11 minute read

Avoiding Common Traps and Mistakes When Deciding to Sell Your Company in a “Recession”

By Len LaPorta Managing Director of Investment Banking, Wiley Bros.-Aintree Capital, LLC

Len LaPorta is a managing director of Investment Banking at Wiley Bros.-Aintree Capital, LLC – a 75-year-old firm, located in Nashville, TN, focused on investment brokerage and underwriting municipal bonds for utility districts in the state of Tennessee. Len brings to the Firm experience in crossborder M&A transactions between USA and Europe, advises business owners on sell-side and buy-side transactions, capital advisory, and valuations. Len is a graduate of the U.S. Naval Academy with MBA from Boston College and a veteran of the U.S. Navy. He is also a member of INDA’s non-woven Technical Advisory Board. llaporta@wileybros.com or (615) 782-4107.

Many readers of my column have become accustomed to hearing on a daily and weekly basis, discussions of an imminent recession, of which business owners should be highly concerned.

Initially, the recession pundits estimated January/February 2023 as the timeframe for the onset of the recession. This resulted in many business owners hitting the pause button on capital expenditures or putting a new strategic initiative on hold.

The markets weathered January/February 2023 and heading into March/April 2023 timeframe, the same pundits who previously touted a recession, were amazed as to how many companies reported strong Q1 2023 financial performance. Recognizing that some industries have struggled, but in my sphere, a majority of companies started the year very well. Many companies showed a much stronger YTD 2023 versus 2022.

The other day in front of the television, it was amazing how many of our gurus are very confident that a recession will happen in “late 2023.” It turns out that Q1 2023 had a strong showing across many sectors.

Hopefully, most of you were able to avoid being in the sand trap for the first 180 days of 2023. Seeking good advice is key when considering or embarking upon a transaction. Often such advice is not found on the news. Maybe it is time for you to engage an investment banker who can examine your business relative to the overall market landscape – your company valuation upon exit might just surprise you.

This article has been prepared solely for informational purpose. This article does not constitute an offer, or the solicitation of an offer, to buy or sell any securities or other financial product, to participate in any transaction or to provide any investment banking or other services, and should not be deemed to be a commitment or undertaking of any kind on the part of Wiley Bros. –Aintree Capital, LLC (“WBAC”) or any of its affiliates to underwrite, place or purchase securities or to provide any debt or equity financing or to participate in any transaction, or a recommendation to buy or sell any securities, to make any investment or to participate in any transaction or trading strategy. Any views presented in this article are solely those of the author and do not necessarily represent those of WBAC. While the information contained in this commentary is believed to be reliable, no representation or warranty, whether expressed or implied, is made by WBAC, and no liability or responsibility is accepted by WBAC or its affiliates as to the accuracy of the article. Prior to making any investment or participating in any transaction, you should consult, to the extent necessary, your own independent legal, tax, accounting, and other professional advisors to ensure that any transaction or investment is suitable for you in the light of your financial capacity and objectives. This article has not been prepared with a view toward public disclosure under applicable securities laws or otherwise.

Seeking good advice is key when considering or embarking upon a transaction. Often such advice is not found on the news.

Roth Composite Machinery Celebrates Double Anniversary

Schlesinger were merged and renamed “Roth Composite Machinery.” Since then, under the motto “Your Performance –made by Roth,” Roth Composite Machinery has stood for machine concepts that are individually adapted to customer needs. www.roth-composite-machinery.com

Spinnova and Renewcell Announce Cooperation to Scale Circular Fashion

Roth Composite Machinery recently celebrated a double anniversary with festivities for the employees at all three locations: 60 years of filament winding expertise going back to the original company Bolenz & Schäfer, and 40 years of coating expertise of the original company EHA. “Today we look back on a total of 100 years of curiosity, innovative strength and skill,” said Managing Director Dr. Andreas Reimann.

Roth Composite Machinery came from the merger of three long-established companies. Since 1963, research and development has been carried out in the field of filament winding technology at the former company Bolenz & Schäfer in Biedenkopf-Eckelshausen. “An absolute future technology in which we are a globally recognized and sought-after player thanks to our decades of expertise,” said Dr. Reimann.

While Bolenz & Schäfer was driving expertise in filament winding, the company EHA in Steffenberg was involved in special coating technologies. EHA was founded in 1983 and became part of the Roth Industries Group in 1995. Bolenz & Schäfer had already become part of the Roth Group in 1989 and, like EHA, initially continued to operate under its own name. In 1999, Bolenz & Schäfer’s filament winding special machinery business was transferred to EHA. In 2016, EHA and the Burgwald-based company create man-made cellulosic fibers, such as viscose. With Spinnova’s transformative technology, the partners can turn CIRCULOSE® into a new, biobased textile fiber without any harmful chemicals in the fiber spinning process.

