4 minute read

Trouble shooting guide for starting motor

Wärtsilä NSD Nederland B.V. Engine type W26 Chapter 1.3 Subject Starting air system Issue date June '00

Trouble shooting guide for starting motor

Problem/probable cause(s) 1. On pressing push-button, starter does not respond and no air flow seems to exist in control circuit.

a) Empty air vessels b) Flow valve(s) closed. c) Control circuit blocked.

Suggested remedy

Charge air vessels Open flow valve(s). Disconnect and clean out.

2. On pressing push-button, starter does not respond, although air flows through control circuit.

a) Leaking control duct. b) Insufficient air pressure. Repair or replace. Increase pressure in air vessel.

c) Piston or valve (x18, x17 or x16) sticking in closed position.

Remove and check both; smoothen guides or change parts. d) Push-button stuck. Remove and clean same e) Excessive length of main air pipework. Approach push-button to starter or install a solenoid valve near the latter.

3. Pinion revolves and advances, but does not engage the ring gear.

a) Ring gear and/or pinion burrs or damaged. b) Lack of clearance between pinion and ring gear.

4. Pinion revolves and advances, but does not advance totally.

a) Push-rod (11) inoperative.

b) Insufficient air pressure. Remove burrs or replace parts if necessary.

Replace pinion by a more adequate one. Check for distortion of ring gear.

Disassemble, check, smoothen guide diameter; clean or replace if corrosion is visible. Increase pressure in air vessel. c) Splined shaft (19) sticking. Disassemble, clean, check spring (22) and reassemble. d) Excessive length of control pipe. Approach push-button to the starter or install a solenoid valve near the latter.

Wärtsilä NSD Nederland B.V. Engine type W26 Chapter 1.3

Trouble shooting (continuation)

Subject Starting air system Issue date June '00

Problem/probable cause(s) Suggested remedy

5. Pinion advances but does not revolve

a) Pneumatic motor inoperative Disassemble, inspect rotors for foreign matters between teeth and for possible wear of gears, spindles and bearings. Clean, oil and reassemble. Replace worn parts. b) Check valve/orifice (13) stuck or blocked Disassemble, clean, oil and reassemble.

6. Pinion engages gear ring, but will not turn the engine.

a) Main valve (26) blocked. Disassemble, clean oil and reassemble or

b) Rotors worn or blocked

c) Insufficient air pressure. replace main valve. Disassemble, clean, oil and reassemble or replace rotors. Increase pressure in air vessel.

d) Main air pipework restricted or of insufficient bore. Check all pipework and replace it if necessary.

7. Starter starts working after opening the flow valve in the feed line, although push-button (or solenoid valve) is not actuated.

a) Incorrect connection of control pipes. (with separate solenoid valve)

Connect control pipes as per installation instructed. b) Main valve (26) blocked and open. Disassemble, clean, oil joint if needed. c) Operating valve (4) is not closing properly Disassemble, clean, oil and reassemble or replace valve if needed.

8. Lack of starter power.

a) Main pipework choked or its bore is less than stipulated for the starter. Check entire pipework for correct bore and replace if incorrect. b) Air strainer (if present) clogged c) Insufficient air pressure. Clean filter Increase pressure in air vessel. d) Badly worn rotors. Disassemble, replace rotors ,oil and reassemble.

Wärtsilä NSD Nederland B.V. Engine type W26 Chapter 1.3 Subject Starting air system Issue date June '00

Trouble shooting (continuation)

Problem/probable cause(s) Suggested remedy

9. After starting the engine, pinion tries to re-engage and hits the ring gear which results in damage to both.

a) Incorrect bore of main pipework. Check entire pipework for correct bore and replace if incorrect. b) Starting period unnecessarily long. Check and adjust timer (if fitted) or press starter push-button for a shorter period. c) Idling of main valve (26) Disassemble, clean, oil and reassemble. d) Sticking of operating valve (4) Disassemble, clean, oil and reassemble or replace valve if needed.

e) Piston or leak valve (x18, x17 or x16) defective

Disassemble, clean, oil and reassemble. Replace if needed. f) Check valve/orifice (13) stuck or blocked Disassemble, clean, oil and reassemble.

10. Starter motor will not stop.

a) Main valve (26) blocked. Disassemble, clean, oil and reassemble. b) Piston or leak valve (x18, x17 or x16) defective Disassemble, clean, oil and reassemble. Replace if needed. c) Check valve (13) keeps open or does not seat properly. Disassemble, check for correct closing of the ball and check if plug presses the valve against its seat. d) Seal ring (32) badly fitted. This is a frequent appearing fault after changing the motor bearings. Check for correct position. e) Incorrect adjustment of controls. Adjust timer (if fitted), or operate push-button for shorter periods.

f) Splined shaft (19) sticking. Disassemble, clean, check spring (22) and reassemble.

