14 minute read

EMERGENT Textiles

IFJ Explores Trending Innovation

I

FJ highlights research from universities and institutions around the world. To highlight your research, email csmith@inda.org. Please write “IFJ Emerging Research” in the subject line. Send a press release and/or summary of the research as you would want it to be printed, a link to the university online story (if applicable), and all high resolution art and short researcher bio(s). All selections could be edited for length.

University Of Southampton And Uwe Bristol

Sustainable

e-Textiles:

Biodegradable Wearables Can Monitor Health and Reduce Waste

esearchers at the University of Southampton and UWE Bristol show that wearable electronic textiles (e-textiles) can be both sustainable and biodegradable.

RAlso included in the study are the universities of Exeter, Cambridge, Leeds and Bath. They describe and test a new sustainable approach for fully inkjet-printed, eco-friendly e-textiles named Smart, Wearable, and Eco-friendly Electronic Textiles,” or “SWEET,” with findings published in the Energy and Environmental Materials journal.

E-textiles are those with embedded electrical components, such as sensors, batteries, or lights in fashion, performance sportswear, or for medical purposes as to monitor people’s vital signs.

These textiles need to be durable, safe, and comfortable, and yet are also in an industry that is highly concerned with clothing waste, the environment, and the end-oflife garment disposal.

Professor Nazmul Karim, University of Southampton’s Winchester School of Art, who led the study, says, “Integrating electrical components into conventional textiles complicates the recycling of the material because it often contains metals, such as silver, that don’t easily biodegrade. Our potential eco-friendly approach for selecting sustainable materials and manufacturing overcomes this, enabling the fabric to decompose when it is disposed.”

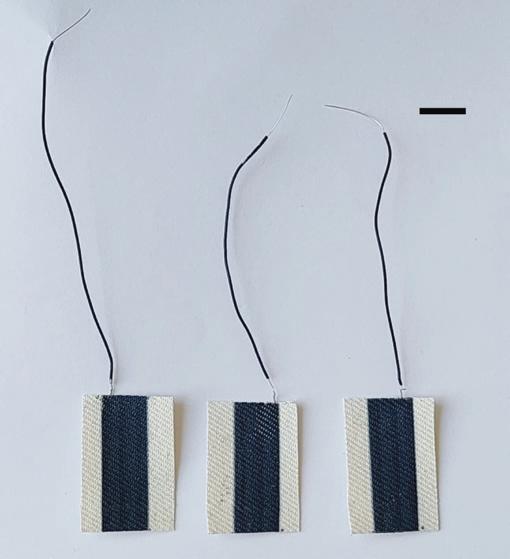

The design has three layers: a sensing layer, an interface layer with the sensors,

Compiled by Ken Norberg, IFN Editorial & Production Manager

Northwestern University

Your Skin is Breathing. This New Wearable Device Can Measure It. First wearable device to gauge health by sensing gases coming from, going into skin.

orthwestern University researchers have developed the first wearable device for measuring gases emitted from and absorbed by the skin.

Nand a base fabric. It uses a textile called Tencel for the base, which is made from renewable wood and is biodegradable. The active electronics in the design are made from graphene, along with a polymer called PEDOT: PSS. These conductive materials are precision inkjet-printed onto the fabric.

