9 minute read

Electric Drive Motor

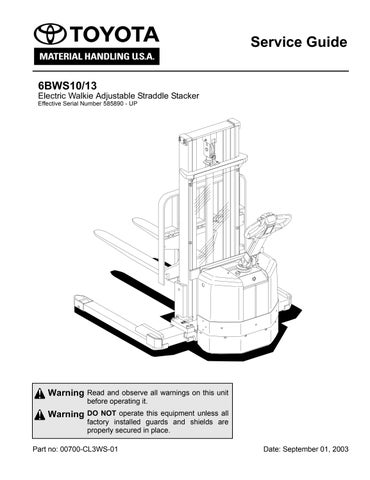

from Toyota Forklift 6BWS10 6BWS13 Electric Walkie Adjustable Straddle Stacker Service Guide Manual PDF

2. Service/Repairs

2.1. Motor Dismantling

•Release the brake disc’s companion flange by first removing the locking ring together with the washer in the end of the rotor shaft. The companion flange can now be lifted off. It may be necessary to unclamp it with an appropriate tool.

•Remove the four plugs that cover the carbon brushes, move the springs on the carbon brushes to one side and pull out the carbon brushes.

•Dismantle the commutator end’s bearing shield (2) together with the carbon brush bridge (5) and carbon brushes (8) by unscrewing the eight screws (1). Now put down the motor with a firm resting point against the edge of the bearing shield, and carefully tap on the rotor shaft’s end with a rubber mallet.

•Dismantle the drive end’s bearing shield (15) together with the rotor (9). Make sure not to damage the motor windings when the rotor is removed from the motor housing.

•After dismantling the motor’s bearing shields and removing the rotor from the motor housing, the gear wheel in the rotor’s drive end is removed. This is done by unscrewing the nuts on the gear wheel and then pulling the gear wheel off with a puller. Note that “Loctite” is used to secure the gear wheel to the rotor shaft.

•Now release the inner locking ring together with the underlying washer. Pull out the rotor shaft from the bearing (18).

•Release the outer locking ring together with its washer, and remove the bearing from the bearing shield.

•Remove the bearing shield’s seal (17) and carefully clean the bearing shield.

•Fit a new seal in the bearing shield.

2.2. Motor Assembling

Assemble the motor in the reverse order.

•Carefully check that the rotor can move freely in the direction of rotation and that the carbon brushes are flush with the commutator.

•Check the motor’s insulation resistance (between respective winding and the motor housing). For a new motor this should lie between 2 - 3 Mohm. When a used motor has been exposed to impurities, an insulation resistance down to approximately 1 Mohm is acceptable.

•Fit a new O-ring in the drive shaft end’s bearing shield and a new seal on the collar of the bearing shield.

2.3. Cleaning

An extremely critical factor to ensure correct functioning of the motor is that it is kept as clean as possible. The motor and the motor compartment must be regularly checked for dust, oil, and other impurities.

WARNING

When using compressed air, wear effective chip-guarding and personal protective equipment. Compressed air used for cleaning MUST be reduced to less than 30 psi (207 kPa).

A vacuum cleaner with an appropriate nozzle can be used to clean the motor if the motor windings and inner compartment are dry, compressed air can be used in combination with a vacuum cleaner. In which case the compressed air must be clean and dry.

A cloth of non-abrasive material should be used if the windings have a coating. The cloth can also be moistened with a grease-dissolving, organic and volatile detergent that does not damage the windings. Use detergent sparingly to avoid it penetrating into the parts of the motor.

Residual detergent should be removed with an appropriate cleaning solution, if it leaves a greasy surface.

If the parts of the motor are dirty it may be necessary to use a cleaning solution that is sprayed onto the parts. It is important

Electric Drive Motor that the detergent is applied in a way to prevent dirt from penetrating into the parts of the motor, especially for the rotor. One method of cleaning the rotor, is to dip it in a cleaning solution. If this is done then the rotor must always be dried with the application of heat. There must be adequate ventilation during the drying process, and the drying should continue until a number of measurements of the insulation resistance provide equivalent and approved results.

3. Technical Data

TypeTSL140S-DS30

Output hp (kW)1.6 (1.2)

IntermittenceS2 60 min.