Spinnova, the sustainable textile material company, will partner with Swedish textile recycling innovator Renewcell to develop and promote a concept to commercialize and scale textile waste-based fiber. The collaboration is the first of its kind, where textile waste-based fiber can be spun into new fiber without harmful chemicals. The first consumer products from this new textile fiber are estimated to be available by the end of 2024.

Spinnova has already made successful trials spinning the CIRCULOSE® pulp into new textile fiber. The first batches of SPINNOVA® fiber made with 100 % CIRCULOSE® have been produced for yarn and fabric development, and the first prototypes are made from a blend of cotton and SPINNOVA® fiber made with CIRCULOSE®. www.spinnova.com

Santoni Shanghai Knitting Machinery Co., Ltd., Acquires Terrot GmbH

Santoni Shanghai Knitting Machinery Co., Ltd., founded and wholly owned by Italy’s Lonati family, announced the strategic acquisition of Terrot GmbH, a leading manufacturer of circular knitting machines based in Chemnitz, Germany. The move comes as the latest development in Santoni Shanghai’s long-term vision to build an ecosystem that aims to reshape and consolidate the circular knitting industry. The transaction will be finalized pending approval from Chinese regulatory authorities.

Award-winning circular innovation companies Spinnova and Renewcell announced their cooperation to introduce a technology concept for scaling the production of next-generation textile fiber from textile waste. The new fiber production concept combines patented technology from both companies and advances the circularity in the fashion and textile industries.

Pioneering a circular economy in the fashion industry, Renewcell recycles cellulosic-rich textile waste such as cotton and viscose using a patented process, which transforms textile waste into a pulp product called CIRCULOSE®. This biodegradable raw material is produced from 100% recycled textiles and can be used to create new fibre. Until now, CIRCULOSE® has been used to

The global circular knitting machine market is expected to see significant growth in the coming years, with a July 2023 report from Consegic Business Intelligence forecasting a 5.7% CAGR from 2023 to 2030, propelled by an increasing consumer preference for breathable and comfortable knitted fabrics as well as increasingly diversification of demand for knitted apparel. To seize this market opportunity, Santoni Shanghai has developed an ambitious strategic plan centered around innovation, sustainability and digitalization. The new partnership with Terrot aims to further this strategy by enhancing Santoni’s integrated and scaled-up ecosystem, while also driving the sustainable development of the global knitting machinery industry. www.santoni.cn

Textil Santanderina Launches

Authentic Black Denim Collection

Based on DIRESUL®

Textil Santanderina, an innovator known globally for the manufacture of quality fabrics with controlled traceability, recently launched its Advanced Black denim collection in collaboration with Archroma, the synthesis process is reduced by 73% for massive savings. The new DIRESUL dyestuff, when adopted with the full Archroma coloration system, delivers a new black color with on-tone wash-down effect and cleaner effluent at the mill. www.archroma.com

Standard Textile Welcomes

Jonathan Simon as EVP

Standard Textile Co., Inc., a global leader in the healthcare and hospitality textile markets, announced the appointment of Jonathan Simon as its new Executive Vice President of Global Growth & Strategy. Simon will play a key role in guiding the company’s vision and overseeing the development and implementation of global growth strategies and initiatives. Simon’s deep global industry experience will offer a broad perspective, setting the stage for an exciting phase of growth and success for the company.

Bally Ribbon Mills Supplies E-WEBBINGS® E-textiles for Torabhaig Atlantic Explorer Gas Balloon

a global leader in specialty chemicals towards sustainable solutions.

The Advanced Black collection by Textil Santanderina uses Archroma’s new DIRESUL® EVOLUTION BLACK LIQ dyestuff to produce on-trend authentic black denim apparel with industry-leading sustainability and resource savings. In addition to allowing fashion and apparel brands to choose eco-friendlier alternatives that demonstrate their commitment to protecting people and planet, Textil Santanderina’s new Advanced Black denim range also offers unique shade and wash-down effects for heightened consumer appeal.

