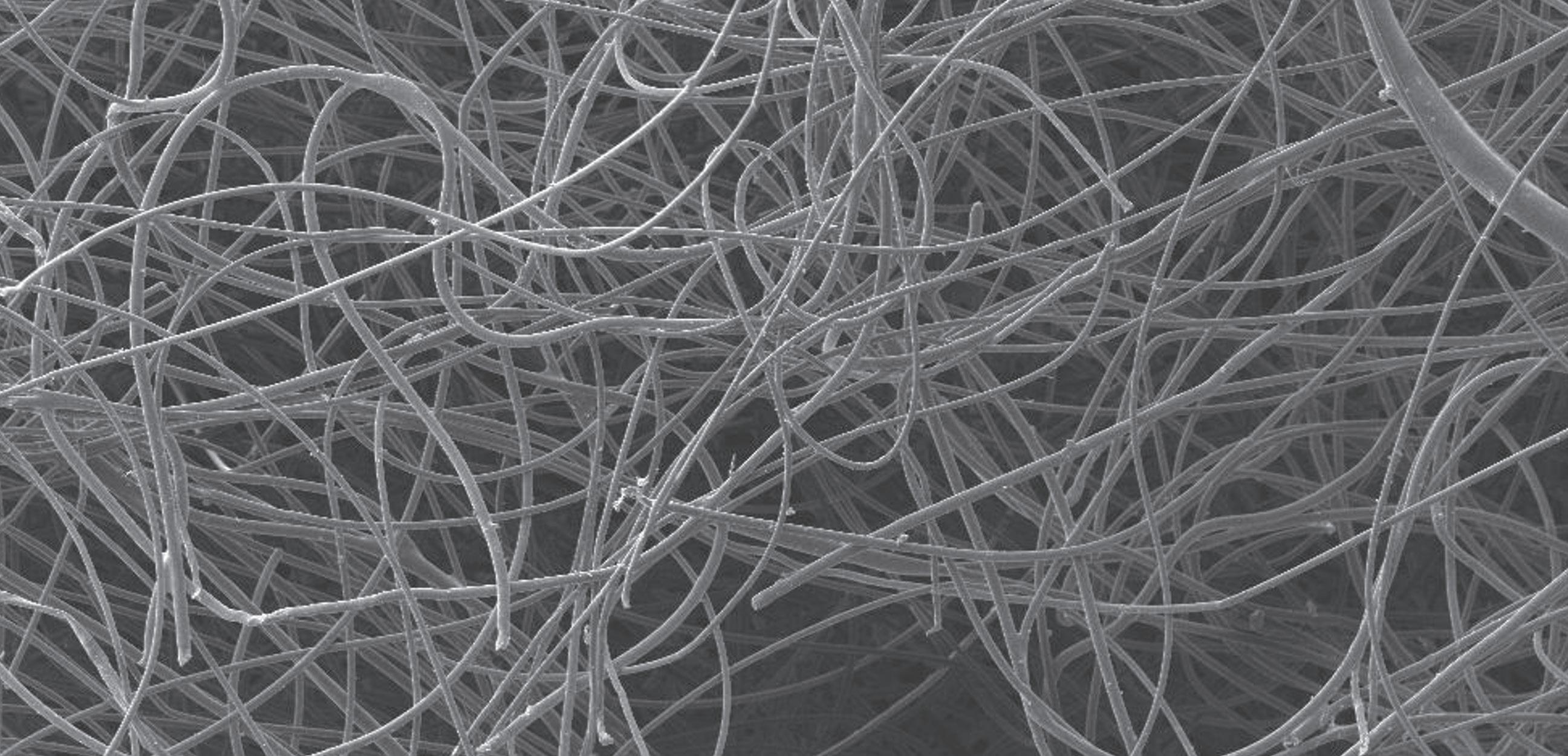

The researchers at Bernal, UL and TUM have now developed a new, efficient method of filtering these substances out legacy PFAS chemicals, this new class of PFAS filters introduces an as-yet-unknown design principle for future adsorbent design.

