8 minute read

Driving Forward with Nonwovens INNOVATION on the OPEN ROAD

Freudenberg battery separator material. Freudenberg Performance Materials

Investments in Eco-Friendly, Recyclable Material Solutions and Innovation in Bio-Based Nonwovens Are Increasingly Shaping the Next Generation of Automotive Interiors.

By Geoff Fisher, European Editor, IFJ

The development of nonwoven materials and associated technologies is likely to lead to even wider adoption in the automotive industry, driven by rising global vehicle production, particularly in the growing electric vehicle (EV) segment, and an intensified focus on sustainable solutions.

While woven and knitted fabrics, as well as leather, continue to dominate visual surfaces in vehicle interiors, nonwoven fabrics are increasingly finding use in the automotive sector, driven by rising demand for lightweight, durable, and cost-effective materials that enhance performance and reduce vehicle weight, thereby improving fuel efficiency. Properties such as sound insulation, filtration, and comfort also make nonwovens suitable for diverse applications across the vehicle interior and exterior.

Current Applications

Nonwovens already find use in more than 40 different parts of a vehicle. They are widely used in interior trim applications such as upholstery, floor coverings, headliners, parcel shelves, seat backs, door panels and trunk liners, as well as air, oil and fuel filters, heatshields, engine covers, and acoustic and thermal insulation components. In addition, pressure on global automakers to reduce emissions and comply with increasingly stringent environmental regulations has led to the widespread adoption of nonwoven fabrics for a diverse and growing range of components. In particular, continued advancements in manufacturing technologies and the growth of the EV market have further expanded the use of nonwovens for thermal and acoustic insulation applications.

Market Value

The global automotive nonwoven fabrics market is estimated to be worth US$3.4 billion in 2025 and is projected to reach US$5.0 billion by 2035, registering a compound annual growth rate (CAGR) of 4% over the period, according to a new report from Future Market Insights.

Polyester is the leading fiber type with a 36.2% market share of automotive nonwovens, based on its mechanical properties, cost-effectiveness, and compatibility with various nonwoven technologies, the report notes. Other key fibers used in the sector include polypropylene (20.3%), polyamide (18.5%), and polyethylene (15.1%).

Polyester-based fabrics are widely used for their resistance to moisture, stretching, and abrasion, making them suitable for automotive interiors, insulation layers, and structural reinforcements. In addition, their thermal stability and recyclability have made them a preferred choice for manufacturers aiming to reduce environmental impact without compromising on performance.

Other Transport Applications

In the overall transport industry, the automotive sector accounts for a major share of nonwoven applications. Some nonwoven fabrics are utilized in aircraft interiors for components such as seat upholstery, carpeting, headliners and wall panels. They are also used for insulation and sound dampening to reduce noise within the aircraft. In terms of structure, they are employed in components such as composite panels for reinforcement.

Meanwhile, nonwovens are used as fire blockers in train seats, placed between the upholstery and the cover fabric to prevent or delay the spread of fire. Nonwoven materials contribute to thermal and acoustic insulation in train carriages and are also used for various interior components such as headliners, seat components, door trim, and other interior fittings.

Improving Noise Insulation

A recent European collaboration has developed a sustainable and high-performance multilayer acoustic nonwoven fabric for improving noise insulation in both electric and internal combustion engine (ICE) vehicles.

The Acoustiwall project aimed to improve sound insulation and absorption in the low- and mid-frequency range for vehicles by developing an energy-efficient, eco-friendly wheel arch liner based on a lightweight nonwoven fabric.

Splittable bicomponent fiber acoustic patches were integrated, using threedimensional (3D) lofting technology, into specific locations of the semi-finished product before it was molded into a 3D product.

The project partners were:

• Autoneum, Switzerland, a Tier 1 automotive supplier for acoustic and thermal management, which undertook the transformation of the twodimensional (2D) material to a 3D product and testing;

• Needlepunched nonwovens producer Hassan, Türkiye, which produced the 2D materials (nonwoven base layer) with integrated acoustic patches;

• Groz-Beckert, Germany, is a manufacturer of carding wires and needles for special fibers.

