7 minute read

Robust Networking in Thriving Global Nonwovens Marketplace

The Asia Nonwovens Technology Expo (ANTEX Asia) is taking place in Bangkok, Thailand at the Bangkok International Trade & Exhibition Centre, November 13-15, 2024. The show fosters networking, knowledge exchange, and an exploration of the everevolving realm nonwoven materials and technology in that region of the world. Organizers expect over 200 exhibitors in more than five pavilions, with 4,000+ attendees from at least 20 countries.

The nonwovens market is thriving globally, with Southeast Asia serving as a key driver of growth. The increasing demand for nonwoven fabrics can be attributed to their growing applications in the healthcare and personal care industries, as well as automotive, especially electric vehicles (EV). Multiple research studies1 indicate that:

• The global nonwoven fabrics market size is projected to reach US$68.1 billion by 2030, growing at a CAGR of 6.0% from 2021 to 2030.

• By 2030, the region will also be home to 60% of the world’s population aged 65 years or older. The total healthcare expenditure in Asia is estimated to exceed US$4 trillion by 2024.

• EV market in Southeast Asia is expected to grow rapidly, with an annual growth rate (CAGR 2023-2028) of 5.5%, resulting in a market volume of US$1,871.0m (US$1,871 million) by 2028. The unit sales of EV market in Thailand are expected to reach 27,000 vehicles in 2028.

• The textile industry in China is booming with increasing investments and government support. Textile production reached 3.18 billion meters of clothing fabric in October 2022. ANTEX Asia 2024 aims to boost the industry’s growth by constructing a knowledge graph to explore emerging ap- plications, anticipate future trends, and comprehend the groundbreaking technologies that will further drive the Asian nonwovens development, particularly in automotive, filtration, wipes, medical and personal care sectors. It goes beyond the current state of the industry with a prominent emphasis on sustainability, showcasing manufacturers who are actively integrating recycled or biodegradable materials and adopting eco-friendly production processes. Additionally, advancements in technology and automation play a pivotal role in enhancing product quality, performance, and manufacturing efficiency.

Industry Leaders with Decades of Experience

The Expo is organized by a team of industry professionals with extensive experience in managing trade shows.

Mr. Nao Kozuka, Tradelink Co. Ltd., is a pioneer who launched the first nonwoven trade show in Asia 35 years ago and has been actively involved in various nonwoven events since. “We are thrilled to launch ANTEX Asia, marking a new era of collaboration and innovation across the nonwoven field,” he said. “An active dialogue with key stakeholders including local government officials has been established and positive responses were received.”

“Bangkok is the perfect location for the Expo as this country is talented with nonwovens manufacturing. It provides a platform for global leaders to share in- sights and business strategies customized for the Southern Asian market,” said Culsin Li, Managing Director at Baobab Tree Event Management Co., Ltd., exhibition and event specialist.

“ANTEX Asia will act as a central hub for industry experts, fostering the exchange of knowledge, technology, and innovation across various sectors.” stated Grace Mak, Managing Director at MGT Expo Planning and Management Ltd. Mak is successful executing successful exhibition strategies in Asia, and is well connected with many professional trade associations globally.

In May 2024, ANTEX Asia announced that the Thailand Textile Institute (THTI) and the Thai Nonwoven Fabrics Industry Association (TNFA) will also co-host the event. Mak welcomed their support, “Together, we aim to host a market-driven event in Thailand, showcasing the immense potential of the nonwovens industry in the ASEAN region. With Thailand’s rich textile heritage, strategic location, and strong manufacturing capabilities, it is the perfect place to host this prestigious trade show.”

