2 minute read

DRY CHEMICAL CLEANUP PROCEDURES......................................................................................1

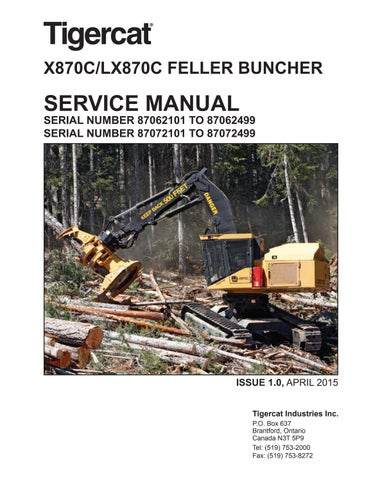

Tigercat X870C/LX870C Feller Buncher

SERVICING SAFETY PRECAUTIONS continued

In the event of any suspected fluid injection injury • Report the injury to your supervisor immediately. • Seek professional medical attention immediately.

As always, the best defence against suffering the effects of fluid injection is to prevent the accident from occurring in the first place.

When searching for possible fluid leaks:

• Never search for leaks with your bare hands.

Always wear thick protective gloves.

• Be sure to wear safety goggles for eye protection. • Keep all body parts well away from the area being investigated for leaks. • Use the end of a long piece of wood to move hoses or other obstacles.

• Place the end of a long piece of wood in the suspected path of any fluid stream. Never use any part of your body. • Recognize that the source of the leak and the fluid streaming from it may be very small and not easily visible. You may only be able to see the fluid that accumulates as a result of the fluid stream.

When performing any service work:

• Stop the engine and relieve all diesel fuel or hydraulic pressure before disconnecting any lines or otherwise working on the system. • Never grab any hydraulic or diesel fuel connectors or hoses when they are subjected to pressure.

Safety

• Always ensure that hoses are rated for the pressures to which they will be subjected. • Never use any hoses that you suspect could be defective.

GREASE INJECTION INJURY WHEN USING PNEUMATIC GREASE GUNS

Pneumatic grease guns can deliver grease at pressures from 17 - 400 Bar (246 - 5801 psi). It takes less than 7 Bar (100 psi) to inject a substance through human skin. ALWAYS get professional medical treatment immediately after any type of injection injury. Provide the physician with information on the type of grease, the pressure setting of the gun, and similar details. The amount of fluid injected, type of fluid (or material), pressure at which it was injected, and the elapsed time between injection and surgery all influence the chances of successful treatment for this type of serious injury.

Prior to using a high pressure pneumatic grease gun, perform the following:

• DO NOT OPERATE a high pressure pneumatic grease gun unless you have been trained in the proper operation and are aware of all safety precautions of such a tool. • All operators of high pressure pneumatic grease guns MUST be trained in the hazards of its operations and the treatment for such injuries. • Wear proper protective equipment such as gloves, safety hat and safety glasses. • Inspect all parts of the grease gun for wear and tear and replace all worn or damaged parts. • Make sure that protective shrouds are installed on all grease gun nozzles as safety devices. • Remove dirt and grease from grease fittings prior to greasing. • Replace any defective grease fittings on equipment with new fittings immediately. • When badly positioned fittings are identified, replace them with angled or swivel fittings for easier access.