The project partners collaborated with German nonwoven equipment manufacturer Dilo, utilizing its 3D lofter to split and lay down the bicomponent fibers onto the nonwoven base layer.

In industrial trials on the prototype wheel arch liner, the airflow resistance, acoustic absorption, tensile strength, elongation, water absorption, stone chipping resistance, and flammability all met the critical physical tests specified by an original equipment manufacturer (OEM).

Furthermore, there was a clear improvement in acoustic performance with the special fibrous patch on semi-finished and molded materials compared to the same base material with a commercial patch and standard production in the low- and mid-frequency ranges. The airflow resistance values on the molded samples were also lower compared to the semi-finished samples, owing to the stretch/non-homogeneity properties.

Polyester Felt-based Sound Insulation

At the Automotive Acoustics Conference held in July in Konstanz, Germany, Autoneum presented a polyester felt-based sound insulation system that is lightweight, resilient, and shapeable, aiming to combine acoustic performance and precise contours with enhanced recyclability.

Flexi-Light PET is manufactured from a novel blend of polyester fibers primarily sourced from recycled polyethylene terephthalate (rPET). Through a state-of-theart production process, Autoneum can adjust the orientation of the fibers to produce a proprietary felt with mechanical and acoustic properties comparable to those of polyurethane foam.

The material is flexible and can be molded into 3D shapes, making it an ideal insulation material for interior components with complex contours, such as carpets and inner dashboards, according to the company.

Composed entirely of PET – up to 90% of which is recycled content – Flexi-Light PET can be used as a decoupler in conjunction with other PET-based technologies within Autoneum’s product range, supporting full circularity and enabling the reuse of production waste and end-oflife recycling of the product.

Enhanced Nonwovens for Molded Parts

A sustainable nonwoven material, designed for use in molded parts of vehicles to enhance sound and thermal insulation, has also been developed by German nonwovens producer Sandler. Said to be ideal for both interior and exterior uses in passenger and commercial vehicles, Finexus replaces the need for multilayer structures with its singlepolymer material. Applications include underbody, headliner, wheel arch liners and trunk liners for both ICE vehicles and EVs.

Customized, complex component geometries are also achievable due to the flexible formability of Finexus nonwovens, which are produced without the use of any chemicals or binders. Besides their robustness and thermal resistance, these nonwovens can contribute to a quieter, safer, and more comfortable driving experience by reducing noise levels inside and outside the vehicle, Sandler stated.

Innovative and Price-Sensitive

Jones Family of Companies, which acquired Amherst, New Hampshire, USAbased Rontex America in 2020, produces needlepunched nonwoven fabrics for Class A interior trim and trunk surfaces, as well as lightweight moldable acoustical insulation that is an integral part of composite materials designed to eliminate engine, road noise, and wind vibrations in the dash, floors, and cargo areas.

The company’s automotive solutions are made from sustainable post-industrial fiber material for a wide range of applications, including facing interior fabrics for trunks, rear decks, and wheel arch liners, as well as moldable materials customdesigned to meet specific dash, floor, and trunk applications. “Our unique blend of cotton, low-melt and synthetic fibers allows us to be innovative and pricesensitive,” said Jones Nonwovens.

Lightweight SoundAbsorbing Material

Along with Toray Textiles Cen tral Europe (TTCE), Toray Advanced Materials Korea has expanded production for its Airlite ultra-fine noiseabsorbing material. The facility, located at the TTCE plant in Prostějov, Czech Republic, commenced commercial production of 1,200 tonnes per year in 2022.

Airlite is a lightweight, meltblown sound-absorbing material that combines polypropylene and PET and is marketed as an eco-friendly material that can reduce energy consumption for vehicles. As the urban air mobility industry continues to grow, the demand for lightweight, sound-absorbing materials is expected to rise further, the company said.