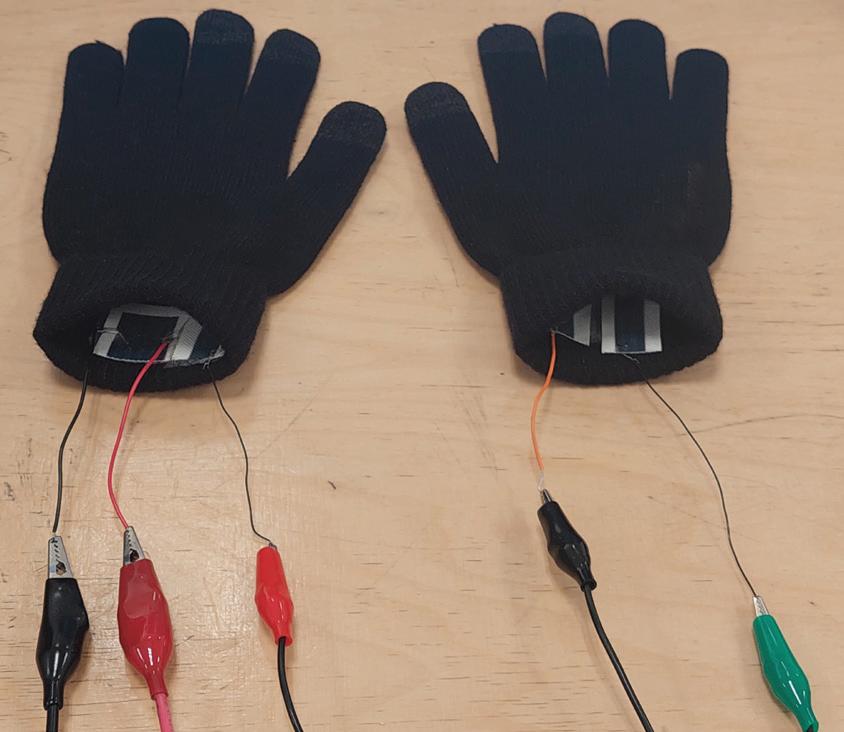

The researchers tested samples of the material for continuous monitoring of human physiology using five volunteers. Swatches of the fabric, connected to monitoring equipment, were attached to gloves worn by the participants. Results confirmed that the material can effectively and reliably measure both heart rate and temperature at the industry standard level.

Dr. Shaila Afroj, Associate Professor of Sustainable Materials from the University of Exeter and a co-author of the study, highlighted the importance of this performance. “Achieving reliable, industrystandard monitoring with eco-friendly materials is a significant milestone. It demonstrates that sustainability doesn’t have to come at the cost of functionality, especially in critical applications like health care.”

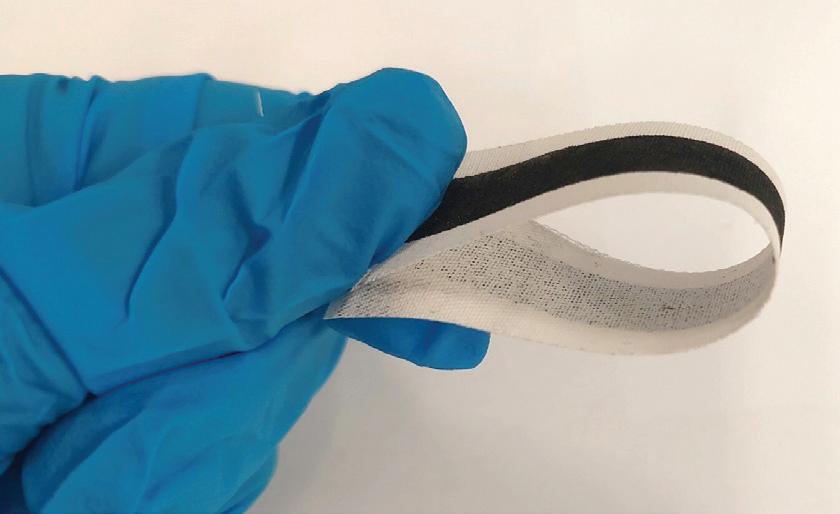

The project team then buried the e-textiles in soil to measure their biodegradable properties. After four months, the fabric had lost 48% of its weight and 98% of its strength, suggesting relatively rapid and also effective decomposition. Furthermore, a life cycle assessment revealed that the graphene-based electrodes had up to 40 times less impact on the environment than standard electrodes.

Marzia Dulal from UWE Bristol is a Commonwealth Ph.D. The scholar and the first author of the study highlighted the environmental impact. “Our life cycle analysis shows that graphene-based etextiles have a fraction of the environmental footprint compared to traditional electronics. This makes them a more responsible choice for industries looking to reduce their ecological impact.”

The ink-jet printing process is also a more sustainable approach for e-textile fabrications, depositing exact numbers of functional materials on textiles as needed, with almost no material waste and less use of water and energy than conventional screen printing.

Professor Karim concluded, “Amid rising pollution from landfill sites, our study helps to address a lack of research in the area of biodegradation of e-textiles. These materials will become increasingly more important in our lives, particularly in the area of health care, so it’s really important we consider how to make them more eco-friendly, both in their manufacturing and disposal.”

The goal is to design wearable garments made from SWEET for potential use in the healthcare sector, particularly in the area of early detection and prevention of heart-related diseases that affect 640 million people worldwide.

