17 minute read

Q+A

IN THIS ISSUE: JUHO UZKURT KALJUNEN

CEO, NPHarvest

Finnish Cleantech NPHarvest, Specializes in Recovering Nutrients from Wastewater with up to 90% Efficiency.

By Caryn Smith, Publisher & Chief Content Officer, IFN

significant expansion potential for nutrient recovery technologies.

More clever marketing boasts: “Invest in the Future of Wastewater. Literally. ... Our startup is building scalable, researchbased tech that turns sewage into circular economy wins. If you’re looking for returns with impact, this is where the sh*it gets serious.” And while their marketing lingo is light and catchy, this team is serious about their core mission to get more from wastewater.

They cite key reasons this makes sense for water treatment operators:

• Russia’s share of EU fertilizer imports has grown from 17% in 2022 to 30% now. In 2024 alone, imports rose by more than 33% to around $2 billion (€1.75 billion). With the EU announcing new significant tariffs on Russian fertilizers, European agriculture is facing the prospect of fertilizers doubling in cost by 2028.

• Pressure to find alternative sources is at an all-time high to prevent further economic volatility for millions in the EU and ensure food security, a critical building block for Europe’s defense.

• The modular technology produces high-purity ammonium sulfate and amorphous calcium phosphate, both essential raw materials for fertilizer production, by utilizing hydrophobic membrane stripping. The process operates without the need for heating, pressure, or aeration, relying solely on alkaline and acid dosing, which makes it highly cost-efficient and easy to operate.

Academic Beginnings

NPHarvest started as a research project at Aalto University in Finland and made the significant jump to a full-fledged company in March 2023. In April 2024, they met the next milestone by raising €2.2M to take their proprietary nutrient catcher machine to the market. The round was led by Nordic Foodtech VC, with participation from Stephen Industries and Maaja vesitekniikan tuki ry. It consisted of a €1.3M equity investment and a €900.000 grant from the Finnish Ministry of the Environment and their RAKI program.

A supporter of this effort, Hamse Kjerstadius, Development Engineer of Swedish NSVA, Northwest Skåne Water and Wastewater, said, “As a public water utility, NSVA needs to pursue climate neutrality to benefit the municipalities we work for. NPHarvest’s technology for nitrogen and phosphorus recovery has the potential to allow increased nutrient recovery from wastewater, which is a promising method that can aid our municipalities in reaching reduced climate impacts.”

Continuing that thought, NPHarvest CEO Juho Uzkurt Kaljunen says, “The entire water management market in Europe is estimated to be worth around 170 billion euros, and the concentrated water management market in the EU is worth approximately 47 billion euros. We are excited to enter the next stage of our company’s journey together with our investors, enhancing food security, creating better environmental impacts, and making wastewater management and nutrient catching a profitable business,” he concluded.

Partners in the effort include Federico Varalta, with over two decades of experience in the organic waste and wastewater sectors, and a rare combination of technical expertise and commercial attention toward clients’ needs. His career spans five countries and roles across plant design, project execution, and company leadership – from managing complex infrastructure builds to leading market entries in the Middle East and Europe. At NPHarvest, his instinct for sales benefits his role leading all commercial activities, using his deep sector knowledge, sharp prioritization, and straight-talking style to build momentum and unlock opportunities across the market.

Burak Yirmibesoglu has over a decade of experience in the biogas and cleantech sector. He has founded and run his own consulting company, Earthtech Oy, and worked across sales, project development, and research roles for biogas and wasteto-energy projects throughout Europe and the Middle East. At companies like Doranova and BiogasWorld, Burak has built tenders, developed markets, and represented international networks. At NPHarvest, he manages everything from demo unit construction to daily operational needs.

Dr. Juho Uzkurt Kaljunen is one of Europe’s leading experts in nutrient recovery from liquid waste streams. This scientist didn’t set out to become an entrepreneur, but did so out of sheer commitment to getting his innovation into real-world use. With a PhD in environmental engineering from Aalto University, Juho’s academic work has been widely recognized, including a dissertation ranked among the top 10% in its field and over 10 peer-reviewed publications.

