3 minute read

履带起重机操作手册

Operator’s Manual for Crawler Crane

1) The hook must be selected to work with the cable, the chain or the strap used in the lifting device.

2) The hook needs to be made according to correct size so that it can hold the load securely.

b) Types: c) Capacity: d) Safe operation:

1) There are many types of hooks available from multiple manufacturers.

2) Hooks must be made of forged steel and equipped with safety latches.

1) Hooks are rated at maximum capacity for vertical pulls and reduces capacity when side loaded.

2) The limit lifting capacity for a hook used in the manner for which it is intended must be equal to or exceed the rated load of the chain, the wire rope, or other suspension member to which it is attached.

3) The designed limit lifting capacity means the limit weight put on the hook bearing point from the load.

4) The manufacturer’s identification must be forged or die stamped on a low-stress and non-wearing area of the hook.

1) Do not side load hooks.

2) Force on the safety latch can cause failure of hooks

3.3.2 Rigging introduction

Care and attention to the rigging is a fundamental part of the operation safety: a) Perform frequent and periodic inspections of the rigging hardware, wire rope, and slings. b) A written equipment record must be kept monthly. Reviewing the history can provide vital information, for example, reveal a faster wear that can be attributed to defects in the crane. c) Remove from service rigging equipment that has been damaged. d) Inspect rigging accessories before each shift. e) Determine the weight of the load and choose appropriate equipment.

Caution

The strength and the integrity of the rigging hardware is another fundamental part of the safe lifting operations. To maintain rigging hardware and its components, frequent and periodic inspections are required.

履带起重机操作手册

Operator’s Manual for Crawler Crane

Operator’s Manual for Crawler Crane

3.3.3 Slings introduction

The predominant characteristics of a sling are determined by the components of that sling. For example, the strengths and the weaknesses of a wire rope sling are essentially the same as those of the wire rope from which it is made.

a) Slings are generally one of the following six types:

1) Chain;

2) Wire rope;

3) Metal mesh;

4) Natural fiber rope;

5) Synthetic fiber rope;

6) Synthetic web b) Factors that must be taken into consideration when choosing the best sling for the job include:

1) Size of the load;

2) Weight of the load;

3) Shape of the load;

4) Temperature;

5) Sensitivity of the material to be moved;

6) Environmental that the sling will be used c) Sling identification tags: all slings should be labeled with identification tags. The Information required to be on the identification tags is as follows:

1) Manufacturer’s name or trademark;

2) Diameter or size of sling;

3) Material of sling;

4) Rated load for the types of sling used;

5) Lifting angle the load rating is based

3.3.4 Sling safety

a) Before making a lift, check to be certain that the sling is properly secured around the load and that the weight and balance of the load have been accurately determined. If the load is on the ground, do not drag the load along the ground. This could damage the sling.

b) Position the hook directly over the load and seat the sling squarely within the hook bowl. This gives the operator maximum lifting efficiency without stressing the sling.

c) Make sure that the load is not clamped, or bolted to the floor.

d) Guard against shock loading by pulling the slack sling straight slowly.

e) Apply power cautiously so as to prevent jerking at the beginning of the lift, and accelerate or decelerate slowly.

履带起重机操作手册

f) Check the tension on the sling. Raise the load a few inches, stop, and check for proper balance and that all items are clear of the path. Never allow anyone to ride on the hook or load.

g) Keep all personnel clear before the load is being raised, moved, or lowered. Crane operators and the rigger should watch the load all the time when it is in motion.

Danger

Never allow anyone to ride on the hook or load!

3.3.5 Sling safety guide

a) Sling must not be shortened with knots, or other makeshift devices.

b) Sling legs cannot be kinked.

c) Slings cannot be loaded in excess of their rated capacities.

d) Slings using a basket hitch can have the loads balanced to prevent slippage.

e) Slings must be securely attached to their loads.

f) Slings must be padded or protected from the sharp edges of their loads.

g) Suspended loads must be kept clear of all obstructions.

h) All personnel must be kept clear of loads that is about to be lifted and of suspended loads i) Hands or fingers cannot be placed between the sling and its load while the sling is being tightened around the load. j) Do not impact the load. k) Do not pull the lifting devices under the load before the load is lifted off the ground.

3.3.6 Taglines

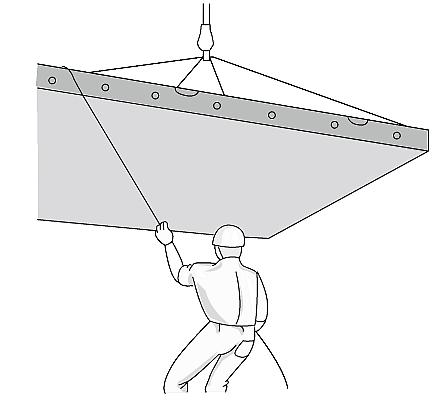

The safest method for a rigger to control a load attached onto the hook is with a tagline (refer to the figure 3-7):

Taglines are used to control load spin Keep the tagline away from the center of gravity.