READ: https://www.uwe.ac.uk/news/researchdevelops-environmentally-friendly-e-textiles University of Southampton: https://www.southampton.ac.uk/ UWE Bristol: https://www.uwe.ac.uk

By analyzing these gases, the device offers an entirely new way to assess skin health, including monitoring wounds, detecting skin infections, tracking hydration levels, quantifying exposure to harmful environmental chemicals, and more.

It comprises a collection of sensors that precisely measure changes in temperature, water vapor, carbon dioxide (CO2), and volatile organic compounds (VOCs), each providing valuable insights into various skin conditions and overall health. These gases flow into a small chamber within the device that hovers above the skin without actually touching it. This nocontact design is particularly useful for gathering information about fragile skin without disturbing delicate tissues.

The study was published on April 9 in the journal Nature and demonstrates the device’s efficacy across small animals and humans.

“This device is a natural evolution of our lab’s wearable electronic devices that collect and analyze sweat,” said Northwestern’s John A. Rogers, who co-led the study. “In that case, we were analyzing sweat to learn about the wearer’s overall health. While useful, that method requires pharmacological stimulation of sweat glands or exposure to a hot, humid environment. We started thinking about what we could capture from the skin that is naturally occurring all the time. It turns out there are all kinds of things coming off the surface of the skin – water vapor, carbon dioxide and volatile organic compounds – that can be correlated to underlying physiological health.”

A bioelectronics pioneer, Rogers is the Louis Simpson and Kimberly Querrey Professor of Materials Science and

Engineering, Biomedical Engineering and Neurological Surgery at Northwestern –with appointments in Northwestern’s McCormick School of Engineering and the Feinberg School of Medicine – and the director of the Querrey Simpson Institute for Bioelectronics.

“This technology has the potential to transform clinical care, particularly for vulnerable populations, including newborn babies, the elderly, patients with diabetes and others with compromised skin,” said Northwestern’s Guillermo A. Ameer, who also co-led the study. “The beauty of our device is that we found a completely novel way to assess the status of delicate skin without having to come in contact with wounds, ulcers, or abrasions. This device is the first major step toward measuring changes in gases and correlating those changes with skin status.” keep water in and irritants, toxins, microbes, and allergens out.”

By tracking changes in the emission of water vapor and gases from the skin, healthcare professionals can gain insight into the integrity of their patients’ skin barriers. While technologies to measure water vapor loss their use in sensitive situations, such as wound care or for individuals with fragile skin,” Rogers said. “Our device overcomes this limitation by creating a small, enclosed chamber above the skin’s surface.”

Ameer is the Daniel Hale Williams Professor of Biomedical Engineering at McCormick and professor of surgery at Feinberg. Rogers and Ameer co-led the study with Yonggang Huang, the Jan and Marcia Achenbach Professor in Mechanical Engineering and professor of civil and environmental engineering.

Empowering Patients at Home

The skin barrier, the outermost layer, serves as the body’s first line of defense against the environment. It maintains hydration by preventing excessive water loss and acts as a barrier against irritants, bacteria, and ultraviolet radiation. When the skin barrier is compromised, it can lead to increased water loss (transepidermal water loss or TEWL), skin sensitivity, and risk of infection and inflammatory conditions like eczema and psoriasis.

“The skin is critical for protecting us from the environment,” said study co-author Dr. Amy Paller, the Walter J. Hamlin Professor of Dermatology and chair of the Department of Dermatology at Feinberg. “A major element of this protective function is the skin barrier, which is largely characterized by a formidable collection of tightly woven proteins and fats that do exist, they are large, cumbersome machines that largely reside within hospital settings. The compact wearable device, on the other hand, is designed to help physicians remotely monitor their patients and empower individuals to take control of their own skin health at home.

“The gold standard for measurement of skin barrier integrity is a large instrument with a probe that intermittently is touched to the skin to collect information about transepidermal water loss – or the flux of water through skin,” Paller said. “Having a device that can measure transepidermal water loss remotely, continuously, or as programmed by the investigator – and without perturbing a patient during sleep – is a major advance.”

How the Device Works

Measuring just two centimeters long and one-and-a-half centimeters wide, the device comprises a chamber, a collection of sensors, a programmable valve, an electronic circuit, and a small rechargeable battery. Instead of touching the skin directly, the chamber hovers a few millimeters above it.