Over the past decade, he has designed, built, and operated pilots across lab and industrial settings, directly laying the technical foundation for NPHarvest’s technology. His technical depth, work ethic and calm decisiveness provide the total committed leadership needed to move the project forward.

International Filtration News spoke with NPHarvest CEO Juho Uzkurt Kaljunen to get the details of this exciting breakthrough project.

International Filtration News: Share how the business started, and went from a research project to a startup company.

Dr. Juho Uzkurt Kaljunen: We had been working on the research for about four years at Aalto University when the team at Aalto Innovation Services said, “This could be something more than just a paper.” They encouraged us to start thinking about patents and commercialization.

That’s when the idea of turning this into a business started.

The more we engaged with industry, the clearer it became that there was real interest. The operators at our research test sites were asking when they could get this solution at full scale – that feedback really pushed things forward.

Things changed when we received funding from Business Finland to explore commercialization. That support allowed us to bring in business developers and establish a startup. During that 1.5-year phase, my co-founders joined the team. And eventually, in 2023, the company was officially founded by the three of us along with the professor who had led our research group, Professor Anna Mikola.

That’s how NPHarvest moved from a lab concept into a real business – with a mission to bring environmental science into practical, scalable use.

IFN: Share about the company’s co-founders and how they came together to create this new company.

Dr. Kaljunen: I was a researcher through and through – I didn’t plan to become an entrepreneur. As the research progressed and the technology started showing real promise, I realized that if I wanted this innovation to make an impact beyond academic papers, I had to find a way to bring it into the real world. That’s ultimately why NPHarvest was founded.

I knew from the beginning that we’d need strong expertise in business and a deep understanding of the key clients to succeed. That’s when Burak and Federico joined.

Burak had over ten years of experience in the biogas sector, especially in sales and customer work, and he immediately understood the value of what we were building and how it could fit into the existing industry landscape. His entrepreneurial background didn’t hurt. Federico joined soon after Burak, bringing more than 20 years of experience in managing international projects in organic waste and wastewater – precisely the kind of operational leadership we needed to turn a research concept into an industrialscale product.

It’s been a great mix: I bring the technical background and the original vision, and Burak and Federico bring the commercial and operational expertise to actually make it happen. We all share the belief that nutrient recovery is essential – not just scientifically interesting, but necessary for a more sustainable and selfsufficient future.

IFN: Explain the business model and mission of the company. What is the current and future target market, and how will you be helping that segment with filtration?

Dr. Kaljunen: At NPHarvest, our mission is simple: we make wastewater valuable so that society and nature can coexist in harmony. Today, nutrients like nitrogen and phosphorus are seen as pollutants in wastewater, even though they’re essential for food production. Our goal is to change that by recovering those nutrients and turning them back into assets.

Our business model is twofold. First, we design and sell our patented nutrient recovery units – called Nutrient Catchers – to wastewater-intensive sectors like biogas plants, animal farms, and municipal treatment facilities. That’s the technology side. The second layer is about the nutrients. Many of our customers don’t want to manage the recovered materials, so we’re also developing services for nutrient valorization – collecting, refining, and selling those nutrients as raw materials or even ready-made fertilizers.

This dual model allows us to create value in both directions: we help reduce the operational and regulatory costs of wastewater treatment, and we generate a new revenue stream from nutrient reuse.

In terms of the target market, we’re currently focusing on Europe because its environmental regulations are fairly coherent across countries. Our first commercial Mini unit is already running on a Dutch dairy farm, and our Demo unit is commissioned at a biogas plant in Ankara, Türkiye.

We’ve also built strong distributor relationships in key markets like Italy, Sweden, the Netherlands, and Spain, so we’re ready to scale.

In the future, we see major opportunities beyond Europe, first in other regions with robust existing regulation on nitrogen discharges or where there’s interest in more circular and self-sufficient agriculture. We want to make nutrient recovery profitable so that regions that otherwise would pollute the environment with excess nutrients would start recovering the nutrients instead.

