2 minute read

NOTES TECH

Sigma Design Company Introduces Sigma Industrial Water Group, Adds Two New Filtration Systems

Sigma Design Company, a leader in the development of patented and innovative water conditioning components, filters, and systems, has introduced the Sigma Industrial Water Group and added two new systems that expand its portfolio of water and wastewater treatment products and solutions. This capability, which builds on more than 25 years of work in the water and wastewater sector, provides clients with fully customizable, engineered solutions for industrial water and nonhazardous wastewater challenges.

The Sigma Industrial Water Group specializes in the development of systems and technologies for industrial water reuse and recovery, separation and filtration, desalination pretreatment, ultraviolet (UV) disinfection, and the reduction of wastewater TSS discharge. The group builds all of its products to spec, and if building a component destined to be part of a bespoke water system, the group en- sures that it can be integrated smoothly into the existing line.

The new systems are:

Model 4613 Automatic Tubular Backwash Filter System with 1-to-1500-micron Filter Elements, designed specifically to filter particulates from the fluid stream. Each filter housing contains a filter element with multiple tubes. To achieve finer filtration levels, each tube can be fitted with a 1-micron (1μ) up to 200-micron polymer filter sleeve. Multiplex units consist of anywhere from 2-20 individual tubular filters piped and valved in parallel to common inlet, outlet, and drain headers. Sigma’s advanced control system includes motor control and protection circuitry and constantly monitors the flow rate and different pressures across the entire system.

Model 4614 UV + Automatic Prefilter Process Water System , which couples Sigma Industrial Water Group’s patented

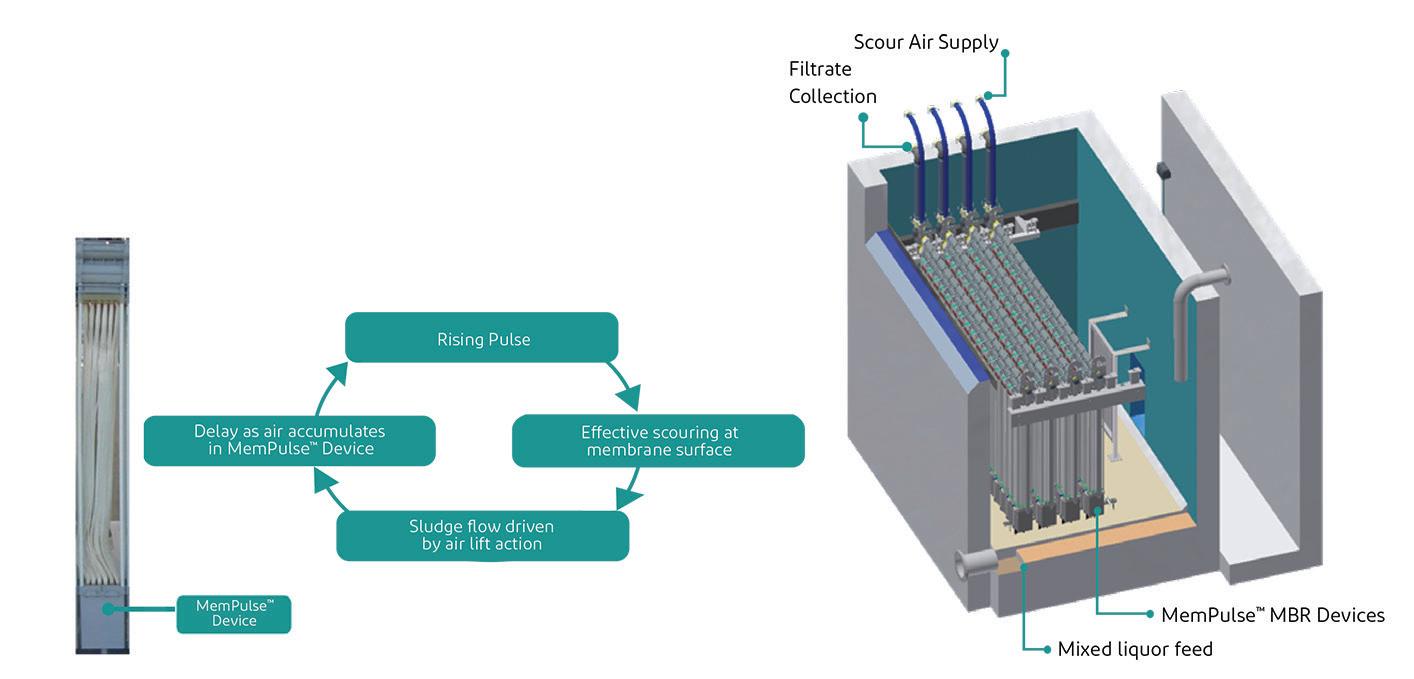

DuPont Membrane Technology Deployed in New Zealand

In collaboration with the Waikato District Council, Watercare, a public water utility in New Zealand has selected DuPont ™ MemPulse ™ membrane bioreactor (MBR) and OxyMem ™ membrane aerated bioreactor (MABR) technology for a new 6.0 MLD wastewater treatment plant to serve the Waikato District community of Raglan. This will be the first deployment of OxyMem™ MABR modules in the country – marking a significant milestone in the adoption of advanced wastewater treatment technologies in New Zealand.

In addition to enabling greater automation and reducing on-site personnel requirements, this multi-tech modular solution can provide compliance with New Zealand’s stringent discharge regulations and provide additional treatment capacity to future-proof the plant. Raglan’s existing wastewater treatment plant combines an oxidation pond system with ultraviolet (UV) treatment before the treated wastewater is discharged into the sea on the outgoing tide. The treatment upgrade to MemPulse™ MBR and OxyMem™ MABR is the first step in removing the connection to the harbor. The clear water permeates discharge from the q DuPont MemPulse: The graphic depicts air scouring efficiencies achieved by introducing a plug flow of air at the base of each module. automatic water filtration technology with UV disinfection, a chemical-free water treatment process that uses ultraviolet (UV) light to kill or inactivate harmful microorganisms, including bacteria, viruses, and protozoa. It provides a highly effective, environmentally friendly, and easy-to-use solution for treating and disinfecting water in a wide range of applications and industries. Examples of applications include wastewater treatment and industrial water reuse and makeup water, while industries range from aquaculture to pharmaceutical production, electronics manufacturing, food & beverage, and other industrial markets. www.sigmadesign.net new treatment plant has helped gain support for a regenerated land-based discharge.

Model 4613: Automatic Backwash Tubular Filter System (left) and Model 4614: Automated Prefilter and UV Water System for effective water disinfection.

The decision to combine MemPulse ™ MBR, which can provide the plant with highquality effluent, with OxyMem™ MABR will help Watercare achieve a lower total nitrogen concentration, making this community’s preference for land discharge viable. www.dupont.com