5 minute read

Securing the Future of CARBON CAPTURE

Direct Air Capture – Technology and Climate Ambition in Alignment

By Adrian Wilson, International Correspondent, IFN

In the One Big Beautiful Bill Act (OBBBA) signed into law by President Donald J. Trump on July 4th this year, the U.S. government reaffirmed its continued support for direct air capture (DAC) – the emerging new industry aiming to filter legacy carbon dioxide (CO2) emissions from the atmosphere.

Deregulation

On one level, this is surprising. Back in March, incoming U.S. Environmental Protection Agency (EPA) administrator Lee Zeldin announced no less than 31 actions in just a few hours, intended to shred almost every major environmental rule in place in the USA. They include a move to halt the plan to cut pollution from coal-fired power plants as well as revisiting pollution standards for cars and trucks, which Zeldin said had imposed a “crushing regulatory regime” on automotive companies.

“Today is the greatest day of deregulation our nation has seen,” Zeldin claimed. “We are driving a dagger straight into the heart of the climate change religion to drive down the cost of living for American families, unleash American energy, bring auto jobs back to the USA and more. The Biden and Obama era regulations now being reconsidered have suffocated nearly every single sector of the American economy.”

Commercial-scale DAC is, in addition, very much former President Joe Biden's baby. Back in August 2023, Biden announced up to $1.2 billion in funding to advance the development of two initial facilities in Louisiana and Texas. These represented the first selections of his administration’s highly ambitious DAC Hubs program, aiming to kickstart a nationwide network of large-scale carbon removal sites to address legacy CO2 pollution and complement rapid emissions reductions.

Smokescreen

At the same time, however, many environmental groups and scientists have opposed DAC as simply a smokescreen to enable the major oil companies to continue with business as usual.

This move certainly dovetails with President Trump’s encouragement to “drill baby, drill.”

The OBBBA significantly narrows the window for full-value tax credit eligibility for wind and solar projects while maintaining the 45Q tax credit of $85 per ton for CO2 sequestered by established carbon capture and storage (CCS) technologies at industrial sites and $180 per ton for that captured via DAC.

Going a stage further, CCS CO2 used or converted into valuable products or injected and geologically stored in a qualified enhanced oil recovery or natural gas recovery site will qualify for the same higher dollar value credit as DAC CO2.

Restrictions

The OBBBA also introduces new restrictions on ‘Foreign Entities of Concern,’ which could prove problematic going forward, since the company currently at the forefront of DAC technology is Zurichheadquartered Climeworks and the biggest mass producer of dedicated filters for the technology is Vancouver-based Svante Technologies.

At the time of going to press, the Trump Administration had slapped tariff charges of 39% and 35% on goods imported to the USA from Switzerland and Canada respectively.

Climeworks

In July this year Climeworks secured a further $162 million in new funding – the largest carbon removal investment round globally to date this year – to take its total funding to over $1 billion.

“Direct air capture has gone from experiment to essential and we’re focused on scaling it by driving down costs and pushing innovation,” said co-CEO and cofounder of Climeworks Christoph Gebald. “Our hybrid model builds long-term demand while generating cash flow today, helping us grow a market that investors now see as inevitable. Crossing the $1 billion equity mark isn’t just a milestone – it shows that carbon removal is real, needed and here to stay.”

In May 2024, Climeworks launched Mammoth, its second DAC facility in Iceland and the largest to date, with a planned annual capacity of 36,000 tons once fully operational.

Benefits

The key benefits of DAC, according to Climeworks, are that it is locationindependent, highly scalable, and measurable, and enables efficient land usage.

CO2 is in the air at the same concentration everywhere in the world which means that DAC plants can be located anywhere as they do not need to be attached to an emissions source. They are only required to be placed near a renewable energy source and in a place where CO2 can be stored.

Climeworks plants are based on a modular technology design, making them highly scalable and they require less land than other CO2 capturing methods. The planting of trees is the most obvious and natural way of absorbing carbon, but on a land area of less than half an acre, a Climeworks plant can remove 4,000 tons of CO2 from the air every year, which is almost 1,000 times more effective than trees. The same land would host around 220 trees with an estimated capacity of 22kg each – only 4.62 tons of CO2 per year.