There is a small misconception regarding filtering, although the difference is almost semantics. We do not technically filter (water does not go through a mesh), but we strip. Our process is based on hydrophobic membranes that allow gases to pass but repel water. Ammonia is the gas that passes through the membrane wall and reacts with an acid on the inside of the membrane fiber. Ammonia and acid react into a salt that is our end product.

IFN: As a “Nutrient Catcher,” why is “food security” an essential element in your company’s objectives? Where did that initiative stem from as your company formed?

Dr. Kaljunen: Food security wasn’t actually relevant at the beginning. Back in 2016, our goal was to make wastewater treatment more environmentally sustainable to reduce pollution and recover nutrients simply because it was the right thing to do for nature. But by the time we founded NPHarvest in 2023, the world had changed significantly.

The war in Ukraine made it clear that global supply chains, especially for critical resources like fertilizers, can’t be taken for granted. What started as an environmental solution also became a question of strategic independence. Nutrient recovery isn’t just about preventing eutrophication or N2O emissions. It’s about enabling countries to produce fertilizers locally, without relying on imports from politically unstable regions.

As a Finnish company, that shift in perspective felt very natural. Finland shares a long border with Russia, and we’ve always had a national mindset around complete national security, ranging way beyond the pure militaristic scope – the idea of being self-sufficient and resilient in crisis. That ethos has shaped how we think about the value of our technology. NPHarvest is not just about sustainability – it’s also about sovereignty. We help countries secure their food systems by providing them with recycled, locally produced nutrients.

IFN: How was the technology created and tested? Provide scientific data or proof of concept that illustrates your solution’s overall effectiveness.

Dr. Kaljunen: Our research started with a membrane fiber strap in a small jar. The idea was to capture ammonia from urine. It worked so well that we began to scale the solution up, initially because the scientific community likes to publish laboratory studies, and field-scale experiments are rarer. We saw more value in larger-scale experiments that are closer to real-world conditions.

Throughout the academic years, we scaled up the process and tested it in different environments, such as wastewater treatment plants, biogas plants, and landfill sites. In Figure 1, the development steps are a) first small batch reactor, b) first continuous reactor, c) field scale membrane contactor, and d) complete field scale process with phosphorus recovery.

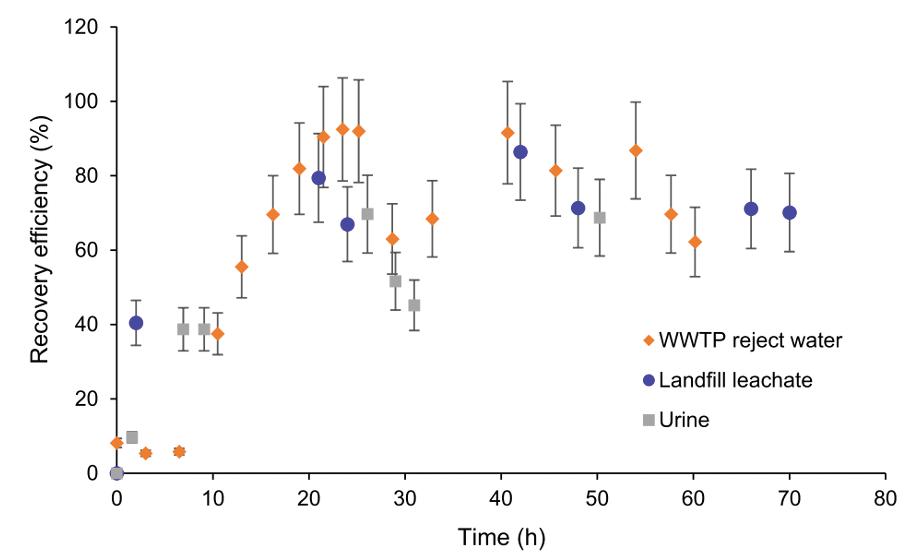

The results from the field were encouraging. Graph 1 shows the ammonia recovery efficiency of three testing sites in Finland. The recovery efficiency averaged to ~70% which gave us enough motivation to find ways to improve the efficiency and start commercialization.