“In fact, this marks the first instance of trace PFAS removal from freshwater containing two parts per billion of PFAS using porous adsorbent materials that demonstrate both rapid removal kinetics and excellent recyclability.” of drinking water. They rely on so-called metal-organic framework compounds, which work much better than the materials commonly used to date. Even extremely low concentrations of PFAS in the water can still be captured.

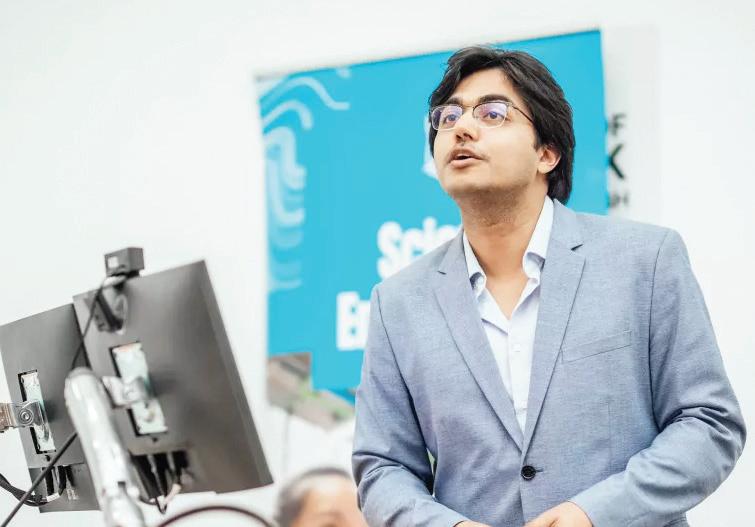

Dr. Soumya Mukherjee, member of the Bernal Institute and an Assistant Professor of Materials Chemistry at UL’s Department of Chemical Sciences, working with researchers in TUM, developed the porous, sponge-like metal-organic frameworks (MOFs) that can filter these PFAS chemicals out of drinking water.

The new discovery has just been published in the Advanced Materials journal.

“The filters delivered removal performance even when they were present in extremely low concentrations of a few parts per billion, that is, only a handful of PFAS molecules among billions of water molecules,” explained Dr. Mukherjee.

“With fast and record-high removal properties realized for at least two of the

The research team identified water-stable metalorganic framework compounds made of zirconium carboxylate as particularly effective PFAS filters.

The bespoke class of materials is characterized by the adaptable pore sizes and surface chemistry. The materials are water-resistant and highly electrostatically charged. By specifically designing the structures and combining them with polymers, the filter capacity has been significantly improved compared to materials already in use, such as activated carbon and special resins.

Dr. Mukherjee highlighted the profound societal impact of removing PFAS from water. “During the Second World War, fluorocarbons became the silent enablers of the 20th century’s greatest technological achievements – the bomb and also Teflon, the stuff of convenience cookware, spaceflight and implantable medical devices.

“Today, these fluorocarbons, PFAS, persist as legacy chemicals prevalent in water systems serving hundreds of millions of people around the world. So extreme is their persistence that science is yet to determine an environmental half-life – the point at which the environmental load would otherwise become half.

“From soil to sea, the PFAS cycle spins a web of contamination across ecosystems far and wide. To mitigate the disquieting effects of PFAS, we have just innovated a new approach to adsorbent design.

“Our team approach was key to this success. The chemistry among our team was just as important as the chemistry of the porous materials.”

According to the researchers, the largescale translation of the newly identified filter material class in water treatment facilities now requires iterative process design across higher technological readiness levels.

“Scaling this innovation from the laboratory to pilot-scale operations arguably presents additional challenges in process engineering,” said Dr. Mukherjee.

“However, it will be some time before this new filter material is adopted on a large scale in waterworks. The newly discovered principle would have to be implemented with sustainably available, inexpensive materials that are safe in every respect. This will require considerable further research and engineering solutions.”

