1 minute read

LIGHTNING SAFETY AWARENESS LIGHTNING SAFETY ................................................................................................................1.23, 1

Safety

SERVICING SAFETY PRECAUTIONS continued

Prior to welding on any part of the machine, the repair area should be cleaned and a fire extinguisher should be made available at the welding location. Care must be taken in attaching the welding machine grounding clamp so current does not pass through bearings, especially the swing bearing. Disconnect the negative (-) battery cable from all the batteries. This machine is equipped with sensitive electronic control equipment thus, prior to welding:

DISCONNECT THE MULTI-PIN PLUG FROM THE ENGINE ANTI-STALL CONTROLLER

822C-03

ENGINE ANTI-STALL DISCONNECT Disconnect the multi-pin plug from the

engine anti-stall controller mounted on the rear electrical cover door inside the cab.

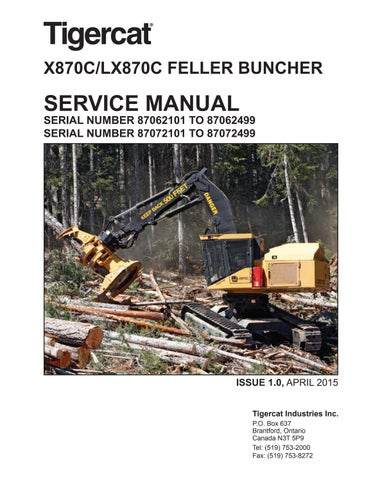

Tigercat X870C/LX870C Feller Buncher

DISCONNECT THE 6 PIN PLUG FROM THE BACK OF THE DISPLAY MODULE

822C-05

IQAN DISPLAY DISCONNECT

Disconnect the IQAN display 6 pin connector from the back of the display module.

DISCONNECT THE 42 PIN PLUG FROM THE XS MODULE

DISCONNECT 4 PIN ENGINE POWER CONNECTOR DISCONNECT THE TWO DISCONNECT THE TWO MULTI-PIN PLUGS FROM THE MULTI-PIN PLUGS FROM ENGINE ECMTHE ENGINE ECM

822C-34 822C-34

ENGINE ECM DISCONNECT - LEFT SIDE OF ENGINE

Disconnect the engine ECM (Engine Control Module) by unplugging the four pin engine power connector and the two multipin connectors from the left side of the engine.

822C-04

IQAN XS MODULE DISCONNECT

Disconnect the IQAN control module 42 pin connector located in the back-right corner of the cab.