filtnews.com Issue 4 | 2023 WEFTEC 2023 SHOW PREVIEW Filtering μ Particles Companies Innovate to Capture More Micron Material from Air, Water and Gas Air Filtration Healthy Air Quality Must Be Defined as an Industry to Achieve It Woven Wire Mesh Innovation in Wire Mesh Ensures Maximum Flow Rates With Smallest Required Pore Sizes Wheels & Washing Machines Advancements Aid Minimizing Microplastics Pollution TM INSIDE BUYER’S GUIDE 2023 Welcome to the future of liquid filtration technology. Single Bag Housings Multi-Bag Housings Polypropylene Housings Indicating Filter Centrifugal Separators Backwashing Systems Coolant Filter Systems High Capacity Elements Filter Bags Contact us today for more information. 800.821.5373 RosedaleProducts.com Rosedale Products Inc. 3730 W. Liberty Rd. Ann Arbor, MI 48103 Email: Filters@RosedaleProducts.com Phone: 734.665.8201 • Fax: 734.665.2214 ©2023 Rosedale Products Inc.

By

By

By

By

By

By Dr. Iyad Al Attar

By

By

By Len LaPorta, Managing Director, Wiley Bros.-Aintree Capital

2 IFN ISSUE 4 2023 CONTENTS

&

Solution Center Showcasing Solutions for Success Chase Machinery & Engineering Epic Resins Rosedale Products, Inc. A Positive Spin on Wheels

Washing Machines

IFN

Aerosols

Adrian Wilson, International Correspondent,

Using Biological Particles as Test

Energy-Efficient

Processes

Bernadette Führer A Woven Wire Mesh for

Filtration

New

Dr.-Ing. Martin Müller Carbon Capture – A Major

Field for Filtration

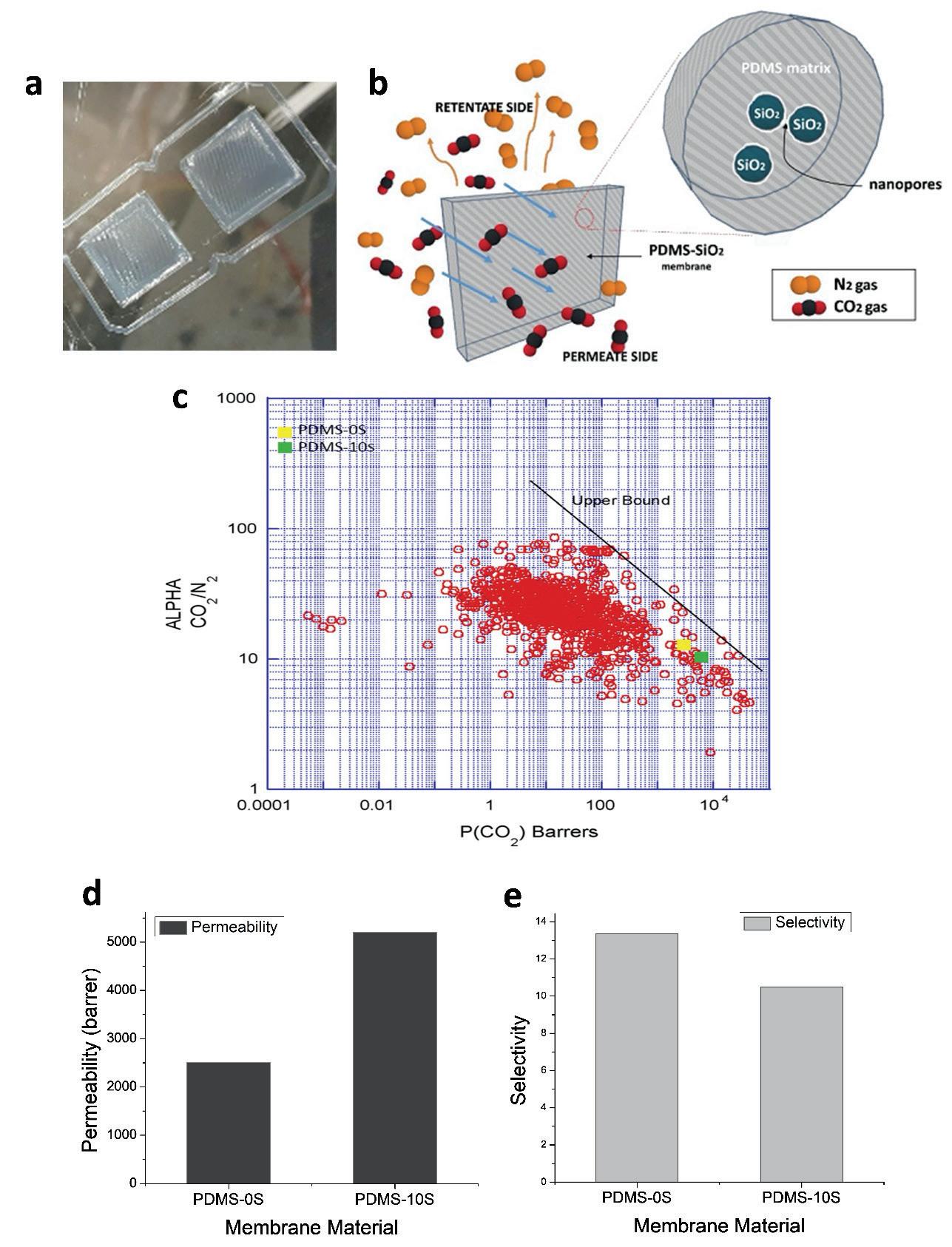

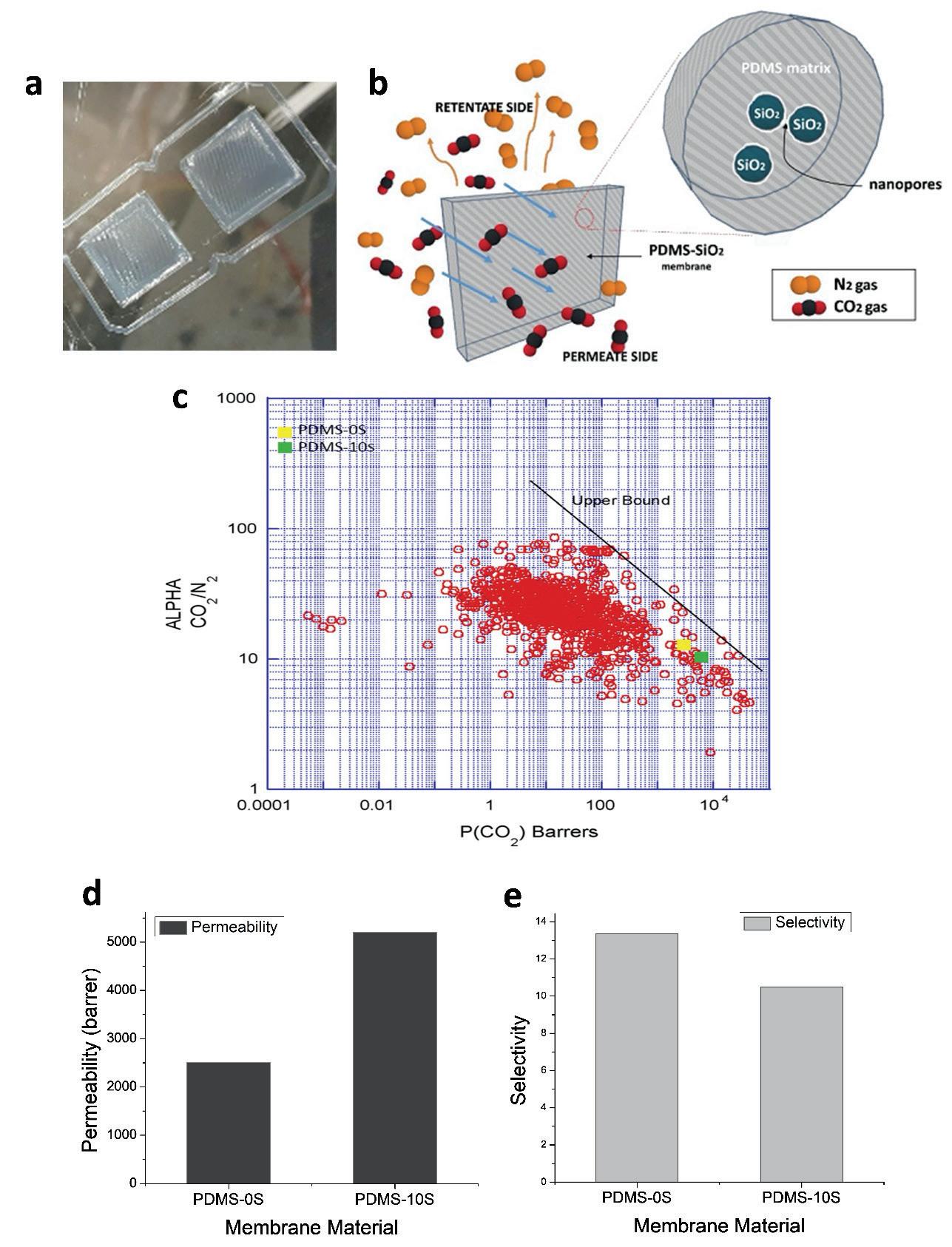

Adrian Wilson, International Correspondent, IFN Additive Manufacturing of Membranes: Greater Design Flexibility and Higher Performance

Rigoberto Advincula Air Quality: Define to Defend

Innovating Tubular Filtration 2022 AFS Engineering Merit Award Recipient Show Preview: WEFTEC