IFN: Mika Kukkurainen, Partner at Nordic Foodtech VC, said about NPHarvest, “No one has done nutrient catching on a real commercial level,” which impressed the investors. What makes your system viable for commercial scale-up? What did the investors bring to the table?

Dr. Kaljunen: What makes our system viable for commercial scale-up is, first and foremost, that we’ve now built our first industrial-scale demo, which is based on a modular design. That means we’re not starting from scratch every time we scale up. We’ve also worked through the key technological bottlenecks, such as improving the suspended solids tolerance for our system so that we can tackle even the most difficult wastewaters. This often holds similar technologies back. We’ve deliberately engineered the system to handle real-world conditions, not just lab scenarios.

We’ve ensured there’s a strong business case. Our recovery process is especially cost-efficient in concentrated waste streams – because the operating costs scale with the volume of water, not the amount of nutrients. That’s a big contrast to many current removal methods, where costs increase in direct proportion to nutrient loads. We’re also operating at ambient pressure and temperature to keep the costs down – we only increase pH. This cost structure is one of the main reasons our approach is commercially viable and scalable.

As for our investors, they’ve brought much more than just capital, which is, of course, critical when you’re scaling hardware. Nordic Foodtech VC, Stephen Industries, and Tukinvest have all provided strong support in helping us navigate the startup landscape, plan future funding rounds, and think strategically about growth. I’ve come from an academic background – I didn’t get into this to build a startup. Having experienced partners around the table that tolerate me asking sometimes even elementary-level questions related to the startup world has been really valuable.

And finally, I must highlight the €0.9 million grant we received from the Finnish Ministry of Environment. That support has been directly earmarked for building the demo unit and absolutely essential.

IFN: What challenges or problems did you have to solve to get to the industrial filtration level? What is the science behind NPHarvest’s patented industrial-scale system, which “provides a circular, energyefficient solution for recovering critical nutrients, such as nitrogen and phosphorus, directly from wastewater streams, including black water, liquid digestate, and manure.”

Dr. Kaljunen: Getting to the industrial stripping level has been a long road. First, the suspended solids tolerance for a membrane solution had to be thought through. We used calcium hydroxide to increase pH, and that enabled us to easily add phosphorus recovery, but using calcium hydroxide was mechanically challenging.

The science behind that statement is based on two core recovery processes that are central to our patented system: chemical precipitation for phosphorus, and hydrophobic membrane stripping for nitrogen.

For phosphorus, we raise the pH of the wastewater using calcium hydroxide. This issue causes the phosphorus to precipitate out of the liquid phase as amorphous calcium phosphate, which we can then separate and collect as a solid fertilizer product.

For nitrogen, we use a process called hydrophobic membrane stripping. Once the pH is raised to around 10, ammonium in the wastewater shifts into a gaseous ammonia form. Our membranes are gaspermeable but water-repellent, so only ammonia gas passes through – no water or solids. On the other side of the membrane, we introduce an acid, typically sulfuric acid, which binds with the ammonia to form ammonium sulfate, a clean and reusable liquid fertilizer.

What makes the system energy-efficient is that neither of these steps requires heat, pressure, or aeration – just pH control and simple liquid circulation. And because we recover nutrients from concentrated streams like black water, digestate, or manure, we generate high yields without having to process vast volumes of diluted wastewater. Some of these liquids have high suspended solids content, which causes issues with other technologies. We have developed our patented process to handle suspended solids up to over 3% without clogging or fouling.

Together, these technologies create a circular solution: they capture nutrients that would otherwise be lost or cause pollution, and turn them back into productive use – helping to reduce greenhouse gas emissions, improve wastewater treatment performance, and support sustainable agriculture.

IFN: What other challenges have you encountered and overcome as you developed your system?