“Traditional wearable sensors rely on physical contact with the skin, limiting

An automatic valve opens and closes the entrance to this chamber – a function that dynamically controls access between the enclosed chamber and the surrounding ambient air. When the valve is open, gases flow in or out of the chamber, enabling the device to establish a baseline measurement. Then, when the valve rapidly closes, it traps gases within the chamber. From there, the series of sensors measures changes in gas concentrations over time.

“If our device didn’t incorporate a programmable valve and a timedynamic measurement approach to quantify flux of species out of and into the skin in a real-time manner, then the system could be confounded by changes in the concentrations of these species that might naturally vary in the surrounding environment,” Rogers said. “Specifically, if the valve were open all the time, the sensor would detect these sorts of changes – not because of anything associated with the skin. On the other hand, if the valve were always closed, then it would perturb natural patterns of flux in a way that also could not account for environmental factors. For workers in potentially hazardous environments, it’s helpful to know how much of those hazardous species are entering the body through the skin.”

Ideal for Wound Care

Using Bluetooth, the device sends this data straight to a smartphone or tablet for real-time monitoring. These rapid results can help healthcare workers make more informed – and speedier – decisions for wound management and administering antibiotics.

Because increased water vapor, CO2, and VOCs are associated with bacterial growth and delayed healing, monitoring these factors can help caregivers detect infections earlier and with more confidence.

“Prescribing antibiotics for wounds can be a bit of a gamble,” said Ameer, who is an expert on regenerative engineering approaches to improve wound healing.

“Sometimes it’s hard to tell if a wound is infected or not. By the time it’s obvious, it might be too late, and the patient can develop sepsis, which is incredibly dangerous. To avoid this, physicians prescribe a wide spectrum of antibiotics. This can lead to antibiotic resistance, a growing problem in healthcare. Being able to closely, continuously monitor a wound and prescribe an antibiotic at the earliest sign of infection is an obvious and important interest.”

While continuous monitoring is important for all types of wounds, it is particularly crucial for diabetic patients. Ameer has previously developed various strategies, including antioxidant gels and regenerative bandages, for treating diabetic ulcers. Just two years ago, Ameer teamed up with Rogers to create the first transient electronic bandage, which used electrical stimulation to accelerate wound healing. The new wearable provides yet another tool to help these vulnerable patients avoid risky side effects.

“Diabetic ulcers are the number one non-traumatic cause of lower limb amputations worldwide,” said Ameer. “Sometimes it might appear that the wound is closing, but the skin barrier function is not quite restored. Our device can precisely measure emitted gases, which provides useful information about the skin barrier function.”

Assessing Efficacy of Bug Repellants, Lotions

The innovative new technology not only offers unprecedented insights into wound healing and skin health, but it also might pave the way for advances in monitoring the efficacy of bug repellents, skin creams, and systemic medications designed to improve skin health.

CO2 and VOCs are the very gases that attract mosquitoes and other pests. So, measuring these emissions from the skin could help researchers understand and mitigate mosquito attraction. The new device could also enable dermatologists and their patients to measure the rate at which lotions and creams penetrate the skin, providing insights into skin permeability and barrier function. These data also could help other researchers develop more effective transdermal drug delivery systems, monitor the effects of systemically delivered drugs for skin diseases, and evaluate the safety of cosmetics and personal care products.

Next, the Northwestern team plans to refine the device’s capabilities, including adding a sensor to track changes in pH levels and developing gas sensors with increased chemical selectivity for early detection of organ dysfunction and other diseases.

“This unusual wearable platform provides a new way to think about and understand skin health,” Rogers said. “This technology is not just about measuring gases and corresponding characteristics of the skin. It’s about predicting overall health, preventing infection and disease, and creating a future where personalized care is driven by real-time, non-invasive, continuous health tracking through a new collection of parameters that complement those that can be captured with conventional wearables.”

The study, “A Non-Contact Wearable Device for Monitoring Epidermal Molecular Flux,” was supported by the QuerreySimpson Institute for Bioelectronics, the Center for Advanced Regenerative Engineering, and the National Institute of Diabetes and Digestive and Kidney Diseases (grant number R01DK131302).

Reach the authors at John Rogers, jrogers@northwestern.edu and Guillermo A. Ameer, g-ameer@northwestern.edu.

