8 minute read

The Filter Homogeneity Lacking in the Timeless Pursuit of Clean Air

Addressing the Challenges of Manufacturing Consistently Homogeneous Filter Media Will Enable the Transition to Circular Filtration

Models

By Dr. Iyad Al-Attar

The pursuit of clean air has been a long-standing focus in the journey of human civilization. Ancient civilizations demonstrated an early awareness of the importance of clean air for survival even before scientific methods were established in ancient Rome, where protective strategies such as using damp cloths were employed by soldiers and miners. The need for cleaner air became further pronounced during the Black Death (1346-1353), leading to the development of respiratory masks (Figure 1), known as theriac, designed to filter “bad air” using as many as 55 herbs[1]. Despite their initial popularity, the effectiveness of these masks was not well understood, and there were conflicting views on their health benefits[2].

While the idea of clean air may seem like a modern concern, its importance and the evolution of filtration technologies have gradually unfolded. The 20th century marked significant milestones, including introducing high-efficiency particulate air (HEPA) filters, passing the Clean Air Act in 1963, and establishing the Environmental Protection Agency (EPA) in 1970, all indicative of a heightened environmental consciousness. Moving into the 21st century, the Internet of Things has brought innovative technology to air filtration systems, offering real-time monitoring and advanced features for heating, ventilation, and air conditioning (HVAC) systems. With rapid urbanization, industrial expansion, and increasing humanmade emissions driving the need for cleaner air solutions, filtration technologies have become essential in tackling these pressing challenges.

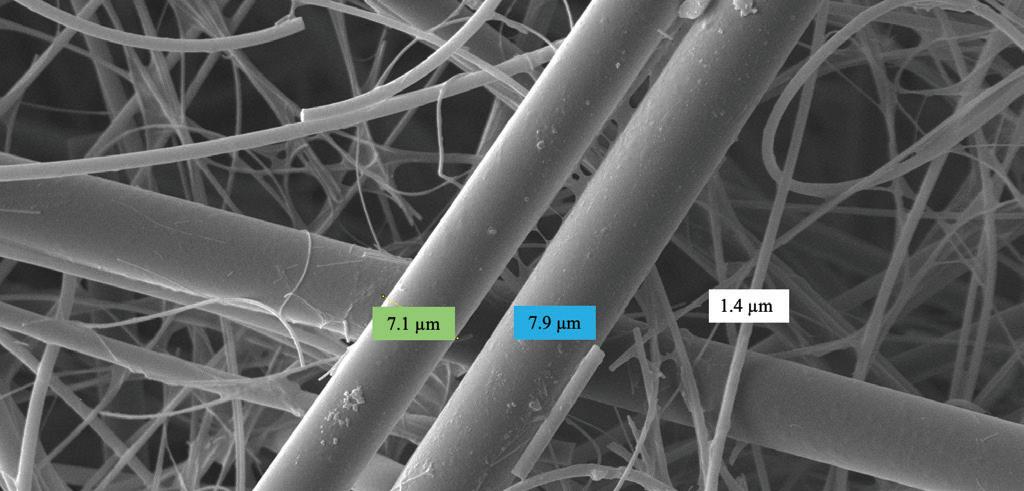

Attaining higher efficiency filtration requires filter media that effectively capture and retain particles at the Particulate Matter (PM1) scale. The performance of modern air filters depends on the properties of the filter media, which can be affected by variations in packing density, thickness, pore size, and fiber size distribution. These inhomogeneities are often caused by manufacturing issues, impact efficiency, pressure drop, lifespan, and operational costs. Understanding these inconsistencies is crucial for ensuring optimal filter performance and meeting air quality standards, especially for ultrafine particles. A homogeneous filter media structure is key to better predictions of filter performance.