The company further points out that direct air capture and storage (DAC+S) is often confused with CCS, but the two are very different. CCS captures CO 2 emissions at a point source, for example, a smokestack at a power plant, where the aim is to offset carbon emissions as they’re being released into the atmosphere. DAC+S works instead to remove unavoidable and historic CO2 emissions already present in the atmosphere.

3M aims to scale to thousands of miles of the MOFs-containing filter material for Svante over the next few years. Svante

In Iceland, the geological storage of CO2 from the two Climeworks plants is dissolved in water before being injected into the ground, where it reacts with rock to form solid carbonate minerals.

Technology

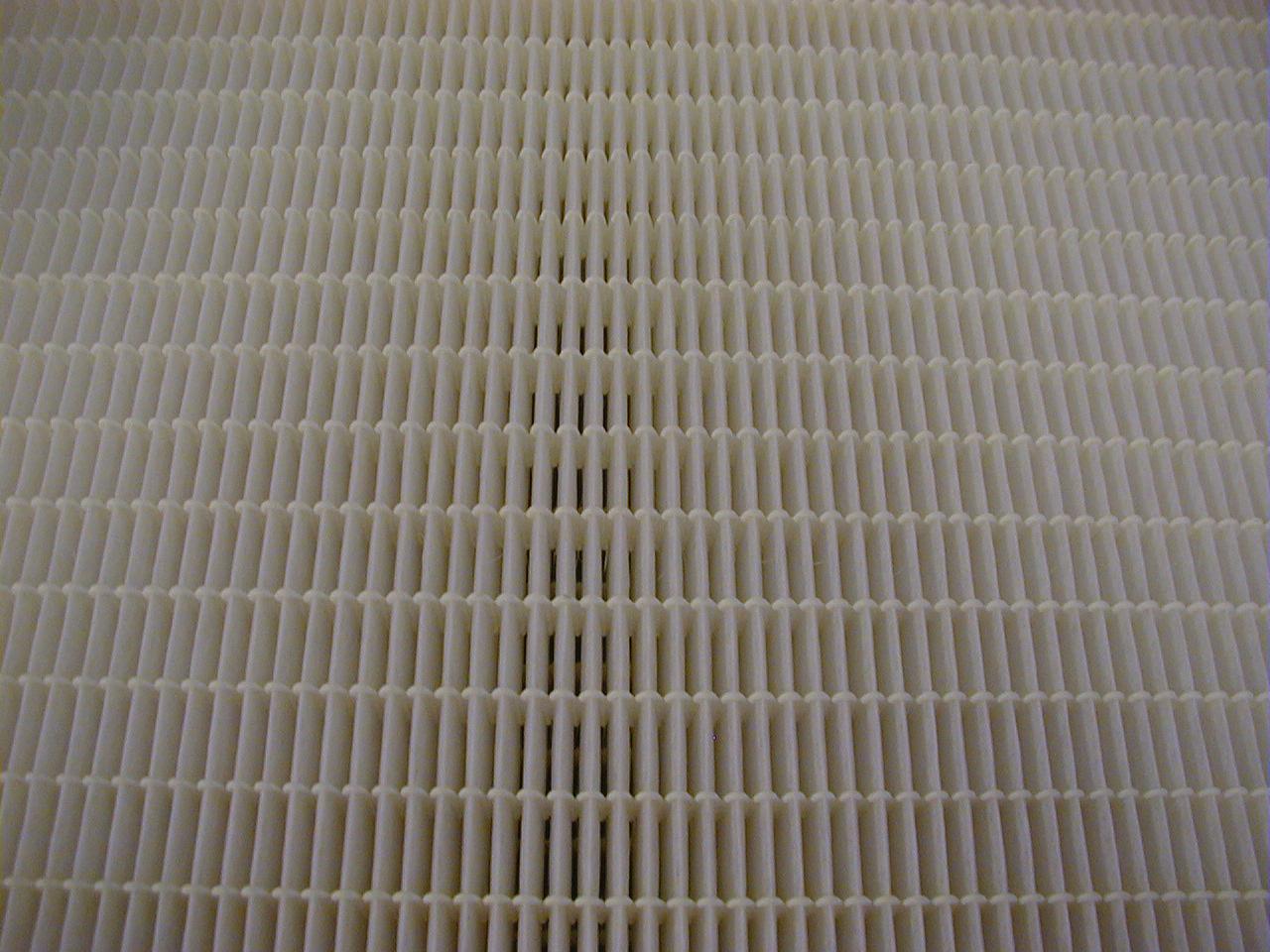

There are a number of different DAC technologies for filtering CO2 from the air but the most promising to have emerged are based on MOFs – metal ions and organic ligands that form a three-dimensional structure with a high surface area and well-defined pore size and porosity. These properties make MOFs ideal for gas storage and separation, including carbon capture, and they can be effectively encapsulated in nonwoven fabrics.