Concurrent Event: Future Fabric Summit

Esteemed leaders and experts will unveil the latest industry insights and technologies at the concurrent Summit, presenting new fabric materials that enable responsible production and enhance sustainability within the nonwovens industry, to help attendees stay ahead of the curve, and become part of the transformative journey in this unique opportunity provided by ANTEX Asia.

www.antexasia.com

1 https://www.antexasia.com/antex-asia-2024-thelargest-dedicated-nonwovens-show-in-southeast-asiaoffering-the-best-marketing-opportunities/

Trelleborg Announces Investment in Rutherford County, North Carolina

Global engineered polymer group Trelleborg has announced a greenfield development for its engineered coated fabrics operations in Gateway West Commerce Park in Rutherford County, North Carolina.

The site, part of Rutherford County’s development vision for advanced manufacturing, will be Trelleborg’s second major facility in the area and is expected to cement Trelleborg’s position both as an industry leader and as a major local employer.

In addition to investments in state-ofthe-art production capabilities Trelleborg will further invest in ensuring that the building and its operations are at the forefront of sustainability. The initial investment exceeds $30 million.

ANDRITZ to Supply Two Tissue Machines to C&S Paper, China

nternational technology Group

IANDRITZ has received an order from C&S Paper to supply two PrimeLineCOMPACT tissue machines for its mill in Suqian City, Jiangsu Province, China. The machines will produce tissue for household paper, napkins, handkerchiefs, facial tissues, and toilet paper at a maximum capacity of 94 t/d each. They have a design speed of 1,650 m/min and a width of 3.5 m.

Both machines will be equipped with suction pressure rolls with innovative roll covers and PrimeDry Steel Yankees for energy-efficient, high-quality production. The scope of supply also includes undermachine pulpers and flow and consistency transmitters for both lines, as well as PrimeControl automation systems for efficient control and monitoring of the entire production process.

C&S Paper Co., Ltd., is one of China’s largest household paper producers, with C&S and Sun as its two main brands.

This order once confirms ANDRITZ’s strong market position as one of the leading suppliers of machines and systems for the Chinese tissue industry, and ANDRITZ’s expertise specifically in highquality and resource-saving components. www.andritz.com

“By investing in sustainability as well as capacity, we will be better positioned to meet our customers’ needs and have a positive impact on our local community,” said Steve Brockman, President of Trelleborg Engineered Coated Fabrics. “Our new facility will be built to achieve LEED certification, and our operations will be carbon neutral and emit zero emissions. This investment helps us expand our use of bio-based polymers and recycled raw materials, aiding Trelle- borg and our customers in meeting their product circularity targets.” www.trelleborg.com

Trelleborg expects to break ground on the new facility in Q4 2024 and start production in Q1 2026.

European Future-Proofing for Eton Systems and Kinnarps

To meet rising demand for its fully automated and digitized fabric and part handling solutions, Eton Systems has just moved into modernized new premises in Borås.

The company was founded in 1967 in Borås – widely known as Sweden’s textile city and home to worldwide brands and companies, as well as the prestigious Swedish School of Textiles – as a result of future-looking research and development at shirt maker Eton Shirts.

Eton Shirts, founded in 1928 and still also headquartered in Borås, was very early to realize the benefits of streamlining its production processes, minimizing downtime and better utilizing factory space. Its internal R&D led to the world’s first overhead unit production system (UPS).

Today, Eton Systems UPS technologies have a positive impact on the productivity of thousands of production lines for a range of industries. Designed to increase value-added time in production by eliminating manual transportation and minimizing handling, the individually addressable product carriers are now fully managed and controlled by the company’s advanced software.

“We’re very happy that we have been able to realize our plans and site our new premises with advanced technologies here in Borås, staying true to our roots and heritage,” says Eton Systems CEO Jerker Krabbe. “Digitalization and the push for more sustainable, shorter and less expensive supply chains are currently making manufacturing in high-cost countries within Europe more attractive and our technologies are very much a part of making reshoring a feasible option for our customers.”