14 11 2023 | VOL 42 | ISSUE 04 14

Buyer’s Guide 2023

Viewpoint Minutiae

Tech

for

Caryn Smith, Chief Content Officer & Publisher Tech Spotlight Cloud Brings Water Filtration Technology to the Smart Home

Notes New Technology Briefs Tech Talk The Path to Finalizing New Standard

Infectious Aerosols

Matt O’Sickey, Director of Education & Technical Affairs, INDA M&A Insights

To Tell the Truth

True

Cost

Movers & Shakers Industry News & Notes 17 FEATURES 17 21 30 27 34 38 41 42 6 72 8 74 75 70 9 COLUMNS & DEPARTMENTS

$15 Billion Industrial Cartridge Market By Bob McIlvaine, President, The McIlvaine Company

21 27 34

Cover: Stock/Svetlozar Hristov

Adrian Wilson

International Correspondent, IFN +44 7897.913134 adawilson@gmail.com

Austrian Research Institute for Chemistry and Technology (OFI) +43 798 16 01 633 bernadette.fuehrer@ofi.at

Spörl KG / G. BOPP + Co. AG martin.muller@spoerl.de www.bopp.com

Governor’s Chair Professor, Department of Chemical and Biomolecular Engineering, UT radvincu@utk.edu

CALL FOR CONTRIBUTORS

Cranfield University iyad.al-attar@cranfield.ac.uk

Director

Education & Technical Affairs, INDA mosickey@inda.org

+1 919.459.3748

Custom Converting and Automation Equipment for the Filtration Industry

EQUIPMENT:

• Pleat Welding

• Ring Welding

• Laminators (Ultrasonic/ Thermal/ Adhesive)

• Slitters (Ultrasonic/ Laser/ Mechanical)

• Traverse/ Spiral winders

• Hollow fiber/ Memb rane Lines (Lab/ Pilot Scale)

• Custom Mac hines

TECHNOLOGY:

• Ultrasonics

• CO2 Lasers

• RF Welding

• Hot Air/ Wedge

• Band Sealing

• Adhesive Dispensing

• Impulse Welding

International Filtration News is actively seeking contributed technical articles from qualified industry professionals and those allied to the filtration industry. If you would like to pitch an article for publication in IFN, contact Caryn Smith at csmith@inda.org or +1 239.225.6137.

We employ our 68 years of web handling experience to benefit our customers. Contact Chase Machine today for your equipment needs!

4 IFN ISSUE 4 2023 CONTRIBUTORS | ISSUE 4 2023

Bob McIlvaine President, The McIlvaine Company +1 847.784.0013 rmcilvaine@mcilvainecompany.com

Caryn Smith Chief Content Officer & Publisher, INDA Media csmith@inda.org

Len LaPorta Managing Director Wiley Bros.-Aintree Capital, LLC llaporta@wileybros.com

ULTRASONIC LAMINATORS HOT MELT LAMINATORS

ULTRASONIC RING WELDERS

� se\<"µ,essed\ iitJICl.�E MA CHINE & ENGINEERING, INC. ._...__. 324 Washington Street, West Warwick, RI (401} 821-8879 • www.chasemachine.com

Matt O’Sickey

of

Dr. Iyad Al-Attar

Visiting Academic Fellow

School of Aerospace, Transport, and Manufacturing

Rigoberto Advincula

Bernadette Führer

Dr.-Ing. Martin Müller

No Photo Available

CSMITH@INDA.ORG +1 239.225.6137

Minutiae

“There’s something in the very small minutiae of life that tells us something about the big, big picture that we see every day all over the place, and so I think the more specific and creative and revelatory you are in the micro, the more powerful the macro will be.”

— Philip Seymour Hoffman

Don’t Sweat the Small Stuff ... and It’s All Small Stuff by Dr. Richard Carlson is a book I read years ago in one of my endless attempts to reduce my stress level It made a lot of sense. From his advice, “Choose Your Battles Wisely” is the phrase that has stuck with me. In raising kids or negotiating work situations, I use this measure to ask myself if I want to die on the hill of the conflict, or live another day in peace. This has served me to make better life choices.

After all, if we get caught up in the small stuff, we can get distracted from the bigger picture ... and lose sight of our ultimate goals.

Well, most of the time.

Thankfully there are some of you who have dedicated your work to the micro-level of science – the real (actual) small stuff – in order to attain real big picture results. This issue highlights products, innovations and ideas that take filtration to the next level ... down. Specifically, capturing harmful microscopic nanoparticles in air, gas and water from washing machines (p. 11), tainted air (p. 17), commercial gas (p. 21) and coal liquefaction (p. 38), and more.

Each article analyzes capturing harmful toxins and particles in filtration for the well-being of people, oh, and the planet. In fact, COVID-19 – invisible enemy #1 of 2020 – proved to be a compelling mass public

jolt into why this is so important, discussed more in “Air Quality: Define to Defend” (p. 34). Despite our best efforts (or are they?), indoor air quality is failing most of us. From wildfires, toxins, bacteria to allergens, our environments are really not built for best air quality situations. They are designed for cost efficiency. Define to Defend’s author says, “While the historic call for adhering to financial responsibilities always hovers in our minds, our social responsibility to avail the best IAQ is equally important. Enhancing indoor IAQ requires policies, relevant standards, and roadmaps to ensure implementation and compliance are entwined, not just the moral forces of the general public.”

And, don’t get me started on oceanic microplastics, a topic of such minutiae that it is not registering in the general public mindset. Why is that? Regardless, some of us do view the details differently to make better choices. Thankfully, filtration expert heroes are taking their experiences and offering us hope that we can battle the microscopic bad guys – a wise and worthy battle – and make our world cleaner for the next gen. In this case only, we should be sweating the small stuff ... every day!

Caryn Smith

Chief Content Officer & Publisher, INDA Media, IFN

International Filtration News Editorial Advisory Board

R. Vijayakumar, Ph.D., Chair

AERFIL

Tel: +1 315-506-6883

Email: vijay@aerfil.com

Rahul Bharadwaj, Ph.D.

Lydall Performance Materials

Tel: +1 603-953-6318

Email: rbharadwaj@lydall.com

Tom Justice, CAFS, NCT

ZENE, LLC Filtration

Tel: 757-378-3857

Email: justfilter@yahoo.com

James J. Joseph

Joseph Marketing

Tel/Fax: +1 757-565-1549

Emai: josephmarketing120@gmail.com

Wenping Li, Ph.D.

Agriltech Research Company

Tel: +1 337-421-6345

Email: wenpingl@agrilectric.com

Ernest Mayer, Ph.D.

E. Mayer Filtration Consulting, LLC

Tel: +1 302-981-8060

Email: ernestmayer6@gmail.com

Robert W. McIlvaine

The McIlvaine Company

Tel: +1 847-784-0013

Email: rmcilvaine@mcilvainecompany.com

Thad Ptak, Ph.D.

TJ Ptak & Associates

Tel: +1 414-514-8937

Email: thadptak@hotmail.com

International Filtration News is published by INDA Media, the B2B publishing arm of INDA, Association of the Nonwoven Fabrics Industry. +1 919.459.3700 info@filtnews.com | www.filtnews.com News & Press Releases to IFNNews@inda.media

Subscription price is $125 per year for non-U.S. subscribers. Periodicals postage paid at Novi, MI, and additional mailing offices. POSTMASTER: Please send address changes to International Filtration News, PO Box 158 Cedar Rapids IA 52406-0158 USA.

MISSION

International Filtration News covers the topics and technologies that will shape the future of filtration and separation. Using subject matter experts from all parts of the industry, IFN is the leading source for the dialogues, debates and innovations across the full spectrum of filtration and separation applications and processes.

If you would like to utilize your expertise to help shape the content in the IFN , consider applying for the IFN Editorial Advisory Board. We welcome participation through input on trends and innovations, new story ideas and overall thought leadership. This is a collaborative board that meets quarterly to discuss the state of the industry. Send an email to Caryn Smith at csmith@inda.org for consideration.

6 IFN ISSUE 4 2023

VIEWPOINT CONTENT | EDITORIAL CHIEF CONTENT OFFICER Caryn Smith Driven By Design LLC csmith@inda.org | +1 239.225.6137 EDITORIAL & PRODUCTION MANAGER Ken Norberg ken@filtnews.com | +1 202.681.2022 ART DIRECTOR Julie Flynn INTERNATIONAL CORRESPONDENT Adrian Wilson ADVERTISING | SALES PUBLISHER Driven By Design LLC advertising@inda.media | +1 239.225.6137 ADVERTISING COORDINATOR Vickie Smead vsmead@inda.org +1 919 459 3700 x 3720 AUDIENCE | CIRCULATION CIRCULATION MANAGER inda@stamats.com | +1 800.553.8878 INTERNATIONAL FILTRATION NEWS (ISSN: 1078-4136x), is published bi-monthly by INDA, Association of the Nonwoven Fabrics Industry, +1 919.459.3700.

TM

SPOTLIGHT TECH

Cloud Brings Water Filtration Technology to the Smart Home

Cloud Water Filters recently announced the launch of their flagship product Cloud RO, an under-sink reverse osmosis water filter that allows customers to monitor water quality and consumption via the Cloud app.

There is a crisis sweeping tap water in America. A crumbling water system infrastructure, and the rise of emerging chemicals like PFAS, have more consumers searching for home water treatment solutions. Cloud is a new player in the residential “point-of-use” filtration space. Cloud’s flagship product, Cloud RO, offers an advanced alternative to reverse osmosis filtration. Cloud incorporates state-ofthe-art technology that controls pressure and flow within the system to maximize filtration performance. Smart sensors track water quality and communicate that data to the consumer via the Cloud app. Cloud provides its customers with visibility into their water quality, filter health, and consumption habits.