READ: https://www.nature.com/articles/s41586025-08825-2

Northwestern University

Stretching Spider Silk Makes it Stronger

New study finds the amount of stretching determines the fibers’ properties.

By Amanda Morris

hen spiders spin their webs, they use their hind legs to pull silk threads from their spinnerets. This pulling action not only helps the spider release the silk but it’s also a crucial step in strengthening the silk fibers, resulting in a more durable web.

WIn a new study, Northwestern University researchers have discovered why stretching plays such a crucial role. By simulating spider silk in a computational model, the team found the stretching process aligns the protein chains within the fibers and increases the number of bonds between those chains. Both factors lead to stronger, tougher fibers.

The team then validated these computational predictions through laboratory experiments using engineered spider silk. These insights could help researchers design engineered silk-inspired proteins and spinning processes for various applications, including strong, biodegradable sutures and tough, high-performance, blast-proof body armor.

“Researchers already knew this stretching, or drawing, is necessary for making really strong fibers,” said Northwestern’s Sinan Keten, senior author. “But no one necessarily knew why. With our computational method, we were able to probe what’s happening at the nanoscale to gain insights that cannot be seen experimentally. We could examine how drawing relates to the silk’s mechanical properties.”

An expert in bioinspired materials, Keten is the Jerome B. Cohen Professor of Engineering, professor and associate chair of mechanical engineering, and professor of civil and environmental engineering at Northwestern’s McCormick School of Engineering.

“Spiders perform the drawing process naturally,” said Northwestern’s Jacob Graham, a Ph.D. student in Keten’s

Spiders perform the stretching process naturally, according to researchers. They spin silk out of their silk gland, using their hind legs to grab the fiber and pull it out. That stretches the fiber as it’s being formed, which makes the fiber strong and elastic. Getty Images/Northwestern University research group nd the study’s first author. “When they spin silk out of their silk gland, spiders use their hind legs to grab the fiber and pull it out. That stretches the fiber as it’s being formed. It makes the fiber very strong and very elastic. We found that you can modify the fiber’s mechanical properties simply through modifying the amount of stretching.”

Stronger Than Steel, Tougher Than Kevlar

Researchers long have been interested in spider silk because of its remarkable properties. It’s stronger than steel, tougher than Kevlar and stretchy like rubber. But farming spiders for their natural silk is expensive, energy-intensive and difficult. So, scientists instead want to recreate silklike materials in the lab.

“Spider silk is the strongest organic fiber,” Graham said. “It also has the advantage of being biodegradable. So, it’s an ideal material for medical applications. It could be used for surgical sutures and adhesive gels for wound-closure because it would naturally, harmlessly degrade in the body.”

Study coauthor Fuzhong Zhang, the Francis F. Ahmann Professor at Washington University (WashU) in St. Louis, has been engineering microbes to produce spider-silk materials for several years. By extruding engineered spider silk proteins and then stretching them by hand, the team has developed artificial fibers similar to threads from the golden silk orb weaver, a large spider with a spectacularly strong web.

Simulating Stretchiness

Despite developing this “recipe” for spider silk, researchers still don’t fully under -

