12 minute read

COMPLEX WITH A LONG FINISH

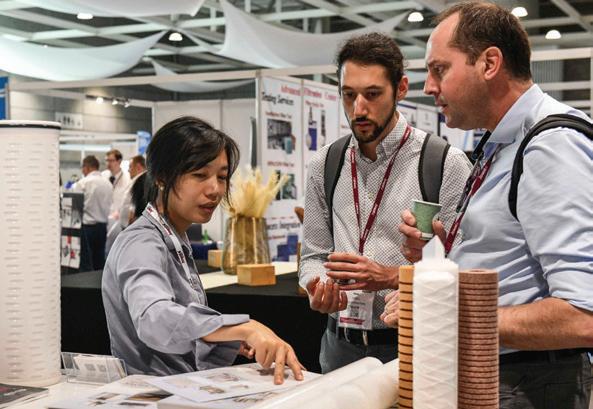

With wine-soaked Bordeaux, France serving as the host region with all it offers, the 14th edition of the World Filtration Congress held in July 2025 was well-attended by international filtration professionals, coming for WFC’s networking, education and expo.

WFC14 opened with remarks from Chairman Pascal Ginisty, IFTS, and Professor Pierre-Yves Pontalier, INP, Toulouse. Members of the organizing committee followed with thoughts on the Congress, which drew approximately 700 participants from 47 countries and six continents together.

Vincent Edery, Managing Director, IFTS, set the tone for attendees, “Your presence from across continents is a powerful testament to the global importance and scientific vitality of our field. Whether you come from academia, industry, public research institutions, you are part of a community united by a common goal to push the boundaries of what filtration and separation science can achieve.

“At its core,” Edery continued, “this Congress is much more than an industry event. It is a scientific forum, a platform

a Fine Bordeaux Wine, WFC14 Delivered a Wide Variety of Complex and Bold Advancements to Congress Attendees

By Caryn Smith, Publisher & Chief Content Officer, IFN

where fundamental research meets application and innovation, where emerging technologies are presented and challenged, and where rigorous peer-topeer exchange helps us move the entire discipline forward. Across plenary sessions, technical presentations, posters, the exhibition and panel discussions, we witness the latest breakthroughs in material science, membrane technology, particle characterization, modeling and simulation, process optimization and much more.

“We’re also witnessing a growing interdisciplinary convergence – where filtration research now contributes to fields as diverse as chemistry, physics, biology, data science and environmental engineering,” Edery said. “This scientific crossover is not only enriching, but essential, as the challenges we face today are complex and multi-faceted, such as clean water, clean air, efficient use of resources, environmental protection and public health.

They are no longer optional goals. They are global imperatives, and they cannot be achieved without robust, reliable and constantly improving filtration solutions. That’s why research presented is not just important for our field, but for society as a whole.”

WFC14 marked 50 years since the inaugural World Filtration Congress was held in Paris in 1975. Called upon to speak as an attendee of the first Congress was Roger Ben Aim, IFTS Founder and WFC14 organizing committee member, who emphasized the power of connecting face to face in this age of digital communication.

“I strongly believe that this conference is really the place for having real contact –talking and being with colleagues, which is very important, and especially in the mixing of generations. There is a growing majority of the younger generation really engaged in research activities of this field. For those researchers, they can have meaningful engagement with the eldergeneration professionals. I believe that this is the main interest of the conference.”