Based on cutting-edge synthesis technology developed by Archroma, DIRESUL EVOLUTION BLACK LIQ delivers an overall impact reduction to 57%*, measuring its effect on human health, ecosystems and resources compared to standard Sulfur Black 1 liquid. Unlike traditional synthesis processes, it does not produce any ammonia, sodium salts waste or liquid effluents, and water consumption in

“We are thrilled Jon is joining Standard Textile,” Gary Heiman, Chairman and CEO of Standard Textile says. “I have known Jon for over twenty years and have been impressed by his humble leadership, innovative mindset, and relentless focus on future growth. Jon is a proven leader with the vision to expand the success we have built over the past 83 years and take us into a new phase of growth and innovation.” www.standardtextile.com

Simon brings significant global experience in corporate strategy, manufacturing, product development, and sales and marketing in the industrial and retail textile industries. In his most recent role as CEO of 1888 Mills, Simon provided inspired leadership for all aspects of the company’s operations while working with the executive board to establish short and long-term goals and related plans and policies. Simon resigned as CEO of 1888 Mills in December of 2020 to serve on its board. Simon’s impressive track record of driving revenue and market share growth, as well as his ability to build and foster meaningful and trusting relationships, has set him apart as a leader in the industry.

Bally Ribbon Mills (BRM), an industry leader in the design, development, and manufacture of highly specialized engineered woven fabrics, announced it provided E-WEBBINGS® e-textiles to Best Aviation Services. Inc., the balloon manufacturing and repair company supplying a tension system to support the Torabhaig Atlantic Explorer gas balloon’s open basket as it prepares to take the first flight across the Atlantic in an open basket gas balloon. The innovative design incorporates electronic components used to dissipate static electricity. The balloon will take off from Maine and then fly over Newfoundland before crossing the Atlantic and landing in Europe.

The new design was critical to meeting the very tight manufacturing timeline by reducing the project’s Bill of Materials and saving Best Aviation hundreds of hours of additional sewing. Bert Padelt, owner of the Bally, Pennsylvania-based balloon manufacturing and repair company, said, “Because of your design and quick turn-around on this R&D work, we were able to meet our tight deadline and launch window schedule.”

The Torabhaig Atlantic Explorer, piloted by UK-based Sir David HemplemanAdams, will collect air samples to look for new scientific discoveries. Sir Hempleman-Adams will be accompanied by Bert Padelt and Swiss explorer, scientist and entrepreneur, Dr Frederik Paulsen. The journey is expected to take four to five days, flying at an altitude of 6,000 to 8,000 feet. It would be the first Atlantic crossing in a hydrogen balloon and may also mark the longest distance covered in this type of balloon. www.ballyribbon.com

Orion S.A. Investing €12.8M in Project for Circular Carbon Black

Orion S.A., a global specialty chemicals producer, is investing €12.8 million – including €6.4 million in funding from the German government and European Union – to further develop and demonstrate a climate-neutral process for producing carbon black from alternative carbon sources, the company said.

The technology is designed to improve Orion’s yield and throughput in the production of carbon black using circular feedstocks and thus potentially reduce the carbon footprint of the process. This could accelerate the shift to a circular economy and feed the growing demand for sustainable materials in the tire industry.

Half of the €12.8 million Orion plans to invest in this initiative, called the “Clean Carbon Black Research and Development Project,” will be provided by the decarbonization program of Germany’s Federal Ministry of Economic Affairs and Climate Action, supported by the EU’s NextGenerationEU fund.

www.orioncarbons.com

Ad Sales

ADVERTISING | SALES

PUBLISHER Driven By Design LLC advertising@inda.media • +1 239.225.6137

Sabine Dussey

GERMANY, FRANCE, AUSTRIA, SWITZERLAND, SCANDANAVIA, BENELUX sabine.dussey@dussey.de • +49 2129.348390

Joan Oakley BUYER’S GUIDE & CLASSIFIED ADS joakley@inda.media • +1 248.347.3486

Ferruccio Silvera & Filippo Silvera ITALY & SPAIN info@silvera.it • +39 02.284.6716

Frank Strazzulla UNITED STATES +1 949.459.1767 • franks@tmsmedia.net

Zhang Xiaohua CHINA ifj_china@126.com • +86 13522898423

ADVERTISING COORDINATOR VICKIE SMEAD vsmead@inda.org • +1 919 459 3700 x 3720

Kelheim to Present Sustainable Innovations at GFC

Kelheim Fibres, a leading manufacturer of specialty viscose fibers, will showcase its latest developments at this year’s Global Fiber Congress in Dornbirn. The focus is on innovative solutions that not only promote environmental sustainability but also strengthen the European supply chain.

