TECH TALK

2023 in the Rearview Mirror, 2024 in the Crystal Ball By Matt O’Sickey

Director of Education & Technical Affairs, INDA Matt O’Sickey, PhD is Director of Education & Technical Affairs at INDA, Association of the Nonwoven Fabrics Industry. Matt was previously Director of Technology for RKW-North America and Global Director of Market Development for Tredegar Film Products and may be reached at mosickey@inda. org or +1 919 459-3748. * International Fiber Journal is owned by INDA, Association of the Nonwoven Fabrics Industry (inda.org).

As director of education and technical affairs, Matt presents regular training related to nonwovens and filter media from INDA’s headquarters in Cary, NC. For more information about upcoming training opportunities, visit inda.org/training.

38 IFN ISSUE 6 2023

L

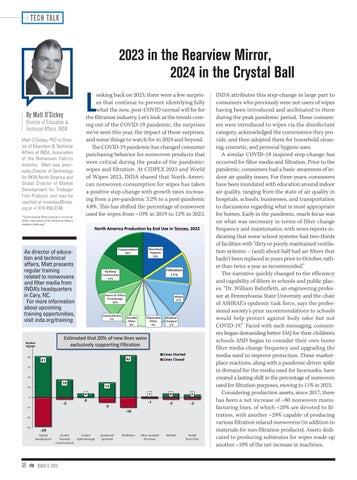

ooking back on 2023, there were a few surprises that continue to prevent identifying fully what the new, post-COVID normal will be for the filtration industry. Let’s look at the trends coming out of the COVID-19 pandemic, the surprises we’ve seen this year, the impact of those surprises, and some things to watch for in 2024 and beyond. The COVID-19 pandemic has changed consumer purchasing behavior for nonwoven products that were critical during the peaks of the pandemic: wipes and filtration. At CIDPEX 2023 and World of Wipes 2023, INDA shared that North American nonwoven consumption for wipes has taken a positive step-change with growth rates increasing from a pre-pandemic 3.2% to a post-pandemic 4.8%. This has shifted the percentage of nonwoven used for wipes from ~10% in 2019 to 12% in 2023.

INDA attributes this step-change in large part to consumers who previously were not users of wipes having been introduced and acclimated to them during the peak pandemic period. These consumers were introduced to wipes via the disinfectant category, acknowledged the convenience they provide, and then adopted them for household cleaning, cosmetic, and personal hygiene uses. A similar COVID-19 inspired step-change has occurred for filter media and filtration. Prior to the pandemic, consumers had a basic awareness of indoor air quality issues. For three years, consumers have been inundated with education around indoor air quality, ranging from the state of air quality in hospitals, schools, businesses, and transportation to discussions regarding what is most appropriate for homes. Early in the pandemic, much focus was on what was necessary in terms of filter change frequency and maintenance, with news reports indicating that some school systems had two-thirds of facilities with “dirty or poorly maintained ventilation systems – (and) about half had air filters that hadn’t been replaced in years prior to October, rather than twice a year as recommended.” The narrative quickly changed to the efficiency and capability of filters in schools and public places. “Dr. William Bahnfleth, an engineering professor at Pennsylvania State University and the chair of ASHRAE’s epidemic task force, says the professional society’s prior recommendations to schools would help protect against body odor but not COVID-19.” Faced with such messaging, consumers began demanding better IAQ for their children’s schools AND began to consider their own home filter media change frequency and upgrading the media used to improve protection. These marketplace reactions, along with a pandemic-driven spike in demand for the media used for facemasks, have created a lasting shift in the percentage of nonwoven used for filtration purposes, moving to 11% in 2023. Considering production assets, since 2017, there has been a net increase of ~80 nonwoven manufacturing lines, of which ~20% are devoted to filtration, with another ~29% capable of producing various filtration related nonwovens (in addition to materials for non-filtration products). Assets dedicated to producing substrates for wipes made up another ~10% of the net increase in machines.