2 minute read

NOTES TECH

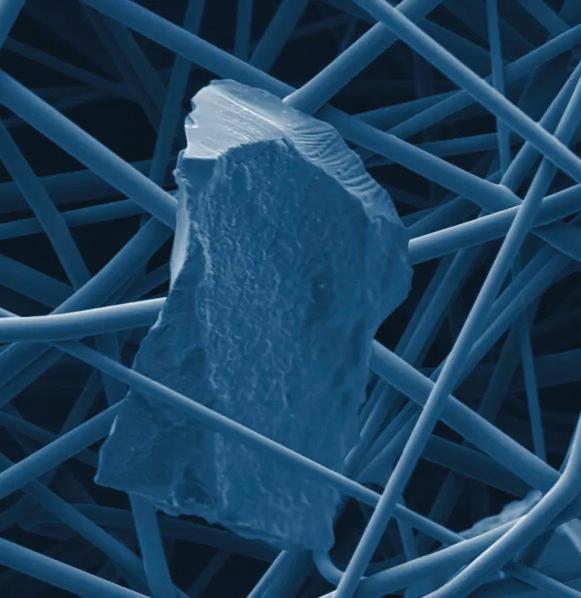

Donaldson Company, Inc., a leading worldwide manufacturer of innovative filtration solutions has released Alpha-Web ® filtration media. This new hydraulic filtration technology significantly improves hydraulic fluid cleanliness which can extend hydraulic component life, decrease downtime and lower the cost of equipment ownership.

Filters must stand up to the challenge of maintaining fluid cleanliness and system protection against frequently changing flow rates prevalent in real-world operating conditions. AlphaWeb filtration technology features a first-of-its-kind fine-fiber layer to trap and lock particles during frequent flow-rate changes, delivering transformational improvement in hydraulic equipment protection. Advanced contaminant retention results in cleaner oil and helps ensure that equipment will continue to perform better, and longer, with a lower risk of wear, damage and unplanned downtime. www.donaldson.com

In response to growing demand for flexibility in process water treatment, Marmon Industrial Water recently launched the Graver mPowdex ® Condensate Polishing Trailers. As the first precoat filter demineralizer on wheels, the mPowdex® system will allow plants to reuse and recover steam condensate on an as-needed basis, providing water, energy and capital savings across manufacturing sectors, including power generation, refining and petrochemical applications.

“The Graver name has been synonymous with condensate polishing for over half a century,” said John Yen, Director of Strategic Marketing & Innovation at Marmon Industrial Water. “Now more than ever, plant managers and operators are in critical need of efficient water treatment technologies that can be deployed quickly, due in part to new environmental regulations, aging infrastructure, and capacity increases. Graver mPowdex® is the solution and we are thrilled to continue sharing our expertise with the sector.” mPowdex ® is a precoat filter demineralizer that combines ion exchange and filtration to remove solid and dissolved particulates, such as iron and copper, from high-value process steam. By removing these contaminants, it protects costly generation assets, such as turbines and deaerators, and maximizes plant uptime. This form of condensate polishing has also been shown to drastically reduce the frequency of required blowdowns, where large amounts of water, energy and labor are lost. www.graver.com

LG Chem announced that the company has shipped more than 10,000 RO membranes to the Guoan lithium extraction project led by CITIC Group, China’s largest state-owned investment company. The Guoan project, which kickstarted its full-scale operation in Qinghai province this year, is the largest salt lake lithium extraction project in China.

TUS-Qingyuan which manages the lithium extraction project across engineering, procurement, and construction (EPC), expects to produce 20,000 tons of lithium carbonate annually by using LG Chem’s RO membranes. This is equivalent to manufacturing batteries for nearly half a million EVs. In addition, this is the world’s largest lithium extraction project using a filtration device.

RO membranes significantly reduce the amount of energy required for lithium production. To obtain lithium dissolved in salt lakes, water must be evaporated to increase its concentration which had been per- formed by applying heat to remove water. With the reverse osmosis process using RO membranes, however, it allows quick filtering out the water molecules without applying heat.

Five out of nine salt lake lithium extraction projects in China adopted the RO membrane method. As a result, the RO membrane market in China expects to grow by more than 8% each year. www.lgchem.com