Plenty of Plenary

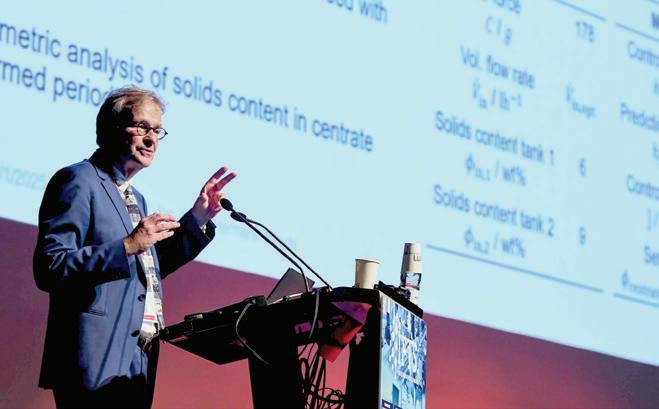

Plenary Lecturer Herman Nirschl, from the Karlsruhe Institute of Technology (KIT), spoke on “Autonomous Processing in Separation Technologies” in the first session of the event. The focus of the work was on filtration, centrifugation, as well as mixing technology and agglomeration. The lecturer presented a deep look at technologies like digital twins and digitalization, and how it would be possible to introduce autonomous processing, not just in separation technologies, but in general for processes, emphasizing the challenges in various industries like mining, beverages, and electro-mobility.

He highlighted the use of AI and machine learning to improve process efficiency and accuracy, particularly in centrifuges and decanters. Examples included scaling up simulations from small devices to large-scale machines, using gray box models to combine white and black box models, and optimizing energy consumption. He also covered the importance of online measurement devices and control systems to achieve autonomous processes, reducing operator intervention and improving product quality.

“The goal is that we get resource and energy-efficient operations for a high product quality, and without any intervention of operators,” he said. “We have already done some parts of our processes. They are driven by computers, but it’s very hard with particle processes, because the conditions are changing all the time, and we also have distributed properties. We always have particle size distributions. We have different surfaces, different volumes and so on. We have changing properties, so how can we achieve this?” He noted, “With AI, we have a possibility to correct our computations. Now this helps us because there’s some information included which never gets into an integration.”

Plenary Lecturer Hervé Buisson spoke on “Water Filtration: Challenges and Opportunities in the Age of Sustainability.”

Buisson is a globally recognized expert in water and wastewater treatment with over three decades of industry experience. He is a Manager of Veolia’s Corporate Research Centre in France and Vice-President of Process Engineering for Veolia Water Technologies Americas.

He emphasized the importance of modularity in water treatment systems to enhance durability and adaptability, especially in the face of climate change and extreme weather events. His key points included the need for robust design to handle increased storm frequency, the development of sustainable processes to minimize energy consumption and raw material use, and the integration of advanced analytical techniques for pollutant detection and removal. The challenges like disposal of disposable filters and the dewatering of waste-activated sludge were also highlighted, with a call for collaborative efforts and innovative solutions to address these and other issues.

“In sustainability, the first consideration was energy consumption, and today we are still really chasing energy,” he notes. “Energy is key for the economy of many countries, so we are still trying to minimize the energy consumption of our processes. One part of it is ‘fit for purpose.’ Do not over design the water plant that you want to do, because it will be a cost on energy. But we have to go beyond energy.”

He suggested the development of durability indexes, KPIs, and best practices to address climate change impacts on water treatment systems; the need for better integration of features to meet customer demands and to develop more sustainable solutions; the development of more sustainable filters, as well as new filtration equipment, advanced sensors, and diagnostic tools to improve plant operations and provide preventive maintenance. He also suggests the need to design filters with fewer components to facilitate recycling and addressing systems as a whole to improve water treatment efficiency and sustainability. Finally, Buisson advocated for stronger measures, especially in choice of raw material usage to pre-qualify material availability. This will help to determine future access and cost considerations. He further stressed the need for detection of pollutants at very low concentrations, the removal of microplastics and other micro pollutants from water, deeper consideration of the positives and negatives of process choices, as well as the critical importance of collaboration between different utilities to determine the impacts of upstream processes on downstream operations.

Plenary Lecturer Kenneth Winston is a recognized expert in the sectors of Energy, Fuels, and Chemical Projects, with business development and process engineering degrees and experience. He works as a Senior Application Engineer for Calgon Carbon, part of Kuraray, a global manufacturer of chemicals, fibers, and specialty materials.