Dr. Kaljunen: There are technical challenges that exist when creating something new, and then there are systematic challenges. Technical challenges I enjoy solving. While there have been a number of those, they haven’t increased my stress levels. Designing the system in a way that it tolerates suspended solids of difficult wastewaters, making sure that the membrane fibers are not subjected to high mechanical stress, but still the system has high recovery efficiency, and in general, making the system as simple and easy to use as possible are examples of challenges that we had to design around. You know, the fun stuff.

Then, there are other kinds of challenges I’ve enjoyed solving less. Obtaining funding was a big challenge already in academic circles, and is even more critical now that we’ve become a startup. The jump from academia to the commercial world has required considerable effort. There’s a lot of bureaucracy to handle and internal systems and processes to set up – it is a lot of work for three co-founders. I haven’t loved these kinds of challenges since, as they take time away from my core purpose: developing technology for nutrient recovery.

IFN: What do you qualify as “nutrient-rich wastewater streams” that benefit from your system?

Dr. Kaljunen: When we talk about “nutrient-rich wastewater streams,” we mean any liquid waste that contains a high enough nitrogen concentration to make

In early August, NPHarvest unveiled an industrial-scale demo unit at the Aslan Biomass biogas plant in Türkiye. It recovers nitrogen and phosphorus from wastewater, critical raw materials for sustainable fertilizer production amid tightening EU restrictions on Russian imports. The demo unit shows that the company’s technology is scalable, energy-efficient, and reliable. NPHarvest nutrient recovery commercially viable – typically anything above 500 mg of nitrogen per liter.

In practice, that includes:

• Biogas plant liquid digestate, usually between 2 to 4 kgN/m³

• Municipal wastewater treatment plant reject waters with about 0.8 to 1.2 kgN/ m³ of nitrogen

• Animal farm liquid proportion of manure, which can go up to 6 kgN/m³ or even more

• These are our main focus areas, but we’re also open to working with other industrial streams that meet similar criteria.

The phosphorus recovery is an optional module in our system, allowing us to treat both wastewaters with and without phosphorus.

On solids content, we typically communicate that our system can handle up to 30,000 mg/l total suspended solids (TSS). That’s not a hard technical limit – it’s more about commercial viability. The higher the solids, the greater the wastewater’s buffering capacity, which means you need more alkaline chemicals to raise the pH for ammonia recovery. That increases operational cost. Still, our system is quite robust – for example, we’re currently operating at a biogas plant with digestate between 3–3.5% TSS, and it’s performing well.

A key reason for the high TSS tolerance is how our core technology works: we don’t filter the water through membranes. Instead, we use gas-permeable hydrophobic stripping membranes where only the ammonia gas passes through – not water or solids – paired with a gentle water flow profile and ambient pressure, which makes clogging and fouling much less of a concern than one would expect for filtering membranes.

IFN: Explain how the project in Ankara came about, how long it took to launch, and how you calculated the expectations.

Dr. Kaljunen: We chose to build our industrial-scale demo unit in Turkey because we found a really strong engineering partner there. As the unit neared completion, it made perfect sense to look for a nearby site to conduct the first field tests. That’s how we began discussions with ASKI, the public wastewater utility in Ankara, in January.

ASKI, was facing a very real nutrient overload issue in the region. Five biogas plants are operating quite close to each other, and between digestate from those plants and local manure production, there’s more nitrogen and phosphorus than the land can safely absorb. ASKI being a public sector actor, was under pressure to find a solution, and not just to solve the problem, but also to set an example for the private sector.

They were very open to piloting a technology like ours. Through them, we connected with Aslan Biomass in April, a local biogas plant, and they became our demo site partner. From Aslan’s perspective, they naturally want to find the most cost-effective way to treat the liquid digestate. One practical option that is often used is shipping the wastewater further away to regions with less nutrient load, but that is also costly, and, in this case, the region is dry. They’d rather recover the water locally to use it again for irrigation.

