2 minute read

Ultrasonics detect crush hazards before they happen

Until recently, secondary guarding systems required an incident to be underway before controls activated, such as the dead-man switch, e-stop, or crush bar. Thankfully, their technology has evolved.

Until recently, secondary guarding systems required an incident to be in the early stages of occurring before controls would activate, such as the dead-man switch, e-stop, crush bar, however technology has evolved.

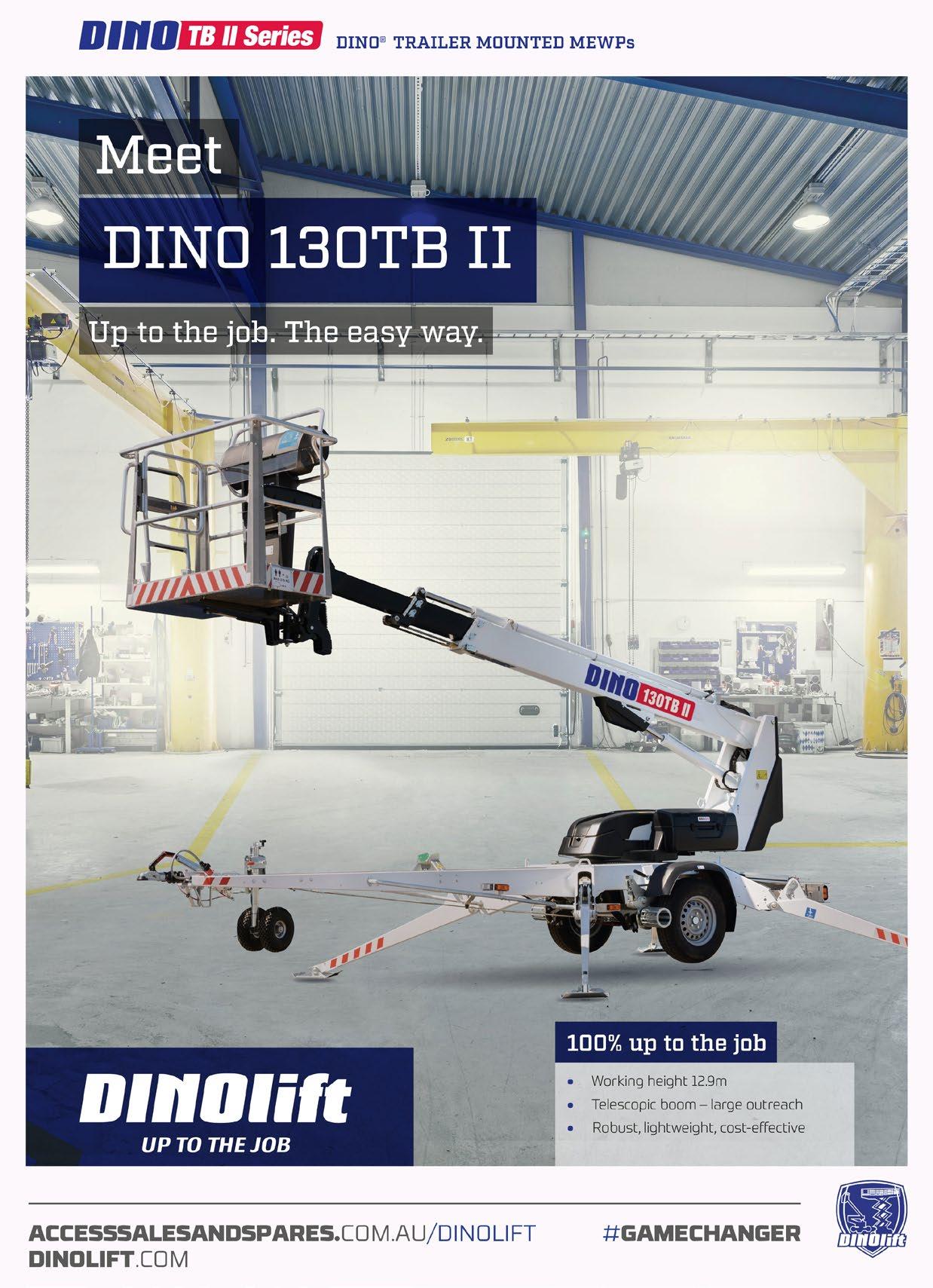

Problem: Mobile Elevating Work Platforms (MEWPs) assist in making working at height safer however there are still risks present that can endanger life. There is a risk that the MEWP operator or platform occupants can become trapped or crushed between the MEWP platform and an external obstruction during the movement of the MEWP. In addition to this, the platform itself can cause considerable property damage when coming into contact with objects or hazards.

Solution: MEWP Shield Ultrasonic Secondary Guarding Systems, in conjunction with safe work planning, help to minimise the risk of crushing and entrapment plus reduce the property damage should contact occur. Conventional secondary guarding systems prevent bad situations from getting worse. MEWP Shield prevents the operator from getting into a bad situation before it occurs. It detects danger before you are in it.

Detecting hazards

MineTech Australia have released their new MEWP Shield for Scissor Lifts. The Shield uses ultrasonic sensing to detect potential crush hazards warning the operator before an incident arises.

The front and back sensors have a six metre range and are positioned to detect potential shear and collision hazards in that direction. The left and right sensors have a ten metre range along and above the side rails of the basket to detect collisions from these directions. All sensors can detect operators and objects overhanging the basket and minimum distance thresholds are configurable allowing the shield to be purpose fitted for any work environment.

These sensors feed back to the central Base Control Unit, which controls the output safety contact based on the current sensor distance readings and their corresponding minimum distance thresholds. The system controls the machine movement lockout, also known as interlock, through a pre-existing safety switch such as a dead-man switch or E-Stop circuit. This is done by connecting a safety relay output to the desired stopping signal circuit.

The shield is easily retrofitted by an auto electrician and compatible with all major MEWP OEMs.

MEWP Shield secondary guarding systems, in conjunction with safe work planning, help to minimise the risk of crushing and entrapment plus reduce the property damage should contact occur. Conventional secondary guarding systems prevent bad situations from getting worse. The MEWP Shield prevents the operator from getting into a bad situation in the first place, because there is no such thing as being ‘half-crushed’.

MEWP Shield for boom

MineTech are running national product trials for the MEWP Shield for scissor lifts. Contact MineTech to find out how your organisation can take the next step in engineered safety solutions at www.mewpshield.com or call 1300 MINE TECH (1300 6463 8324).