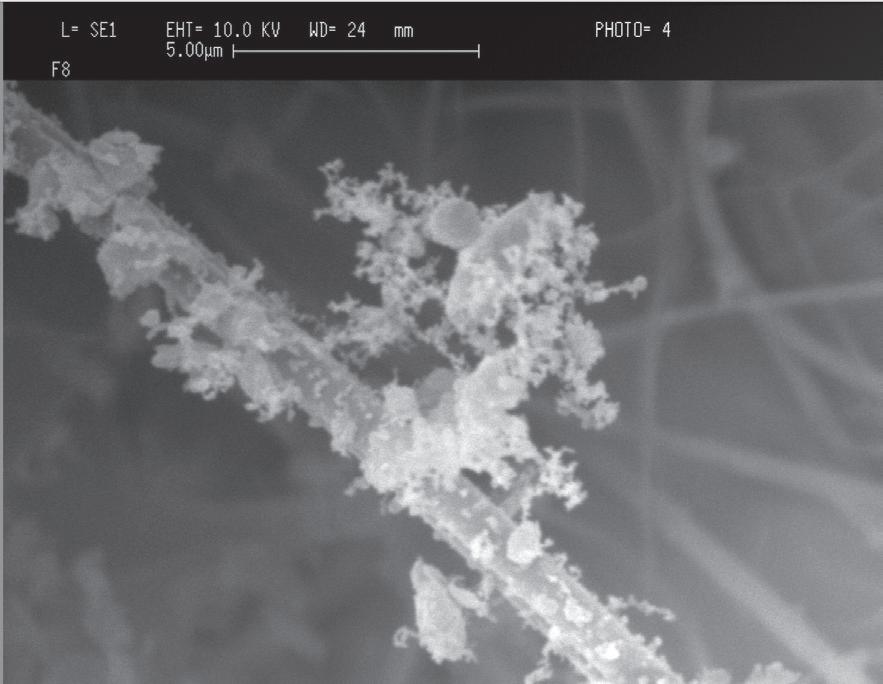

Davies’s model (1952, 1973) focuses on clean filters and highlights discrepancies between predicted and experimentally measured pressure drops[3,4]. Theoretical calculations by Happel, Kuwabara, Fuchs, and Stechkina for viscous flow around parallel cylinders differ from Davies’ empirical model, which is widely used and tested against extensive experimental data [5,6,7]. Thomas et al. (1999, 2001) noted that theoretical predictions often overestimate pressure drops in fibrous filters due to non-uniform structures[8,9], which also affect dendrite and dust cake formation (Figure 2) and particle dynamics during loading[10]