He walked attendees through the technology-drivers and current global industrial projects and investments, that include technologies for reducing and reusing carbon dioxide to green and renewable fuels and chemicals. He looked at modern gas processing innovations and technologies for carbon capture and reuse, renewable energies, green fuels and chemicals in fast-moving projects, and focused on ecological footprint investments.

He discussed the complex energy industry with the fluctuations caused by the regulatory and market impacts. The conversation also touched on the challenges of scaling up renewable fuels, such as ethanol and bio gas, and the need for research on super critical CO2 contaminants. He concluded with a focus on the potential of hydrogen, particularly for maritime and industrial applications, and the importance of continued research and policy support.

“The new commodities to watch, the new research that we need to be doing, is hydrogen, ammonia, methanol and ethanol. So let’s take a quick look at the chemical processing. In the green and blue hydrogen projects around the world –once the field levels – it will leave 355 high probability projects for green and blue hydrogen. The chemical processes industry continues on. As I mentioned, there’s ammonia and methanol. Once the project probability is calculated, we still have 89 high ammonia and methanol projects.

“The engineers working on these projects need research, data, and support,” he continued. “They can ask for equipment from the equipment vendors, but a lot of times there’s no data. All of us who design equipment regularly, we read paper after paper to try and keep up and find the data that we can to design these systems. And more than likely, we’re going to recommend a pilot unit because we don’t have good data. That raises the cost of the facility and slows implementation. Technology and data deficits are reasons that we have the low probability projects. Sometimes it’s not that we run out of money, we just don’t know how to build it yet.”

Plenary Lecturer Dr. Christine Sun, President, with Dr. Iyad Al-Attar, Strategic Director, of World Filtration Institute highlighted how filtration is fundamental to providing clean air and ensuring water quality suitable for a myriad of applications. The duo underscored the innovative solutions their organization is pioneering to tackle some of the world’s most pressing environmental challenges.

“Filtration is more than just a process; it is a cornerstone of a sustainable and healthy future,” said Dr. Sun. “From the air we breathe to the water we drink, filtration is essential to protect public health and preserve our planet’s delicate ecosystems.”

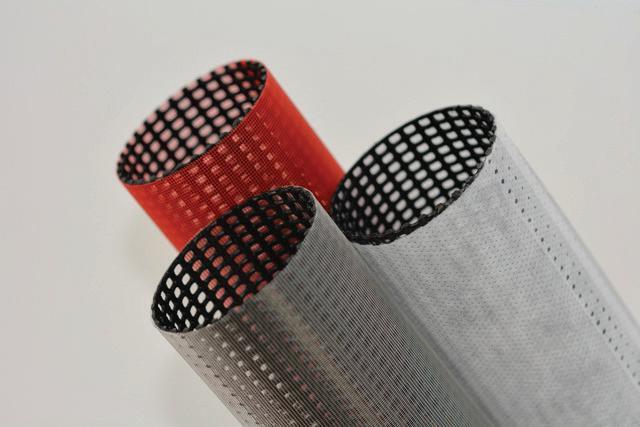

Custom plastic filtration netting, mesh screens, and cores with various configurations and pore sizes.

• Rigid plastic cores

• Flexible tubular sleeves

• Flow channel spacers

• Media, pleat support

• Welded tube overwraps

• You design it, we create it!

Dr. Al-Attar, also a writer for the IFN, elaborated on the strategic importance of investing in filtration research and development.

“Our work redefines the capabilities of filtration technologies while highlighting the collective responsibility we all must embrace for more sustainable, energy-efficient, and environmentally friendly living,” he stated. “By advancing the limits of what is achievable, our children and grandchildren can enjoy a planet much cleaner than the one they could inherit and dream of a sustainable future worth fighting for.”

Throughout WFC14, attendees enjoyed sessions from seven educational tracks, complete with cutting-edge research presentations, as well as networking with vendors at the WFC Exposition and special social opportunities. Look for articles from presenters of agenda sessions to be featured in future editions of the IFN.