“This inside view has been lacking in the water filtration industry,” stated Cloud’s Co-Founder and CEO, Ben Zvaifler.

“Consumers need to know that their filter is working and that the water their family is drinking is clean and healthy,” he added.

Cloud is one of the first water filtration companies to focus heavily on the smart home. Water quality data is aggregated across all the installed devices to give Cloud a high-level view of water quality across the country.

In addition to connectivity, Cloud also delivers powerful filtration and adds healthy

minerals to the purified water. A multi-stage, reverse osmosis filter eliminates all of the top contaminants including lead, PFAS, fluoride, pharmaceuticals, and pesticides. After the water has been purified, a remineralization filter adds back calcium, magnesium, potassium, and other trace minerals. These minerals improve the water’s taste and raise the pH leaving the water alkaline.

Residential water filtration is on the rise as a multitude of problems erode the public’s trust in tap water. Nine million lead service lines deliver water to homes across the country, and the emergence of PFAS, or “foreverchemicals” has the EPA scrambling to set new health standards that will leave many water utilities in violation. In addition, new regulations around single-use plastics are encouraging families to ditch plastic water bottles and switch to an in-home filtration solution.

“The issues facing water quality are pushing more Americans towards point-of-use filtration.

“It’s a rising tide in a well-established $6 billion industry. Even though we are the new kids on the block, Cloud is well-positioned for immediate growth,” added Cloud’s Co-Founder and CFO Nick Braun.

Cloud launched earlier this year and has already shipped and installed systems in over 30 states. In their first few months in business, Cloud has filtered thousands of gallons of water, accounting for more than 20,000 water bottles saved. “It’s a metric we love to track,” said Braun, “We know we are doing good, and

my kids are blown away when they check our app to see how many bottles we are saving as a family.”

The price for Cloud RO is $750. Filter replacements are all usage-based, but customers can expect to spend about $200 a year on an ongoing basis. Cloud offers DIYers easy-tofollow video installation instructions as well as a handyman database for customers who prefer a professional installation experience.

Cloud RO is currently available online at CloudWaterFilters.com.

Based in San Diego, CA, Cloud is a water company developing connected filtration technology that allows users to track water quality from their smartphone. Cloud launched to the public in early 2023. Their flagship product, Cloud RO, combines design and technology to deliver the most advanced drinking water experience available.

www.CloudWaterFilters.com

For details on how to submit your company’s technology for consideration as a “Technology Spotlight” in IFN , contact Ken Norberg at ken@filtnews.com or +1 202.681.2022.

8 IFN ISSUE 4 202 3

“Consumers need to know that their filter is working and that the water their family is drinking is clean and healthy.”

t Cloud RO lives under your sink and connects to your phone via the Cloud app. CloudWaterFilters.com

NOTES TECH

Feed Spacers for RO filter elements

Water is essential for life, and having access to potable and safe water is one of the key factors in maintaining health. Water filtration systems play a critical role in ensuring that our tap water is free from contaminants and other impurities that can impact our health.

Veolia, a leader in water technologies, will lead, via its subsidiary SIDEM, a consortium in charge of the engineering, procurement and construction (EPC) on the Mirfa 2 desalination project commissioned by Abu Dhabi National Energy Company PJSC (TAQA) and ENGIE. Located in Abu Dhabi, this state-of-the-art Reverse Osmosis Desalination will be the third-largest desalination plant in the United Arab Emirates (UAE). With a production capacity of 550,000 cubic meters per day of potable water, it will provide clean drinking water to approximately 210,000 households while offering increased efficiency and a reduced environmental footprint. The contract represents revenue of approximately 300 million euros for Veolia. Project construction will begin in Q2 2023 so the plant can be commissioned by 2025.

Most of the drinking water used in the UAE comes from the sea. To manage the growth in water consumption and to compensate for the aging of existing facilities, mainly thermal desalination plants, the country has decided to use the latest advanced technologies and engineering processes to increase its desalination capacity while reducing its energy consumption. A strategy that strongly supports the country’s 2050 carbon neutrality ambition.

Relying on Veolia’s worldwide expertise in water desalination, the Mirfa 2 plant will follow the latest developments in environmental and efficiency standards for desalination, featuring advanced technological processes such as reverse osmosis, which represents strong efficiency gains compared to traditional thermal desalination, to lower energy consumption and improve productivity. These technological advancements allow to slash energy use by 80% compared to the 1980s, when thermal desalination was predominant. www.veolia.com

Naltex™ diamond nettings are used as feed spacers for spiral wound water filtration membrane elements for Reverse Osmosis, Nano, Ultra, and Micro Filtration. Naltex feed spacers are specifically designed to optimize the hydraulic conditions of the feed water by creating turbulence on the membrane surface which reduces fouling and pressure losses through the membrane element. These specially crafted spacers are made by a strong yet flexible plastic mesh that provides superior hydraulic flow capability which improves the flux of the membrane. In addition, their unique design helps to evenly disperse the feed water across the filter surface, providing optimal contact time with the filter media and improving overall filter performance. Naltex™ feed spacer technologies can improve the efficiency of your water filtration system by increasing the flux of each membrane element while also extending the life and robustness of a membrane element by reducing fouling on the membrane surface contributing to less cleaning and maintenance downtime.

Naltex™ diamond nettings are made of FDA approved materials, offering superior strength and flexibility. Additionally, all Naltex™ products are tested to ensure they meet strict standards for lead, chlorine and other contaminants commonly found in drinking water. With regular cleaning and maintenance, these diamond nettings can extend the life of your filter while ensuring safe, pure water for your entire family. www.gessner-filtration.com

Porometer to Distribute ATI’s Automated Filter Tester in Europe

Porometer, a part of Aptco Technologies will collaborate with Air Techniques International (ATI), a designer and manufacturer of specialized testing equipment, on the European distribution of the 100X Automated Filter Tester to enhance our offerings and provide our customers with even more comprehensive filtration solutions.

The 100X Automated Filter Tester is designed for testing and quality control of the efficiency and resistance of filter media, replaceable particulate filters, and masks used in medical and industrial hygiene applications. The 100X meets leading global industry standards such as EN 132747:2019, NIOSH 42 CFR Part 84, GB 2626, and ASTM F3502-21. It is a high-capacity automated solution ideally suited to meet the precise and rigorous requirements of both development and production quality control environments.

The 100X is perfect for testing FFP, N95, KN95, and P100 respirator masks. www.porometer.com

ISSUE 4 2023 FILTNEWS.COM 9

Veolia to Deliver Third Largest Desalination Plant in UAE

NOTES TECH

Ohio Fabricators Company (OFCO), a leading manufacturer of stock and custom strainers, breathers, diffusers and screen assemblies for the filtration and fluid power industries, has created new screen assemblies for water and petroleum-based solutions.

OFCO’s “PS” strainers were specifically designed for use with portable insect control equipment but are applicable to any business requiring a high-quality strainer.

“PS” strainers are constructed for water-based fluids where corrosion and low cost are competing factors. The cap and base are made from one-piece high strength nylon. The inner perforated support core is constructed of galvanized steel which adds strength to the pleated stainless-steel wire cloth and is epoxy bonded for leak-proof service. Connections are currently available in sizes of 1/2” female, 3/8” male and 3/8” female NPT hex nut sizes. www.ohfab.com

Samsung Launches Less Microfiber™ Filter to Protect Oceans from Laundry Plastics

Samsung Electronics announced the launch of the new Less Microfiber™ Filter, an external washing machine filter designed to significantly reduce plastic microfiber emissions during laundry cycles. Designed with inspiration from apparel maker Patagonia and expertise from the global ocean conservation organization Ocean Wise, the filter builds on the success of last year’s Less Microfiber™ Cycle to substantially cut microplastics and enable sustainable laundry washing that is both effective and effortless. The new filter is now available in Korea and the U.K. and will roll out to other countries in the third quarter.

Porometer, a leading provider of pore size measurement solutions, has announced the launch of its latest product, the POROLUX™ Revo. Building on its reputation for innovation and cutting-edge technology, Porometer has developed a new instrument that takes pressure control to the next level, offering unrivalled accuracy and reproducibility in pore size measurement.

The POROLUX™ Revo features the patent pending MP² (Multistage Pressure Process) technology, which ensures a smooth pressure increase during the measurement process and speeds up the process of reaching flow and pressure stability.

This advanced pressure built-up process makes it possible to do measurements with smaller, perfectly uniform pressure steps, leading to the most accurate and reproducible pore size results.

One of the advantages of the MP² technology is the more gentle approach towards the desired pressure point, making it possible to register a data point even in the pore opening region. This results in a smoother wet and more detailed pore size distribution curves, providing users with even greater insights into their samples. www.porometer.com

“With microplastics emissions to our oceans continuing to increase and regulations being strengthened in many countries, as well as microplastics becoming a growing health concern for people everywhere, Samsung worked with Ocean Wise and Patagonia to engineer technology to prevent the release of microplastics from our daily life,” said Moohyung Lee, Executive Vice President and Head of R&D Team of Digital Appliances Business at Samsung Electronics. “With innovations like the Less Microfiber™ Filter and Cycle, Samsung is enabling Everyday Sustainability in a wider array of products and making eco-conscious daily practices second nature in the home.”

To enable customers to cut microplastic emissions from their laundry, Samsung first developed the Less Microfiber™ Cycle, a wash course that reduces microplastic shedding by 54% in part by leveraging Samsung’s proprietary Ecobubble™ technology. By using bubbles to help dissolve and absorb detergent, less heat and energy is required to wash clothes, resulting in reduced abrasion which in turn prevents microplastic emissions.

