5 minute read

TECH

Notes

Freudenberg Launches Sustainable, Low-Level BPA Thermal Insulation Products

Freudenberg Performance Materials Apparel, a leading provider of innovative technical solutions in the apparel industry, recently launched two advanced thermal insulation products made from low-level Bisphenol A (BPA) recycled PET fibers (rPET) into the global range of comfortemp®, Freudenberg’s thermal insulation brand. The introduction of DOWN FEEL WA 150LB and FIBERBALL WB 400LB underscores Freudenberg’s commitment to innovation and sustainability.

The additions of DOWN FEEL WA 150LB and FIBERBALL WB 400LB to the comfortemp® global range serve as high-quality and ecologically-minded alternatives to down, enhancing the comfort and sustainability of your garments. DOWN FEEL WA 150LB is an extremelylightweight, loose fiber thermal insulation with a super-light loft, while FIBERBALL WB 400LB uses clusters of extra-fine fibers to offer optimal breathability, maximum comfort, and minimal clumping after washing and drying.

PFNonwovens Launches Product Portfolio Based on 100% Renewable and Compostable Materials

Global nonwoven fabric manufacturer

PFNonwovens, a leading innovator in the nonwovens industry, announced the launch of its newest sustainable nonwoven product portfolio based on 100% renewable resin, leveraging the latest Reicofil 5 technology. The portfolio is highlighted by a number of breakthrough materials made entirely from polylactic acid (PLA) resins. These products are setting new standards for eco-friendly spunmelt nonwovens and reinforce PFNonwovens’ commitment to sustainability and environmental stewardship.

Freudenberg´s comfortemp® DOWN FEEL WA Series.

Freudenberg Performance Materials

Both products are crafted using Freudenberg’s advanced technology, utilizing 100% GRS-certified rPET fibers, customizable to desired fill levels. Additionally, these new products not only comply with but significantly surpass the stringent OEKO-TEX ® STANDARD 100 Class I certifications (the strictest requirements, suitable for babies). While OEKO-TEX ® categorizes lowlevel BPA as less than 100 parts per million (ppm), these new products contain less than 1 ppm BPA, a testament to Freudenberg’s unyielding standards. www.freudenberg-pm.com

The LYCRA Company Launches New LYCRA® FiT400™ Fiber

The LYCRA Company, a global leader in developing innovative and sustainable fiber and technology solutions for the apparel and personal care industries, recently announced the launch of new LYCRA® FiT400™ fiber for knits.

The company’s latest EcoMade offering is a unique bicomponent fiber engineered to optimize the performance and comfort of knits. It delivers a durable soft hand-feel, low shrinkage and high uniformity to fabrics. LYCRA® FiT400™ fiber is made from 60% recycled PET and 14.4% from bio-derived resources and is

GRS certified. It includes two different polyester polymers, which together create a helical crimp, providing permanent stretch and recovery properties, as well as breathability, cooling comfort and chlorine resistance to fabrics.

LYCRA® FiT400™ fiber helps set the stage for circularity, a key priority for The LYCRA Company. In controlled tests under specific conditions, this fiber was recycled back into new polyester fibers, thereby demonstrating the technical feasibility of this process. www.lycra.com www.pfnonwovens.com

The commercial launch of the new biobased nonwoven products, produced from 100% PLA and enabled by the Reicofil 5 technology, is the most recent step in the company’s drive to address environmental challenges. These innovative materials set new standards for eco-friendly spunmelt nonwovens, while delivering the performance and quality levels expected in applications such as advanced hygiene products, filtration, medical and many others. These new products composed entirely of PLA (from NatureWorks LLC) are industrially compostable and include both spunbond and SMS structures. Developing products that met the goal was a challenge and was enabled by the state-of-the-art Reicofil 5 technology.