In the presentation “Towards high performing plant-based AHP products – a joined approach of Pelz and Kelheim Fibres,” Dr. Ingo Bernt, Project Leader of Fiber & Application Development at Kelheim Fibres, together with Dr. Henning Röttger, Head of Business Development at PelzGROUP, will introduce the development of a plastic-free yet highperformance panty liner. The water-repellent Kelheim specialty fiber Olea plays a crucial role in both the top and backsheet of the panty liner. This product emerged from the ambition to offer eco-friendly alternatives to conventional disposable hygiene solutions without compromising product performance.

A similar approach is pursued in the second presented project – but Kelheim Fibres takes it even further. Under the title “Performance Fibres Meet Sustainable Design –example of a reusable Baby Diaper,” Natalie Wunder, Project Leader from Kelheim Fibres’ New Business Development team, together with Caspar Böhme, Co-Founder of Sumo, will introduce the washable and reusable SUMO diaper. Made from biobased materials and featuring a unique construction with Kelheim specialty fibers, this combination offers double environmental benefits compared to conventional disposable baby diapers. www.kelheim-fibres.com

Space Application for ITMA Asia + CITME 2024 Opens

ITMA ASIA + CITME 2024 space application is now open. Asia’s leading business platform for textile machinery will be held October 14-18, 2024, at the National Exhibition and Convention Centre, Shanghai, China.

The regular biennial sequence of the ITMA Asia + CITME exhibition was disrupted due to the global COVID-19 pandemic. Originally slated for 2022, the exhibition had to be rescheduled to 2023. The ITMA Asia + CITME exhibition uniquely combines the Asian edition of the renowned ITMA exhibition with the China International Textile Machinery Exhibition (CITME). Over the past eight editions, it has established a stellar track record and holds significant importance within the textile and machinery industry. www.itmaasia.com/shanghai2024/

PET/PBT/PBAT/PBS/PTT/PLA/PETG/PC/PA6/PA66..

Polymers Recycling

POLYMER: Physics / Chemistry

GAS & COAL CHEMICAL

BDO/EG/MeOH/Heat recovery and comprehensive u�liza�on

HP

Hydrogen Peroxide, H2O2

R&D

Own R&D Center and pilot plant

Engineering

Project EPC Contrac�ng (Turn-key)

Equipment Technical Service

Manufacturing of Cri�cal Equipment

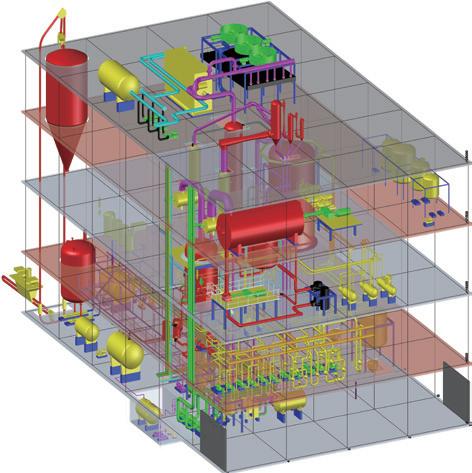

POLYTEX is a professional chemical engineering company and technology supplier integra�ng R&D, engineering, equipment manufacturing, procurement and EPC management services. From technology licensing, project planning, equipment manufacturing and engineering design, procurement and construc�on management, as well as start-up and opera�on services, Polytex provides diversified services and one-stop solu�ons to customers all over the world.

Polytex Engineering Group

Corp: 5th Floor, No.20 Wenchang Mid Rd. Yangzhou, Jiangsu, PRC.

Head: No.1, Private Industrial Park, Yuetang, Yizheng, Jiangsu, PRC.

Tel: +86-514-85553618; +86-514-87859276

Mail: market@polytex.cc; polytex@vip.sohu.com

Website: www.polytex.cc

24/7 Technical Support & Service

EPLASTMER NEW MATERIAL CO., LTD

Bo�le grade, Tex�le grade, Film grade PET chips will be launched soon. Our own factory capacity in phase-1st will reach up to 1260 tons per day.

China Sales:

Mr Sun Mob: +86-133 1990 0139; Email: sg_sun@e-plastmer.com

Mr Cao Mob: +86-181 5290 1436; Email: cao@e-plastmer.com

Ms Pu Mob: +86-185 0992 5214; Email: pu@e-plastmer.com

Russia and Central Asia Sales:

Mr Li Mob: +86-189 5105 3772; Email: �ger@e-plastmer.com

Mr Gao Mob: +86-138 5159 0251; Email: gaocx@e-plastmer.com

Mr Dos Mob: +86-135 1991 0418; Email: dos@e-plastmer.com

Other markets:

Ms Emma Mob: +86-158 9939 1075; Email: emma@e-plastmer.com