In terms of expectations, the nutrient recovery calculations are based on the wastewater characteristics – primarily the ammonium nitrogen and phosphorus concentrations in the digestate. Our recovery efficiency is around 90%, and we know from previous trials that we produce liquid ammonium sulfate at a concentration slightly above 30%. We calculated that over a full year of continuous operation, the 20 m³/day demo could recover roughly 93 tons of ammonium sulfate.

For phosphorus recovery, we focus on the phosphorus concentration and the overall solids content of the digestate –we’ve previously tested our process with a variety of wastewaters in smaller units, so we used that historical data to extrapolate the expected amount of precipitated P-product here. Of course, this test run will only last a few months, but those figures give a good estimate.

When extrapolating to a full-scale scenario, we used Assan’s actual digestate volume, which is about 700 m³/day. Scaling up from 20 to 700 m³/day with the same wastewater characteristics yields around 3,255 tons of ammonium sulfate and 2,555 tons of phosphorus product annually.

IFN: You report that “fertilizer prices are volatile, and they need to be imported from abroad, decreasing self-sufficiency.” How does your technology provide selfsufficiency in the marketplace you are operating?

Dr. Kaljunen: Fertilizer prices have become a real point of vulnerability for many countries, especially in Europe. Most nitrogen fertilizers are produced using natural gas, and the cheapest sources have historically come from countries such as Russia. That creates both price volatility and geopolitical risk, which we’ve seen firsthand in recent years.

A few other facts:

• In 2021 (the last year Russia reported trade data), they were the largest global exporter of mineral or chemical fertilizers containing nitrogen, exporting 5 900 kt. For comparison, the second largest (the EU) exported only 2 200 kt.

• For 2022, World Population Review estimated that Russia was the second largest global producer of urea (after India) and ammonium sulphate (after the USA). For fertilizers overall, Russia was the third largest producer –behind only the USA and India. Our technology addresses this by turning domestic wastewater – whether from farms, biogas plants, or treatment facilities – into a local source of high-quality fertilizer. Instead of importing synthetic fertilizers made abroad, we enable countries to recover nitrogen and phosphorus on-site and use it directly or process it further within the local economy.

