The Hiperfloor™ method: GRIND – FILL – HARDEN – POLISH – PROTECT The concrete floor is first ground to establish the required flatness and /or aggregate exposure. This also removes what is in many cases the softer, unstable surface layer of concrete. ■ Small holes, air-bubbles and other small surface imperfections are then filled using Husqvarna’s GM 3000™ to ensure a smooth uniform surface. ■ The surface of the concrete is then treated with Husqvarna’s Hiperhard™ water based concrete hardener. This produces a homogenously hardened surface and creates a non-dusting floor. ■ Polishing via progressively finer stages of resin bond diamond tools to achieve desired surface gloss. ■ Protection by impregnation using Hiperguard™ to enhance water and stain resistance of floor. ■

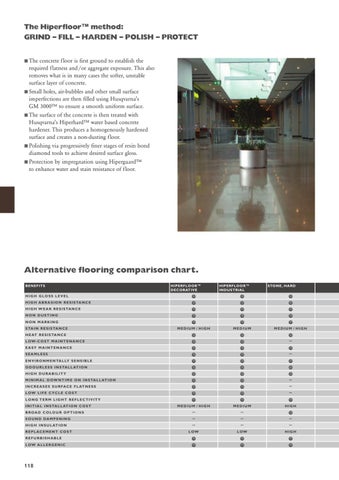

Alternative flooring comparison chart. BENEFITS

HIPERFLOOR™ DECORATIVE

HIPERFLOOR™ INDUSTRIAL

STONE, HARD

● ● ● ● ●

● ● ● ● ●

● ● ● ● ●

STAIN R E SI STA N C E

M E DI U M / H I GH

M E DI U M

M E D IU M / HIG H

HEAT R ESI STA N C E

● ● ● ● ● ● ● ● ● ● ●

● ● ● ● ● ● ● ● ● ● ●

●

M E DI U M / H I GH

M E DI U M

HIG H

HIGH GLO SS L E V E L HIGH A B RA SI O N RE SI S TA N C E HIGH WE A R RE SI STA N C E NO N D U ST I N G NO N M A RK I N G

L OW-COST M A I N T E N A N C E EASY M A I N T E N A N C E SE AM L E SS E NVIRO N M E N TA L LY S E N S I B L E O D O U R LE SS I N STA L L AT I O N HIGH D URA BI L I T Y MINIMA L DOWN T I M E O N I N S TA L L AT I O N INCR E A SE S SURFAC E F L AT N E S S L OW L IF E C Y C L E C O S T L O NG TE RM L I G H T RE F L E C T IV I T Y INITIA L I N STA L L AT I O N C O S T B ROA D C O L O UR O P T I O NS SO U ND DA M P E N I N G HIGH INSUL AT I O N R E PL ACEM E N T C O ST R E FU R B ISH A BL E L OW A L LE RG E N I C

118

– – –

– – –

–

●

–

● ● ●

– – –

● ●

– –

LOW

LOW

HIG H

● ●

● ●

● ●