2 minute read

NOTES TECH Aqua-Aerobic Systems, Inc. Introduces PFAS Removal System

Aqua-Aerobic Systems, Inc. introduced the first in their line of PFAS Solutions, the AquaPRS™ PFAS Removal System. This system utilizes a unique sorbent suspension to adsorb pre- and polyfluoroalkyl substances (PFAS) and a robust separator to produce clean water from the suspension. The suspended adsorbent slurry prevents biofouling and controls solids and mineral buildup. Additionally, the adsorbent material is specially engineered to adsorb much more PFAS (ug of PFAS/g of sorbent) than can be adsorbed by the same amount of GAC, ion-exchange resins, or other adsorbents, resulting in significantly less operating life cycle costs and net present value.

Smith & Loveless Inc. Introduces TITAN MEM-BOX™

Some of its features and advantages include:

• Extremely high sorbent adsorption rates of PFAS compared to other sorbents

• Fouling and scaling controlled by slurred adsorbent

• Waste volumes are substantially lower when compared to GAC or IX Resin

• Enhanced removal of short-chain PFAS in a single process

• Process is completely automated, including adsorbent replacement The process is completely automated, including replacement of the adsorbent. The removal process allows parameter adjustments in response to varying influent concentrations of PFAS, if necessary. Single stage operation removes PFAS/PFOA and other regulated PFAS contaminants to levels below EPA standards with low to moderate influent levels.

For very high PFAS concentrations (1,000+ ng/L of PFAS) or difficult influent water characteristics, a two-stage configuration/operation can achieve effluent levels to meet EPA effluent standards. www.aqua-aerobic.com

Smith & Loveless, a leader in factory-built Membrane BioReactors (MBRs), recently introduced its latest factory-built membrane system innovation, TITAN MEM-BOX™, a packaged membrane process zone that transforms activated processes into fully functional MBRs.

The integration of TITAN MEM-BOX™ into a treatment process scheme elevates conventional wastewater treatment plants to cutting-edge water resource recovery facilities (WRRFs) by (a) improving plant capacity (b) improving effluent quality (c) implementing water reuse to counter water scarcity and (d) meeting population growth and tightening permit demands.

Designed for both existing and newly proposed plants, the TITAN MEM-BOX™ membrane system eliminates the need for constructing additional treatment basins while streamlining the design process.

This approach drastically reduces project time and costs associated with concrete tank construction. The factory-built and tested system arrives at the plant site ready to be integrated into the treatment scheme to produce superior effluent and achieve biological nutrient removal.

The TITAN MEM-BOX ™ comes with integral hollow-fiber or flat-sheet membranes (depending upon the application). With S&L’s intuitive QUICKSMART™ PLC controls and plant automation, which includes automatic membrane cleaning, TITAN MEM-BOX ™ is designed to make operation and maintenance the easiest of any membrane system.

The TITAN MEM-BOX ™ also integrates with S&L’s largeflow Model R OXIGEST ® treatment system to form the OXIGEST MBR™, offering a complete MBR treatment solution for flows of 250,000 gpd and larger, up to 2+ MGD per train.

Smith & Loveless’ experienced technical staff assists project designers and end-users through every step of the project, from the pre-design phase to field installation and beyond with complete and reliable lifetime after market support as proven during S&L’s 75-plus years. www.smithandloveless.com