Minimum length of carbon brush, inch (mm)0.5 (13)

Minimum commutator diameter, inch (mm)1.85 (47)

Resistance, shunt field winding Ω at 77° F (25° C)0.49

Resistance, armature winding, Ω at 75° F (24° C)0,0156

Insulation resistance between windings and motor housing>= 1Mohm

Weight, lbs (kg)30 (14)

1. Component Parts

Pos NoDescriptionNote

01Drive gear complete

2Air valve

3Cover

4Dip stick

5Washer

6Gasket

7NutTightening torque 52 ft-lbs (70 N•m)

Locked with punch mark

8Washer

9Gear wheelPrimary gear

10Conical roller bearing

11Shims

12ScrewTop cover and gear housing

Tightening torque 20 ft-lbs. (26.6 N•m)

Lock with Loctite 242

13Shims

14Conical roller bearing

15Pinion/ Crown gearCog clearance 0.004-0.006 inch (0.10-0.15 mm)

Pretension bearing with 2-5/100

Stamped size on pinion adjusted with shims

16NutTightening torque 221 ft-lbs (300 N•m)

Locked with punch mark

17Shims

18Conical roller bearing

19Shims

20ScrewBottom cover and gear housing

Tightening torque 20 ft-lbs (26.6 N•m)

Lock with Loctite 242

21ScrewBottom cover and gear housing

Tightening torque 20 ft-lbs (26.6 N•m)

Lock with Loctite 242

22Cover

23Gasket

24Gear wheelMotor gear

25Washer

26NutTightening torque 22 ft-lbs (30 N•m)

Locked with punch mark

Lock with Loctite 603

27ScrewMotor and gear housing

28NutTightening torque 20 ft-lbs (26.6 N•m)

Lock with Loctite 242

29Conical roller bearing

30Shims

31Seal

32Drive shaft

1.1. Technical Data

Type of gear2-step angle gear

Gear ratio14,20:1

Oil volume, liters1,75

Oil typeHypoid oil

Viscosity, normal temperatureSAE 80W90

Viscosity, < 5° F (-15°C)SAE 75W

2. Top Cover Leakage

Dismantling

•Lift up and block the truck to ensure that it is stable.

•Unscrew the drive wheel.

•Unscrew the M8 nuts (28), that hold the gear and motor, with a box wrench. Support the gear so that it does not drop.

•Release the M8 bolts (12), that hold the cover (3), with a 0.25 inch (6 mm) hex socket wrench.

•Change the gasket (6).

Assembling

•Assembling is carried out in the reverse order

•Tighten the four M8 bolts and the four M8 nuts to a torque of 20 ft-lbs (26.6 N•m) Lock with Loctite 242.

•Tighten the drive gear five bolts to a torque of 48 ft-lbs (65 N•m).

3. Drive Shaft Sealing Ring Replacement

The drive shaft sealing ring can be changed with the gear mounted in the truck. Follow the instructions below if oil is leaking from the drive shaft.

Dismantling

•Unscrew the drive wheel (1).

•Remove the lower cover (22) and drain off the oil.

•Release the drive shaft nut (16). Remove the nut and washer (17).

•Carefully tap out the drive shaft (32) with a brass drift and hammer.

•Pull off the bearing (29) from the drive shaft with tool 08-13022.

•Check that the bearing washers (30) are not damaged. If they have been damaged by the puller tool, measure the total thickness of the shim washers and change them before assembling.

•Remove the sealing ring (31) from the drive shaft.

Assembling

Assembling of the gear after changing the drive shaft sealing ring is carried out in the reverse order to dismantling. Pay special attention to the following during assembling:

•Fill the sealing ring with grease after fitting it on the drive shaft.

•Make sure that only undamaged shim washers with the same total thickness as the originals are put on the drive shaft.

•Press the bearing on the drive shaft and make sure not to damage the bearing shim washers.

•When fitting the drive shaft with bearing, shim washers and seal, make sure that the shaft keys correspond with the crown gear keys and that the bearing and seal are correctly positioned in the gear housing before the shaft is pressed in completely.

Drive Unit/Gear

•Put the distance ring on the drive shaft end, and put on the shaft nut. Always use a new nut. Tighten the shaft nut to a torque of 221 ft-lbs (300 N•m) and lock it with a punch mark in the middle. The drive shaft nut should be lubricated before it is put on the shaft.

•Change the gasket before fitting the bottom cover. Make sure that it is not damaged. Fit the cover and tighten the bolts to a torque of 20 ft-lbs (26.6 Nm). The bolts should be lubricated before they are fitted. Fill up with oil in accordance with the instructions for replenishing the oil.

Fit the drive gear and tighten the bolts to a torque of 50 ft-lbs (65 N•m).

1.

Main Components

Electromagnetic Brake

2. Maintenance

It is recommended according to the planned maintenance schedule, on a regular basis, to check the brake disc for wear. Also check the gap between the magnetic coil housing and the pressure plate.

2.1. Basic Gap Adjustment

The nominal gap between the coil housing and the pressure plate, in applied position, shall be 0.008 inch (0.2 mm). The maximum gap before readjustment is necessary is 0.20 inch (0.5 mm)

Loosen the tension of the three adjustment bolts.