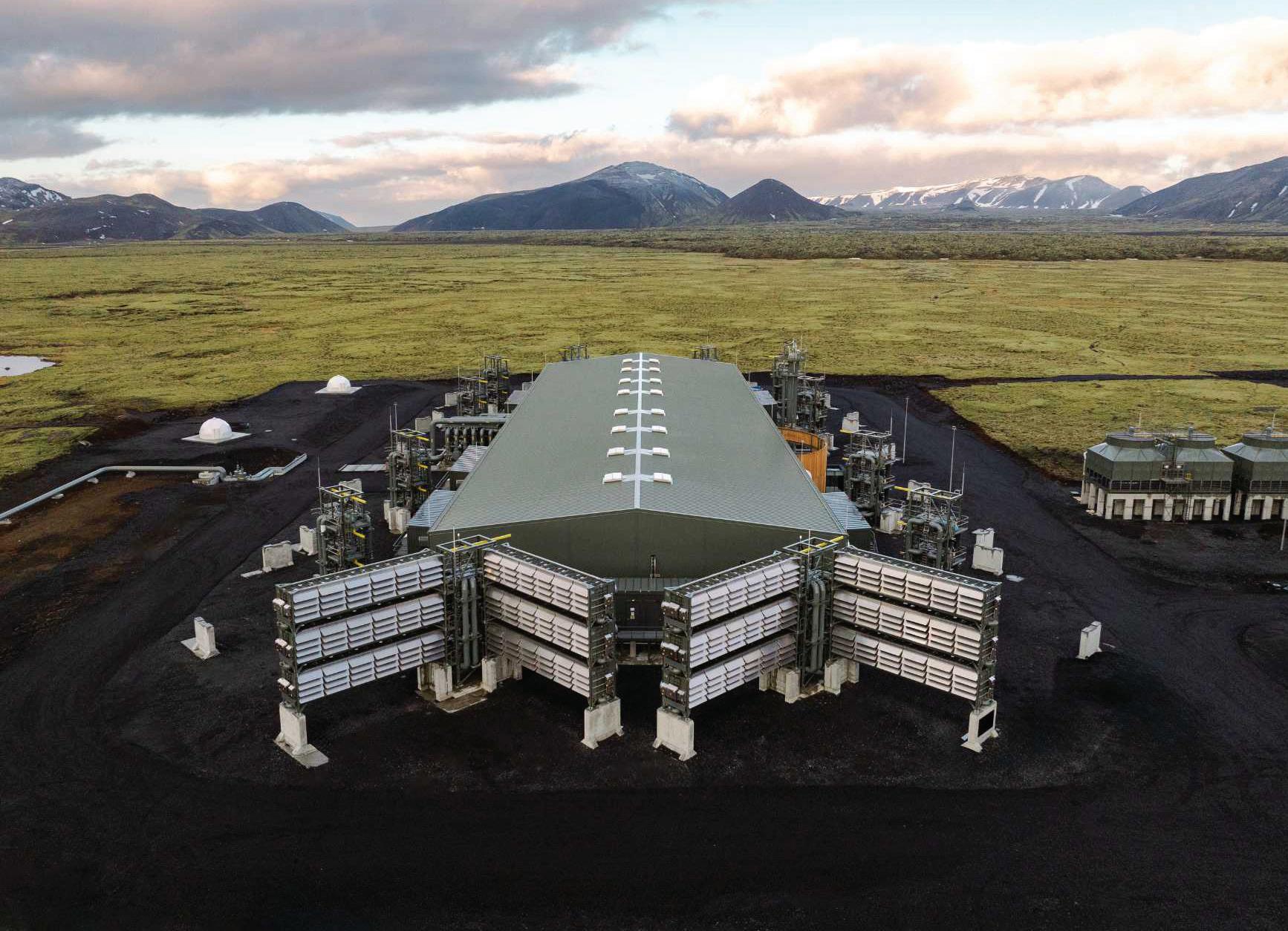

So, we’re creating a circular, decentralized fertilizer supply. It boosts self-sufficiency, lowers reliance on global markets, and helps stabilize costs while reducing environmental impact. That’s a win not only for farmers, but for national food security policies and sustainability goals. www.npharvest.fi qClimeworks, launched Mammoth, its second DAC facility in Iceland and the largest to date, in May 2024. Climeworks

IFN: Overall, how will your system be used to achieve sustainable, circular environmental benefits, for wastewater management?

Dr. Kaljunen: At its core, our system is designed to shift wastewater management from linear disposal to circular recovery. Traditionally, nutrients like nitrogen and phosphorus are treated as pollutants –something to remove and dispose of at high cost, often with significant environmental impact. Our approach flips that model by recovering those nutrients in reusable form, turning wastewater into a resource rather than a liability.

By capturing up to 90% of nitrogen and phosphorus from concentrated streams like manure, digestate, and reject water, we not only reduce emissions and eutrophication risks but also provide clean, locally sourced fertilizer inputs. This helps close the nutrient loop – from soil to food to waste and back to soil – which is exactly what a sustainable circular system should do. Our system eliminates N2O emissions from N treatment practically completely compared to traditional wastewater treatment – typically these constitute over half of the scope 1 GHG-emissions from wastewater treatment.

In practice, this means lower treatment costs for plant operators, less pollution to air and water, and a reduced dependency on fossil-based fertilizer production. Whether it’s supporting food security, decarbonization, or cleaner waterways, our system is a practical tool for building a more sustainable and circular future for wastewater management.

IFN: Do you have any final thoughts?

Dr. Kaljunen: Sometimes when I look in the mirror, I’m reminded that chasing something meaningful isn’t supposed to be easy. This journey hasn’t been smooth or glamorous – but I never wanted a steady office job. I wanted to build something that helps society and nature live in balance. And that’s what keeps me going.