Read: https://www.ul.ie/bernal/news/bernalresearchers-discover-solution-to-eliminate-foreverchemicals-from-drinking-water

©University of Limerick

BAKER HUGHES AND THE UNIVERSITY OF CALIFORNIA, BERKELEY

Baker Hughes and the University of California, Berkeley, Establish Global Decarbonization Research Institute

Baker Hughes, an energy technology company, and the University of California, Berkeley have announced a new long-term research partnership to establish the Baker Hughes Institute for Decarbonization Materials at UC Berkeley’s College of Chemistry. The institute will connect breakthrough academic research with commercial innovation to accelerate the deployment and scaling of costeffective climate technology solutions that drive sustainable energy development.

As part of the agreement, Baker Hughes will fund collaborative research to develop next-generation materials for a range of energy and industrial applications, including carbon capture, utilization and storage (CCUS), hydrogen, and clean power generation, among others. Baker Hughes will be closely involved from the earliest stages of research to shape the programs based on evolving market and customer needs, as any discoveries may potentially be scaled across the company’s portfolio of climate technology solutions.

“Innovation, collaboration and partnership are critical to building the diversified portfolio of technology solutions neces- sary to meet the energy demands of today and tomorrow. Partnering with UC Berkeley’s College of Chemistry is an important step forward in our commitment to sustainable energy development,” said Chris Pin Harry, vice president of Technology, Industrial & Energy Technology (IET) at Baker Hughes.

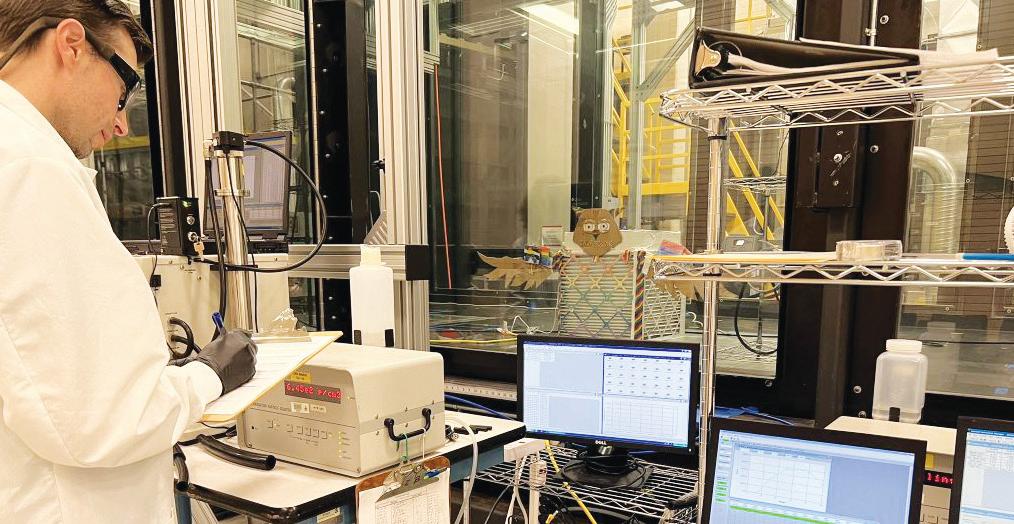

The institute will be led by C. Judson King Distinguished Professor and UC Berkeley Professor of Chemistry Jeffrey Long, a globally recognized material’s expert who pioneered the use of metalorganic frameworks (MOFs) for adsorbing carbon dioxide and other molecules from industrial emissions streams. Baker Hughes’ funding will support Berkeley researchers, with expertise in materials development and discovery, computational chemistry, advanced characterization, process engineering and techno economics. Chris Pin Harry and Daniela Abate, VP CCUS, Climate Technology Solutions at Baker Hughes, will serve on the institute’s joint steering committee.

Initial research projects will focus on advanced material design, including creating and testing new chemical structures like MOFs, as well as developing gas separation and chemical conversion systems. Additionally, the projects will leverage AI and machine learning to accelerate the discovery and development of improved materials and new technology solutions.

“Our aim is to make materials that not only adsorb gases more efficiently, but also without high energy requirements,” said Professor Long, the institute’s executive director. “As chemists, we know how to adjust materials at the atomic level, but we need partners like Baker Hughes who can scale and industrialize the technology. Lowering emissions is an urgent task, and I am confident that together, we can make scalable, commercially relevant materials that can quickly hit the market and make a difference.”