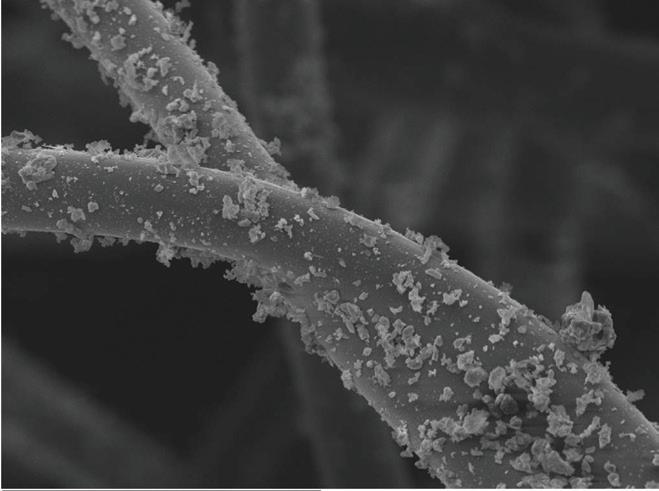

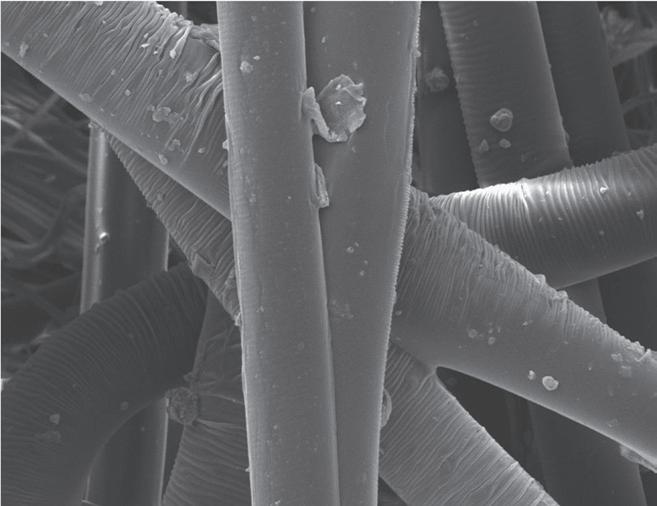

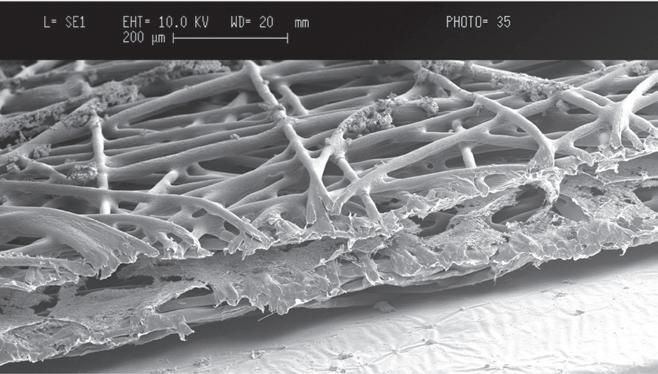

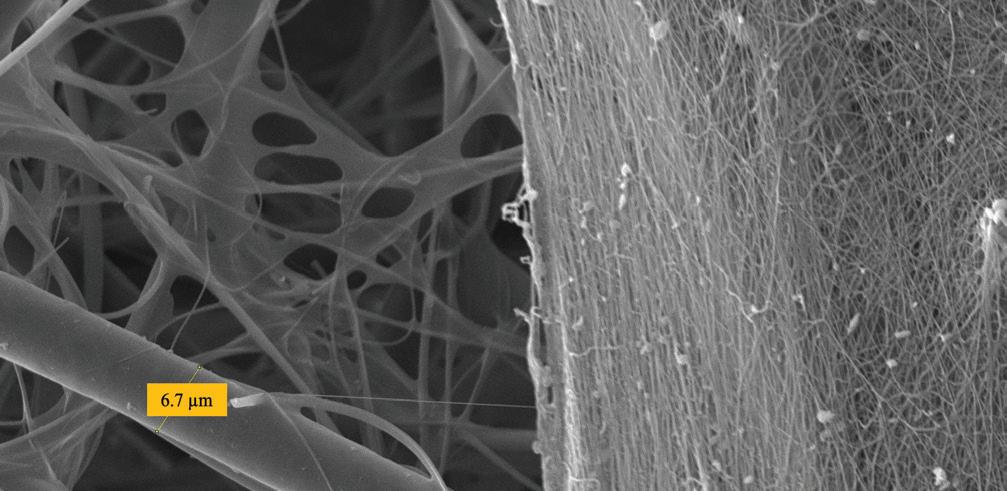

The performance prediction of filters faces several challenges, including the interference of neighboring fibers (Figure 3), fiber orientation (Figure 4), and inhomogeneity in the filtration medium, which disrupts ideal airflow patterns. These irregularities lead to non-uniform gas flow, impacting filtration behavior. To account for this, the inhomogeneity factor, ξ , has been introduced. However, it led to an over prediction of the pressure drop of filters. Furthermore, it is vital to consider the appropriateness of applying this factor to flat, pleated, or progressive media (Figure 5) for better filter performance predictions. Ultimately, while previous research has been focused on carefully selecting inhomogeneity factors for various filtration scenarios, current efforts should steer filter media technologies to manufacture a structured media so that filter performance can be predicted using existing models. This would allow filter designers to have more control over air quality outcomes.

Uneven particle loading further complicates the predictability of filter performance, particularly as surface deposition of particles precedes depth deposition. Particle loading and settlement within the media depth change the interstitial space’s characteristics and cause the filter’s pressure drop to rise. The structural inhomogeneity of filter media affects both initial performance and long-term durability. Filters with inconsistent material properties degrade unevenly, leading to variation in permeability and local media velocities, which can result in premature clogging in certain areas. Furthermore, inhomogeneity diminishes the constituency of filter performance, complicating standardization efforts and compliance with international filtration standards, such as ISO 16890 and ASHRAE 52.2[11,12]

Another challenge that can be encountered during filter loading, particularly in the presence of media inhomogeneity, is the elevated particle concentration during sandstorms. These storms alter particle loading conditions and the dynamics of particle capture change. Particles may begin to bridge prematurely, leading to increased surface deposition and ineffective use of the filter’s medium depth. Filter media inhomogeneity further exacerbates the complexity of particle loading, rendering air filter assessment rather tedious. Studies have shown that variability in fiber alignment and distribution during production can create uneven filtration zones[13,14] Additionally, filter media degradation over time can worsen inhomogeneity, particularly in environments with high humidity or chemical exposure[15,16]

The Importance of Nanotechnology in Air Filter Media

Filter media inhomogeneity can impede advancements in filter media performance. Traditional air filter media, consisting of macroscopic fibers, struggle to capture ultrafine particles, including viruses, bacteria, and PM2.5, which pose significant health risks.