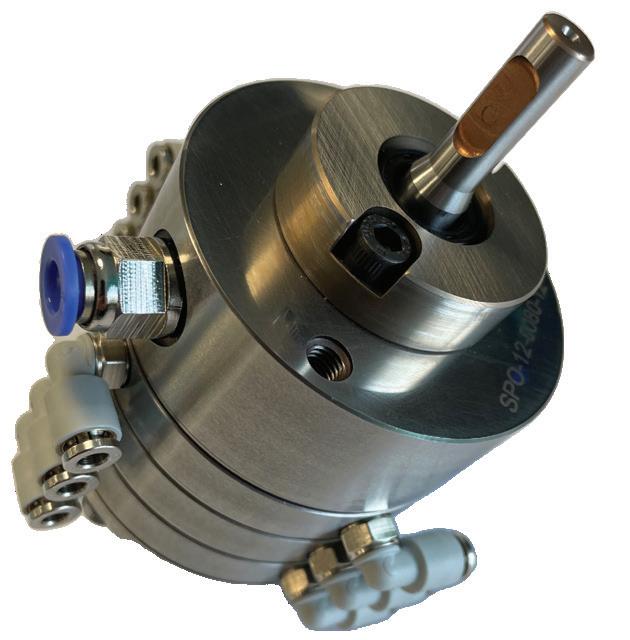

Precision gear metering spe cialist Slack & Parr showcased its updat ed Spin Finish Pump for the polyester market alongside its range of fluid metering technologies for specialty fibers at ITMA Asia in Shanghai, China.

This is the first time the company has brought its newly redesigned SPO Spin Finish Pump to the AsiaPacific market since the technology was launched at ITMA, Milan, in June 2023. The pump has been re-engineered with fewer components and a modular design that is simple and cost-effective to operate and maintain but capable of very high levels of accuracy. It has been developed for the application of finish emulsions onto filaments typically used in hot-melt manufacture of POY and FDY polyester yarns. Featuring a compact design and robust build, it is used to meter and apply oil-based emulsions onto yarns to improve efficiency in downstream processes and offers capacities down to 0.014cc/rev with very high accuracy including at low speeds. www.slackandparr.com

High-Performance Hydrophobic Fiber

Slack & Parr Showcases Spin Finish Pump for Polyesters Mara

Spinnova Unveils Sustainable Denim at Kingpins Trade Show

With a global market of 3.1 billion pairs in 2022, denim jeans could easily be considered a wardrobe staple. Despite this, there has been limited innovation to address the many sustainability challenges of denim production, such as water and resource intensity, heavy chemical use and dyeing, as well as limited recyclability when blended with materials such as polyester and elastane.

Sustainable textile material company Spinnova recently presented the first blended denim fabrics made with wood-based SPINNOVA® fiber at the annual Kingpins denim trade show in Amsterdam. The pilot products showcase the Spinnova technology potential to improve the sustainability of denim on multiple fronts. When SPINNOVA® fiber is produced from certified eucalyptus pulp, it has various environmental benefits such as 99% less water consumption and 74% fewer CO2 emissions compared to conventional cotton. The fiber spinning process uses zero harmful chemicals and thanks to the unique mechanical process, the fiber has a natural hand-feel. Finally, the raw material used to make SPINNOVA® fiber can be traced back to its origin.

The denim industry doesn’t compromise on quality, which has been a challenge for denim manufacturers exploring new materials in the past. While most man-made fibers lack the quintessential, sturdy feel of cotton-based denim, early tests have shown that denim produced with a blend of SPINNOVA ® and cotton maintains those qualities and meets the aesthetic requirements of denim. www.spinnova.com

With the growing demand among brands and consumers for plastic-free materials and ingredient transparency, VEOCEL ™, the flagship specialty nonwovens brand of Lenzing Group, showcased LENZING™ Lyocell Dry fiber at Hygienix 2023. LENZING™ Lyocell Dry fiber which is not classified as “plastic” according to EU SUPD, meets the growing interest for plastic-free nonwoven products across the industry and among consumers. Additionally, along with being an environment-friendly solution, the fiber delivers high-performance dryness and comfort which makes it the optimum fiber choice for absorbent hygiene applications.

Comprised of mostly fossil-based materials, absorbent hygiene products are an essential part of many consumers’ daily lives. With heightened concerns towards environmental impact, the product segment has been undergoing a change caused by shifting consumer preferences, increased consciousness and concerns towards plastic waste, and technology advancement. LENZING™ Lyocell Dry fiber has embraced these changes without compromising on quality or performance. www.lenzing.com

Sustainable luxury designer Mara Hoffman has released her first dress design using Circ® Lyocell, a filament lyocell derived from 50% recycled textile waste.

Dubbed “The Dress that Changes Everything,” this collaboration between Mara Hoffman and Circ, the fashion technology company that recycles polycotton textile waste back into new fibers, is the first time Circ Lyocell is being used in the luxury market. The dress also heralds an ongoing partnership as the designer announces her commitment to transitioning to from virgin lyocell to Circ Lyocell in her collections over the next three years. www.marahoffman.com