The Less Microfiber™ Filter takes this a step further, preventing up to 98% of microplastics released during laundry from escaping into the ocean, equivalent to eight 500ml plastic bottles per year when used four times a week. In addition, to help more customers get involved in cutting microplastic emissions, the Less Microfiber™ Filter has a mountable design style that allows it to be used with standard washing machine models, demonstrating the company’s dedication to long-term sustainability and helping customers embrace sustainability at home. www.samsung.com

10 IFN ISSUE 4 202 3

New Pore size Instrument From Porometer

Ohio Fabricators Announces New PS Screens

Chase Machine and Engineering Designs and Builds Custom Converting and Automation Equipment for your Application

For over 68 years, Chase Machine and Engineering has been designing and building a variety of standard and custom converting machinery for WovenNonwoven Fabrics, Films and Foils. From integrating independent modules to supplying Full-Scale Production Lines, we offer a comprehensive range of machinery that play an essential role in the success of well-known brands and products worldwide.

As one of the premier design and manufacturing companies for custom web handling machinery, Chase serves a wide range of customers in the Textile, Medical, Nonwoven, Converting, Geotextile, Extrusion, Filtration, and Packaging Industries. We partner with leading manufacturers to produce application-specific equipment ranging from Festooners, Accumulators, Inspection Machines, Unwinds/Rewinds and Traverse Winders, to Ultrasonic Slitters, Laminators, and Cut-To-Length Machines.

Chase specializes in the integration of technologies such as Ultrasonics, Impulse Welding, RF Welding, Band Sealing, Hot Air Welding, Glue Dispensing, Hot Knives and Conventional Blade Slitters as well as Vision and Marking Systems.

Chase is a vertically integrated company, utilizing State-of-the-Art 3D Solid Modeling Software for our machine designs. Within our 28,000 sq. foot facility, located in West Warwick RI, we program our PLC’s and HMI’s, build our Electrical Control Panels and Machine, Weld/Fabricate, Paint and Assembly our Equipment while maintaining tight control of quality and delivery.

We place a high priority on customer and product confidentiality, and

Chase specializes in the integration of technologies such as Ultrasonics, Impulse Welding, RF Welding, Band Sealing, Hot Air Welding and Glue Dispensing, and more.

constantly seek to improve our quality and process controls as we help our customers improve their products and processes. Working together with our customers, Chase will deliver equipment that is newer, faster, more efficient, and more reliable for a timely return on your investment.

For those interested in product development, the Chase Materials Application Lab exists to help your team take their ideas to the next level. Whether creating new products or improving existing ones, Chase can determine the optimum method for manufacturing. Lab capabilities include web handling systems with ultrasonic technology for laminating, embossing, welding, slitting as well as impulse welding machines.

and learn why Chase Machine and Engineering has adopted the tagline “EXPECT TO BE IMPRESSED.”

www.chasemachine.com

ISSUE 4 202 3 FILTNEWS.COM 11 ADVERTORIAL | SOLUTION CENTER: FILTRATION

Visit us at www.chasemachine.com

Ultrasonic Ring Welder.

q Chase Ultrasonic Laminators.

Resilient Molded End Cap Polyurethanes

Epic Resins Adds a Resilient Line of Molded End Cap Polyurethanes

There are many challenges facing the filtration industry today. Epic Resins’ epoxy and polyurethane solutions have solved complex filter manufacturing problems for more than 60 years. They specialize in potting and encapsulation compounds, molded end cap polyurethanes, adhesives and seam sealing products. The experts at Epic Resins partner with you, leveraging their experience to recommend products or formulate solutions with:

• Consistent performance

• Technical support

• Superior value

Epic Resins is committed to serving global customers as a trusted partner in superior quality resins and polymers to enhance their profitability and performance. Their philosophy is based on listening to your needs and developing quality solutions to meet your challenges. The company was built on technologyproven chemistry and a wealth of market and application knowledge. This guarantees consistent products and maximum value.

Because Your Design Can NOT Be Compromised

Whether you’re a spa equipment supplier wanting a filter end cap material, an OEM

supplier seeking an air filter potting compound or an automotive manufacturer looking for a chemical resistant filter adhesive, Epic Resins can formulate it.

• POOL & SPA manufacturers want chemically resistant polyurethane casting compounds with reliable performance. Epic Resins offers polyurethane solutions that inhibit mold, mildew and bacteria growth.

• AIR & HEPA filtration systems require air-tight bonding for proper functioning. Epic Resins formulates durable HEPA polyurethane adhesives strong enough to withstand rough handling and harsh environments.

• OIL & GAS filters used to separate contaminants from oil, gasoline, greases and coolants require compounds that are chemically resistant and maintain adhesive qualities in harsh environments. Epic offers hundreds of chemically resistant solutions.

Molded End Cap Solution

ToughPleat is a line of two-component polyurethanes for molded end caps developed by Epic Resins. These VOCfree polyurethanes are designed to have excellent tear resistance and high

strength for demanding molded filter end cap applications. Being strong, flexible materials, ToughPleat polyurethanes are well-suited for filters that will be subjected to constant pulsing, pressure drops and/ or may take some effort to remove or install. The high tear resistance prevents the filter from being damaged during the installation or removal process.

With a convenient mix ratio by volume and low viscosity, the ToughPleat Series is easy to dispense and can be used with many types of metering equipment. The fast gel time ensures a quick turnover of filters, helping to reduce WIP time in many production configurations.

ToughPleat benefits for molded end cap applications:

• High tensile strength

• High elongation

• Excellent tear resistance

• Easy to dispense

• Reduced WIP time

ToughPleat property versions available, based on your application:

• Hardness

• Tensile strength

• Elongation

• Tear strength

If you need help choosing one of Epic Resins’ standard products or need a formulated material, let their technical sales team help you determine the best solution for your application ... get started now.

www.epicresins.com

12 IFN ISSUE 4 202 3

ADVERTORIAL | SOLUTION CENTER: FILTRATION

p Epic Resins development and quality assurance labs are equipped with the latest in analytical testing equipment, ensuring product consistency and superior technical support.

p The chemists at Epic Resins work directly with your engineering and manufacturing departments, enabling us to provide you with effective solutions to fit your demanding needs.

p ToughPleat series is a solvent-free formula designed to have excellent tear resistance and high strength for demanding molded filter end cap applications.

Rosedale Products Inc. Comprehensive Solutions for Critical Industry Filtration Needs

Rosedale Products, Inc. is a leading technology developer in the field of liquid filtration systems and waste minimization products for customers around the globe. With more than 50 years of experience, Rosedale offers an exceptional product line that includes high-performance filtration solutions for multiple industries. Rosedale technicians help customers find the best, most cost-effective approaches to their filtration needs.

Rosedale product lines set the industry standard in versatility and reliability and includes bag and cartridge filters, basket strainers, automatic back washing filters, filter cartridges, and many special application products. Together with ongoing consulting, troubleshooting, and support from our team of in-house experts, Rosedale provides comprehensive solutions for every critical industry filtration need.

Rosedale is committed to your vision. Rosedale manufactures industrial filtration products for virtually any industry where liquid and gas flows are present.

With a vast product line that suits many needs, as well as the flexibility to customize standard products. Rosedale’s sales staff has knowledge of many industrial practices, giving customers the confidence that their filter solution is the best available for their specific need. The most popular products are bag filters, pleated cartridge filters, and basket strainers. Rosedale High Flow horizontally mounted filter vessels are setting the industry standard with containing 1 to 31 large pleated cartridges in 40 or 60 inch lengths. The High Flow product line boasts flow rates of up to 400 gallons per minute for each element in select applications.

Whatever your filtration application, Rosedale Products, Inc. offers a product designed to meet your needs. From filters that accept high-efficiency filter cartridges to filter bags, Rosedale products deliver superb performance at an exceptional value.

Innovation + Design + Experts. Rosedale Product Offering:

• High-Flow Housings

• Single/Multi-Bag Housings

• Polypropylene Housings

• Indicating Filter

• Centrifugal Separators

• Backwashing Systems

• Coolant Filter Systems

• High Capacity Elements

• Filter Bags

Call 800.821.5373 or write us today at filters@rosedaleproducts.com for more information.

www.RosedaleProducts.com

ISSUE 4 2023 FILTNEWS.COM 13

ADVERTORIAL | SOLUTION CENTER: LIQUID FILTRATION

p Custom design to in-stock solutions. Call about our vast selection of in-stock filter products.

p Rosedale Products High Flow Filter Housing: 1 to 31 filter elements, 40” and 60” lengths, up to 400 gpm per cartridge, absoluterated cartridges, compact design, and operator-friendly.

p Rosedale Products Multi-Bag Filter Housing.

A POSITIVE SPIN ON WHEELS & WASHING MACHINES

By Adrian Wilson, International Correspondent, IFN

By Adrian Wilson, International Correspondent, IFN

In his memorable TedTalk from 2010, the great Swedish physician and academic Hans Rosling, who sadly died in 2017, proposed the washing machine as the greatest invention of modern times.

“I was only four years old when I saw my mother load a washing machine for the first time in her life,” he explained. “That was a great day for my mother – my parents had been saving for years to buy that machine. My grandma was even more excited. Throughout her life she had been heating water and hand-washing laundry for seven children and now she was watching electricity do that work. She was mesmerized – to my grandma that washing machine was a miracle.”

Rosling continues to make sound reasons for his nomination –not least giving women the time to read books – in an illuminating talk well worth watching.

However, the general consensus elsewhere is that the automobile is the greatest invention of the 20th century ... and the invention of the wheel the most significant in the history of civilization.