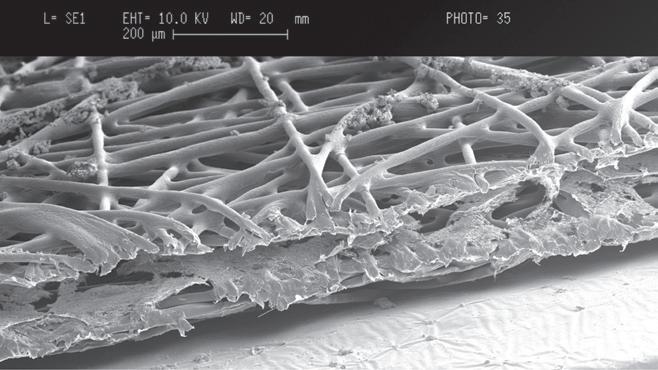

Nanotechnology involves using nanoscale materials to enhance air filter media by improving their ability to capture these ultrafine particles. Developing nanofiber-based media through electrospinning produces highly porous structures that boost particle capture efficiency while maintaining low-pressure drops. Functional nanomaterials can selectively target specific pollutants, improving air quality and promoting sustainability. Innovations in filter media utilize multilayer stacking, a technique that involves layering a submicron substrate with a nano-sized layer, which enables the filter to capture a broader spectrum of particle sizes (Figure 6). By stacking layers of nanofibers with lower basis weights, these filters aim to achieve higher particlecapturing efficiency comparable to that of single-layer filters with a negligible rise incorporating fibers with larger diameters, which can better withstand the forces exerted by fluid flow. This helps prevent issues such as filter media compression, pleat deformation, and deflection of the pleated panel. However, it is critical to strike a balance, as the filter media must also remain flexible enough for pleating and to minimize creasing. As shown in Figure 7, preserving the filtration properties throughout the pleating process is essential. Ultimately, the final filter cartridge must allow the pleated media to operate effectively, ensuring reliable and consistent performance in particle capture.

Filter Media Regeneration and Circularity

in pressure drop. Another approach to enhancing particle capture is integrating fibers of varying sizes and dimensions, such as microfibers and nanofibers. However, considering the particle size distribution and concentration challenge is essential relative to the new media properties obtained after introducing the nano fibers or layers for efficiency enhancements.

The main objective in manufacturing highly efficient and sustainable filter media is to ensure it effectively captures particles of various sizes while maintaining its structural integrity. One approach to achieve this is by

In the context of sustainability, filter media must move beyond traditional linear consumption models to adopt circular strategies that enhance performance. This entails focusing on regeneration and self-cleaning capabilities, which improve filtration efficiency, reduce energy consumption, and extend filter lifespan – key aspects of the circular economy. What must be kept front of mind is the development of sustainable air filtration solutions that promote filter longevity, recyclability, and regeneration.

Transitioning to reusable and regenerative air filter media is vital for fostering a circular economy in air filtration. By optimizing media selection, manufacturing processes, and filter designs, we can significantly reduce waste, conserve resources, and lessen environmental impacts. On- going research is essential for creating more efficient air filtration solutions and addressing the disposal of loaded filters in smart cities. However, challenges exist in achieving the reproducibility of filter media, as producing homogeneous filters can hinder performance prediction and circular model adoption. Additionally, developing cost-effective regeneration techniques while minimizing environmental impacts remains a priority.

Conclusion

The quest for clean air is a timeless pursuit shaped by historical events and technological advancements. From the masks worn by plague doctors to today’s sophisticated smart air filtration systems, our drive for clean air has spurred innovations in filtration. Yet, even with these advancements, air pollution remains a pressing issue.