Having manufactured such materials for vehicles since 2013, Toray Advanced Materials Korea plans to expand this business to Europe to strengthen cooperation with global automakers and major parts makers, and said it will increase environmentally added value by developing products using recycled materials. Meanwhile, Japan-headquartered Toray Industries also offers Gulfeng. This nonwoven/woven fabric combines flame retardance with fire-shielding properties, available in various types, from thin (60 μm) paper to thick felt. It will not rip or open holes when exposed to fire, providing a shield against the spread of flames that prevents fire from reaching flammable objects on the other side. Its shielding properties also reduce the levels of heat transfer.

Technological Portfolio

Global nonwovens producer Tenowo manufactures nonwoven products and components for vehicle interiors and exteriors, such as luggagecompartment covers, headliners, package trays, door panels, wheel arch liners, underhood covers, heatshields, and acoustic insulation parts, as well as secondary backing for carpets, floor mats,

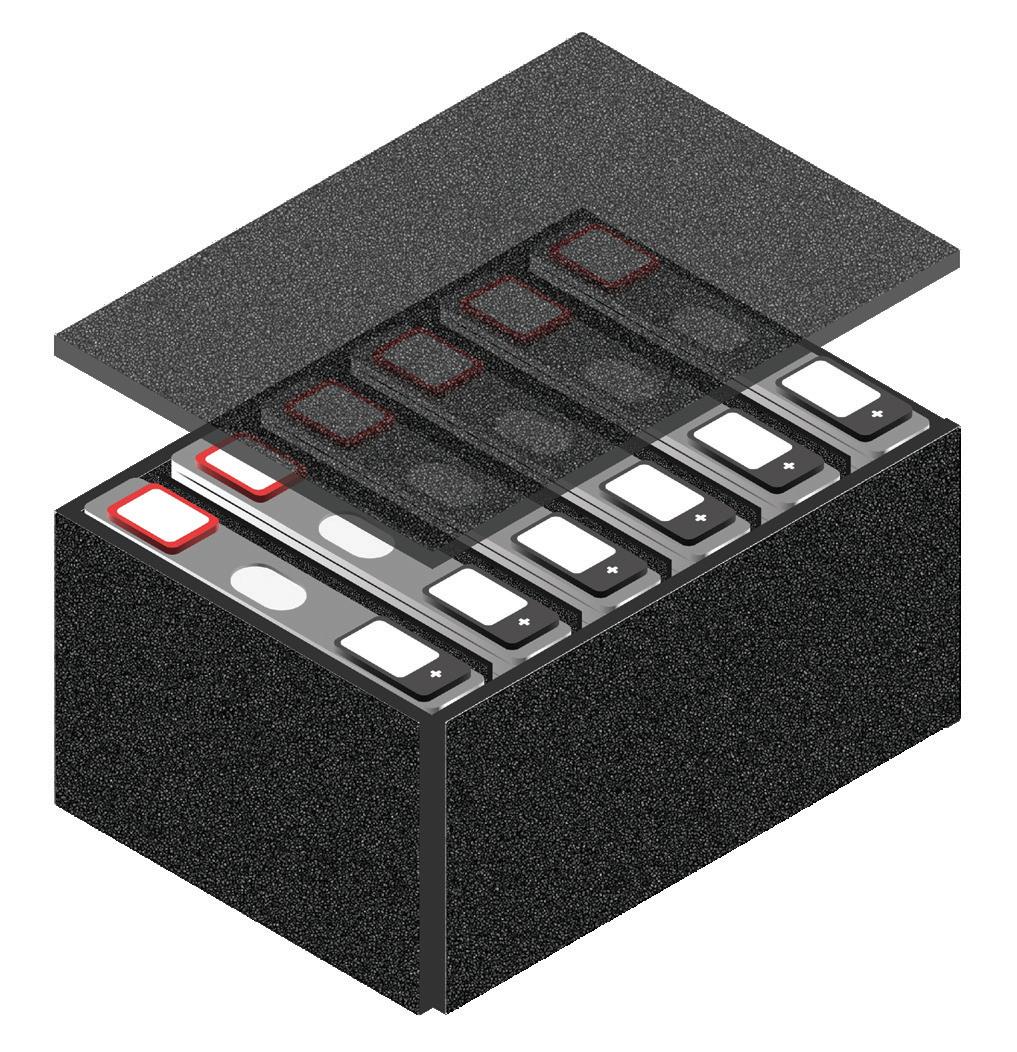

Application example of Lastan in an electric

Enhancing EV Battery Safety

and underbody components, and as a foam replacement for vehicle seats.