Other potential applications for MOFs include chemical feedstock preparation, direct lithium extraction, improving HVAC filtration and refrigeration reclamation.

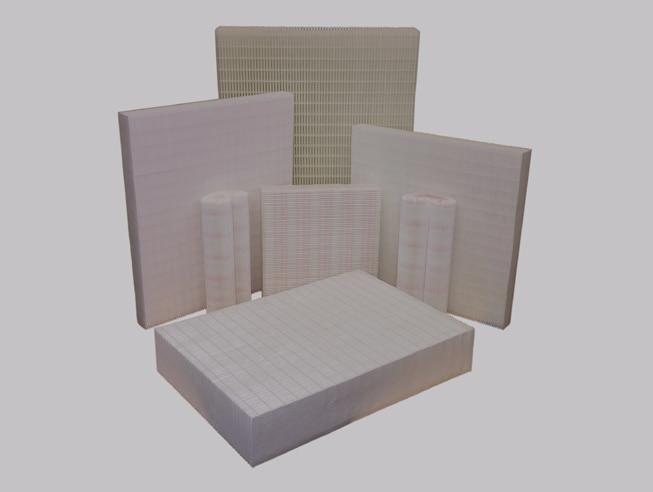

In May 2023, 3M, headquartered in Saint Paul, Minnesota announced a partnership with Svante Technologies to mass produce MOF-embedded nonwoven sheets. These sheets can be stacked into high-performance filters designed for both industrial point-source and DAC. Svante is also collaborating with BASF, headquartered in Ludwigshafen, Germany, to scale up the production of the crucial MOF sorbents. These tailor-made solid sorbents have an exceptionally high storage capacity for CO2 – a sugar-cubesized quantity of the material boasts the surface area of a football field.

Additionally, Svante has developed structured adsorbent filters capable of capturing and releasing CO2 in under 60 seconds – a significant improvement over other solid sorbent technologies, which can take hours.

Stepping Up

In May this year, Svante officially completed the commissioning of its new Centre of Excellence for Carbon Capture and Removal manufacturing facility (Redwood) in Burnaby, British Columbia.

The Redwood plant spans 141,000 square feet and is equipped to manufacture enough solid sorbentbased filters to capture up to 10 million tons of CO 2 annually –equivalent to the emissions of more than 27 million cars.

In addition to manufacturing filters for Climeworks and DAC, Svante is also targeting biogenic carbon dioxide removal (CDR) for sectors like pulp and paper, ethanol production, and waste-to-energy, where carbon concentrations in postcombustion flue gas are higher, and capture costs are lower, to generate CDR credits.

Capturing the emissions from other industries such as cement, steel, and fossil fuels is an essential part of a sustainable energy transition. With the commissioning of Redwood, Svante is stepping up to the challenge. The plant’s launch follows a $145 million capital investment.

Svante’s technology is already powering several major carbon capture pilot projects, including installations at oil and gas major Chevron’s Kern River plant in the San Joaquin Valley in California.

“The Redwood gigafactory is a critical step forward in building the infrastructure necessary to scale up the carbon management industry and to build a marketplace for physical CO2,” said Claude Letourneau, president and CEO of Svante. “This is a demonstration of what’s possible when technology and climate ambition align to lend nature a hand in managing global CO2 emissions.”

Adrian Wilson is an international correspondent for International Filtration News . He is a leading journalist covering fiber, filtration, nonwovens and technical textiles. He can be reached at adawilson@gmail.com.

& ASHRAE

Pleat heights 1/2” to 12” upto 39” wide. Interrupted beads, many configurations.

Mini-Pleat: H.E.P.A. & ASHRAE

Pleat heights 3/4” to 4” upto 25” wide. Interrupted beads, many configurations.