What was not widely known in 1952, however – when Hans Rosling was just four years old – was that advancements of both washing machines and automobiles have caused damage on the environment and now are threatening the future health of both humanity and the planet, as implications are become clearer.

Impacts of Progress

Scientists estimate there are around 14 million tons of microplastics on the ocean floor, and a further 24 trillion grains floating on the surface of the oceans – with 35% of this pollution generated from the turbulence and friction of putting clothing, sheets and towels through the washing machine.

Meanwhile, researchers from Imperial College London’s Transition to Zero Pollution initiative report that six million tons of tire wear particles are released globally each year, contributing to the microplastics problem, as well.

As tires break down they release a range of particles, from visible pieces of tire rubber to nanoparticles. Large particles are

14 IFN ISSUE 4 202 3

MICROPLASTICS

Courtesy of CLEANR Stock/LeManna

carried from the road by rain into rivers, where they can leach toxic chemicals into the environment, while smaller particles become airborne and breathed in. They are small enough to reach into the deep lung and can contain a range of toxic chemicals, including polyaromatic hydrocarbons, benzothiazoles, isoprene and heavy metals like zinc and lead.

Despite this, research on the environmental and health impacts of tire wear has been neglected in comparison to the research and innovations dedicated to tackling fuel emissions. The Imperial researchers say that the effect of new technologies on the generation and impact of tire wear should be a priority.

“Tire wear particles pollute the environment, the air we breathe, the water run-off from roads and have compounding effects on waterways and agriculture,” said Dr. Zhengchu Tan, of Imperial’s Department of Mechanical Engineering. “Even if all our vehicles eventually become powered by electricity instead of fossil fuels, we will still have harmful pollution from vehicles because of tire wear.

“We urge policymakers and scientists to embark on ambitious research into tire wear pollution to fully understand and reduce their impacts on biodiversity and health, as well as research to reduce the generation of these particles.”

Solutions

Effective solutions based on advanced filtration for both of these problems are either in development or already exist, and can be expected to be widely implemented in the coming years.

GKD Group, for example, the leading woven mesh filtration manufacturer headquartered in Düren, Germany, has teamed up with Cleveland, Ohio-based CLEANR, one of a number of developers of advanced microplastics filtering technologies for washing machines

The two companies are collaborating on the development, engineering and manufacturing of CLEANR’s solutions which are said to efficiently filter microplastics from residential, commercial and industrial washing machine wastewater.

CLEANR’s patent-pending technology can be applied as an external filter or be readily integrated into modern washing machine designs as a pre-installed solution. The technology has been shown to capture over 90% of microplastic fibers larger than 50 microns in size. CLEANR also offers a consumer-friendly dry disposal mechanism that prevents hands-on contact with the microfiber waste and prevents it from being washed down the drain.

Pending Washer Regulations

“Washing-machine manufacturers around the world are facing growing demand for consumer-friendly, costefficient microplastic filtering solutions to address pending regulations in Europe, North America and beyond,” said CLEANR CEO Max Pennington. “Our partnership with GKD ensures the highest quality and precision manufacturing capabilities for our clients, based on GKD’s 100-year track record of woven mesh innovation.”

and distribution centers. This is an opportunity to help deliver a filtration solution that actually meets upcoming regulatory requirements for Europe and beyond.”

Legislation

A number of governments are studying the problem and developing new rules to curb the flow of plastic microfibers from washing machines into waterways. Beginning in January 2025, France will require all new washing machines sold in the country to include a microplasticfiltration solution. Meanwhile, members of the UK parliament, California, Illinois, and Oregon state legislators in the USA, and provincial legislators in Ottawa in Canada, are working through similar proposals, with other governments around the world following suit.

“The growing focus on microplastic pollution by consumers, governments, healthcare organizations and manufacturers of textiles, apparel and appliances has created a dynamic market with potential to achieve rapid change,” said Terry Moore, chairman of CLEANR’s board of directors. “By closely collaborating with washing-machine manufacturers and global leaders like GKD, CLEANR will help overcome the world’s number one source of microplastic pollution, while driving growth for our clients and shareholders.”

Tire Abrasion

GKD has also been closely involved with the Tire Abrasion in the Environment research project (RAU) with the Technical University of Berlin in Germany and is building on the results in the development of a year-round filter for road traffic applications.

“Microplastic pollution is becoming an urgent environmental and public health concern, but the microplastic filtering of washing-machine wastewater is a game changer,” added GKD Group CSO Stephan Kufferath. “We’re keen to help CLEANR achieve its market potential by leveraging our 50 micron stainless-steel mesh for capturing microplastics and long-established network of global manufacturing

“We worked with TU Berlin to identify hotspots, such as intersections that see a great deal of traffic and are currently developing a filter basket which is purged during the regular cleaning of conventional drainage shafts,” explained development engineer Dominik Herper. “This is then included in the standard maintenance cycle, which is both efficient and saves costs. However, this is no easy undertaking, since road run-offs catch more than just microplastics. In fact, they

ISSUE 4 202 3 FILTNEWS.COM 15

p Founders at the 2022 startup of CLEANR (left to right): Chip Miller, Co- Founder & COO, Max Pennington, Co-Founder & CEO, and David Dillman, Co-Founder & CTO, who met while attending Case Western Reserve University.

also attract leaves, general waste, cigarette butts and dog excrement.

“As such, our filter media must not only be very rugged, but also capable of reliably filtering road runoff water without getting clogged. It must also continue to perform over an extended time period, specifically between scheduled maintenance intervals.

“Our mesh expertise – coupled with the fact that we have been focusing intensively on the topic of microplastics since 2016 – provides clear benefits when developing products of this kind.”

Getting to a Global Solution

Microplastics are ultimately a global problem, Herper stressed, and it’s therefore important not just to have one solution, but approach the issue from various angles.

“As a general rule, the first step is always to prevent plastics from being released into the environment in the first place,” he said. “We know that tire abrasion from

road traffic is the number one cause of microplastics and less road traffic would certainly help, but this is unlikely to happen.

“In fact, tire abrasion is likely to increase even further as the modern world focuses increasingly on electric mobility because electric vehicles are heavier than their combustion engine counterparts and tend to generate more abrasion.

“Installing drain filters in locations such as major intersections is therefore an initial step that could make a meaningful difference. This would certainly reduce the proportion of microplastics in rainwater. However, it also requires a cost-effective solution, as well as corresponding legislation.”

Adrian Wilson is an international correspondent for IFN . He is a leading journalist covering fiber, filtration, nonwovens and technical textiles. He can be reached at adawilson@gmail.com.

With our extensive knowledge

We offer the following services to our customers:-

MINI-PLEAT-GLASS

Mini-Pleat: H.E.P.A., ULPA & ASHRAE

Pleat heights 1/2” to 12” upto 39” wide. Interrupted beads, many configurations.

MINI-PLEAT-SYNTHETIC

Mini-Pleat: H.E.P.A. & ASHRAE

Pleat heights 3/4” to 4” upto 25” wide. Interrupted beads, many configurations.

We can incorporate the following features in your elements: Edge Seal - allowing economical frame sealing Slitting/Perforating - multiple packs

“W” pleat Fire retardant glue

16 IFN ISSUE 4 202 3

Filter Manufacturing Machinery Solent Technology Inc cps@solentech.com A service of South Carolina, USA. Tel. +1(803)739-0770 Fax:+1(803)739-0814

SERVICES C NTRACT PLEATING GLASS | SYNTHETICS | PAPER | MEMBRANE

in production of the innovative SOLTECH “Mini Pleat” Systems, and over 20 years of contract pleating with our revolutionary glue bead technology.

Stock/Svetlozar Hristov

Using BIOLOGICAL Particles as TEST AEROSOLS

Research Project Aeropore Provides Innovative Test Methods

By Bernadette Führer

Many biological hazards such as viruses, bacteria, fungi and allergens being present as airborne infectious or allergenic particles had a low profile in aerosol research until the COVID-19 pandemic. At the beginning of the pandemic, the main control strategies focused on the disinfection of surfaces and hand hygiene rather than virus transmission via air, which turned out to play the most important role regarding the source of hazardous infections. Measures, such as ventilation or air purification and face masks, that lead to a reduction in the viral load in the air we breathe, are therefore considered as the most effective protective strategy against infectious airborne pathogens (e.g., Ebola, influenza, endemic coronaviruses or molds) and against airborne allergens such as pollen spread via air.

Status Quo: Air Filter Evaluation with Non-biological Aerosols

The greatly increased transparency on the topic of bioaerosols in the scientific community and social media caused a significant increase in research activities as well as the need for solution concepts on efficient reduction options of these airborne pathogenic aerosols in indoor air, and vice versa. Thus, many innovative concepts are developed to enable lownoise and energy-efficient reduction of pathogens in indoor air. However, the efficiency of air purification to remove airborne pathogens in a real indoor environment can still only be estimated to a very limited extent at present. While established test standards with precisely defined test germs and conditions have been developed for decades in the field of surface hygiene, there is currently a

strong need in the field of air hygiene for test methods that can reliably measure and quantify the efficiency of measures to reduce infectious pathogens such as viruses in indoor air.