The Germany-headquartered company offers a range of production processes, such as stitch-bonded nonwovens technology, mechanical needling, and hydrodynamic or thermal consolidation.

Battery Separators for Stationary Energy Storage

Germany-based technical textiles manufacturer Freudenberg Performance Materials produces a range of nonwoven battery separators that increase the cycle life, performance, and safety of batteries for stationary energy storage systems, as well as batteries used in transportation, communications, and computer systems, that include nickel-cadmium, nickel-metal hydride, nickel-zinc, nickel-hydrogen, metal-air, and lead-acid batteries.

The latest surface finishing technology from Freudenberg is said to provide excellent electrolyte absorption as well as increase the speed. The company can combine this new technology with a range of other finishes and its nonwoven technologies to develop further custommade separators that meet the needs of energy storage system manufacturers and other battery manufacturers in the aviation, rail vehicle construction, or computer systems sectors.

Asahi Kasei has introduced a new material solution for enhanced EV battery safety. Lastan, a flame-retardant and flexible nonwoven fabric, is offered as an alternative to conventional materials for thermal runaway protection, which can be utilized in top covers, busbar protection sleeves and other applications within the EV battery pack.

According to the Japanese technology company, Lastan is a non-mineral, flame-resistant fabric made by air baking a special acrylic fiber at 200–300°C. It is characterized by high flame resistance and good electrical insulation, which are further improved by a special coating process that also augments abrasion resistance. This allows the material to provide effective protection against particle bombardment from venting gas.

Even when a 1300 ° C flame is applied, the temperature on the opposite side of Lastan remains below 400°C. And while a limiting oxygen index (LOI) value of 27 or higher is generally considered to indicate flame retardance, the material has an LOI value of 50 or higher.

In UL94 flame retardance testing, Lastan obtained the highest rating of 5VA. Further, no holes are formed in the material, even when exposed to a flame of 1300 ° C for one minute. Lastan is also resistant to high-pressure impact by particles of 200–500 μm, and provides electrical insulating capacity of up to 3.5 kV at a thickness of 1 mm.

Having integrated production of Lastan in Japan, Asahi Kasei is considering future production in the U.S. and other countries.

Aftermarket Relaunch

AJ Nonwovens is relaunching Multipile, a versatile, high-performance nonwoven product designed to meet the evolving needs of the automotive aftermarket. Now made with sustainable materials and manufactured in the U.S., multipile offers “a reliable, domestic alternative to imported substrates – without sacrificing quality or performance,” according to the company of Charleston, South Carolina, USA.

Multipile is engineered for durable applications, including automotive buffing pads, abrasive backings, and other technical uses. With increasing demand for environmentally responsible sourcing and shorter supply chains, the company’s latest iteration of Multipile offers customers a domestically made option in a traditionally import-heavy category. It is available in a variety of colors, allowing customers to match their brand identity or product differentiation requirements easily.

Meanwhile, AJ Nonwovens is expanding its range of US-made, sustainable nonwoven solutions engineered for both interior and exterior vehicle applications, including seat composites, headliners, wheel arch liners, and underbody shields for OEMs and Tier 1 suppliers.

With U.S. production facilities in Missouri, New Hampshire, and Texas, the nonwovens producer offers strategically located, regionally optimized manufacturing to reduce lead times, control freight costs, and ensure a resilient supply chain for critical production schedules, according to Sam Hyden, Director of Automotive Sales.

Geoff Fisher is the European editor of International Fiber Journal and editorial director of UK-based Textile Media Services, a B2B publisher of news and market reports on transport textiles, medical textiles, smart materials and emerging markets. He has 40 years of experience covering fibers and technical textiles and can be contacted at gfisher@textilemedia.com.