Atlas-SSI Expands Capabilities with Acquisition of WTR Engineering

Atlas-SSI, Inc., North America’s premier provider of water management solutions, announced the strategic acquisition of WTR® Engineering, a trusted leader with over 100 years of expertise in mechanical water filtration. This acquisition enhances Atlas-SSI’s ability to provide comprehensive and robust water management solutions across diverse industries, including municipal, industrial, utility, and commercial sectors.

WTR Engineering is widely recognized for its expertise in identifying and solving complex water filtration issues, such as raw water intakes for industrial plants, condenser protection for power plants, and headworks challenges in sewage treatment facilities.

Atlas-SSI will leverage WTR’s deep technical knowledge and proven track record to enhance its product offerings, including the Talon Rake®, traveling water screens, fish-friendly screens, debris handling equipment, wastewater headworks, and stormwater management systems. Additionally, this acquisition provides Atlas-SSI with enhanced capabilities, further solidifying its role as an industry leader in sustainable water management. www.atlas-ssi.com

PowerChina Wins $4 Billion Contract for Iraqi Desalination Plant

PowerChina has won a contract worth around $4 billion to build Iraq’s first large-scale seawater desalination plant in the southern city of Basra, in partnership with an Iraqi company, officials said.

Iraqi Prime Minister Mohammed Shia al-Sudani inaugurated the project, which will have a daily capacity of 1 million cubic meters and is expected to begin commercial operations in June 2028. The plant is part of government efforts to address severe water shortages in the southern region.

The project also includes the construction of a 300-megawatt power plant to supply electricity to the desalination facility, according to two Iraqi officials.

Italian Pump Manufacturer to Become Part of Atlas Copco Group

CRI-MAN S.p.A., an Italian pump manufacturer, will become part of Atlas Copco Group.

CRI-MAN was founded in 2000 and is located in Correggio, Italy. As part of the acquisition, 85 employees will join the Atlas Copco Group.

The company manufactures and sells chopper pumps, separators, and mixers for anaerobic flow, processing slurry in biogas, and domestic and industrial wastewater treatment plants. Main customers can be found within the biogas and wastewater industries.

The purchase price was not disclosed and in 2024 the company had revenues of approximately 30M Euro.

The acquisition is subject to regulatory approval and is expected to close during the fourth quarter of 2025. The company will become part of the Industrial Flow division within the Power Technique Business Area. www.atlascopcogroup.com

Doug Kirby Joins Tri-Mer Corp. Sales Team

Doug Kirby, Production Manager at Tri-Mer Corp., has become the company’s newest sales engineer. Kirby spent 12 years at Tri-Mer mastering every facet of manufacturing air pollution control equipment before being tapped for the production management position in 2017. In his new post, Kirby will manage projects for several of the company’s largest customers in the semiconductor and alloy manufacturing sectors.

Tri-Mer is a manufacturer of equipment for control of air emissions from industrial and municipal sources, such as particulates, process gases, heavy metals, toxic fumes, odors and oil mists. www.tri-mer.com

Centrisys/CNP Opens New 70,000-Square-Foot Building in Wisconsin

Centrisys/CNP, a leading North American manufacturer of decanter centrifuges and advanced biosolids treatment technologies, recently celebrated the ribbon-cutting of a new 70,000-square-foot facility on its Kenosha campus. Known as “Building 4,” the addition increases Centrisys/CNP’s total footprint to approximately 300,000 square feet and represents a significant investment in U.S.-based manufacturing, advanced service capabilities, and the company’s long-term growth strategy.

From the ribbon cutting of the Centrisys/CNP expansion in Wisconsin.

The expanded space supports Centrisys/CNP’s production and repair of its largest centrifuges to date, while also providing dedicated space for aftermarket services and its growing rental fleet support. As utilities and industrial clients shift toward largerscale systems, the facility is designed to help meet increasing demand with improved turnaround times, greater in-house capacity, and enhanced customer support.