In current routine standard operations, non-biological aerosols such as salt particles, oil-like droplets or fine dust are applied for air filter evaluation (ISO 16890, DIN EN 71460-1, ÖNORM/EN 149). Regarding the investigation of air cleaners, there are promising studies aiming at more realistic indoor test scenario using e.g. NaCl aerosols (Küpper et al., 2019). While these particles represent the size of viruses, nanometerscale particle deposition is also largely related to the physicochemical properties of, for example viruses, which cannot be easily simulated by a saline aerosol. It becomes particularly difficult when it is

ISSUE 4 2023 FILTNEWS.COM 17

AIR FILTRATION

q Optical counting of viruses or bacteria is used to calculate filtration efficiency. OFI /Michael Pyerin

not a matter of pure filtration, but when the viruses are to be inactivated (e.g., by UV light ionization or electrochemical processes). Here, realistic experiments with infectious pathogens cannot be substituted, since the determination of the infectivity of the particles plays an essential role.

Testing with Real Airborne Microorganisms

Testing with real biologically active viruses, bacteria or allergenic particles, especially at large scales can be challenging and complex. However, they could support better understanding of infection control and pathogen transmission, especially for risk minimization instruments such as filtration systems in health care settings. As working with very hazardous and harmful pathogens is often not possible, the application of less harmful microbial model strains is recommended in several aerosol studies.

One possibility to mimic pathogenic viruses are bacteriophages, which are bacterial viruses infecting specific bacterial host cells, which means, they are nonpathogenic to humans. Although these bacterial viruses reflect the properties of critical pathogens such as Ebola, influenza or various endemic or pandemic coronavirus strains quite well, they can-

The Research Project AEROPORE

In the FFG-funded research project “Aeropore,” the Austrian Research Institute for Chemistry and Technology (OFI) together with the Center for Electron Microscopy Graz (ZFE), both members of ACR (Austrian Cooperative Research), have developed a novel filter test rig. This enables filter systems to be assessed not only on the basis of their permeability to particles in terms of number and size, but also according to their biological risk. Starting in autumn 2023, OFI expert Bernadette Führer will be researching in the project “AeroMobil” how this novel test facility can also be used in mobile applications.

not infect humans, but just bacteria. Thus, a high level of operational safety can be ensured. Bacteriophages might support and facilitate aerosolization studies and subsequently, prediction and estimation of behavior and reactivity of highly pathogenic airborne viruses.

As biological particles such as viruses behave differently and comprise detectable infectious potential compared to inert non-biological particles, it is important for the design and testing of filtration and ventilation systems to investigate the interactions between bioaerosols and filters as well as air conditioning and cleaning devices. These non-biological particles may represent the size of e.g. viruses but do not necessarily reflect the separation mechanisms on nanometric scale, which are often connected to physio-chemical characteristics of viruses, which cannot be simulated by an e.g. salt particle.

In general, it is known, that nonenveloped viruses are more persistent towards environmental stress such as temperature, relative humidity, irradiation via UV or disinfection agents, whereas in the case of enveloped viruses, additionally possessing a lipid membrane carrying, e.g. characteristic membrane spike proteins, are more sensitive towards environmental influencing factors. Furthermore, bacteria or fungal spores may change size and shape depending on

cell membrane and wall characteristics as reaction environmental factors such as desiccation, temperature, humidity or the presence of surrounding carrier fluids, droplets or particles. The potential of applied bioaerosols lies furthermore in serving as extension tool to commonly used non-biological aerosols such as salt or DEHS particles for evaluation of potential reduction of biological risk by e.g. air filters or Heating, Ventilation and Air Conditioning (HVAC) systems.

Breathe Easy: Insight into the Research Project Aeropore

Within the research project “Aeropore” conducted at OFI, an independent testing and research institute in Austria and member of ACR (Austrian Cooperative Research), the subject was intensified. In the course of the project, it was possible to develop a pilot-scale simulation filter test rig (at right) for testing air filters with airborne biological hazards belonging to biological safety level 1 (BSL1).

Even before COVID-19 pandemic the topic air hygiene and biological safety played a major role for OFI. Thus, the development of reproducible and comparable methods allowing the performance of single-pass tests using bioaerosols (determination of filter passage, fresh “air mode”) for evaluation of air filters from a biological and immunological perspective could be enabled.

18 IFN ISSUE 4 2023

In protective gear, Bernadette Führer works with bioaerosols on the filter test rig set up as part of the "Aeropore" research project. OFI

Whereas everything started with a focus on allergens, pollen and fungal spores, the testing scope has been extended further during the course of the project. Working with bioaerosols containing bacteria and viruses used for filter testing was enabled at OFI within a second step, whereas the COVID-19 pandemic definitely enhanced transparency and attention on the topic.

It is known, that handling airborne particles functioning as test bioaerosol can be challenging. Each microbial strain or bioparticle requires proper preparation, sampling, aerosolization and detection techniques due to different characteristics and structural features of the biological particles, especially in airborne state. In addition, capability to survive as well as to maintain specific biological activity in airborne state is required by applied microbes for being able to detect them.

As there are very strict safety regulations when working with highly patho-

For the investigation of air filters, this filter test rig was developed at OFI, which can also be used to classify filter systems in terms of their separation performance for biological hazardous substances. OFI

genic and infectious microorganisms such as SARS-CoV-2, influenza viruses, Ebola or Mycobacterium tuberculosis at laboratory, many research studies recommend safe and non-pathogenic models for human viruses.

To give an example, commonly used virus surrogates for aerosol experiments are MS2 bacteriophage and phi6 bacteriophage, which are also used at OFI for filter and air cleaner evaluation. MS2 bacteriophage, a well-known bacterial virus with an average size of 27 nm, was chosen as representative for a robust non-enveloped virus comparable to noroviruses. On the other hand, phi6 bacteriophage with an average size of 86 nm was selected as enveloped virus posing as a surrogate for Ebola virus or Coronavirus.

During method development, both viral surrogates were compared regarding their stability and recovery as airborne particles for testing air filters within

What is a Bioaerosol?

If an aerosol mixture contains biological material or microorganisms, the term bioaerosol or biological aerosol is used. Such a biological aerosol consists of living and non-living components or fragments such as pollen, fungi, bacteria and viruses. These differ in size:

• Size of fungal spores: most commonly observed size range of spores is 2 to 10 μm but can vary from around 1 to 50 μm

• Size of bacteria: 0.5 up to 4 μm is assumed depending on bacteria species as well as sampling and analysis techniques

• Size of viruses: 15-500 nm

• Size of pollen: average between 25 and 40 µm, subpollen particles (“Ubisch bodies” ~0.5 µm)

ISSUE 4 2023 FILTNEWS.COM 19

Testing with real biologically active viruses, bacteria or allergenic particles, especially at large scales can be challenging and complex. However, they could support better understanding of infection control and pathogen transmission, especially for risk minimization instruments such as filtration systems in health care settings.

OFI filter test rig. For checking the suitability of the selected strains as a stable bioaerosol recovery and viability after aerosolization into the test rig were investigated. Liquid aerosol generator from Topas GmbH was used for aerosolization of selected bioaerosols at different volume flow rates ranging from 40-300 m³/h for defined period of time per run. The nebulized airborne viruses sprayed into the test duct were sampled via collection filter media mounted at the end of the test duct followed by liquid extraction, which is just one of several bioaerosol sampling techniques.

The quantification of the viruses is usually done via double layer method by optically counting plaque forming units (PFU) being the golden standard for detection of bacteriophages. The method requires incubation of the host bacteria together with the sample solution containing the target virus at specific conditions. So-called plaques are formed by present bacteriophages as a result of infecting host bacteria, grown

References:

on agar plates containing nutrient media. For evaluation of retention capacity or filtration efficiency of air filters regarding hazardous bioparticles, tests with and without a test filter, (a cabin air filter) are done.

Following general issues were important to consider during development of test bioaerosols applied within a filter test rig:

1. Stability and recovery of viruses, bacteria, fungal spores or allergenic pollen on surfaces.

2. Stability and recovery of airborne particles in airborne state after aerosolization within whole test duct.

3. Checking suitability of bioaerosol for single-pass tests for air filters, filter media and air cleaners.

More Research is Needed

The application of bioaerosols for a standardized air filter evaluation is still a black box within aerosol research and filter testing, which could be further opened for supporting estimation and

1. Whitworth, C., Mu, Y., Houston, H., Martinez-Smith, M., NobleWang, J., Coulliette-Salmond, A., & Rose, L. (2020). Persistence of bacteriophage Phi 6 on porous and nonporous surfaces and the potential for its use as an Ebola virus or coronavirus surrogate. Applied and Environmental Microbiology, 86(17), e01482-20.

2. Verreault, D., Marcoux-Voiselle, M., Turgeon, N., Moineau, S., & Duchaine, C. (2015). Resistance of aerosolized bacterial viruses to relative humidity and temperature. Applied and environmental microbiology, 81(20), 7305-7311.

3. Küpper, M., Asbach, C., Schneiderwind, U., Finger, H., Spiegelhoff, D. and Schumacher, S. (2019). Testing of an Indoor Air Cleaner for Particulate Pollutants under Realistic Conditions in an Office Room. Aerosol Air Qual. Res. 19: 1655-1665. https://doi.org/10.4209/ aaqr.2019.01.0029

4. Miaskiewicz-Peska, E., & Lebkowska, M. (2012). Comparison of aerosol and bioaerosol collection on air filters. Aerobiologia, 28(2),

improvement of infection control and prevention but also proper selection of a filter providing energy-saving performance within an effective filtration or air cleaning system. The implementation of biological methods within more realistic scenarios using selected infectious bioaerosols could be realized further within real-life test setups as, for example, within a car for evaluation of a car HVAC system.

In the future, OFI will deal with this topic even more intensively: in the autumn of 2023, the research project “AeroMobil” will start. The aim is to facilitate the assessment of air purification measures in different room concepts by developing a mobile test station.