Wärtsilä NSD Nederland B.V. Engine type W26 Chapter 1.3

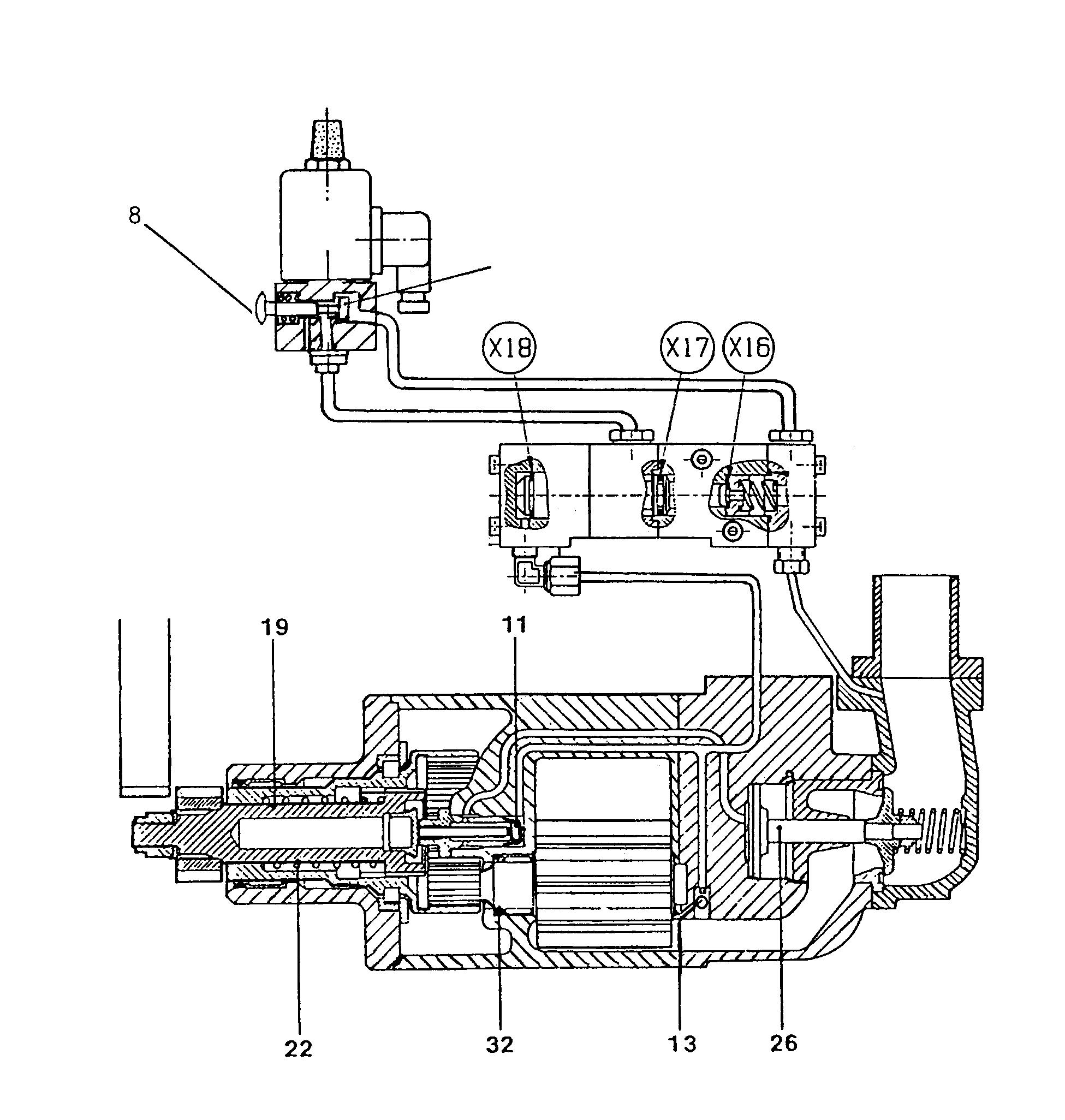

Starting motor

Subject Starting air system Issue date June '00

4

20

4 operating valve 8 push button 11 piston 13 check valve orifice 19 splined shaft 20 bendix

22 spring 26 main valve 32 seal ring x16 valve x17 and x18 piston