“Sustainable interior design is as much about the present as the future,” says Kinnarps Global Range Director Jenny Hörberg. “When choosing interior design and furniture, it is important to take the entire life cycle into account. It’s also about choosing furniture with carefully selected materials that are designed and prepared for renewal, to maximize the life span and create conditions for sustainable circularity.” www.etonsystems.com

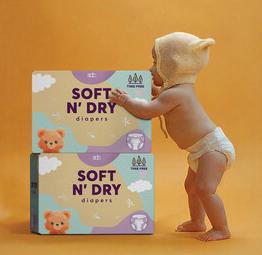

Soft N Dry Tree Free Diapers Now in European Markets

INDA, NWI Announce Collaboration Agreement

oft N Dry Diapers Corp. recently announced the launch of their innovative Tree Free disposable baby diapers in Europe, with sales and distribution capabilities in France, Germany, and the UK on a white label basis for retailers. Soft N Dry is marketready at scale for its customers in the EU and complies with the EU Deforestation-Free Regulation (EUDR) era, which ensures disposable baby diapers sold in the EU do not cause deforestation and degrade the climate. Under the EUDR, diaper manufacturers using tree fiber must comply by January 1, 2025. As part of this strategic growth, the company has also appointed Alexander Valle Burkert as the new Chief Technology Officer (CTO), effective July 11, 2024. www.softndrycorp.com

Ad Sales

ADVERTISING | SALES

PUBLISHER Driven By Design LLC advertising@inda.media • +1 239.225.6137

Frank Strazzulla UNITED STATES franks@tmsmedia.net • +1 949.459.1767

Sabine Dussey GERMANY, FRANCE, AUSTRIA, SWITZERLAND, SCANDANAVIA, BENELUX sabine.dussey@dussey.de • +49 2129.348390

Joan Oakley BUYER’S GUIDE & CLASSIFIED ADS joakley@inda.media • +1 248.347.3486

Ferruccio Silvera & Filippo Silvera ITALY & SPAIN info@silvera.it • +39 02.284.6716

Zhang Xiaohua CHINA ifj_china@126.com • +86 13522898423

ADVERTISING COORDINATOR VICKIE SMEAD vsmead@inda.org • +1 919 459 3700 x 3720

NDA, the Association of the Nonwoven Fabrics Industry, and The Nonwovens Institute (NWI), announced a collaboration agreement to provide continuing education to the nonwovens industry. This agreement expands upon the ongoing partnership between INDA and NWI, whereby the two organizations have successfully presented training programs, covering the full spectrum of the nonwovens value chain from raw materials to processes to products.

Under terms of the agreement, INDA and NWI will develop and present a full roster of training courses, featuring a combination of classroom learning supported by hands-on activities in NWI’s world-class nonwoven production and testing labs on the Centennial Campus of North Carolina State University. The two organizations will also work together to explore additional educational programming to serve the needs of the nonwovens industry as they evolve over time.

“This collaboration agreement represents a significant next step in the partnership between INDA and NWI, as we build upon our training course offering to ensure it is meeting the needs of the nonwovens industry now and going forward,” said Matt O’Sickey, director of education and technical affairs at INDA. “We are also committed to pursuing new avenues to expand the knowledge base of professionals working in areas related to nonwovens.”

The current roster of INDA/NWI training courses include:

• Elementary Nonwovens

• Intermediate Nonwovens

• Fiber and Filament Extrusion Fundamentals

• Meltblown Technology

• Nonwoven Bonding Fundamentals

• Nonwoven Fabric Property Development and Characterization

• Nonwoven Product Development and Innovation

• Spunbond Technology

Course registration is open to INDA/NWI members and non-members. The INDA/ NWI Short Course Value Pack program enables companies to purchase a block of registrations, which can be used by any combination of employees to register for any combination of training courses, at a discounted rate. Value Packs are available in bundles of 5, 10, 15, and 20 registrations, with discounts ranging from 10 percent to 25 percent, depending on the size of the Value Pack. For more information about the Value Pack program, visit https://thenonwovensinstitute.com/short-course-value-pack/. www.inda.org/training