Biotechnologist Bernadette Führer has been working in applied research at Austrian Research Institute for Chemistry and Technology (OFI) since 2017, where she specializes in filter analysis and air hygiene. She contributes her know-how to various RDI projects: Within the project "Aeropore", she was instrumental in setting up a new methodology with which air filters can be evaluated using allergens, viruses and bacteria in a particularly realistic way. Visit www.ofi.at. Reach Bernadette Führer at +43 798 16 01 633 or bernadette.fuehrer@ofi.at.

185–193. https://doi.org/10.1007/s10453-011-9223-1

5. Després, V. R., Alex Huffman, J., Burrows, S. M., Hoose, C., Safatov, A. S., Buryak, G., Fröhlich-Nowoisky, J., Elbert, W., Andreae, M. O., Pöschl, U., & Jaenicke, R. (2012). Primary biological aerosol particles in the atmosphere: A review. In Tellus, Series B: Chemical and Physical Meteorology (Vol. 64, Issue 1). https://doi. org/10.3402/tellusb.v64i0.15598

6. Souza, A. S. R., Fernandes, A. S., Vanderlei, L. C. D. M., Costa, A. A. R. D., Ferreira, A. L. C. G., Dubeux, L. S., ... & Cabral Filho, J. E. (2021). Transparency in research and publications on COVID-19. Revista Brasileira de Saúde Materno Infantil, 21, 5-7.

7. Tang, S., Mao, Y., Jones, R. M., Tan, Q., Ji, J. S., Li, N., ... & Shi, X. (2020). Aerosol transmission of SARS-CoV-2? Evidence, prevention and control. Environment international, 144, 106039.

8. Nazarenko, Y. (2020). Air filtration and SARS-CoV-2. Epidemiology and health, 42.

20 IFN ISSUE 4 2023

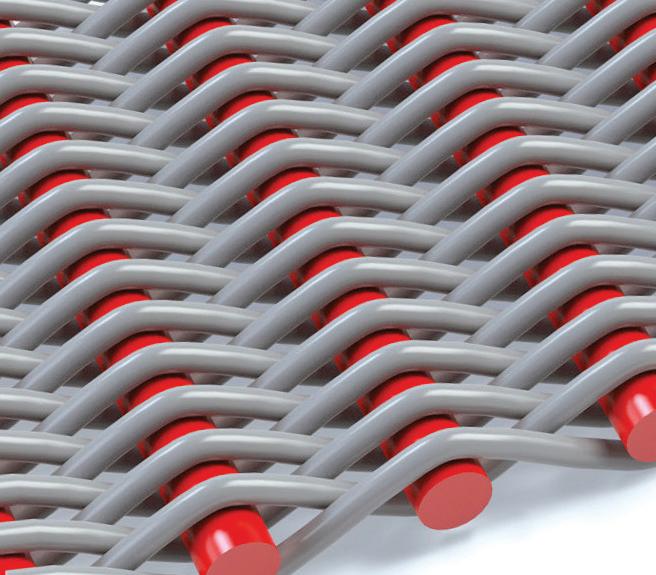

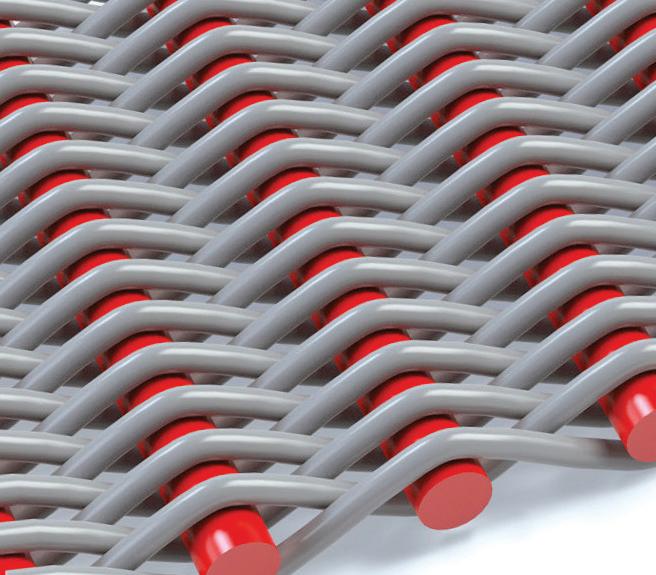

A Woven Wire Mesh for ENERGY-EFFICIENT Filtration Processes

By Dr.-Ing. Martin Müller

The filter medium is the core element of every filter unit. The main task of the filter medium is to retain the impurities, which have to be deposited. At the same time, the filter medium needs to be able to withstand the chemical, thermal and mechanical stresses which occur. For an energy-efficient filtration process, the filter medium should have a high permeability and a large dirt-holding capacity, which is associated with a long service life. For filtration processes with a large dirt load, the filter medium should be easily cleaned (e.g., by pulsejet or back flushing). Many of these filtration properties mentioned are contrary to each other and cannot be combined in one filter medium at the same time. For example, a high separation efficiency due to a small pore size is always associated with a high flow resistance.

For demanding process conditions, (e.g., in the form of high-process pressures and temperatures or if sharp-edged particles have to be deposited), metallic filter media and, in particular, metal woven wire meshes are often used. Dutch Twilled Weaves, as one of the weaving types of woven wire meshes, are established filter media for the deposition of finest particles down to the single-digit micrometer range. To achieve these small pore cross sections, the weft wires need to be woven as closely together as possible. This results in a fabric with a low porosity, low free passage area and low number of pores, and therefore, a high pressure loss and power consumption of the filtration process. Furthermore, the narrowest pore cross section is located

inside the fabric, which is why this weaving type is very difficult to clean.

An alternative weaving type to produce finest wire meshes are the so-called Betamesh-PLUS fabrics. In these plain weave fabrics, the diameters of the warpand weft-wires as well as the pitches are combined in such a way that these fabrics are characterized by a high permeability, a high dirt holding capacity and ideal back flushing properties. Thus, the Betamesh-PLUS fabrics combine a large number of the advantageous properties in one filter medium. So far, these fabrics could only be woven for pore sizes of approximately 10 μm and coarser. By adapting the weaving technology and the wires used, it has yet been possible to produce this advantageous weaving type for energyefficient filtration processes down to geometric pore sizes of 5 μm.

Introduction

Filter cloths are the core element for the separation of particle laden fluid streams with filter apparatus and are frequently used in process engineering plants in all industrial sectors. In order to reduce the energy consumption of the filtration process, on the one hand the process sequence, such as the type and frequency of backwashing, can be subjected to optimization, and, on the other hand, the filter medium itself can be optimized. This work will focus on the second possibility.

Using metallic filter media, almost the complete range of filtration tasks can be handled. Especially in filtration processes with high-quality requirements, metal woven wire cloths are selected as filter media. In industrial applications, metal wire meshes are used – for example, in the separation filtration or solids recovery,

ISSUE 4 2023 FILTNEWS.COM 21

FILTER MEDIA

p Dr.-Ing. Martin Müller presenting on Betamesh-PLUS at FILTECH this year in Germany.

for clarification filtration, for the purification of fuels and hydraulic fluids, for water treatment and for the separation of dirt particles from polymer melts and solutions.

Due to their advantageous filtration properties compared to filter media of other materials such as plastics, textiles or ceramics, metal woven wire cloths have this broad application profile. The main advantages of the metal woven wire cloths are:

• With their regular and well-defined structure, metal wire meshes have a narrow pore size distribution [1] and guarantee an excellent separation and classifying accuracy. The pore size only depends on the type of weave, on the diameters of the used wires as well as on the pitches and can be determined before the cloth is manufactured[2]. Time- and cost-intensive weaving tests to calibrate the pore size are therefore not necessary.

• Due to their high chemical, thermal and mechanical resistance, metallic filter media can be used in demanding operating conditions, for example, given as high-process pressures and temperatures or sharp-edged particles, which have to be deposited.

• Depending on the type of weave, metal woven wire cloths can be easily backwashed[3] and thus ensure a long service life of the filter elements. This leads to cost savings compared to textile fabrics or ceramic elements.

The basis of the metal wire cloths are cold-drawn wires made of different metals or metal alloys. The used wire diameter varies between a few micrometers and several millimeters. Usually metal wires with a circular crosssection are applied, although stranded wires or ropes are also used for special applications. Parallel to the weaving direction pretensioned warp wires form the carrier material, into which the weft wires are successively drawn in. Depending on the combination of the warp wires and the weft wires during the weaving process, the production of different types of weave with different aperture sizes and different filtration behaviors is possible.

Types of Weave of Woven Wire Meshes

A over a wide range of pore sizes used weaving type is the Square Mesh. In a Square Mesh (see Figure 1, left), the warp and weft wires have an identical diameter and are interwoven at the same distance from each other, the so-called mesh width w. A low flow resistance and thus a low pressure loss during filtration can be achieved. The backwash properties of these fabrics are excellent. In addition to the plain weave shown in Figure 1, Square Meshes are also produced in twill weave. Mesh sizes of down to approx. 20 μm can be realized. To produce Square Meshes with such small pore sizes, very thin wires have to be used. They are very expensive and mechanically less stable.

In so-called “opaque fabrics” either the warp or the weft wires are woven in such a way that they touch each other and no mesh is visible in the projection. One of the most common opaque fabrics is the Single Plain Weave (see Figure 1, right), in which the weft wires are woven together as closely as possible during the weaving process. This results in a high degree of filtration accuracy. Both the diameter of the warp wires and the distance between

two center lines of the warp wires, which is called the pitch t, are larger compared to the weft wires. As a result, the mesh count of the weft wires is higher than the mesh count of the warp wires. The mesh count indicates the number of wires per inch. The disadvantage of this type of plain weave is that the narrowest pore passage is within the mesh in the triangular shaped cross section between the warp wire and two weft wires, making it more difficult to back-clean the filter media. With this type of weave, pore sizes down to approx. 45 μm are realizable.