Turn the lock nuts counterclockwise and tighten the bolts slightly while checking the gap on three points with a 0.008 inch (0.2 mm) feeler gauge. Tighten the lock nuts 4 ft-lbs (5.5 N•m) and recheck the gap with the feeler gauge.

2.2. Brake Disc Replacement

The brake disc should be replaced when its total thickness has been reduced to 0.22 inch (5.5 mm).

•Disconnect the electrical wires of the brake.

•Loosen and remove the three mounting bolts and remove the brake coil.

•Replace the brake disc on the hub and make a visual inspection of the wear of the friction plate. Replace the friction plate if the surface is worn uneven.

•Unwind the lock nuts on the coil at least 0.24 inch (6 mm) to make sure there is a gap between the coil and the pressure plate when the coil is refitted.

•Mount the coil on the motor end and carry out adjustment of the gap according to “Basic Gap Adjustment” on page48.

•Reconnect the electrical wiring.

Electromagnetic Brake

This page is intentionally left blank.

2. Brake Microswitch Adjustments

Switch (23) is always adjusted to its lowest position.

•Unscrew the screws (13, 20) that hold the switch and the distance.

•Press down the switch and tighten the screws.

•Check that the switch is actuated by the cam (18) in the arm’s top and bottom position.

3. Steering (Tiller) Arm Handle

3.1. Dismantling/Assembling

•Dismantle cover (2), (keyboard option).

•Remove the screws (35), hold top cover (7) firm.

•Disconnect the cable connected to the electronic circuit board (4).

•Remove the screws (34).

•Carefully lift off the lower cover (33), and place a finger between the lower cover (33) and button (30) to hold the button (30) in place.

•Assembling is carried out in the reverse order.

NOTE! Static electricity!

Risk of static discharge that can damage the electronics.

Make sure to take the necessary precautions before working with the electronics.

3.1.1. Signal Button/Switch (9, 10) Replacement

•Dismantle the button as per the diagram.

•Disconnect the connection for the switch on the electronic circuit board (4).

•Press out the switch from its mounting.

•Assembling is carried out in the reverse order.

Steering

3.1.2. Lift/Lowering Button (13) Replacement

•Remove the button by placing a screwdriver in the hole (A) as per the diagram below.

•Unscrew the holder (18) so that the arm (12) comes loose.

•Assembling is carried out in the reverse order.

3.1.3. Push Button (16) Replacement

•Press the button by hand sideways.

•Place a screwdriver as per the diagram and carefully pry the button loose.

•Unscrew the button’s holder and arm.

•Assembling is carried out in the reverse order.

1. Electrical Parts

Electrical Systems

2. List of Symbols and Electrical Wiring Diagram

SymbolDescriptionFunctionNotes

A1Transistor regulator

A2Electronic card

A6Display

A17KeypadPIN-number login

E1LightFlashing

F1FuseDrive motor circuit125 A

F3FusePump motor circuit125 A

F50FuseOperating circuit A57,5 A

F51FuseOperating circuit A17,5 A

F52FuseOptional equipment10A

G1Battery24 V

H1Horn

K10ContactorMain contactor

K30ContactorPump motor

K101ContactorRelayFlashing light

A2:S1-S9

A2:S10-S18 Speed controlForward/Rearward

M1MotorDrive motor

M3MotorPump motor

P2Pressure switchPressure switch fork lift1740 psi (120 bar)

R1PTC-resistorPower supply15 Ohm

Electrical Systems

SymbolDescriptionFunctionNotes

Sh. = Sheet or page of Diagram

2.1. Electrical Diagram 1(6)

First Number = Previous page wire was found.

Second Number = Next page wire is found

Electrical Systems

Sh. = Sheet or page of Diagram

First Number = Previous page wire was found.

Second Number = Next page wire is found

Sh. = Sheet or page of Diagram

2.3. Electrical Diagram 3(6)

First Number = Previous page wire was found.

Second Number = Next page wire is found

Electrical Systems

Sh. = Sheet or page of Diagram

First Number = Previous page wire was found.

Second Number = Next page wire is found

Sh. = Sheet or page of Diagram

2.5. Electrical Diagram 5(6)

First Number = Previous page wire was found.

Second Number = Next page wire is found

Electrical Systems

Sh. = Sheet or page of Diagram

First Number = Previous page wire was found.

Second Number = Next page wire is found

3. Functional Description

3.1. Starting the Truck

•Battery connector plugged in.

•S21 closed.

•A17 on.

3.2. Driving

•S10 closed.

•The speed control activated in any direction.

3.3. Neutral Speed Reduction

•The speed control to neutral position, motor starts to work as generator. Brake energy comes back to battery.

•Y1 will be applied when the truck comes to a stand still even if the tiller is in drive position.

3.4.

Picture 3

Energy back to the battery. The transistors (T2) for the generated brake current are not live.