The partnership builds on Baker Hughes’ wider development of innovative climate technologies, including its work in CCUS with Mosaic Materials direct air capture (DAC) technology. Acquired by

Baker Hughes in 2022, Mosaic Materials was born out of Professor Long’s lab at UC Berkeley, and pilot units are currently being tested to accelerate deployment at commercial scale.

The institute underscores Baker Hughes’ commitment to investing in emerging technologies that will efficiently reduce or eliminate emissions across multiple industries.

Read: https://www.bakerhughes.com/company/ news/baker-hughes-and-university-californiaberkeley-establish-global-decarbonization

University Of Connecticut

UConn Keeping Air in Connecticut Classrooms Safe

By Lauren Woods, Schools of Medicine and Dental Medicine

Several years of community service and real-world research of the crosscampus UConn Indoor Air Quality Initiative has led to the awarding of $11.5 million in state support to UConn to bring access to low-cost, do-it-yourself “Corsi-Rosenthal” air-purifiers to every individual public school classroom in Connecticut.

On October 22 the State Bond Commission in Connecticut approved funding for the UConn Indoor Air Quality Initiative to administer and implement the purchase of equipment and materials for the con- struction and installation of individual classroom air purifiers. The state funding awarded to UConn will be part of SAFECT: Supplemental Air Filtration for Education Supplemental under the Clean Air Equity Response Program.

“We are pleased to offer these inexpensive devices to all classrooms across Connecticut,” said the Director of the UConn Indoor Air Quality Initiative, Marina Creed, an APRN who also serves UConn Health as a neuroimmunology nurse practitioner. “When schools, students, and teachers run one of these inside their classrooms it will reduce their exposure to viruses and bacteria, reducing the risk of disease transmission, meaning they are less likely to get sick.”

Creed added, “Thank you to the Governor, Lieutenant Governor, and General Assembly for putting the health of our students and teachers first.”

Although these devices are created simply with just $60 of hardware store materials, they have been shown to be incredibly effective. The EPA and UConn jointly tested the devices in the EPA’s large bioaerosol test chamber, and results showed that in just 60 minutes it effectively removes over 99 percent of airborne viruses including the virus that causes COVID-19. Plus, recently published collaborative research findings by UConn and Arizona State University also show that DIY air purifiers work better than commercial HEPA air cleaners for a fraction of the cost.

“Our scientific results are huge!” said Creed, who also serves as an instructor of neurology at UConn School of Medicine. “These air purifiers immediately improve indoor air quality, which has been shown to decrease student absences from asthma and respiratory illness such as influenza, COVID, and RSV, and is also associated with improved academic performance including test scores.”

In 2021, UConn launched its crosscampus community service initiative during the pandemic to battle the COVID-19 virus with faculty, students, and staff volunteering to build and donate over 700 of the public health intervention tools to public schools and other community settings like the Veteran’s Administration (VA) Medical Center. The UConn Indoor Air Quality Initiative was initially started by Creed as an effort to better protect her immunocompromised multiple sclerosis patients and other vulnerable people in the community. Since that time, the reach of the Initiative has greatly expanded. In fact, building and testing the air filters has become part of a UConn Engineering class curriculum (ENGR 1166) as a public service learning project.

Creed’s Initiative co-collaborators at UConn are Kristina Wagstrom, Ph.D. of the College of Engineering and Misti Zamora, Ph.D. of the School of Medicine.

“We look forward to working with students from kindergarten through university-levels to provide opportunities for hands-on learning and engagement about solutions to improve indoor air quality,” shared Wagstrom, an associate professor in Chemical and Biomolecular Engineering in the College of Engineering at UConn-Storrs who specializes in improving estimates of the human and ecosystem health impacts of air pollution.

“We are excited to be able to use our experiences and expertise to help improve indoor air quality in Connecticut’s schools. This is more than a work project for us. It is very personal since many of our team have children attending schools in Connecticut, and we know how sensitive children can be to the air they breathe,” shared Zamora, an expert in assessing air quality and how it impacts our bodies who serves as an assistant professor in Public Health Sciences at UConn School of Medicine.