If smaller pore sizes are required in a filtration process, so-called Dutch Twilled Weaves (DTWs) need to be used. In this weaving type, the weft wires are positioned as close together as possible and one weft wire overstretches two warp wires (see Figure 2, left). By shifting the weft wire one diameter to the side, a typical diagonal pattern is created. Dutch Twilled Weaves are an established weaving type in filtration applications. Pore sizes down to 5 μm can be realized. However, due to the pore geometry, they tend to clog, which results in a sharp drop in flow rates. This leads to a low dirt holding capacity and poor backwashing properties (see also next section).

22 IFN ISSUE 4 2023

p Figure 1: Model of a Square Mesh (left) and Single Plain Weave (right); warp wires: red, weft wires: grey.

p Figure 2: Model of a Dutch Twilled Weave (left) and Betamesh-PLUS (right); warp wires: red, weft wires: grey.

Betamesh-PLUS fabrics are a further development of Single Plain Weaves. The weft wires are extremely thin compared to the warp wires. During the weaving process they are shifted into each other to such an extent that partial deformations occur at their contact points. Due to the chosen wire diameters and pitches, the flow resistance and thus the pressure loss of this wire cloth is reduced compared to Single Plain Weaves and Dutch Twilled Weaves. So far, it was only possible to produce Betamesh-PLUS fabrics with a pore size of approx. 10 μm and coarser. By adapting the weaving technology, the fabric structure parameters and the mechanical properties of the wires, it has been possible to halve the pore size again. It is now possible to produce Betamesh-PLUS fabrics with geometric pore sizes down to 5 μm. These newly developed fabrics will be characterized in more detail below.

Filtration Performance of Betamesh-PLUS Fabrics

The Betamesh-PLUS fabrics are characterized with regard to their permeability, dirt holding capacity and cleaning behavior. The focus is on geometric pore sizes smaller than 15 μm. The Betamesh-PLUS fabrics are compared with Dutch Twilled Weaves. So far, this weaving type had to be used to achieve such small pore sizes. The production of the fabrics in a plain weave – as it is now possible in the Betamesh-PLUS fabrics – has not been possible yet.

The pore size of the wire cloth is characterized based on the geometric pore size. The geometric pore size is the diameter of the ideal spherical particle, which the brand new wire cloth can just pass through, filtering a liquid. The diameter is determined by a detailed geometrical description of the pore geometry. For details, please refer to the literature, e.g.[2]

Permeability

Figure 3 shows the flow curves for atmospheric air of Betamesh-PLUS fabrics and Dutch Twilled Weaves of identical geometric pore size. The curves of identical color have to be compared with each

other. The significantly greater permeability of the Betamesh-PLUS fabrics becomes clear. The reason for this is the greater porosity, the larger open area and the larger number of pores of these newly developed fabrics in comparison with the Dutch Twilled Weaves.

The increased permeability results in a reduced pressure loss. The possible higher flow rates lead to a higher amount of filtrate and therefore the productivity of the filtration process increases. The reduced use of resources and reduced operating

costs are directly linked to the reduced power consumption of the process due to the reduced pressure loss. Is in the filtration process an identical pressure loss and power consumption compared to a filtration process with a Dutch Twilled Weave as filter medium allowed, using a Betamesh-PLUS fabric the required filter area is significantly smaller. This saves installation space as well as reduces the weight of the filter element.

The Betamesh-PLUS fabrics are characterized by a low flow resistance com-

ISSUE 4 2023 FILTNEWS.COM 23

p Figure 4: -number as function of the geometric pore size for Dutch Twilled Weaves and Beta-mesh-PLUS fabrics.

p Figure 3: Flow curves for ambient air (25°C, 1bar) of Betamesh-PLUS and Dutch Twilled Weaves (DTWs) of same geometric pore size.

bined with small pore sizes, as shown in Figure 4. The filtration processes in which these fabrics are used are energetically more favorable. The Euler-number with .

Dirt-Holding Capacity

The main task of a filter medium is to retain unwanted contaminations from the filtrate. The initial pressure loss is only present at the beginning of the filtration process. The contaminations retained by the filter medium continuously block

the filter media pores, whereby the permeability continuously decreases with increasing filtration time or retained particles.

Figure 5 compares the change in pressure loss as function of the specific filter loading, i.e. the mass of separated particles, of Betamesh-PLUS fabrics and Dutch Twilled Weaves when separating the standardized test dust Arizona Test Dust Coarse according to ISO 12103-1 from atmospheric air. Again, curves of identical coloration have to be compared

(fabrics with identical geometric pore size). When using a Betamesh-PLUS fabric, a significantly larger amount of dirt can be removed until the identical pressure loss is achieved compared to using a Dutch Twilled Weave. The BetameshPLUS fabrics are characterized by a greater dirt-holding capacity and thus service life.

Dutch Twilled Weaves have a small number of pore openings and their narrowest pore cross section is located inside the fabric in the triangular pore passage between the warp wire and two adjacent weft wires. Therefore, a single particle can block this pore. As a result, the pressure loss and thus also the power consumption of the filtration process increase sharply immediately at the start of the loading. The pressure loss increases massively until the filtration process transitions to cake filtration. In this filtration state, there is a linear relationship between pressure loss or pressure loss increase and filter loading.

In Betamesh-PLUS fabrics, the wire diameters and pitches are combined to each other in such a way that the narrowest pore is located on the outside of the fabric between two weft wires. This slotshaped pore geometry can’t be blocked by a single particle. If a particle is deposited, the flow still has sufficient free area to pass through. Supplemented by the large number of pore openings, this results in an only moderate increase of the pressure loss during loading. This larger dirtholding capacity means, that the filtration process runs for a longer operation time, before the filter medium needs to be cleaned or exchanged. This lower number of filter elements which have to be exchanged saves costs. The higher dirt-holding capacity is linked directly to reduced downtimes and consequently increases the productivity of the filtration process.

When the filtration process finally turns into cake filtration, the filter cloth only has the task to mechanically support the filter cake. Using a Betamesh-PLUS fabric, the cake filtration process runs at a significantly lower pressure loss level and thus power consumption level compared to the use of Dutch Twilled Weaves.

24 IFN ISSUE 4 2023

p Figure 6: Cleaning behavior of Betamesh-PLUS and Dutch Twilled Weaves of same geometric pore size.

p Figure 5: Change of pressure loss during the loading of Betamesh-PLUS and Dutch Twilled Weaves of same geometric pore size.

The filtration process is more energyefficient. All these benefits are present at the same geometric pore size and consequently separation performance compared to the Dutch Twilled Weaves.

Cleaning Behavior

The cleaning behavior by cleaning with a pulse-jet is investigated in accordance to DIN ISO 11057. Figure 6 shows the remaining pressure loss after a pulsejet cleaning in the different states of the filter medium (cycle 1-30: new filter medium; cycle 31-60: artificially aged filter medium). The artificial and thus standardized aging over 2500 cleaning cycles is indicated by the vertical black dashed line. If fabrics of identical geometric pore size (identical coloration) are compared, the advantageous cleaning properties of the Betamesh-PLUS fabrics become clear. The remaining pressure loss due to blocked pores by separated particles is lower. These advantageous cleaning properties are caused by the position of the narrowest pores on the outside of the fabric. Particles can be easily removed from this cross section by a pulse-jet.

As already mentioned, in Dutch Twilled Weaves the smallest pore cross section is in the interior of the mesh. Particles separated in this cross section can’t be removed easily, the remaining pressure loss and thus the power-consumption after cleaning is higher compared to the Betamesh-PLUS fabrics. The slit-shaped pores on the outer side of the BetameshPLUS fabrics have also the benefit, that if the separated particles are the recyclable fraction of the filtration process, a higher amount of the fraction can be extracted using this newly developed type of weave.

Summary & Conclusions

If pore sizes smaller than approximately 10 μm were required in a filtration process, Dutch Twilled Weaves had to be used up to now. Due to their low permeability, either the filter area had to be very large or the filtration process was associated with a large pressure loss and thus power consumption. Due to the low dirtholding capacity the filter media often had to be replaced or recleaned. However,

recleaning was only possible to a limited extent.

Herein, Betamesh-PLUS fabrics were presented in detail and subjected to a filtration technology evaluation. BetameshPLUS fabrics are plain weave wire cloths with a high porosity and a large number of pores. Pore sizes down to 5 μm can be realized. For their automated production, the weaving technology had been

further developed and the fabric structure parameters ideally adapted to the geometric conditions.

Due to the large porosity and number of pores, the fabrics are characterized by a high permeability and thus flow rate. Due to the advantageous slit-shaped narrowest pore opening on the outside of the fabric, there is no blocking of the fabric by deposited particles. This makes it

Filtration Adhesives VALUE-ADDED

A Wide Variety of Polymers for Your Filtration Needs…

Epic Resins’ epoxy and polyurethane solutions have solved complex filter manufacturing challenges for decades. Our experts partner with you, leveraging our experience to recommend products or formulate solutions designed for:

ISSUE 4 2023 FILTNEWS.COM 25

SEPARATION AIR&HEPA POOL&SPA www.EpicResins.com CONSISTENT PERFORMANCE | TECHNICAL SUPPORT | SUPERIOR VALUE

Moldable End Caps | Seam Sealing | End Cap Adhesives Potting & Casting Compounds

possible to achieve a high dirt-holding capacity. The fact that the narrowest pore is on the outside of the fabric means that the fabrics can also be back-cleaned very easily by pulse-jet.