A crucial aspect of air filtration is the uniformity of filter media, which greatly influences filtration efficiency, pressure drop, and how particles settle. Making strides in developing highly uniform filter media through cuttingedge manufacturing techniques and materials is certainly the order of the day toward a predictable and reliable filter performance. Continuous research is vital for enhancing air filtration technologies and creating filter media that effectively capture particles, gases, and bioaerosols. As we aim to uncover modern filtering solutions that ensure clean air, we must redefine what we consider to be “modern” technologies and tap into their vast potential for creating not just a better filter but a better future.

Dr. Iyad Al-Attar is a mechanical engineer and an independent air filtration consultant. He is a Visiting Academic Fellow in the School of Aerospace, Transport, and Manufacturing at Cranfield University, consulting for air quality and filter performance relevant to land-based gas turbines. Dr. Al-Attar is also the strategic director, instructor, and advisory board member of the Waterloo Filtration Institute. In 2020, Eurovent Middle East appointed Dr. Al-Attar as the first associated consultant for air filtration.

Recently, he became the Indoor Air Quality (IAQ) patron for EUROVENT. With engineering degrees (BSc, MSc, Ph.D.) from the University of Toronto (Canada), Kuwait University, and Loughborough University (UK), respectively, he is now reading for an MSc in sustainable urban development for air quality inclusion at the University of Oxford. His expertise is on the design/ performance of high-efficiency filters for HVAC and land-based gas turbine applications, focusing on chemical and physical characterization of airborne pollutants.

References

1. Blakemore, E., 2020. Why plague doctors wore those strange beaked masks. National Geographic, 12.

2. Ahnfelt, N.O., Fors, H. and Wendin, K., 2022. Making and taking theriac: an experimental and sensory approach to the history of medicine. BJHS Themes, 7, pp.39-62.

3. Davies C.N. 1952. “The separation of airborne dust and mist particles,” Proc. Inst. Mech. Engng 1B, 185-198.

4. Davies, C. N. (1973). Air filtration. London, New York: Academic Press.

5. Happel, J. (1959). Viscous flow relative to arrays of cylinders. AIChE Journal, 5, 174–177. https://doi.org/10.1002/ aic.690050211

6. Kuwabara, S., 1959. “The forces experienced by randomly distributed parallel circular cylinders or spheres in viscous flow at small Reynolds numbers,” J. Physical Society Japan, 14, 527–532.

7. AA, K. and NA, F., 1967. The fluid flow in a system of parallel cylinders perpendicular to the flow direction at small Reynolds numbers. Journal of the Physical Society of Japan, 22(5), pp.1251-1255.

8. Thomas D., Contal P., Renaudin V., Penicot P., Leclerc D. and Vendel J., 1999. “Modelling pressure drop in HEPA filters during dynamic filtration,” J. Aerosol Sci., 30(2), 235-246.

9. Thomas D., Penicot P., Contal P., Leclerc D. and Vendel J., 2001. Clogging of fibrous filters by solid aerosol particles

Experimental and modelling study, Chem. Eng. Sci., 56(11), 3549-3561.

10. Dittler A., Gutmann B., Lichtenberger R., Weber H. and Kasper G., 1998. “Optical in situ measurement of dust cake thickness distributions on rigid filter media for gas cleaning,” Powder Technol., 99 (2), 177-184

11. ISO, I., 2016. 16890-1: 2016 Air Filters for General Ventilation—Part 1: Technical Specifications, Requirements and Classification System Based Upon Particulate Matter Efficiency (ePM).

12. ASHRAE (2017a) ANSI/ASHRAE Standard 52.2-2017 method of testing general ventilation air-cleaning devices for removal efficiency by particle size. American Society of Heating, Refrigerating and Air –Conditioning Engineers, Georgia

13. Spurny, K.R., 1998. Advances in aerosol gas filtration. CRC Press.

14. Spurny, K., Lodge, J.P., Frank, E.R. and Sheesley, D.C., 1969. Aerosol filtration by means of Nuclepore filters: structural and filtration properties. Environmental Science & Technology, 3(5), pp.453-464.

15. Zhu, M., Han, J., Wang, F., Shao, W., Xiong, R., Zhang, Q., Pan, H., Yang, Y., Samal, S.K., Zhang, F. and Huang, C., 2017. Electrospun nanofibers membranes for effective air filtration. Macromolecular Materials and Engineering, 302(1), p.1600353.

16. Berry, G., Beckman, I. and Cho, H., 2023. A comprehensive review of particle loading models of fibrous air filters. Journal of Aerosol Science, 167, p.106078.