The

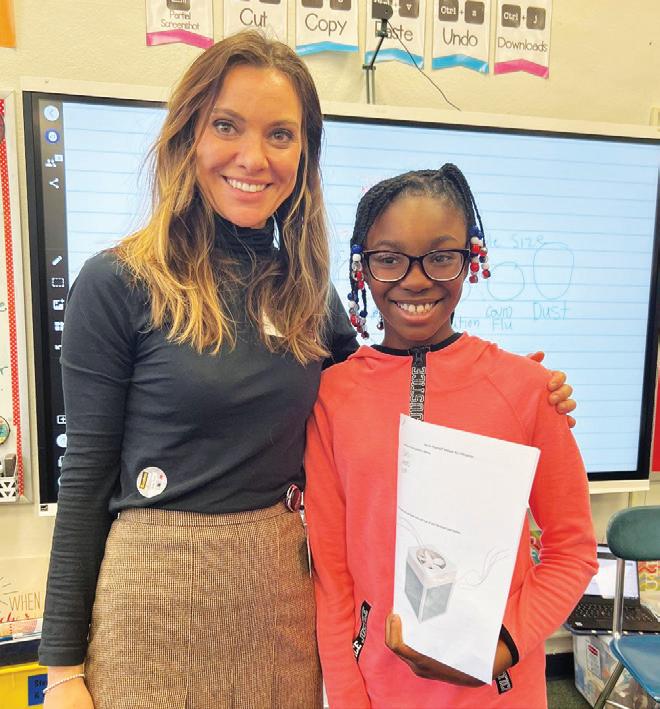

Power of UConn and a Little Girl’s Letter

Eniola Shokunbi, an elementary school student in Middletown, wrote and mailed UConn Health a letter inviting them to her public school to help her class build an air purifier device. The student wanted to have UConn’s help to build these air filters to improve her nearly 100-year-old school’s indoor air quality, reduce her fellow students’ risk of illness, and also run her own science experiment testing the effectiveness of the devices across classrooms by tracking sick absences.

The inexpensive, build-it-yourself “Corsi-Rosenthal” box air purifiers have become part of a national movement during COVID-19 to help everyone more easily remove unhealthy air particles from indoor community settings, and even during national wildfire poor air-quality events. The movement has grown from the West Coast creators of the device at the University of California-Davis (Richard Corsi, dean of engineering at UC California-Davis, and Jim Rosenthal, CEO of Texas-based company Tex-Air Filters) all the way to the East Coast’s University of Connecticut.

UConn researchers were instrumental in taking the air filters on a road trip first to the White House’s Office of Science and Technology Policy and then for testing by the U.S. Environmental Protection Agency’s (EPA) Homeland Security Division Laboratory at the EPA’s Office of Research and Development in Research Triangle Park, North Carolina for high-tech, advanced biochamber research testing of the device. For two weeks the EPA scientists tested the efficacy of the low-cost DIY device against the non-pathogenic bacteriophage MS2, a surrogate virus for SARS-CoV-2, the virus that causes COVID-19. The team of EPA scientists led by Katherine Ratliff showed that the box removes 97% of infectious aerosols in just 30 minutes, and 99.4% within 60 minutes including the surrogate virus for SARSCoV-2, the virus that causes COVID-19.

The UConn Indoor Air Quality Initiative’s cross-campus collaborators include UConn Health and its Comprehensive Multiple Sclerosis Center, UConn School of Medicine and its Department of Public Health Sciences, UConn College of Engineering, UConn School of Nursing, Connecticut Area Health Education Center Network (CT AHEC), UConn Neag School of Education, and Connecticut Children’s.

You can learn how to build your own simple, affordable DIY air cleaner with UConn’s simple online directions whether for your home, your classroom, or community setting. Also, view a how-to video by UConn College of Engineering students.

Read: https://today.uconn.edu/2024/10/uconnkeeping-air-in-connecticut-classrooms-safe/# © 2024 University of Connecticut