1 minute read

Oil suction pipe and sump

8. Install lock pin 9997005 for the crankshaft in the engine block, please refer to “Engine, disassembly, timing gear”.

Carefully clean the crankshaft and flywheel mating faces.

Turn the engine round and install the flywheel.

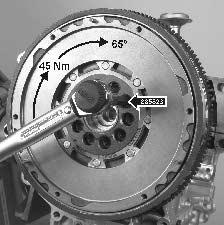

Tighten the screws with socket no. 885823 alternately in two stages as specified in “Technical

Data”. NOTE! The flywheel is heavy. Be careful when handing it.

Install the clutch and tighten the screws alternately as specified in “Technical data”.

Install the flywheel housing and tighten the screws alternately as specified in “Technical data”. The screws which are fixed to the sump must be torqued later on, when the sump is in place.

9. Oil suction pipe and sump

Install a new, oiled O-ring on the oil suction pipe.

Put the pipe in place. Ensure that the O-ring (1) goes down into the engine block. Then screw the pipe in place.

Install new, oiled seal rings (2) in the grooves that seal between the sump and the engine block.

2 1

10.Clean the gasket plane with denatured alcohol.

Apply sealant no. 30731319 as in the figure, using a min 2 mm wide line. NOTE! The sump must be installed within 5 minutes after applying the seal.

IMPORTANT! Old gasket residue must have been fully removed before a new seal is applied.

NOTE! On engines with serial number before 334747, sealant 1161059 must be used, which is rolled on.

11.Insert two guide dowels, 885818, into diagonally opposed holes in the corners of the engine block gasket plane.

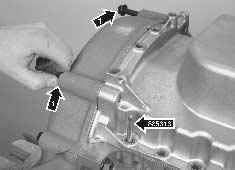

Install the sump and press it against the flywheel housing at the same time, before it reaches the gasket plane. Screw the remaining flywheel housing screws (1) in until they bottom. Torque them later on.

IMPORTANT! Liquid gasket is easily damaged if the sump is slid when put in place. If this happens, new liquid gasket must be applied.