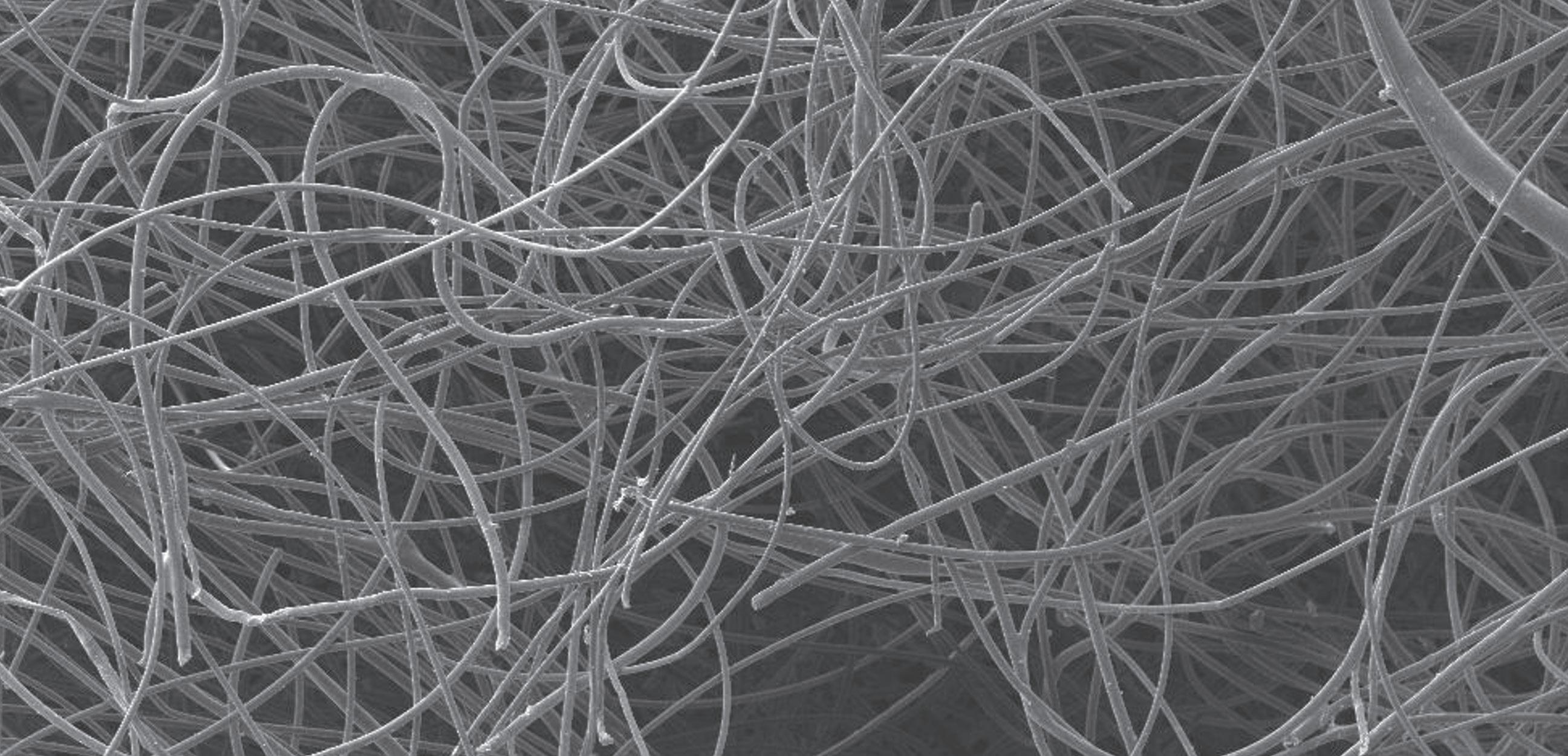

New Microplastics Water Filter Made With Cotton and Squid Bone Could Be 99.9% Effective

In a new study led by researchers at Wuhan University, scientists have developed a filter, made with cotton and squid bone, that can be used to adsorb certain microplastics in aquatic environments, and they determined the filter was 98% to 99.9% effective in filtering microplastics.

The study, published in the journal Science Advances , explored the development of a foam filter made with cellulose, from cotton plants, and chitin, a type of natural biopolymer found in the exoskeletons of arthropods and mollusks, as well as in some cell walls of fungi and algae, according to ScienceDirect. Both cellulose and chitin are considered “two of the most abundant polysaccharides found in nature,” according to the study, and they are already used fre- quently for removing larger pollutants from wastewater. The researchers are applying the use of cellulose and chitin in a novel way to tackle microplastic pollution in water, which has typically been addressed with magnets, surface-engineered adsorption methods or coagulation methods, all of which can be difficult and expensive to scale. www.science.org