4 minute read

Electrical Systems

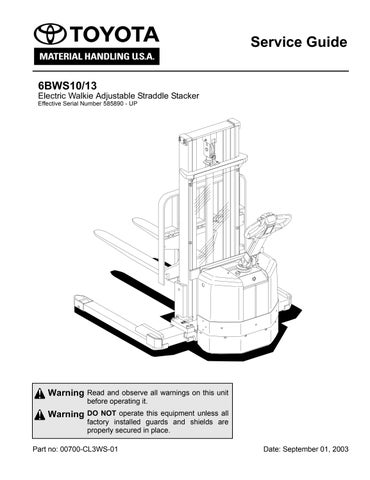

from Toyota Forklift 6BWS10 6BWS13 Electric Walkie Adjustable Straddle Stacker Service Guide Manual PDF

10. Technical Specifications – Curtis 1243

* During specific test conditions.

Hydraulic System

1.1 Main Components

1Lift CylindersFork lift

2Hydraulic UnitA = Non return valve

B = Lowering valve, manual

C = Lowering valve, el

D = Overflow valve

E = Flow control valve

F = Filter

M = Pump motor

P = Pump

1.2 Description

1.2.1 Lift

When the pump motor starts, the oil flows through the nonreturn valve to the lift cylinders.

1.2.2 Lowering

When the lowering valve is actuated by the lowering lever on the chassis, or the lowering button on the steering (tiller) arm, the valve opens to allow the oil in the pressure lines to return to the oil tank. The lowering speed can be regulated by the movement of the lowering lever on the chassis. Lowering using the button on the steering (tiller) arm gives a constant lower speed.

1.2.3 Operating Pressure

The operating pressures at rated load are:

•2800 psi (193 bar)

1.2.4 Relief Valve

The relief valve opens at the following pressures:

•3046 psi (210 bar)

Main lift chain system

Main lift chain system

1. Checking the chain settings

The lift chains must be adjusted at regular periods due to stretching. The chain setting is checked during servicing as set out in the maintenance schedule.

Any adjustment is made with the chain mounting bolts. Adjust the forks height.

2. Chain inspection

The chains are exposed to two types of wear, outline wear and stretching. Wear to the pins and disc holes is caused by sketching. The chains are also affected by the environment they are used in.

2.1. Noise

If lubrication has been insufficient there will be metallic friction on the chain and this will result in noise.

The chains should be replaced.

2.2 Surface rust

Surface rust is easy to recognize as the chain will be reddish brown. Deep-seated rust has generally started and the chain has impaired strength.

The chains should be replaced.

2.3 Rusty links

Fretting corrosion results in a reddish brown powder being visible by the outer discs. It can also appear as if the chain is bleeding when lubricated.

The chains should be replaced.

Main lift chain system

2.4 Stiff links

If it is not possible to pull out the chain to its normal position this can be because of link rust or seizing. The chains should be replaced.

2.5 Pin rotation

Pin rotation can be a phenomenon of stiff links. It is easy to see when comparing with a new chain. The chains should be replaced.

2.6 Loose pins

If a pin is loose it will protrude from the side of the chain, which is due to a stiff link or pin rotation. The chains should be replaced.

Main lift chain system

2.7 Outline wear

P = Pitch

H2 = Nominal disc height.

H3 = Minimum disc height.

A new lift chain has a specific nominal disc height, defined as H2 in the figure. As the truck is used the lift chain wears radically, on the side that runs over the chain sprocket. The minimum disc height is defined as H3 in the figure and denotes the minimum permitted value of the disc height.

NOTE! Maximal permitted outline wear is 5% of the height H2. If a lift chain reaches the maximum level of wear, the chain should be replaced.

The nominal and minimum disc heights for respective lift chains are stated in the table in the section “Stretching”.

Main lift chain system

2.8 Stretching

The amount of Stretch on a lift chain is measured on the part of the chain that runs over the chain sprocket. The amount of stretch may, at the most, be 2% on the most worn section of the chain. Measurement is suitably made over 12-40 inches [300-1000 mm] of the chain.

The nominal and maximum permitted chain lengths for chains are stated in the table below.

NOTE! Wear to the pins and around the holes on the discs are a reason why the chain stretches. The chain should be replaced if stretching is more than 2%.

Main lift chain system

2.9 Damage

The chain should be replaced if damaged in any way.

2.10 Damaged discs

If a disc has broken on the chain, this can be due to overloading or corrosion. The chains should be replaced.

2.11 Damaged pins

It can be difficult to discover whether a pin has broken. It can appear as pin rotation and/or that the outer disc is loose. The chains should be replaced.

2.12 Dirty chain

If a chain is very dirty it is first and foremost recommended that it is replaced. It can also be dismantled and cleaned as set out in the section “Cleaning”.

Main lift chain system

3. Cleaning

If a chain is very dirty it is recommended the it be replaced. Dirty chains should be cleaned before they are lubricated, by cleaning with solvent.

•The chain should be blown dry using compressed air and lubricated directly after cleaning.

NOTE! Exercise care with degreasing agent as these can contain abrasives.

4. Lubrication

Mineral and synthetic oils can be used to re-lubricate lift chains.

NOTE! Lubricant must not contain substances such as molybdenum disulphide, PTFE or the like.

A lift chain should be off-loaded from the weight of the fork carriage (hanging free) when lubricated.

•Lubrication intervals:

- 500 hours with normal operations

- 100 hours when driving in rugged environments such as cold storage and corrosive environments.

The chains are sprayed with lubricant. Note the entire chain must be lubricated (10W40 motor oil), even the fastening bolts. It is especially important that the part of the chain which runs over the chain sprocket is well lubricated.

NOTE! Do not use a special rust protective agent to prevent rust on the lift chains. These agents impair the lubrication of the chains. Regular lubrication is the best method to prevent rust form forming.