“This expansion reflects both the momentum of our business and our commitment to building solutions here in the U.S.,” said Michael Kopper, CEO and Founder of Centrisys/ CNP. “With new technologies, additional manufacturing space, and increased service capabilities, we’re in a strong position to support larger projects and continue providing the high level of responsiveness our partners expect.” www.centrisys-cnp.com

Asahi Kasei’s Microza Membrane Division Receives EcoVadis Gold Rating

Japanese technology company Asahi Kasei announced that its Microza & Water Processing Division, which provides Microza® hollow-fiber membranes for filtration and separation, received a Gold rating in the EcoVadis sustainability assessment conducted in June 2025. EcoVadis is a sustainability assessment company based in France that performs the review annually. This rating places the Asahi Kasei division among the top 5% of all entities assessed.

Microza® is used broadly in two areas: water treatment processes, such as water purification and wastewater/industrial water reuse; and industrial processes, including filtration and separation in biopharmaceuticals, pharmaceutical water, food, and industrial chemicals. By providing membrane technology for these applications, Asahi Kasei contributes to improved productivity, reduced environmental impact, and effective utilization of limited water resources.

The EcoVadis assessment evaluates corporate sustainability initiatives across four categories: Environment, Labor & Human Rights, Ethics, and Sustainable Procurement. This assessment targeted manufacturing at the Microza® Fuji Plant and related supply and value chain activities. The Microza & Water Processing Division received particularly high marks in the Environment category.

EcoVadis ratings are based on international sustainability standards and have been awarded to over 150,000 companies across 185 countries and 250 industries. The EcoVadis evaluation has become a globally recognized benchmark for objectively assessing corporate sustainability efforts. www.asahi-kasei.com

Filter King Opens New Manufacturing in Pennsylvania

Filter King LLC, a leading manufacturer of UL-certified custom HVAC filters, announced the grand opening of a state-of-the-art manufacturing and distribution center in Bethlehem, Pennsylvania. The announcement comes hot off the heels of the February launch of its Las Vegas, Nevada plant, and last year’s opening of its Miami, Florida headquarters and production facility. The 61,600 square-foot Bethlehem facility, equipped for production, warehousing, and distribution, significantly enhances Filter King’s ability to serve the Northeast’s growing demand for premium air filtration solutions.

“Our goal is to reach the entire continental U.S. with next-day delivery. With the addition of the Pennsylvania facility,

Hengst Filtration Acquires Chinese Air Filtration Specialist CSC Tech

Germany-based company Hengst Filtration has taken a further step in its transformation from automotive supplier to filtration specialist in new areas. The company has signed an agreement to acquire the Chinese air filtration specialist CSC Tech, making it a full-service provider for the semiconductor industry.

CSC Tech manufactures fan filter units (filter-fan units) as well as HEPA and ULPA filters for the clean room production of Chinese and Taiwanese microchip manufacturers and electronics production. This ideally complements Hengst’s expertise in the field of particle and harmful gas filtration, as well as trace gas filtration at Artemis Control AG. In the future, the Hengst Group will therefore offer a full range of products for cleanroom and semiconductor production.

Like Hengst China, CSC Tech is based in the Yangtze River Delta (Shanghai, Jiangsu, Zhejiang and Anhui): Administration and sales are in Suzhou, a city with a population of 13 million, while production is located in Kunshan, which is part of Suzhou. Hengst also has its two Chinese locations in Kunshan and further north in Jinan (Shandong province). www.hengst.com which means we now have a total of 200,000 square feet of operational space across three states and a workforce of more than 125 employees, we are well on our way to achieving this goal,” said Rick Hoskins, Founder and CEO of Filter King.

Strategically located in the Lehigh Valley, the Bethlehem site was chosen for its proximity to major metropolitan areas, including Philadelphia and New York City, placing it within a sevenhour drive of 40% of the U.S. population. The facility’s access to robust transportation networks and a skilled local workforce supports Filter King’s rapid expansion and commitment to operational excellence, and commitment to American manufacturing. www.filterking.com

FEB 2 -4 2026