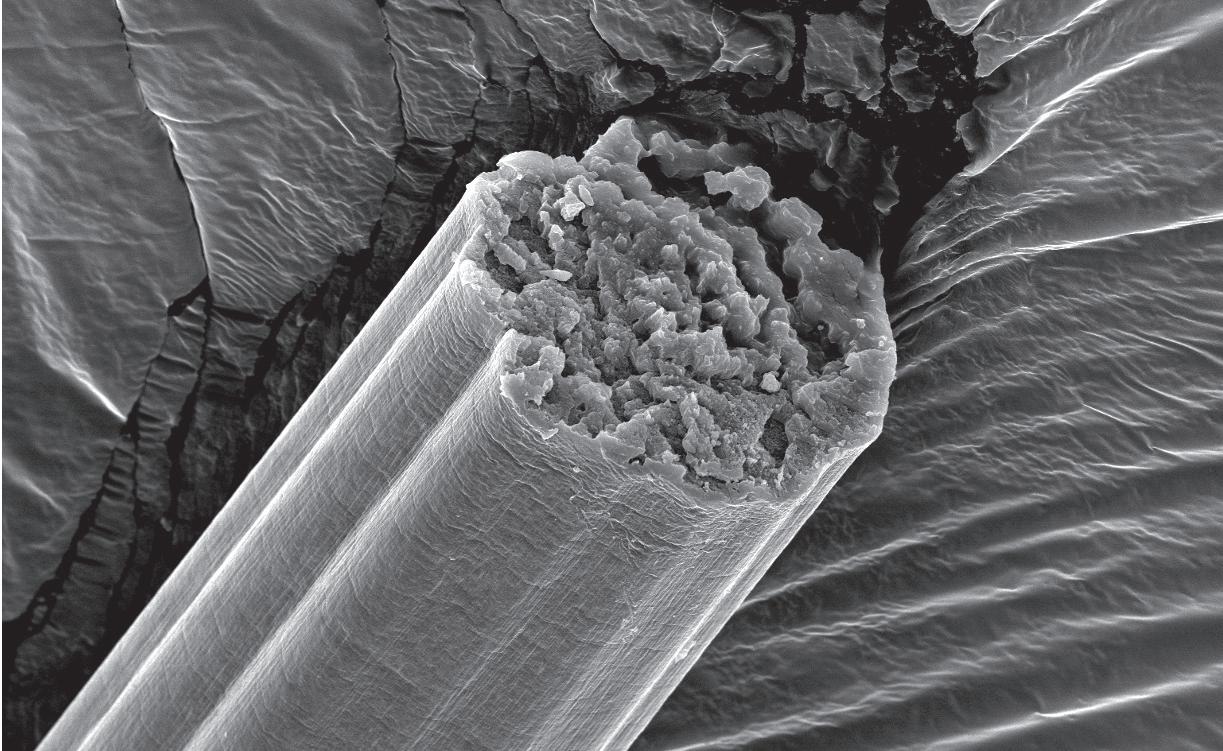

Researchers have long been interested in spider silk because of its strength and stretchability. But farming spiders for their natural silk is expensive, energy-intensive, and difficult. So, scientists instead want to recreate silk-like materials in the lab. Pictured is an electron microscopy image of fibers from engineered spider silk. Washington University in St. Louis stand how the spinning process changes fiber structure and strength. To tackle this open-ended question, Keten and Graham developed a computational model to simulate the molecular dynamics within Zhang’s artificial silk.

Through these simulations, the Northwestern team explored how stretching effects the proteins’ arrangement within the fibers. Specifically, they looked at how stretching changes the order of proteins, the connection of proteins to one another and the movement of molecules within the fibers.

Keten and Graham found that stretching caused the proteins to “line up,” which increased the fiber’s overall strength. They also found that stretching increased the number of hydrogen bonds, which act like bridges between the protein chains to make up the fiber. The increase in hydrogen bonds contributes to the fiber’s overall strength, toughness and elasticity, the researchers found.

“Once a fiber is extruded, its mechanical properties are actually quite weak,” Graham said. “But when it’s stretch up to six times its initial length, it becomes very strong.”

Experimental Validation

To validate their computational findings, the team used spectroscopy techniques to examine how the protein chains stretched and aligned in real fibers from the WashU team. They also used tensile testing to see how much stretching the fibers could tolerate before breaking. The experimental results agreed with the simulation’s predictions.

“If you don’t stretch the material, you have these spherical globs of proteins,”

Graham said. “But stretching turns these globs into more of an interconnected network. The protein chains stack on top of one another, and the network becomes more and more interconnected. Bundled proteins have more potential to unravel and extend further before the fiber breaks, but initially extended proteins make for less extensible fibers that require more force to break.”

Although Graham used to think spiders were just creepy-crawlies, he now sees their potential to help solve real problems. He notes that engineered spider silk offers a stronger, biodegradable alternative to other synthetic materials, which are primarily derived from petroleum-based plastics.

“I definitely look at spiders in a new light,” Graham said. “I used to think they were nuisances. Now, I see them as a source of fascination.”

Sinan Keten, Jerome B. Cohen Professor of Engineering, professor and associate chair of mechanical engineering and professor of civil and environmental engineering can be reached at s-keten@northwestern.edu.

Jordan Graham, Ph.D. student, is also a contributing author and can be reached at JacobGraham2025@u.northwestern.edu.

READ: https://news.northwestern.edu/stories/ 2025/03/stretching-spider-silk-makes-it-stronger/

The study was published in the journal Science Advances (https://www.science.org/doi/10.1126/ sciadv.adr3833) and supported by the National Science Foundation.