1 minute read

Precision Cutting for Technical Textiles –How Laser Technology Optimizes Efficiency

High-precision, contactless, and fully automatable – laser cutting technology is revolutionizing the processing of technical textiles. From personal protective equipment and high-performance filters to advanced composites and architectural textiles, German laser specialist eurolaser offers scalable solutions that enable manufacturers to meet the modern demands for precision, flexibility, and sustainable productivity.

Advanced Laser Systems for a Diverse Textile Sector

As the textile industry expands into ever more specialized fields – such as geotextiles for infrastructure, interior components in the automotive industry, or filter media in medical and industrial settings – cutting requirements are becoming increasingly complex. Conventional mechanical methods often reach their limits, particularly with synthetic fibers and tension-sensitive materials.

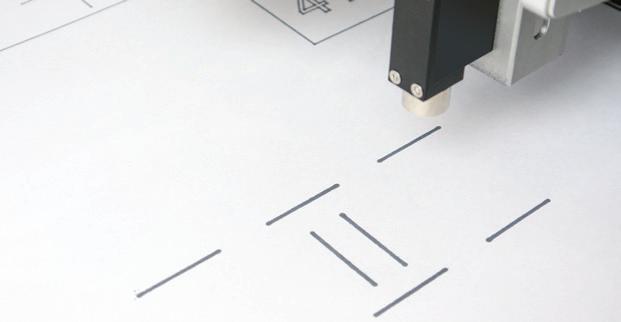

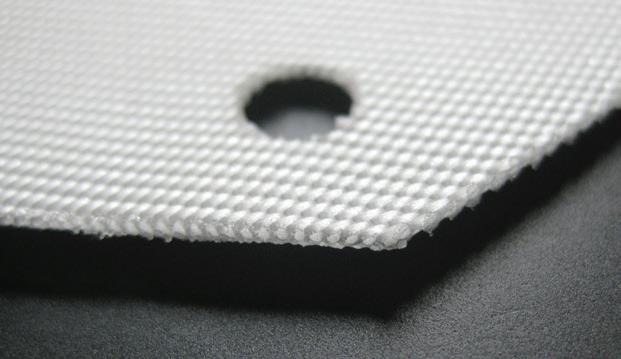

Laser technology offers a compelling alternative: consistent cutting quality with- out tool wear, clean sealed edges, minimal material distortion, and seamless integration into automated workflows. For synthetic textiles, the laser’s thermal process can simultaneously cut and seal, significantly reducing post-processing steps.

Large-Format CO₂ Laser Systems

Designed for Industry

eurolaser, headquartered in Lüneburg, Germany, has been a partner to the textile sector for over 30 years. The company specializes in modular, large-format CO₂ laser systems tailored specifically to non-metal materials. System widths up to 3,200 mm allow the processing of standard industrial roll formats, ideal for continuous operations and integration into digital production environments.

With its modular system architecture, eurolaser offers extensive customization: from laser power and automation levels to add-ons such as camera-based pattern recognition, mechanical tools, or labelling modules. The goal is clear – maximum efficiency and flexibility for every production setup.

Applications: From PPE to Automotive Interiors

eurolaser systems are used globally across a wide range of applications:

Protective apparel: Consistently highquality cutting of hard-to-process materials – no blade wear, no loss in precision.

Filtration media: Accurate, repeatable cuts even in high-volume runs, ensuring filter integrity and throughput.

Composites: Contactless and deformation-free cutting, suitable for 24/7 operations.

Automotive textiles: Fast, precise contour cuts, including pattern-matching functionality – ideal for interiors, upholstery, and technical linings.

Home textiles: From detailed cutouts to rapid throughput – suitable for curtains, cushions, blinds, and upholstery.

Soft signage: High-precision cutting of large format printed textiles, fully automated using QR-code recognition for print-on-demand workflows.

Integrated Automation for Scalable Efficiency

One of eurolaser’s core advantages lies in its holistic automation strategy.

The Conveyor System supports continuous feeding of roll materials, while the POSITIONplus camera system detects printed graphics or fabric structures for precise alignment.

Add-ons such as labeling modules, ink markers, and mechanical processing tools (e.g., routing, creasing, kiss-cutting) can be integrated into a single workflow. Combined, these features enable fully digitalized and automated textile production – from raw roll to finished cut part.

www.eurolaser.com